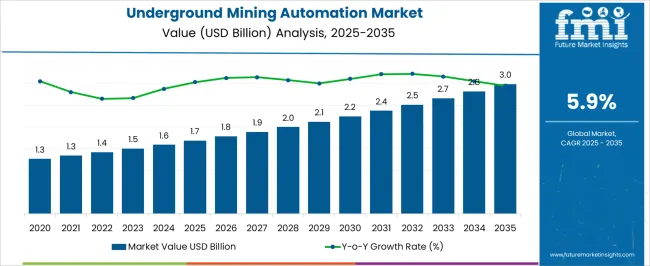

The Underground Mining Automation Market is estimated to be valued at USD 1.7 billion in 2025 and is projected to reach USD 3.0 billion by 2035, registering a compound annual growth rate (CAGR) of 5.9% over the forecast period.

| Metric | Value |

|---|---|

| Underground Mining Automation Market Estimated Value in (2025 E) | USD 1.7 billion |

| Underground Mining Automation Market Forecast Value in (2035 F) | USD 3.0 billion |

| Forecast CAGR (2025 to 2035) | 5.9% |

The underground mining automation market is expanding steadily as mining companies strive to enhance operational efficiency, worker safety, and production output in increasingly complex and hazardous environments. Automation technologies are being adopted to address challenges such as ore depletion, labor shortages, and the need for continuous mining processes in deep and confined spaces.

Advancements in robotics, sensor integration, and connectivity have enabled remote operations, predictive maintenance, and real time data analytics, all contributing to reduced downtime and increased resource utilization. Rising pressure to minimize environmental impact and comply with safety regulations is further accelerating the integration of automation systems.

The market outlook remains strong as industry players focus on modernizing legacy systems and investing in scalable automation solutions that align with productivity and sustainability goals.

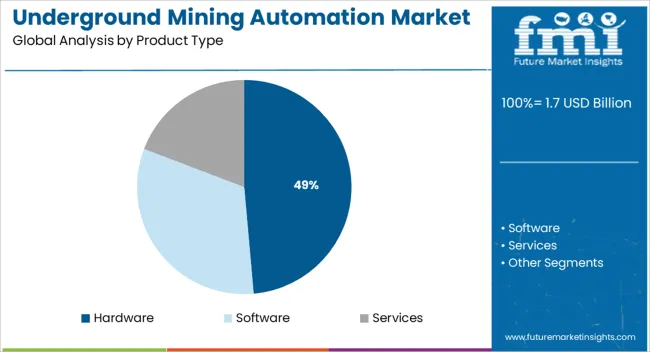

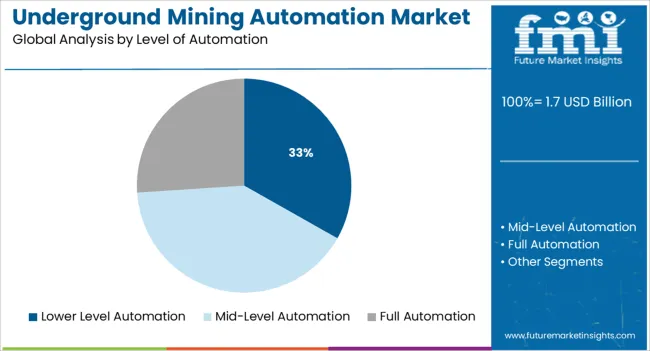

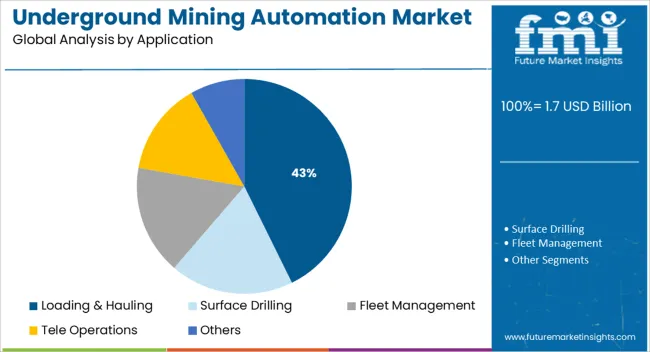

The market is segmented by Product Type, Level of Automation, Application, and End Use and region. By Product Type, the market is divided into Hardware, Software, and Services. In terms of Level of Automation, the market is classified into Lower Level Automation, Mid-Level Automation, and Full Automation. Based on Application, the market is segmented into Loading & Hauling, Surface Drilling, Fleet Management, Tele Operations, and Others. By End Use, the market is divided into Chromium mining, Coal mining, Diamond mining, Gold mining, Iron ore mining, Manganese mining, Platinum and palladium mining, Uranium mining, and Others. Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The hardware segment is expected to account for 48.60% of total revenue by 2025 within the product type category, making it the most dominant. This growth is supported by the rising deployment of automation enabled machines, sensors, cameras, and control systems in underground mining operations.

Hardware solutions are critical for enabling real time monitoring, equipment control, and safety assurance in challenging mining environments. Investments in ruggedized and interoperable equipment have increased, particularly for autonomous drills, loaders, and ventilation systems.

The need to upgrade existing infrastructures with automated tools has reinforced the hardware segment’s leadership, driven by its foundational role in operational automation.

The lower level automation segment is projected to contribute 33.20% of market revenue in 2025 under the level of automation category. This share reflects growing interest in partial automation systems that improve efficiency without fully replacing manual operations.

Lower level automation allows for the remote or assisted control of machines and processes while keeping human oversight intact. It offers a cost effective entry point for mines transitioning from manual to semi autonomous systems.

Additionally, this level of automation is easier to integrate with existing equipment, reducing capital expenditure and implementation risks. The balance it provides between control, safety, and performance has solidified its role as the preferred approach in many underground operations.

The loading and hauling segment is anticipated to hold 42.70% of total market revenue by 2025 within the application category, making it the leading area of adoption. This is driven by the high demand for efficiency, speed, and safety in material transport within underground mines.

Automated loading and hauling systems reduce cycle times, fuel usage, and operator exposure to dangerous environments. Integration with fleet management software and real time tracking systems enhances productivity and minimizes delays.

As these processes represent a major portion of operational costs and production time in underground mining, automation has become a strategic imperative. Consequently, the loading and hauling application has emerged as the key contributor to growth in the underground mining automation market.

The worldwide underground mining automation market was valued at USD 1,307.9 Million in 2024 and is expected to reach USD 2,516.7 Million by 2035.

The global underground mining automation market is expected to grow at a CAGR of 5.9% during the forecast period. This is due to factors such as the growing demand for efficiency and productivity in mining operations and the growing need for mechanization of the mineral extraction process. The increasing use of robots in mining is also expected to boost the growth of this market during the forecast period. Increasing demand for minerals and metals from emerging countries such as China and India is driving the growth of this market.

Underground mining operations are considered extremely risky because of potential risks such as poor ventilation, poisonous gas exposure, and bad health impacts. This issue has produced a demand for improved mining equipment for underground mining procedures to safeguard miners, boosting the market.

Employee safety and low production rates are two major factors behind the rising adoption of underground mining automation. Furthermore, the rise of digital mines, digital twins, and other technological advancements has influenced the global underground mining automation market, which is further expected to expand during the forecast period due to the increasing trend of industrial automation and the significant development of artificial intelligence(AI).

The growth of communications in underground mining is a key factor driving the adoption of underground mining automation solutions and services.

A major challenge in the underground mining automation market is the lack of acceptance of the technology among professionals in developing countries. Underground mining automation providers are now taking steps such as providing training and raising awareness by offering technology exhibitions. The adoption of automation in mining requires highly skilled and qualified laborers. Shortage of manpower required to operate the technology and lack of manpower required in such background acts as a major restraint to market growth.

Manufacturers from developed countries such as Germany, the USA, the United Kingdom, France, and Japan are leaders in providing automated solutions for underground mining. Mining activity is prominent in countries such as Australia, Russia, China, Canada, Indonesia, South Africa, Peru, Brazil, and other African countries.

Mining companies are now focused on investing in the automation of underground mining, with a focus on African countries. Government regulations play an important role in the adoption of underground mining automation systems. However, some countries have adopted stringent regulations to protect the environment which are hindering mining activities resulting in negatively impacting the underground mining automation market.

Using automated solutions for underground mining allows miners to move to dangerous and difficult locations. In countries such as Australia, Brazil, and Africa the deployment of underground mining automation solutions by mining operators will have a positive impact on the underground mining automation market.

New mining projects in Southeast Asia, Latin America, and African countries are expected to increase opportunities for the underground mining automation market.

The mining automation market is highly fragmented. A large number of players participate in the vast competition to win the large consumer base. Players engage in activities such as research and development to explore new developments and ideas in mining automation.

The strategic partnership is important to add value to the growth trajectory of the mining automation market. Players get into mergers, joint ventures, partnerships, and acquisitions initiatives to increase their influence in untapped regions. These factors are ultimately contributing to the growth in the mining automation market.

Key Players operating in the global underground mining automation market are ABB, Atlas Copco, General Electric, Glencore, Hexagon, Hitachi, Komatsu, Redpath, Rio Tinto, Rockwell Automation, Sandvik AB, Siemens AG, and others.

| Attribute | Details |

|---|---|

| Growth Rate | CAGR of 5.9% from 2025 to 2035 |

| Base Year for Estimation | 2024 |

| Historical Data | 2020 to 2024 |

| Forecast Period | 2025 to 2035 |

| Quantitative Units | Revenue in USD Million, Volume in 000’Units, and CAGR from 2025 to 2035 |

| Report Coverage | Revenue Forecast, Volume Forecast, Company Ranking, Competitive Landscape, Growth Factors, Trends, and Pricing Analysis |

| Segments Covered | Product Type, Level of Automation, Application, End Use, Region |

| Regions Covered | North America; Latin America; Europe; East Asia; South Asia & Pacific; Middle East and Africa |

| Key Countries Covered | USA, Canada, Mexico, Brazil, Germany, Italy, France, United Kingdom, Spain, Benelux, Russia, China, Japan, South Korea, India, ASEAN, Australia and New Zealand, GCC Countries, Turkey, South Africa, North Africa |

| Key Companies Profiled | ABB; Atlas Copco; General Electric; Glencore; Hexagon; Hitachi; Komatsu; Redpath; Rio Tinto; Rockwell Automation; Sandvik AB; Siemens AG |

| Customization & Pricing | Available upon Request |

The global underground mining automation market is estimated to be valued at USD 1.7 billion in 2025.

The market size for the underground mining automation market is projected to reach USD 3.0 billion by 2035.

The underground mining automation market is expected to grow at a 5.9% CAGR between 2025 and 2035.

The key product types in underground mining automation market are hardware, software and services.

In terms of level of automation, lower level automation segment to command 33.2% share in the underground mining automation market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Underground Mining Equipment Market Size and Share Forecast Outlook 2025 to 2035

Competitive Overview of Underground Mining Equipment Market Share

North America Underground Mining Vehicle Market Size and Share Forecast Outlook 2025 to 2035

Underground Rainwater Collection Modules Market Size and Share Forecast Outlook 2025 to 2035

Mining Lubricant Market Size and Share Forecast Outlook 2025 to 2035

Mining Remanufacturing Component Market Forecast Outlook 2025 to 2035

Mining Hose Market Size and Share Forecast Outlook 2025 to 2035

Mining Equipment Industry Analysis in Latin America Size and Share Forecast Outlook 2025 to 2035

Mining Tester Market Size and Share Forecast Outlook 2025 to 2035

Mining Pneumatic Saw Market Size and Share Forecast Outlook 2025 to 2035

Underground Hydrogen Storage Market Size and Share Forecast Outlook 2025 to 2035

Mining Drilling Service Market Size and Share Forecast Outlook 2025 to 2035

Underground Coal Gasification Industry Analysis in Asia Pacific Size and Share Forecast Outlook 2025 to 2035

Underground Cabling EPC Market Size and Share Forecast Outlook 2025 to 2035

Mining Trucks Market Size and Share Forecast Outlook 2025 to 2035

Automation Testing Market Size and Share Forecast Outlook 2025 to 2035

Mining Dump Trucks Market Size and Share Forecast Outlook 2025 to 2035

Mining Shovel Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Mining Flotation Chemicals Market Size, Growth, and Forecast 2025 to 2035

Automation COE Market Insights by Organization Size, Service Type, End User Verticals, and Region through 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA