With greater awareness on the part of various industries towards secure, efficient, and reusable packaging solutions, the dunnage tray sector is undergoing rapid growth. The demand for these packaging containers is ever-increasing in automotive, electronics, and industrial applications, compelling manufacturers to innovate with sturdy, lightweight, and recyclable materials. Molding technologies driven by AI, RFID tracking, and sustainable polymer molding are all being incorporated to streamline the supply chain and curb wastages.

Manufacturers are implementing automation, precise high-end forming technologies, and tailor-made tray designs to enable better protection and efficiency of handling products. The industry also focuses on eco-friendly dunnage trays, anti-static ones, and modular designs to cater to the needs of high-functional industries.

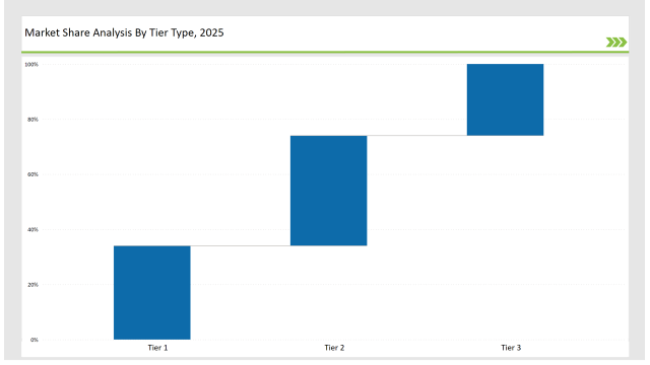

Tier 1 players, including ORBIS Corporation, Sonoco Products, and DS Smith, have the market share of 34% based on their capability in material innovation, mass production, and their advanced logistics solutions.

Tier 2 companies like Schoeller Allibert, SSI Schaefer, and Nefab Group account for 40% of the market by offering cost-effective, custom-engineered dunnage tray solutions for specific industries.

Among Tier 3 companies are regional and niche players specializing in bio-based trays, ESD-safe materials, and vacuum-formed dunnage, occupying 26% of the overall market. These companies focus on localized production, sustainable materials, and smart packaging solutions.

Global Market Share by Key Players (2025)

| Category | Market Share (%) |

|---|---|

| Top 3 (ORBIS Corporation, Sonoco Products, DS Smith) | 16% |

| Rest of Top 5 (Schoeller Allibert, SSI Schaefer) | 10% |

| Next 5 of Top 10 (Nefab Group, Dunapack Packaging, RPC Group, Greif Inc., Sealed Air) | 8% |

The dunnage tray industry serves multiple sectors where product safety, reusability, and efficiency are critical. Companies are developing advanced packaging solutions to support high-value products and supply chain optimization.

Manufacturers are optimizing dunnage trays with smart tracking, eco-friendly materials, and lightweight designs. They are enhancing tray durability with reinforced structural support to withstand heavy loads. Additionally, companies are integrating UV-resistant coatings to extend the lifespan of trays used in outdoor storage and shipping.

The dunnage tray industry is undergoing transformation through sustainability and automation. Companies are integrating AI-based quality control, bio-based polymer alternatives, and modular tray systems into production. In addition, there are RFID-enabled trays which will boast improved inventory management. Manufacturers are developing vacuum-formed and thermoformed trays that stack better and utilize space more efficiently. In addition, companies are implementing closed-loop recycling programs to minimize waste and lower manufacturing costs.

Technology suppliers should focus on automation, digital tracking, and sustainable materials to support the evolving dunnage tray market. Partnering with automotive, electronics, and industrial manufacturers will drive growth.

| Tier Type | Example of Key Players |

|---|---|

| Tier 1 | ORBIS Corporation, Sonoco Products, DS Smith |

| Tier 2 | Schoeller Allibert, SSI Schaefer, Nefab Group |

| Tier 3 | Dunapack Packaging, RPC Group, Greif Inc., Sealed Air |

Leading manufacturers are advancing dunnage tray technology with AI-driven tracking, sustainable materials, and customized precision designs. They are optimizing mold precision to reduce material waste and enhance structural integrity. Additionally, companies are incorporating advanced stacking features to improve space efficiency during transport and storage.

| Manufacturer | Latest Developments |

|---|---|

| ORBIS Corporation | Launched RFID-integrated returnable dunnage trays in March 2024. |

| Sonoco Products | Developed lightweight, high-strength thermoformed trays in April 2024. |

| DS Smith | Expanded sustainable fiber-based dunnage tray solutions in May 2024. |

| Schoeller Allibert | Released modular stacking trays for logistics in June 2024. |

| SSI Schaefer | Strengthened anti-static packaging solutions in July 2024. |

| Nefab Group | Introduced compostable dunnage trays in August 2024. |

| Dunapack Packaging | Pioneered water-resistant laminated paperboard trays in September 2024. |

The dunnage tray market is evolving as companies invest in smart tracking, sustainable materials, and precision engineering. They are leveraging AI-powered defect detection to enhance manufacturing accuracy and reduce waste. Additionally, businesses are integrating IoT-enabled sensors into trays to provide real-time condition monitoring and optimize supply chain performance.

Manufacturers will continue integrating AI-driven quality control, smart tracking, and sustainable polymers. Companies will refine moisture-resistant and heat-stable materials to improve performance. Businesses will develop collapsible dunnage trays to optimize storage efficiency. Firms will expand digital labeling to improve inventory management. Smart QR and NFC-enabled features will enhance supply chain transparency. Additionally, organizations will strengthen automation-driven production lines to increase output and reduce costs. Companies will also invest in advanced molding techniques to improve precision and reduce material wastage. Furthermore, they will integrate predictive analytics to optimize tray design and enhance load-bearing capacity.

Leading players include ORBIS Corporation, Sonoco Products, DS Smith, Schoeller Allibert, SSI Schaefer, Nefab Group, and Dunapack Packaging.

The top 3 players collectively control 16% of the global market.

The market shows medium concentration, with top players holding 34%.

Key drivers include automation, sustainability, smart tracking, and lightweight materials.

Explore Similar Insights

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA