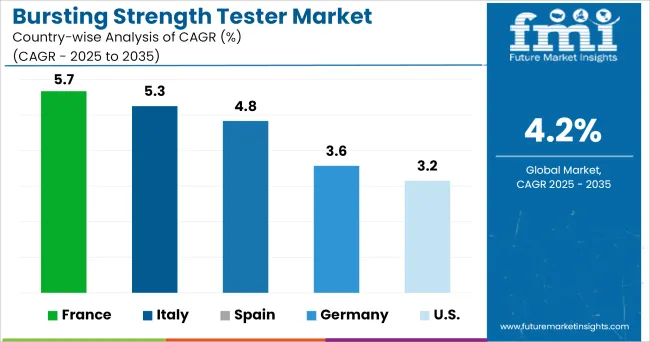

The Bursting Strength Tester Market is estimated to be valued at USD 131.0 million in 2025 and is projected to reach USD 197.7 million by 2035, registering a compound annual growth rate (CAGR) of 4.2% over the forecast period.

The bursting strength tester market is advancing steadily, driven by the critical role these instruments play in quality assurance across various manufacturing sectors. Increasing emphasis on product durability, compliance with stringent international standards, and the growing adoption of automated testing solutions have fueled demand for reliable and precise testers.

Industry journals and corporate technical whitepapers highlight how advancements in sensor technology and digital interfaces have enhanced accuracy and ease of operation, making these devices indispensable for material testing laboratories. Sustainability initiatives within textiles and packaging industries have also increased the need for robust quality checks to minimize material waste and optimize production processes.

Future growth is anticipated to be bolstered by investments in R&D for portable and multi-material capable testers, alongside expanding applications in emerging markets where manufacturing output is rising. Collaborative initiatives between equipment manufacturers and industrial clients are paving the way for improved adoption and technological evolution.

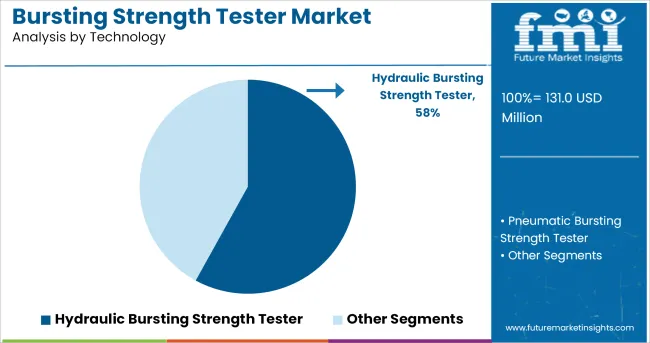

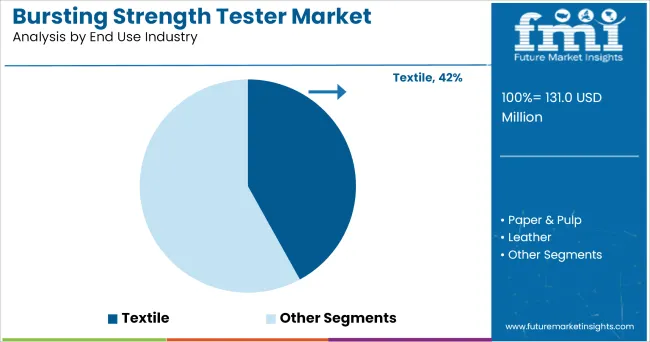

The market is segmented by Technology and End Use Industry and region. By Technology, the market is divided into Hydraulic Bursting Strength Tester and Pneumatic Bursting Strength Tester. In terms of End Use Industry, the market is classified into Textile, Paper & Pulp, Leather, Fiberboard, and Others.

Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

When segmented by technology, the hydraulic bursting strength tester is projected to hold 58.0% of the total market revenue in 2025, making it the leading technology segment. This dominance has been supported by the proven reliability, robustness, and precision of hydraulic systems, as reflected in technical specifications outlined in supplier product catalogs and industrial equipment reviews.

Hydraulic testers have been favored for their ability to apply uniform pressure, accommodate a wide range of material thicknesses, and deliver consistent results even under demanding production environments. Their compatibility with industry-standard testing protocols and certifications has further strengthened their adoption, particularly in sectors where compliance and repeatability are paramount.

Moreover, enhancements in hydraulic system design have reduced maintenance requirements and improved operator safety, which has reinforced their preferred status. This combination of durability, regulatory alignment, and operational reliability has ensured the continued prominence of hydraulic technology in the market.

Segmenting by end use industry, the textile sector is expected to account for 42.0% of the bursting strength tester market revenue in 2025, positioning it as the leading industry segment. This leadership has been driven by the textile industry’s stringent focus on material quality and compliance with international durability standards, as documented in textile engineering journals and corporate quality assurance guidelines.

Manufacturers have increasingly adopted bursting strength testers to evaluate fabric performance under pressure, ensuring resistance to tearing and wear. The sector’s reliance on standardized testing procedures to meet export requirements and maintain brand reputation has fueled the deployment of these instruments at both production and R&D levels.

Furthermore, the growing demand for technical textiles and high-performance fabrics in automotive, healthcare, and sportswear applications has intensified quality expectations, reinforcing the textile industry’s investment in advanced testing solutions. The interplay of regulatory requirements, customer expectations, and competitive differentiation has consolidated the textile segment’s dominance.

With need for testing the performance and strength for plethora of the materials like corrugated boards, paperboards, leather, paper, rexine, industrial fabric, filter cloth, solid fireboards, etc., the usage of bursting strength tester has gained significant traction. In addition to this, the procedures related to design innovation and compliance to quality standards are said to be the growth drivers for its demand.

With paper industry clocking significant growth due its variety of application in printing, packaging, etc. inherent processing and quality testing of paper products is anticipated to fuel the market growth of the device.

Demand from the paper industry to test the quality of different kind of paper and paperboards is understood to be the key user of bursting strength tester. Properties of paper are dependent on many things such as, formation, type of fibre, chemical, weight.

The bursting strength in paper can be increased by refining as it improves the fibre to fibre bonding. To provide various quality of paper to various type of functions and various requirements, the device plays vital part in the paper industry.

Asia Pacific region is anticipated to lead the global bursting strength tester market owing to growing packaging and textile industries. The developing countries in Asia Pacific region like China, India has large textile and paper industry, so these countries to dictate the market in this region.

Furthermore, emerging markets of Vietnam and Bangladesh are expected to fuel the demand of the device on the backdrop of burgeoning leather goods industry growth.

Another crucial aspect related to the region being a lucrative market is that European Union envisaging of green economy and ecological production. Leather industry is also expected to be the other key end user of the device in production hubs of Italy and France.

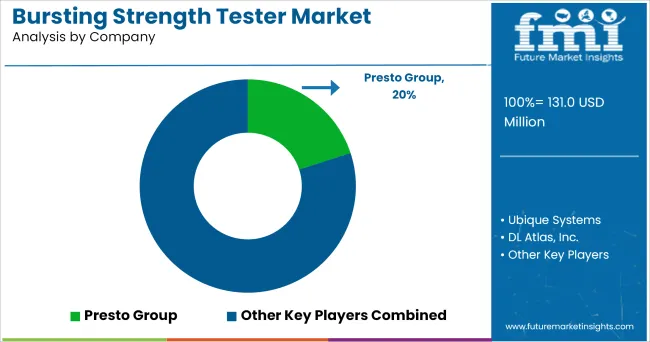

Some of the leading manufacturers and suppliers include

Leading players are adopting the strategies like online selling and enhancing product portfolio to gain competitive edge on their peers. For e.g. Ubique Systems, one of the leading manufacturers has recently launched a prototype for combination of board and paper with various advanced features.

This tester is touch screen and has auto version, LCD version, and LED version. Manufacturers are continuously focussing on to provide the model with latest technology and advanced features.

The report is a compilation of first-hand information, qualitative and quantitative assessment by industry analysts, inputs from industry experts and industry participants across the value chain. The report provides in-depth analysis of parent market trends, macro-economic indicators and governing factors along with market attractiveness as per segments.

The report also maps the qualitative impact of various market factors on market segments and geographies.

The global bursting strength tester market is estimated to be valued at USD 131.0 million in 2025.

The market size for the bursting strength tester market is projected to reach USD 197.7 million by 2035.

The bursting strength tester market is expected to grow at a 4.2% CAGR between 2025 and 2035.

The key product types in bursting strength tester market are hydraulic bursting strength tester and pneumatic bursting strength tester.

In terms of end use industry, textile segment to command 42.0% share in the bursting strength tester market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Wet Strength Paper Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

High-Strength Polyester Thread Market Size and Share Forecast Outlook 2025 to 2035

Nail Strengtheners Market

Rapid Strength Concrete Market Size and Share Forecast Outlook 2025 to 2035

Burst Strength Tester Market

Skin-Barrier Strengthening Phospholipids Market Size and Share Forecast Outlook 2025 to 2035

Packaging Burst Strength Test Market Size and Share Forecast Outlook 2025 to 2035

5G Tester Market Growth – Trends & Forecast 2019-2027

RF Tester Market Growth – Trends & Forecast 2019-2027

LAN tester Market Size and Share Forecast Outlook 2025 to 2035

SCC Tester Market Size and Share Forecast Outlook 2025 to 2035

LED Tester Market

DSL Tester Market Growth – Trends & Forecast 2019-2027

Drug Tester Market Size and Share Forecast Outlook 2025 to 2035

Gold Tester Market Size and Share Forecast Outlook 2025 to 2035

Tube Tester Market Size and Share Forecast Outlook 2025 to 2035

CCTV Tester Market Size and Share Forecast Outlook 2025 to 2035

RFID Tester Market Size and Share Forecast Outlook 2025 to 2035

Pump Testers Market Size and Share Forecast Outlook 2025 to 2035

Food Tester Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA