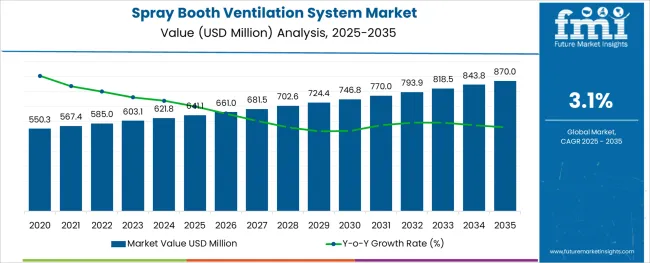

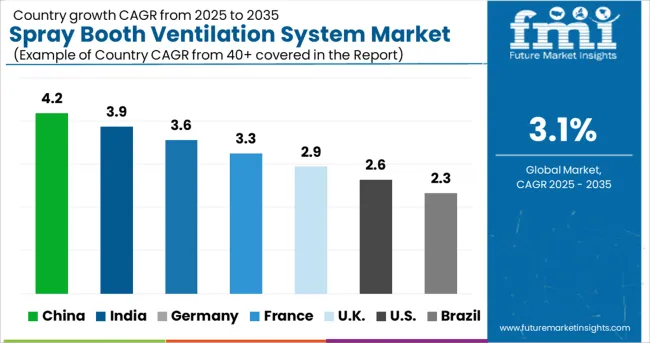

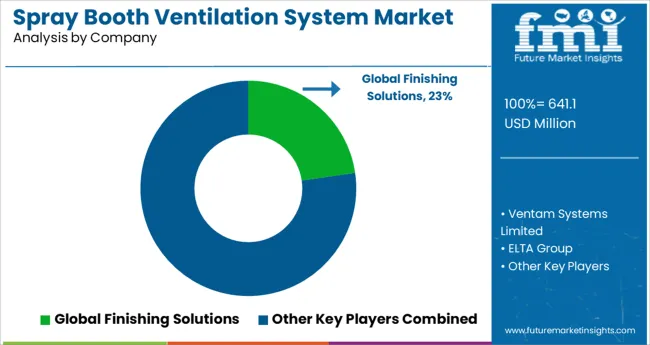

The Spray Booth Ventilation System Market is estimated to be valued at USD 641.1 million in 2025 and is projected to reach USD 870.0 million by 2035, registering a compound annual growth rate (CAGR) of 3.1% over the forecast period.

The spray booth ventilation system market is expanding as industries prioritize workplace safety and environmental compliance. Increasing production activities in sectors such as automotive have driven the demand for efficient ventilation to control airborne contaminants and improve air quality. Regulations focused on reducing hazardous emissions and protecting worker health have reinforced the need for advanced ventilation technologies.

Technological improvements in airflow design and filtration systems have enhanced the effectiveness of spray booth ventilation, ensuring better capture of overspray and fumes. The growth of automotive manufacturing and repair industries globally has particularly supported demand for specialized ventilation systems.

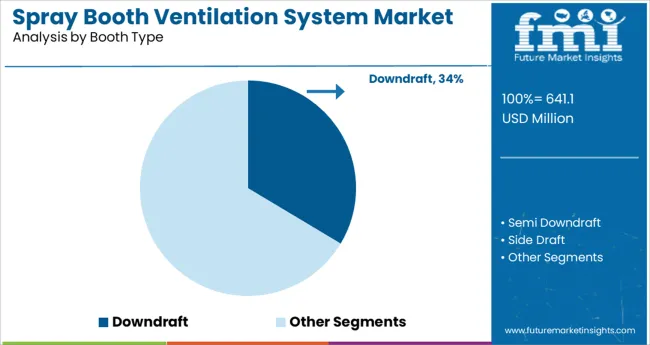

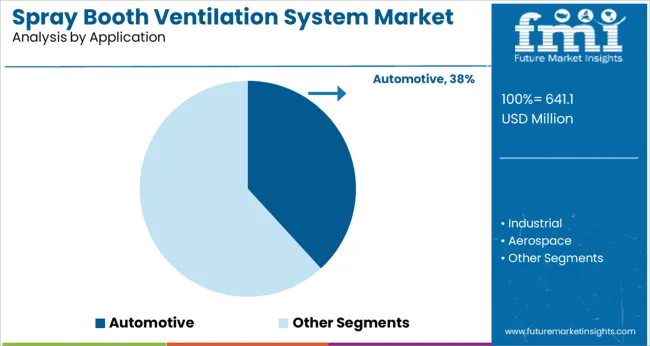

As environmental standards become more stringent and production volumes rise, the market is expected to grow steadily. The demand is anticipated to be led by downdraft booth types favored for their superior airflow management and automotive applications due to the sector’s high volume and safety requirements.

The market is segmented by Booth Type and Application and region. By Booth Type, the market is divided into Downdraft, Semi Downdraft, Side Draft, Cross Draft, Open Face, and Bench. In terms of Application, the market is classified into Automotive, Industrial, Aerospace, Construction, Marine, and Railways.

Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The Downdraft booth type segment is projected to hold 33.6% of the spray booth ventilation system market revenue in 2025, positioning it as the leading booth design. This preference has been driven by its effective air circulation that directs overspray downward away from the operator, reducing contamination risks. The downdraft design is well suited for applications requiring high-quality finishes, as it minimizes dust and particulate settling on sprayed surfaces.

Manufacturing and maintenance teams have favored downdraft booths for their ability to improve worker safety and product quality simultaneously. The segment benefits from technological enhancements that optimize airflow patterns and filtration efficiency.

As industries continue to emphasize operational safety and environmental responsibility, the downdraft booth type segment is expected to sustain its market leadership.

The automotive application segment is projected to contribute 38.2% of the spray booth ventilation system market revenue in 2025, marking it as the dominant sector for these systems. The automotive industry’s reliance on paint and coating operations requires stringent ventilation to manage volatile organic compounds and particulates.

Workshop and manufacturing facilities have increasingly adopted specialized ventilation systems to meet regulatory requirements and ensure product quality. The growth in automotive production and vehicle customization has further driven the installation of advanced spray booth ventilation solutions.

Emphasis on worker safety and environmental standards has made ventilation systems an essential part of automotive painting processes. With the sector’s continued expansion, the automotive application segment is expected to remain a primary growth driver for spray booth ventilation systems.

Rising applications of spray booth ventilations systems in industries like automotive, aerospace, construction, marine etc., implementation of stringent regulation by government and regulatory bodies, and innovations in spray booth ventilation system design and technology are some of the major factors driving growth in the global spray booth ventilation system market.

Spray booth ventilation systems have become ideal solutions for industries to improve workplace safety. These ventilation systems help end users to eliminate harmful gases and chemicals by removing the polluted air. They have proven effective in eliminating and avoiding fire caused by the paint fumes coming in contact with reactive chemicals or electrical discharge

Rising focus towards improving the safety of workers across various industries is playing a key role in pushing the demand for spray booth ventilation systems. Many standard professional-grade spray paints contain volatile organic compounds (VOCs), which are harmful for both workers and the environment. Exposure to these compounds causes diverse health effects in humans ranging from skin allergies and vomiting to respiratory diseases. In order to address this issue and enhance workers’ safety, industries employ spray booth ventilation systems.

Similarly, various standards and regulations laid down by regulatory bodies such as OSHA and EPA regarding workers’ safety, spray booth ventilation, and designing spray booths to filter out flammable contaminants and moving the air currents towards an exhaust for the proper ventilation is expected to boost the growth of spray booth ventilation system market during the forecast period.

Furthermore, growing demand for ventilation environment across applications such as aircraft paint booths, automotive pre-stations, mix storage rooms, open face gel booths, large equipment paint booths, and small & big spray booth, among others will foster the growth of the spray booth ventilation system during the forecast period.

Despite rising popularity of spray booth ventilation systems, there are certain factors that are impeding the growth in spray booth ventilation systems market. Some of these factors include the high cost of spray both ventilation systems and low awareness levels about these systems across lower economies

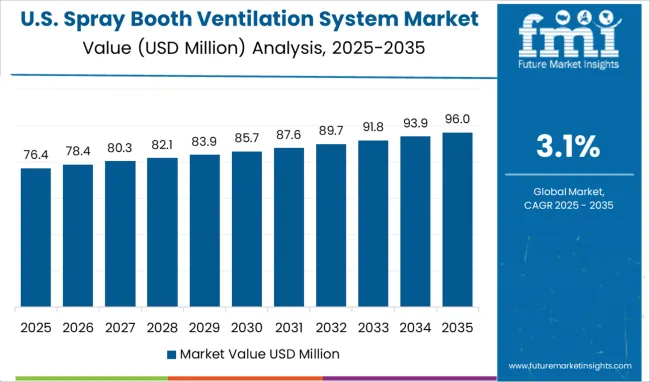

Over the years, North America has become hub for the spray booth ventilations systems on the back of heavy presence of end-use industries, implementation of stringent government regulations pertaining to worker’s safety and environmental protection, presence of various regulatory bodies, and availability of advanced products.

Majority of industries across countries like the USA and Canada are installing spray booth ventilation systems in their facilities to improve worker’s safety and reduce emission levels. They are inclined towards using advanced ventilation technologies to improve the safety of their facilities. This is expected to bode well for the spray booth ventilation system market growth in the region.

As per FMI, the European spray booth ventilation system market is slated to experience considerable growth rate during the upcoming period owing to the rapid adoption of spray booth ventilation systems to enhance productivity, quality of the service, and efficiency of the plant.

Similarly, rapid growth of industries like automotive, aerospace, construction etc. along with surge in diseases related to inhalation of harmful gases is expected to propel the demand for spray booth ventilation systems in the region during the forecast period.

Some of the leading manufacturers of spray booth ventilation system include Ventam Systems Limited, PAINT PERFECT SPRAY BOOTH SYSTEMS, Moldow A/S, Spray Systems, Global Finishing Solutions, ELTA Group, Nova Verta, KAYCO SPRAY BOOTHS, DJK Europe GmbH, and FAM SRL, among others.

These leading players are focused on introducing novel spray booth ventilation systems with highly energy efficient and ecofriendly features. Besides this, they have adopted growth strategies such as partnerships, acquisitions, mergers, collaborations etc., to expand their global footprint. For instance, in November 2024 Gallagher Kaiser (GK) launched the Kaiser Compact Eliminator (KCe), an efficient spray booth scrubber.

Similarly, companies like Ventam Systems Limited, PAINT PERFECT SPRAY BOOTH SYSTEMS, and DJK Europe GmbH are expanding their product portfolios to meet end users demands.

| Report Attributes | Details |

|---|---|

| Growth Rate | CAGR of 3.1% from 2025 to 2035 |

| Market Expected Value (2025) | USD 641.1 million |

| Market Projected Value (2035) | USD 870.0 million |

| Base Year for Estimation | 2024 |

| Historical Data | 2020 to 2024 |

| Forecast Period | 2025 to 2035 |

| Quantitative Units | Revenue in million and CAGR from 2025 to 2035 |

| Report Coverage | Revenue Forecast, Volume Forecast, Company Ranking, Competitive Landscape, Growth Factors, Trends and Pricing Analysis |

| Segments Covered | Booth Type, Application, Region |

| Regions Covered | North America; Latin America; Western Europe; Eastern Europe; APEJ; Japan; Middle East and Africa |

| Key Countries Profiled | USA, Canada, Brazil, Argentina, Germany, UK, France, Spain, Italy, Nordics, BENELUX, Australia & New Zealand, China, India, ASEAN, GCC, South Africa |

| Key Companies Profiled | Ventam Systems Limited; PAINT PERFECT SPRAY BOOTH SYSTEMS; Moldow A/S; Spray Systems; Global Finishing Solutions; ELTA Group; Nova Verta; KAYCO SPRAY BOOTHS; DJK Europe GmbH; FAM SRL |

| Customization | Available Upon Request |

The global spray booth ventilation system market is estimated to be valued at USD 641.1 million in 2025.

It is projected to reach USD 870.0 million by 2035.

The market is expected to grow at a 3.1% CAGR between 2025 and 2035.

The key product types are downdraft, semi downdraft, side draft, cross draft, open face and bench.

automotive segment is expected to dominate with a 38.2% industry share in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Spray-dried Animal Plasma (SDAP) Market Size and Share Forecast Outlook 2025 to 2035

Spray Polyurethane Foam Market Size and Share Forecast Outlook 2025 to 2035

Spray Adhesives Market Size and Share Forecast Outlook 2025 to 2035

Spray Painting Machine Market Size and Share Forecast Outlook 2025 to 2035

Spray Caps Market Size and Share Forecast Outlook 2025 to 2035

Spray Covers Market Size and Share Forecast Outlook 2025 to 2035

Spray Dried Food Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Spray Foam Insulation Market 2025 to 2035

Spray Cheese Market Analysis by Flavours, Distribution Channel and Region through 2035

Spray Dryer Market Growth – Trends & Forecast 2025-2035

Spray Nozzle Market Growth – Trends & Forecast 2024-2034

Sprayer Cap Market Growth & Trends Forecast 2024-2034

Spray Washer Market

Spray Drying Equipment Market

Mini Spray Bottles Market Size and Share Forecast Outlook 2025 to 2035

Mist Sprayer Pumps Market by Pump Type & Application Forecast 2025 to 2035

Competitive Breakdown of Mist Sprayer Pumps Providers

Nasal Sprays Market Analysis - Size, Share, and Forecast 2025 to 2035

Dermal Sprays Market Size and Share Forecast Outlook 2025 to 2035

Throat Sprays Market Analysis - Size, Share & Forecast 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA