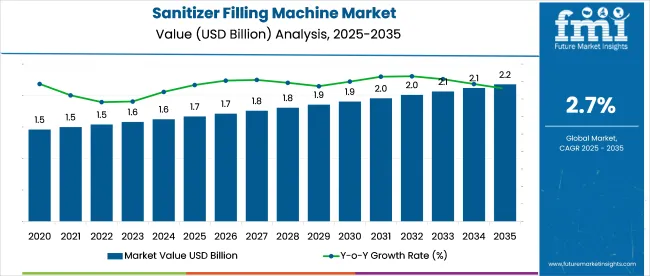

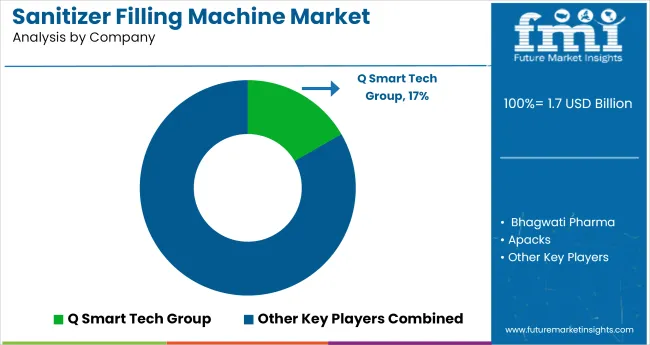

The Sanitizer Filling Machine Market is estimated to be valued at USD 1.7 billion in 2025 and is projected to reach USD 2.2 billion by 2035, registering a compound annual growth rate (CAGR) of 2.7% over the forecast period.

The sanitizer filling machine market continues to grow steadily, fueled by sustained demand for hygiene and disinfectant products in both institutional and consumer sectors. The market is being shaped by a focus on contamination control, rapid production cycles, and the need for flexible machinery that can handle varying viscosities of sanitizer formulations.

The adoption of automation and cleanroom-compatible equipment has gained momentum, especially in pharmaceutical-grade and large-volume production environments. Manufacturers are prioritizing precision filling, integrated capping systems, and minimal human interaction to meet regulatory and throughput requirements. Additionally, advances in filling technology such as servo-driven nozzles and anti-drip systems are enhancing production efficiency while reducing waste.

With the growing presence of private-label sanitizers and bulk refill formats, the demand for scalable, modular filling systems is expected to remain strong. The market outlook remains positive, supported by ongoing public health awareness, evolving compliance standards, and demand for operational resilience in health and hygiene supply chains.

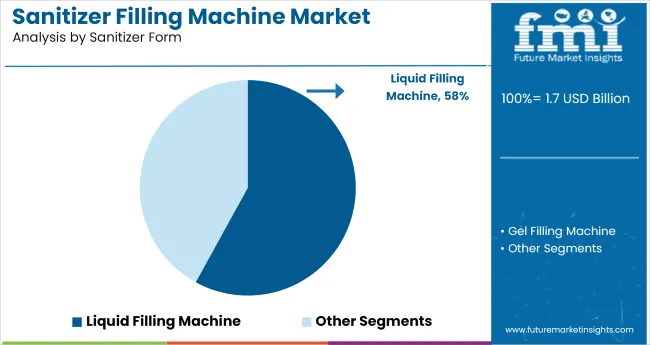

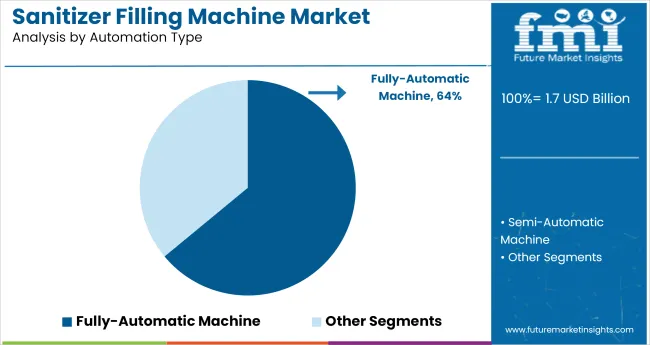

The market is segmented by Sanitizer Form and Automation Type and region. By Sanitizer Form, the market is divided into Liquid Filling Machine and Gel Filling Machine. In terms of Automation Type, the market is classified into Fully-Automatic Machine and Semi-Automatic Machine.

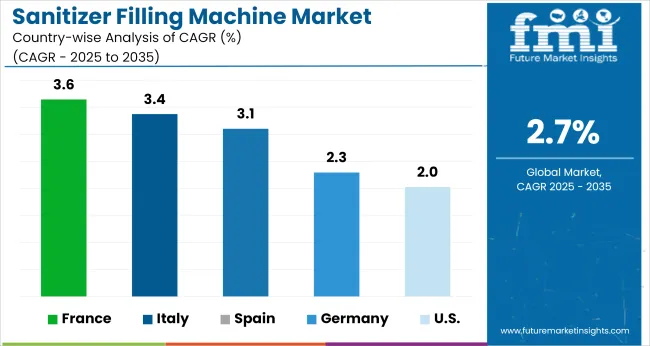

Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

Liquid filling machines are expected to account for 58.0% of the total revenue share in the sanitizer filling machine market in 2025. This segment’s leadership is being supported by the dominance of liquid formulations in the sanitizer industry, where accurate volumetric dosing and leak-proof filling are critical. Liquid filling machines offer versatility in handling different bottle sizes, container types, and viscosity levels, making them highly suitable for commercial-scale sanitizer production.

Their integration with clean-in-place (CIP) systems and non-contact filling options aligns with hygiene-critical environments. The adoption of liquid filling lines has been further accelerated by demand for high-speed, contamination-free operations and compatibility with plastic and recyclable packaging.

Additionally, liquid filling machines are adaptable to pump, spray, and flip-top closures, offering flexibility across diverse packaging formats. The segment’s performance is being reinforced by increased private-label production, which favors efficient, automated, and flexible filling systems for cost-effective scalability.

Fully-automatic machines are projected to hold 64.0% of the total sanitizer filling machine market revenue in 2025, emerging as the top-performing automation type. The segment’s growth is being driven by the need for uninterrupted, high-throughput production with minimal manual intervention. Fully-automatic systems integrate multiple functions such as filling, capping, labeling, and container sorting into a single streamlined line, significantly reducing downtime and labor costs.

These machines are preferred in high-compliance environments where cleanliness, speed, and consistency are critical. Their compatibility with various container shapes and closure systems enhances operational flexibility, especially for contract manufacturers and large-scale producers. The shift toward touchless production and digital monitoring systems has made fully-automatic filling solutions more attractive amid rising hygiene concerns and regulatory scrutiny.

As brands scale up production to meet fluctuating demand and maintain quality standards, fully-automatic systems remain the cornerstone of efficient, scalable, and safe sanitizer manufacturing operations.

Growth in sales of sanitizers is elevating the demand for sanitizer filling machines across the globe.

To cater this huge rise in demand sanitizer and disinfection product manufacturers have increased their production capacities, which created substantial demand for filling machines.

With the spreading awareness towards sanitization and disinfection in developing economies, demand is expected to rise exponentially form the developed as well as developing regions.

However, adverse effects of chemical ingredients used in sanitizers is acting as a restraining factor for sanitizer usage and can thus impact demand for filling machines.

Awareness towards sanitization to prevent transmission of various transmissible diseases (such as cold, cough, fever and other flu viruses) in hospitals, Institutions, commercial buildings, Residential buildings, and others is propagating at very fast pace. The global pandemic conditions have made sanitizer products ubiquitous across places.

This rising demand for sanitizers has compelled manufacturers to expand their production, processing and packaging capacities which is creating great demand for sanitizer filling machines at a significant rate.

In addition, many chemical manufactures faced losses due to preventive measures taken to control outbreak of corona virus due to discontinuity in supply chain activities, limited availability of raw materials.

To compensate the losses and leverage huge demand for sanitizers, various chemical manufacturers shifted their production lines to manufacture sanitizers which created a substantial demand for sanitizer filling machines market in 2024 and 2024.

Although the spike in demand is expected to taper within a couple of years once the pandemic situation is brought under control, the long term prospects remain positive for the market.

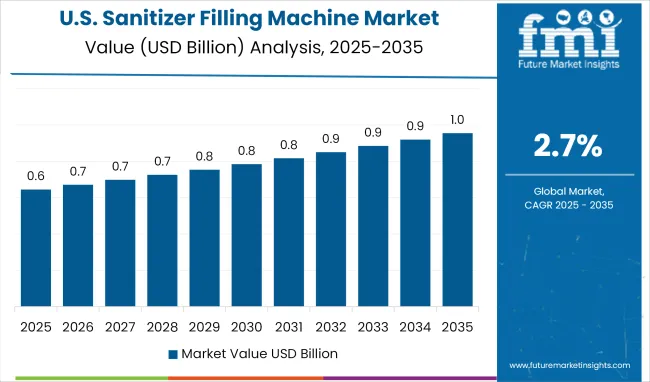

USA is one of largest market for chemicals and materials owing to strong presence of industries in the country. USA was heavily impacted by outbreak of novel coronavirus. A huge number of American citizens were affected by the disease.

Dedicated efforts by regulatory authorities has led to growth in awareness relating to preventive measures at a very fast pace, which created substantial rise in demand for sanitizers. This in turn created substantial demand for sanitizer filling machine in the country during the forecast period.

China is one of the largest consumer of sanitizer filling machine owing to such a vast population and strong presence of chemical industry in the country. China is the most crucial choice for the manufacturers to expand. Sanitizer manufacturers in the country ramped up capacity to meet domestic as well as export demand, driving sales of filling machines.

Europe is one of the most lucrative market for these machines. Government level emphasis on the importance of sanitization and disinfection and high citizen awareness has helped boost demand.

Countries like Italy, France, and UK was impacted heavily by the coronavirus outbreak. Owing to these factors Europe has substantial demand for sanitizers which attracts manufacturers to expand in the region. Manufacturers in the region have competitive advantage. They have access to various cutting edge technologies to tackle the market challenges.

Some of the leading manufacturers and suppliers include

Manufacturers are focusing on research and development activities to enhance and improve machinery to cater huge demand for sanitizers.

Research and development investments from the manufacturer side are increasing to cater to the shifting demand and attract the market with new and innovative products, this will be a key strategy for the manufacturers to elevate their revenues and establish footprints. Moreover, Manufacturers are turning to long-term strategic collaborations and agreements with end-user to smoothen the fluctuations in demand.

The report is a compilation of first-hand information, qualitative and quantitative assessment by industry analysts, inputs from industry experts and industry participants across the value chain.

The report provides an in-depth analysis of parent market trends, macro-economic indicators, and governing factors along with market attractiveness as per segments. The report also maps the qualitative impact of various market factors on market segments and geographies.

The global sanitizer filling machine market is estimated to be valued at USD 1.7 billion in 2025.

The market size for the sanitizer filling machine market is projected to reach USD 2.2 billion by 2035.

The sanitizer filling machine market is expected to grow at a 2.7% CAGR between 2025 and 2035.

The key product types in sanitizer filling machine market are liquid filling machine and gel filling machine.

In terms of automation type, fully-automatic machine segment to command 64.0% share in the sanitizer filling machine market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Market Share Breakdown of Sanitizer Filling Machine Providers

Sanitizer Sachet Market Size and Share Forecast Outlook 2025 to 2035

Sanitizer Packaging Market Growth – Demand & Trends Forecast 2025 to 2035

Key Companies & Market Share in Sanitizer Sachet Industry

Sanitizers Market

Hand Sanitizer Spray Pen Market Size and Share Forecast Outlook 2025 to 2035

Hand Sanitizer Market Analysis - Size, Share, and Forecast 2025 to 2035

Laundry Sanitizers Market Analysis - Trends, Growth & Forecast 2025 to 2035

Toothbrush Sanitizer Market

Latin America Hand Sanitizer Market Size and Share Forecast Outlook 2025 to 2035

Filling and Dispensing System for Nuclear Medicine Market Size and Share Forecast Outlook 2025 to 2035

Filling Fats Market Size, Growth, and Forecast for 2025 to 2035

Industry Share Analysis for Fillings and Toppings Companies

Filling and Sealing Machine Market Size and Share Forecast Outlook 2025 to 2035

Cup Filling Machines Market Forecast and Outlook 2025 to 2035

Box Filling Machine Market from 2025 to 2035

Drum Filling Machine Market Size and Share Forecast Outlook 2025 to 2035

Wine Filling Machine Market Size and Share Forecast Outlook 2025 to 2035

Tube Filling Machine Market Size and Share Forecast Outlook 2025 to 2035

Market Share Distribution Among Tube Filling Machine Manufacturers

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA