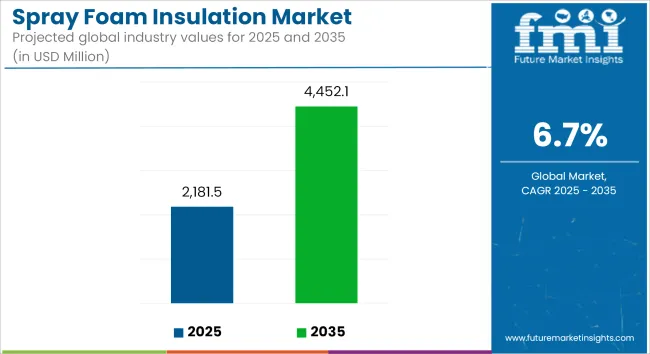

The global spray foam insulation market is estimated to reach USD 2,181.5 million in 2025 and is projected to grow to USD 4,452.1 million by 2035, advancing at a CAGR of 6.7% during the forecast period. Growth is being supported by increasing demand for energy-efficient building materials, evolving sustainability regulations, and the material’s superior thermal insulation capabilities.

| Attributes | Key Insights |

|---|---|

| Estimated Value (2025) | USD 2,181.5 million |

| Projected Size (2035) | USD 4,452.1 million |

| Value-based CAGR (2025 to 2035) | 6.7% |

Spray foam insulation is being adopted in both residential and commercial construction due to its high R-value, air sealing properties, and long-term energy savings. As building codes and green certifications become more stringent, spray foam is being used to meet thermal performance and energy conservation standards in new constructions and retrofitting projects. Its ability to minimize air infiltration and moisture accumulation is contributing to reduced HVAC loads and improved indoor comfort.

Wall insulation is expected to remain the dominant application, accounting for approximately 41.9% of the total market value in 2025. This is being driven by increased awareness of building envelope performance and the direct role that wall insulation plays in minimizing heat loss. Spray foam's conformability and expansion properties make it particularly suitable for hard-to-reach cavities and irregular surfaces.

The market is also witnessing rising adoption of low-pressure DIY spray foam kits. These systems are being selected by homeowners for small-scale applications such as attic insulation, wall crack sealing, and basement moisture control. The U.S. Department of Energy has indicated that proper air sealing can reduce heating and cooling costs by up to 15%, reinforcing the appeal of self-applied spray insulation products.

Retail distribution of these kits is expanding through e-commerce and home improvement outlets. In response to growing demand, manufacturers are developing user-friendly packaging, low-emission formulations, and instructional support tools. This segment is expected to grow further as consumers become more engaged in home energy optimization and climate-conscious renovation practices.

The spray foam insulation market is expected to maintain a strong growth trajectory through 2035, supported by building performance requirements, innovations in formulation, and the increasing integration of DIY-friendly solutions for energy-efficient construction.

The following table is a graphical illustration of the annual growth rates of the Spray Foam Insulation industry from 2025 to 2035. This report starts with the base year of 2024 and extends into the present year, studying how the industry growth curve shifts between the first half of the year, namely January through June (H1) to the second half comprising July through December (H2). This will give stakeholders a great perspective of how the sector has evolved and possible development directions.

Below is the table demonstrating sector growth between the half-year periods from 2024 through 2025. The growth for H1 in 2024 was predicted at a CAGR of 6.3%. For the half-year period H2, there is an upward trend is seen.

| Particular | Value CAGR |

|---|---|

| H1 (2024 to 2034) | 6.3% |

| H2 (2024 to 2034) | 6.7% |

| H1 (2025 to 2035) | 6.4% |

| H2 (2025 to 2035) | 6.9% |

Going forward into the second period, between H1 2025 and H2 2025, the CAGR is projected to be 6.4% in the former half and will increase to 6.9% in the latter half. In H1 and H2, the sales have increased by 10 and 20 BPS respectively.

Growing Emphasis on Energy Efficiency in Buildings Drives Demand for Advanced Spray Foam Insulation

Demand for insulation materials like spray foam is heightened by the increasing cost of energy and stringent efficiency regulations. Increasing utility costs drive home and corporate clients to energy efficiency solutions that mitigate energy consumption and promote comfort. Spraying foam insulation in global buildings that seek such ratings as Leadership in Energy and Environmental Design has promoted its use in new constructions and renovation projects.

The USA Department of Energy reported that buildings constitute 40% of the nation's total energy consumption, where heating and cooling account for the majority. The USD 15 billion worth of energy savings through the Better Buildings Challenge by 2022 is testifying of the critical roles advanced insulation materials could play in cutting operational costs and increasing energy efficiency. Spray foam insulation is becoming a popular choice because of its excellent thermal properties and long-term durability.

Rising Demand for HVAC Efficiency Boosts Adoption of Spray Foam Insulation in Building Systems

Spray foam gains momentum due to its efficiency in enhancing the ability of HVAC system operation by preventing leakage and heat transmission. The greater thermal properties cause energy consumption lower than that necessary for the most optimal system performances concerning applications in residential, commercial, or industrial buildings. Due to the focus on energy efficiency, spray foam insulation is finding application in HVAC operations in construction designs.

The USA Department of Energy points out that heating and cooling consume about half of the average energy consumed in homes. Therefore, efficient insulation solutions play a significant role in such conditions. Spray foam inhibits air leaks, thereby reducing the burden on HVAC systems and thus saving energy besides creating greater comfort indoors. Another initiative taken is by DOE's Better Buildings Residential Program in its efforts toward the integration of energy-efficient insulations to fulfill the sustainable energy agenda.

Strict Regulatory Standards Create Challenges for Spray Foam Insulation Manufacturers and Market Expansion

A prime challenge in the spray foam insulation market is related to strict environmental and safety standards, particularly VOC limits. Manufacturers need to adhere to such stringent standards that often demand expensive production adjustment and certification procedures. It does not only make the operations more expensive but also acts as a barrier to small players entering this market.

In the United States, the EPA enforces regulations under the Clean Air Act regulating VOCs from construction materials, including spray foam insulation. Often, compliance with these standards requires the development of low-VOC formulations and additional investment in advanced production technologies. Complexity can deter new entrants and reduce competition within the market, thereby limiting growth potential.

Development of Soundproofing-Specific Spray Foam Unlocks New Opportunities in Urban and Commercial Applications

Spray foam insulation, particularly the recently developed soundproofing products, will bring huge innovations in this aspect. Advanced formulae for developing such products take into consideration an increased demand from noise-sensitive surroundings such as city high-rise apartments, recording studios, entertainment facilities, and any other places needing to reduce disturbance levels.

The USA Department of Housing and Urban Development (HUD) emphasizes noise mitigation in residential and mixed-use developments to enhance the standards of living in cities. Spray foam offers dual functionality-thermal insulation and soundproofing, and therefore attracts builders and property developers to achieve such regulatory and consumer demands. This added value further includes less material for use in a construction project.

Manufacturers investing in co-working offices with luxury apartments will be well-positioned to capture the growing market segment, knowing that this product has been versatile to meet acoustic as well as energy efficiency demands. This trend creates an opportunity for the development and commercialization of innovative spray foam solutions tailored to soundproofing.

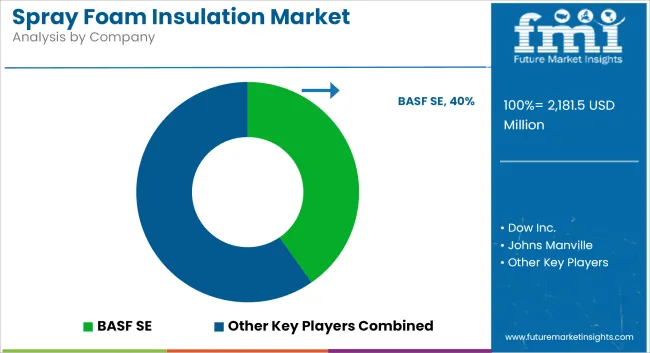

The players that are in Tier 1 of the spray foam insulation market are BASF SE, Dow Inc., Saint-Gobain S.A., and Huntsman Corporation. They are generating revenues of over USD 100 million and cover around 35-40% of the market.

The players lead the industry with the best production facilities, state-of-the-art technology, and the most extensive products. Their dominance in the global market and the capacity to innovate provide them with a commanding position in the spray foam insulation market.

Tier 2 & 3 Players comprise Lapolla Industries, Icynene-Lapolla, Demilec (USA), Nucor Insulated Panels, Johns Manville, and Rockwool International. Tier 2 & 3 players, all have revenues less than USD 100 million, and capture 60-65% of the market, but lack Tier 1 player's global reach since they focus on regional markets and particular applications. They remain important players in the spray foam insulation market for driving regional growth and filling specific local market needs.

The Spray Foam Insulation Market is expected to grow significantly in countries like India, China, the United States, Canada, and the United Kingdom. India and China are witnessing high demand for energy-efficient solutions for insulation mainly due to construction and urbanization.

The growth in the United States and Canada is steady owing to a conscious effort towards reducing energy consumption through residential and commercial buildings. The United Kingdom is investing in sustainable building practices, which further fuels the demand for spray foam insulation solutions in the region.

| Countries | Value CAGR (2025 to 2035) |

|---|---|

| India | 7.5% |

| China | 7.0% |

| United States | 6.5% |

| Canada | 6.0% |

| United Kingdom | 5.8% |

India is projected to reach a market value of USD 299.2 million by 2035, with a CAGR of 7.5%.

The construction sector of India is changing rapidly towards becoming sustainable. The use of such green building certifications has been rising enormously since the Indian Green Building Council (IGBC) and the Green Rating for Integrated Habitat Assessment (GRIHA) use increased.

These certifying agencies emphasize energy efficiency, low carbon footprint, and the use of green building materials. Due to its high R-value and excellent energy-saving characteristics, spray foam insulation has emerged as the favorite choice of developers and builders in meeting such green building standards.

Rapid urbanization in India's metropolises has further accelerated demand for energy-efficient construction materials. As cities grow, the demand for residential, commercial, and industrial space is increasing with energy efficiency and improved thermal performance. Spray foam insulation is at the forefront of fulfilling these demands as it regulates temperatures effectively and decreases reliance on heating and cooling-intensive systems.

As governmental programs to provide tax rebates to the citizens of those green building initiatives come to be promoted under the Energy Conservation Building Code, there will also be more increases in using spray foam insulation for houses and other building construction processes.

Canada is expected to achieve a market value of USD 89.9 million by 2035, growing at a CAGR of 6.0%.

The frigid climate of Canada and the increasing demand for temperature-sensitive storage solutions are major growth drivers for the spray foam insulation market. Cold storage facilities, which are necessary for maintaining pharmaceuticals, fresh produce, and frozen goods, require advanced insulation materials such as spray foam to maintain consistent temperatures.

Spray foam is ideal for reducing energy consumption in these facilities because of its superior thermal resistance and energy efficiency, thus meeting both cost and environmental goals.

The government of Canada has also encouraged energy efficiency and rewarded businesses to upgrade their facilities through its energy-efficient policies. For example, the Energy Efficiency for Buildings program launched by Natural Resources Canada is a great initiative to establish advanced materials like spray foam insulation that could give better thermal performance and reduce energy costs.

Focus on sustainability and operational efficiency will ensure that spray foam insulation will continue to experience robust demand in the warehousing and cold storage sectors of Canada.

The United Kingdom is forecasted to reach USD 132.0 million by 2035, driven by a 5.8% CAGR.

Fire safety in construction works has become much more focused with incidences such as that of the Grenfell Tower, which exposed this sector to some of the stringent fire safety rules. Spray foam insulation became one of the preferred options as it can now come with fire-retardant qualities to please the regulatory frameworks and meet their high safety levels for occupancy.

Builders and developers in the UK are increasingly giving importance to fire-resistant insulation solutions both in new construction projects and retrofit projects. Spray foam insulation meets the requirements of fire safety and provides a host of benefits, including thermal efficiency and durability.

The material's ability to reduce fire spread and withstand high temperatures has placed it as a key component in the construction of residential, commercial, and public buildings, especially those requiring enhanced fire protection.

The spray foam insulation market is becoming increasingly competitive, with key players focused on expanding their product lines with low-GWP blowing agents, recyclable foam technologies, and hybrid formulations. Strategic acquisitions, such as insulation-focused mergers and the expansion of polyurethane foam divisions, are driving consolidation.

Companies are investing in smart spraying equipment and software-controlled application systems to improve job-site productivity and foam consistency. Vertical integration strategies are being employed to manage raw material volatility, particularly for isocyanates and polyols. Rising demand for green construction and energy-efficient retrofits across key regions is expected to keep the market on a strong growth trajectory.

In terms of Product Type, the industry is divided into Open-Cell Spray Foam, Closed-Cell Spray Foam, High-Pressure Spray Foam, and Low-Pressure Spray Foam.

In terms of Application, the industry is divided into Wall Insulation, Roofing & Flooring, Attics and Ceilings, HVAC systems, and Others.

In terms of End Use, the industry is divided into Residential, Commercial, and Industrial.

The report covers key regions, including North America, Latin America, Western Europe, Eastern Europe, East Asia, South Asia Pacific, and the Middle East and Africa (MEA).

The spray foam insulation market is expected to reach a valuation of USD 2,181.5 million in 2025, continuing its upward trend.

By 2035, the market for spray foam insulation is projected to reach USD 4,452.1 million, reflecting robust growth in demand.

The demand for spray foam insulation is driven by the increasing need for energy-efficient solutions in residential, commercial, and industrial applications, alongside growing awareness of environmental impact.

Regions including the United States, China, India, and Canada are leading the growth of the spray foam insulation market, driven by advancements in construction practices and energy efficiency standards.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Foam Insulation Market Growth – Trends & Forecast 2024-2034

Spray Polyurethane Foam Market Size and Share Forecast Outlook 2025 to 2035

CUI & SOI Coating Market Growth – Trends & Forecast 2024-2034

Foam Type Vacuum Gripping System Market Size and Share Forecast Outlook 2025 to 2035

Foam Mixing Machine Market Size and Share Forecast Outlook 2025 to 2035

Foam Market Size and Share Forecast Outlook 2025 to 2035

Foam-Free Pad Formers Market Size and Share Forecast Outlook 2025 to 2035

Foam Cups Market Size and Share Forecast Outlook 2025 to 2035

Insulation Tester Market Size and Share Forecast Outlook 2025 to 2035

Insulation Films Market Size and Share Forecast Outlook 2025 to 2035

Foam Bottle Technology Market Size and Share Forecast Outlook 2025 to 2035

Spray-dried Animal Plasma (SDAP) Market Size and Share Forecast Outlook 2025 to 2035

Insulation Paper Market Size and Share Forecast Outlook 2025 to 2035

Foaming Agents Market Size and Share Forecast Outlook 2025 to 2035

Insulation Market Size and Share Forecast Outlook 2025 to 2035

Insulation Coatings Market Size and Share Forecast Outlook 2025 to 2035

Insulation Boards Market Size and Share Forecast Outlook 2025 to 2035

Foam Glass Granulate Market Size and Share Forecast Outlook 2025 to 2035

Foam Plastics Market Size and Share Forecast Outlook 2025 to 2035

Foaming Creamer Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA