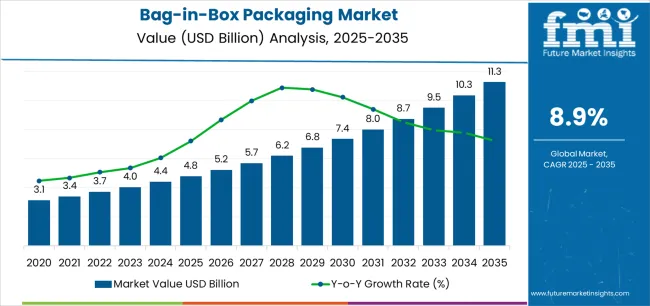

The bag-in-box packaging market is valued at USD 4.8 billion in 2025 and is projected to reach USD 11.3 billion by 2035, rising at an 8.9% CAGR, adding USD 6.4 billion in total. The magnitude and trajectory of expansion reflect accelerating shifts toward convenient liquid dispensing, extended shelf-life solutions, and cost-efficient distribution formats across beverages, liquid foods, and industrial fluids. Between 2025 and 2030, the market grows to USD 7.4 billion, accounting for 40.6% of the decade’s increase as beverage producers adopt low-waste dispensing systems, hospitality operators scale wine-on-tap programs, and liquid food processors prioritize inventory optimization. The larger 59.4% growth contribution during 2030–2035 stems from wider penetration of aseptic technology, premium barrier films, and smart dispensing systems with portion-control features supporting foodservice automation and value-added consumer experiences.

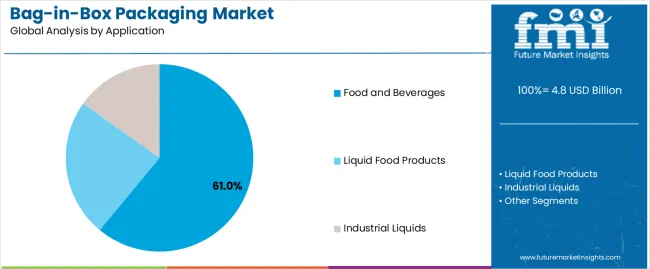

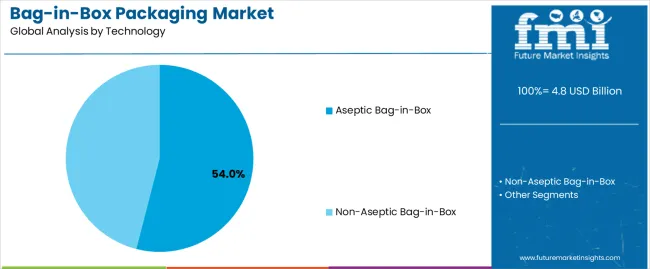

Technology segmentation reinforces these preservation and efficiency priorities: aseptic bag-in-box systems hold ~54% share, driven by ambient-stable dairy alternatives, nutritional beverages, and juice applications requiring microbiological safety and extended distribution cycles. In application terms, food & beverages command ~61%, reflecting dominant use across wine, juice, liquid dairy, beverage concentrates, and on-premise dispensing systems in QSR chains and hospitality environments. Industrial liquids form the next major cluster, supported by chemical handling, lubricants, and detergents adopting safer bulk-dispensing formats.

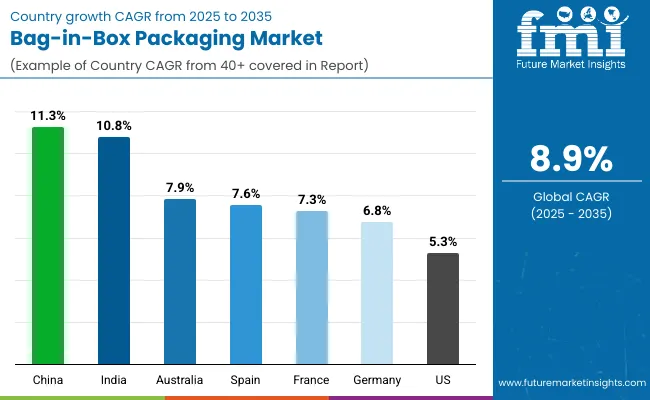

Geographically, growth is led by China (11.3% CAGR) and India (10.8%), supported by expanding beverage consumption, liquid food processing modernization, and rapid foodservice infrastructure scale-up. The USA (8.1%) and Australia (7.9%) benefit from craft beverage markets, wine-export packaging, and premium dispensing system innovation, while Spain (7.6%), France (7.3%), and Germany (6.8%) gain momentum through wine industry modernization, barrier-film advancements, and industrial liquid applications. Competitive structure is moderately concentrated, with Smurfit Kappa, DS Smith, Scholle IPN, Liqui-Box, and Rapak collectively shaping 30–35% of global supply through integrated film technologies, fitment innovation, and strong beverage-sector partnerships. Regional converters such as Optopack, CDF Corporation, Aran Group, and local packaging specialists compete through faster lead times, customized barrier structures, and application-specific dispensing solutions aligned with emerging foodservice and industrial needs.

Technological advancement is accelerating adoption across premium and sensitive products. High-barrier films with improved oxygen and light resistance allow storage of wines, dairy products, and specialty beverages for longer durations. Enhanced filling lines, aseptic technologies, and automated sealing systems ensure higher sterility standards and reduced contamination risks. In industrial settings, multi-layer bags capable of handling corrosive chemicals, lubricants, adhesives, and agrochemicals are expanding the format’s utility beyond consumer applications.

| Metric | Value |

|---|---|

| Estimated Value in (2025E) | USD 4.8 billion |

| Forecast Value in (2035F) | USD 11.3 billion |

| Forecast CAGR (2025 to 2035) | 8.9% |

Market expansion is being supported by the increasing global demand for convenient beverage dispensing and the corresponding need for cost-effective packaging solutions that can provide extended shelf-life, reduced transportation costs, and improved space utilization across foodservice, retail, and industrial liquid distribution channels. Modern beverage producers are increasingly focused on implementing packaging formats that can support brand differentiation, minimize product waste, and provide consistent quality throughout the consumption cycle. Bag-in-box packaging's proven ability to deliver exceptional product protection, convenient dispensing functionality, and freight optimization make them essential solutions for contemporary liquid product distribution and consumer convenience applications.

The growing emphasis on cost efficiency and distribution optimization is driving demand for bag-in-box packaging that can support reduced packaging weight, lower carbon footprint logistics, and simplified inventory management systems. Manufacturers' preference for packaging formats that combine product protection with handling convenience and storage efficiency is creating opportunities for innovative bag-in-box implementations. The rising influence of wine-on-tap adoption and craft beverage distribution is also contributing to increased demand for bag-in-box packaging that can provide preservation integrity, dispensing reliability, and premium presentation capabilities.

The bag-in-box packaging market is poised for rapid growth and transformation. As industries across beverages, liquid foods, industrial fluids, and personal care seek packaging formats that deliver exceptional convenience, product protection, and distribution efficiency, bag-in-box solutions are gaining prominence not just as commodity packaging but as strategic enablers of brand differentiation and supply chain optimization.

Rising wine consumption in emerging markets and expanding foodservice operations globally amplify demand, while manufacturers are leveraging innovations in barrier film technologies, smart dispensing systems, and premium finishing options.

Pathways like premium wine packaging, aseptic processing integration, and application-specific customization promise strong margin uplift, especially in high-value segments. Geographic expansion and vertical integration will capture volume, particularly where regional production capabilities and supply chain proximity are critical. Regulatory pressures around packaging waste reduction, food safety compliance, beverage quality standards, and recyclable material adoption give structural support.

The market is segmented by capacity, material type, technology, application, end use industry, and region. By capacity, the market is divided into small (up to 5 liters), medium (5-10 liters), and large (above 10 liters). By material type, it covers plastic films (polyethylene, EVOH, metallized films), cardboard outer packaging, and fitments & taps. By technology, it is segmented into aseptic bag-in-box and non-aseptic bag-in-box. By application, it includes beverages (wine, juice, liquid dairy, water, others), liquid food products, and industrial liquids. By end use industry, it is categorized into food & beverage, hospitality & foodservice, industrial, and retail. Based on distribution channel, the market includes direct sales, distributors, and packaging converters. Regionally, the market is divided into North America, Europe, East Asia, South Asia & Pacific, Latin America, and the Middle East & Africa.

The food & beverage segment is projected to account for 61% of the bag-in-box packaging market in 2025, reaffirming its position as the leading application category. Beverage producers increasingly utilize bag-in-box formats for their superior product preservation, convenient dispensing functionality, and cost-effective distribution characteristics in applications ranging from wine and juice to liquid dairy products and beverage concentrates. Bag-in-box packaging technology's advanced barrier capabilities and dispensing reliability directly address the industry requirements for extended shelf-life and operational efficiency in both retail and foodservice environments.

This application segment forms the foundation of modern liquid food distribution operations, as it represents the packaging format with the greatest versatility and established market demand across multiple beverage categories and consumption occasions. Manufacturer investments in enhanced barrier film technologies and premium dispensing systems continue to strengthen adoption among beverage producers. With companies prioritizing product quality and distribution cost optimization, bag-in-box packaging aligns with both preservation performance requirements and supply chain efficiency objectives, making them the central component of comprehensive liquid packaging strategies.

Aseptic bag-in-box systems are projected to represent 54.0% of bag-in-box packaging demand in 2025, underscoring their critical role as the primary technology platform for ambient-stable liquid food products requiring extended shelf-life without refrigeration. Food and beverage manufacturers prefer aseptic bag-in-box solutions for their exceptional microbiological safety, validated sterilization processes, and ability to maintain product quality throughout extended distribution cycles. Positioned as essential packaging for modern liquid food processing, aseptic bag-in-box systems offer both preservation advantages and distribution flexibility benefits.

The segment is supported by continuous innovation in sterilization technologies and the growing availability of validated aseptic filling equipment that enables premium product quality with enhanced shelf-life characteristics. Additionally, liquid food manufacturers are investing in aseptic processing capabilities to support ambient distribution strategies and reduced cold chain dependency. As dairy alternative demand becomes more prevalent and nutritional beverage consumption increases, aseptic bag-in-box applications will continue to dominate the technology market while supporting advanced product formulation and distribution optimization strategies.

The bag-in-box packaging market is advancing rapidly due to increasing demand for convenient beverage dispensing solutions and growing adoption of cost-effective packaging formats that provide extended shelf-life and reduced distribution costs across foodservice, retail, and industrial liquid applications. However, the market faces challenges, including consumer perception barriers regarding premium product positioning, compatibility limitations with certain liquid formulations, and the need for specialized filling equipment investments. Innovation in barrier film technologies and smart dispensing systems continues to influence product development and market expansion patterns.

The growing adoption of wine-on-tap programs in restaurants, bars, and hospitality venues is enabling beverage suppliers to offer premium products with reduced waste, improved cost economics, and enhanced freshness guarantees. Wine-on-tap systems provide improved profitability while allowing more efficient inventory management and consistent quality across service locations. Beverage distributors are increasingly recognizing the competitive advantages of bag-in-box formats for premium market positioning and operational excellence.

Modern bag-in-box packaging producers are incorporating electronic monitoring systems, automated portion control mechanisms, and dispensing analytics to enhance operational efficiency, enable consumption tracking, and deliver value-added solutions to foodservice operators. These technologies improve inventory management while enabling data-driven purchasing decisions and waste reduction programs. Advanced dispensing integration also allows manufacturers to support premium service positioning and operational optimization beyond traditional bulk packaging supply.

| Country | CAGR (2025-2035) |

|---|---|

| China | 11.3% |

| India | 10.8% |

| Australia | 7.9% |

| Spain | 7.6% |

| France | 7.3% |

| Germany | 6.8% |

| United States | 5.3% |

The bag-in-box packaging market is experiencing strong growth globally, with China leading at an 11.3% CAGR through 2035, driven by the expanding wine consumption, growing liquid food processing sector, and significant investment in modern foodservice infrastructure development. India follows at 10.8%, supported by rapid dairy industry modernization, increasing juice consumption, and growing adoption of organized retail formats. The USA shows growth at 5.3%, emphasizing craft beverage distribution and premium wine packaging innovation. Australia records 7.9%, focusing on wine export packaging and domestic beverage market sophistication. France demonstrates 7.3% growth, prioritizing wine industry innovation and premium beverage packaging excellence. Germany exhibits 6.8% growth, emphasizing quality control and industrial liquid packaging. Spain shows 7.6% growth, supported by wine production leadership and beverage processing expansion.

The report covers an in-depth analysis of 40+ countries top-performing countries are highlighted below.

Revenue from bag-in-box packaging in China is projected to exhibit exceptional growth with a CAGR of 11.3% through 2035, driven by expanding wine consumption habits and rapidly growing liquid food processing capacity supported by urbanization and rising middle-class beverage preferences. The country's growing position in global wine imports and increasing investment in modern foodservice operations are creating substantial demand for convenient liquid packaging solutions. Major beverage distributors and foodservice chains are establishing comprehensive bag-in-box sourcing capabilities to serve both domestic consumption and regional distribution networks.

Revenue from bag-in-box packaging in India is expanding at a CAGR of 10.8%, supported by the country's growing organized dairy sector, expanding juice consumption, and increasing adoption of modern retail formats. The country's rising disposable income and growing preference for packaged liquid foods are driving requirements for efficient liquid packaging capabilities. International packaging suppliers and domestic converters are establishing extensive production and distribution capabilities to address the growing demand for bag-in-box solutions.

Revenue from bag-in-box packaging in the USA is expanding at a CAGR of 5.3%, supported by the country's thriving craft beverage industry, strong emphasis on premium wine packaging, and robust demand for convenient dispensing solutions in hospitality applications. The nation's mature wine market and high-value beverage focus are driving sophisticated bag-in-box capabilities throughout the distribution chain. Leading packaging converters and beverage suppliers are investing extensively in advanced barrier technologies and premium finishing options to serve both domestic and export markets.

Revenue from bag-in-box packaging in Australia is growing at a CAGR of 7.9%, driven by the country's leadership in wine production, expanding domestic beverage consumption, and growing investment in premium packaging development. Australia's concentration of major wineries and commitment to export quality standards are supporting demand for high-performance bag-in-box solutions across multiple market segments. Manufacturers are establishing comprehensive quality assurance capabilities to maintain competitive positioning in key export markets.

Revenue from bag-in-box packaging in France is expanding at a CAGR of 7.3%, supported by the country's wine production heritage, advanced packaging innovation capabilities, and strategic focus on quality liquid food packaging. France's wine industry leadership and beverage packaging expertise are driving demand for bag-in-box solutions in premium wine distribution, juice production, and specialty liquid food applications. Manufacturers are investing in comprehensive development capabilities to serve both domestic wine producers and international premium markets.

Revenue from bag-in-box packaging in Germany is growing at a CAGR of 6.8%, driven by the country's expertise in packaging technology, emphasis on quality control, and strong position in industrial liquid packaging and beverage distribution. Germany's established packaging manufacturing capabilities and commitment to operational excellence are supporting investment in advanced filling technologies throughout major production centers. Industry leaders are establishing comprehensive quality management systems to serve domestic beverage producers and industrial liquid markets.

Revenue from bag-in-box packaging in Spain is expanding at a CAGR of 7.6%, supported by the country's wine production scale, growing beverage processing industry, and strategic position in European liquid food distribution. Spain's wine export capabilities and integrated beverage manufacturing ecosystem are driving demand for cost-effective bag-in-box packaging in bulk wine distribution, juice concentrates, and liquid food applications. Leading manufacturers are investing in production capacity to serve the growing requirements of domestic and export markets.

The bag-in-box packaging market in Europe is projected to grow from USD 1.9 billion in 2025 to USD 4.1 billion by 2035, registering a CAGR of 8.0% over the forecast period. France is expected to maintain its leadership position with a 28.0% market share in 2025, projected to reach 28.5% by 2035, supported by its strong wine industry, advanced beverage packaging capabilities, and comprehensive liquid food processing base serving diverse bag-in-box applications across Europe.

Germany follows with a 24.0% share in 2025, projected to reach 24.2% by 2035, driven by robust demand for bag-in-box packaging in industrial liquids, dairy alternatives, and beverage distribution, combined with established packaging manufacturing capabilities and quality control excellence. The United Kingdom holds a 15.0% share in 2025, expected to maintain 15.0% through 2035, supported by strong wine consumption and growing foodservice adoption. Spain commands an 18.0% share in 2025, projected to reach 18.5% by 2035, while Italy accounts for 8.0% in 2025, expected to reach 8.2% by 2035. The Netherlands maintains a 3.5% share in 2025, growing to 3.6% by 2035. The Rest of Europe region, including Nordic countries, Eastern Europe, Belgium, Switzerland, Austria, and Poland, is anticipated to gain momentum, with its collective share adjusting from 3.5% to 2.0% by 2035, attributed to increasing wine consumption in Eastern Europe and growing craft beverage distribution in Nordic countries implementing modern packaging programs.

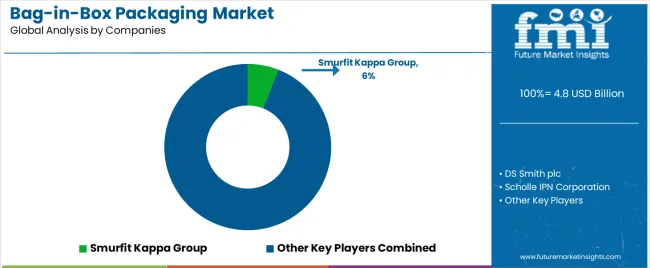

The bag-in-box packaging market features 10–15 players with moderate concentration, where the top three companies collectively hold around 46–52% of global market share, driven by strong expertise in flexible films, dispensing technologies, and long-standing partnerships with beverage, food, and industrial liquid brands. The leading company, Smurfit Kappa Group, commands roughly 6% of the market share, supported by its advanced Bag-in-Box systems, proprietary Vitop® dispensing technology, and global manufacturing footprint. Competition centers on film barrier performance, dispensing reliability, product safety, sustainability, and filling-line compatibility rather than simple price-based strategies.

Market leaders such as Smurfit Kappa Group, DS Smith plc (Rapak), and Liqui-Box Corporation maintain dominant positions by offering high-performance bags, taps, fitments, and integrated filling systems tailored for wine, dairy, juices, water, and foodservice applications. Their strengths include multilayer film innovation, oxygen-barrier technologies, and strong sustainability programs that reduce plastic usage and extend product shelf life.

Challenger companies including Amcor plc, Scholle IPN Corporation, and CDF Corporation compete with specialized films, custom dispensing solutions, and recyclable Bag-in-Box formats targeted at both consumer and industrial liquid packaging.

Additional competition arises from Optopack Ltd., TPS Rental Systems Ltd., and Aran Group, which enhance regional presence through cost-effective production, flexible customization, and reliable supply for foodservice, chemical, and bulk liquid applications.

| Items | Values |

|---|---|

| Quantitative Units (2025) | USD 4.8 billion |

| Capacity | Small (up to 5 liters), Medium (5-10 liters), Large (above 10 liters) |

| Material Type | Plastic Films (Polyethylene, EVOH, Metallized Films), Cardboard Outer Packaging, Fitments & Taps |

| Technology | Aseptic Bag-in-Box, Non-Aseptic Bag-in-Box |

| Application | Beverages (Wine, Juice, Liquid Dairy, Water, Others), Liquid Food Products, Industrial Liquids |

| End Use Industry | Food & Beverage, Hospitality & Foodservice, Industrial, Retail |

| Distribution Channel | Direct Sales, Distributors, Packaging Converters |

| Regions Covered | North America, Europe, East Asia, South Asia & Pacific, Latin America, Middle East & Africa |

| Countries Covered | United States, Canada, United Kingdom, Germany, France, Spain, China, Japan, South Korea, India, Australia, Brazil and 40+ countries |

| Key Companies Profiled | Smurfit Kappa Group, DS Smith plc, Rapak (DS Smith), Liqui-Box Corporation, Amcor plc, Scholle IPN Corporation, CDF Corporation, Optopack Ltd., TPS Rental Systems Ltd., and Aran Group |

| Additional Attributes | Dollar sales by capacity and application category, regional demand trends, competitive landscape, technological advancements in barrier systems, aseptic processing integration, dispensing innovation, and supply chain optimization |

The global bag-in-box packaging market is estimated to be valued at USD 4.8 billion in 2025.

The market size for the bag-in-box packaging market is projected to reach USD 11.3 billion by 2035.

The bag-in-box packaging market is expected to grow at a 8.9% CAGR between 2025 and 2035.

The key product types in bag-in-box packaging market are aseptic bag-in-box and non-aseptic bag-in-box.

In terms of application, food and beverages segment to command 61.0% share in the bag-in-box packaging market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Demand for Bag-In-Box Packaging in USA Size and Share Forecast Outlook 2025 to 2035

Packaging Supply Market Size and Share Forecast Outlook 2025 to 2035

Packaging Testing Services Market Size and Share Forecast Outlook 2025 to 2035

Packaging Tubes Market Size and Share Forecast Outlook 2025 to 2035

Packaging Jar Market Forecast and Outlook 2025 to 2035

Packaging Barrier Film Market Size and Share Forecast Outlook 2025 to 2035

Packaging Films Market Size and Share Forecast Outlook 2025 to 2035

Packaging Laminate Market Size and Share Forecast Outlook 2025 to 2035

Packaging Burst Strength Test Market Size and Share Forecast Outlook 2025 to 2035

Packaging Tapes Market Analysis - Size, Share, & Forecast Outlook 2025 to 2035

Packaging Materials Market Size and Share Forecast Outlook 2025 to 2035

Packaging Labels Market Size and Share Forecast Outlook 2025 to 2035

Packaging Equipment Market Size and Share Forecast Outlook 2025 to 2035

Packaging Resins Market Size and Share Forecast Outlook 2025 to 2035

Packaging Inspection Systems Market Size and Share Forecast Outlook 2025 to 2035

Packaging Design And Simulation Technology Market Size and Share Forecast Outlook 2025 to 2035

Packaging Suction Cups Market Size and Share Forecast Outlook 2025 to 2035

Packaging Straps and Buckles Market Size and Share Forecast Outlook 2025 to 2035

Packaging Coating Market Analysis - Size, Share, & Forecast Outlook 2025 to 2035

Packaging Testing Equipment Market Analysis & Growth 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA