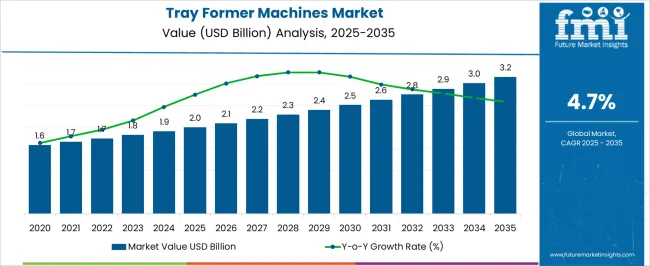

The Tray Former Machines Market is estimated to be valued at USD 2.0 billion in 2025 and is projected to reach USD 3.2 billion by 2035, registering a compound annual growth rate (CAGR) of 4.7% over the forecast period.

| Metric | Value |

|---|---|

| Tray Former Machines Market Estimated Value in (2025 E) | USD 2.0 billion |

| Tray Former Machines Market Forecast Value in (2035 F) | USD 3.2 billion |

| Forecast CAGR (2025 to 2035) | 4.7% |

The tray former machines market is experiencing accelerated growth as manufacturers across multiple sectors increasingly prioritize packaging automation to enhance operational efficiency and reduce labor dependency. Food and agriculture producers, in particular, are adopting tray formers to improve throughput, reduce damage during transit, and meet the rising need for shelf-ready and sustainable packaging formats.

Investments in advanced servo-driven systems, quick-change tooling, and integrated inspection sensors are enabling faster format shifts and minimal downtime. Growing demand for consistent packaging quality and space-efficient tray designs has also contributed to greater machine standardization and modular system configurations.

Sustainability initiatives across industries are encouraging the use of recyclable corrugated materials, which pair well with modern tray formers. As e-commerce and cold chain logistics continue to evolve, automated and adaptable tray forming equipment is expected to remain critical in supporting high-volume packaging operations across sectors such as agriculture, processed food, consumer goods, and pharmaceuticals.

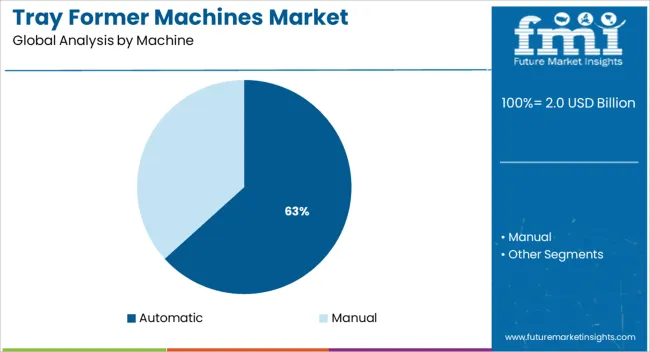

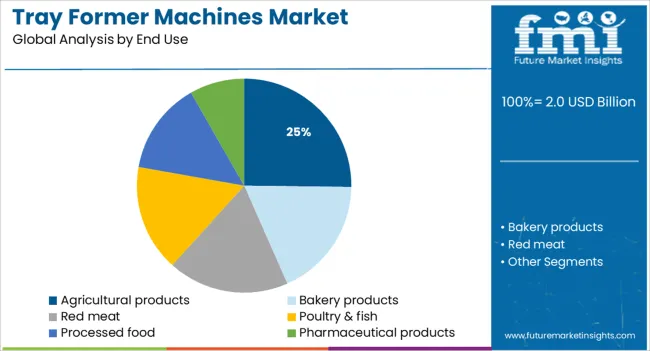

The market is segmented by Machine and End Use and region. By Machine, the market is divided into Automatic and Manual. In terms of End Use, the market is classified into Agricultural products, Bakery products, Red meat, Poultry & fish, Processed food, and Pharmaceutical products. Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The automatic machine segment is expected to account for 63.3% of total revenue within the tray former machines market in 2025, positioning it as the leading machine category. This leadership is driven by the high efficiency, precision, and scalability offered by fully automated systems in high-demand production environments. Automatic tray formers significantly reduce the need for manual labor, enabling faster tray formation cycles with consistent output quality.

These machines are equipped with programmable logic controls, touch screen interfaces, and self-diagnostic features, which facilitate seamless integration into smart packaging lines. As manufacturers seek to minimize downtime and improve OEE metrics, automatic systems have become the preferred solution for both high-volume and diverse tray configurations.

Additionally, the ability to support multi-format compatibility has reinforced their adoption across industries that require flexible packaging setups. As throughput targets continue to rise, automatic tray forming equipment is anticipated to dominate purchasing decisions across global packaging operations.

The agricultural products segment is projected to hold 25.2% of total revenue in the tray former machines market in 2025, establishing it as the leading end-use segment. This dominance can be attributed to the growing need for safe, efficient, and durable packaging of fresh produce, particularly fruits and vegetables, across domestic and export markets.

Tray formers are increasingly being used in agriculture to ensure secure handling, optimized stacking, and ventilation of perishables during transit and retail display. The transition toward recyclable and biodegradable materials in farm-to-shelf packaging has further boosted the demand for advanced tray forming solutions compatible with corrugated and molded fiber substrates.

The seasonality and variability in product size have made flexible tray forming systems essential for agricultural packers aiming for rapid changeovers and reduced waste. Additionally, the expansion of cold chain logistics and regional food hubs has elevated the importance of standardized packaging systems, reinforcing the agricultural sector’s contribution to market growth.

Packaging equipment that supports the production capacities of leading packaging manufacturers are inculcated with features such as high speed and quick format changeover.

Tray former machines are vested with easy handling mechanism, transferring and forming convenience, smooth process flows, simple adjustment needs, progressive tray forming mechanism and flexibility of adapting to multiple tray types.

Packaging equipment such as tray former machines are immensely significant part of overall packaging value chain. Tray former machines not only have to ensure quality of packaging products such as trays but also have to maintain efficiency in the production process.

Tray former machine manufacture trays with varying speeds without sacrificing the quality of the products. Tray forming machine has a wide range of application for the agricultural, bakery, meat and pharmaceutical products. Tray former machine has drastically reduced generation of waste and time required for manufacturing of tray packaging.

Tray former machine market is driven by innovations in design and material usage of trays. Trays have application for various consumer products such as meat, vegetables, pet food, ready to eat meal, etc. Tray former machines have to incorporate the forming of die required for various sizes of trays.

Tray former machines manufacturers are increasingly producing machines with improved level of automations. Automation level enhances the production efficiency of packaging products manufacturers by reducing the overall requirement of manual operations and cost of labor.

The growth of the thermoform and flexible packaging market positively influences the tray former machines market. The consumable packaging market is estimated to be USD 700 billion and is expected to grow at a CAGR of 3% over the forecast period.

The thermoform packaging market is witnessing a trend of trays manufactured using post-consumer recycled materials. Trays utilize less material and have a smaller carbon footprint in comparison with other similar forms of packaging which makes it eco-friendly, while boosting the demand for tray former machines market.

Food products packed in trays enhances the visibility of the food products which in turn improves the turnover ratio of the food product suppliers, resultantly supporting the growth for tray former machines market.

The property of tray former machines in providing high speed of operations while producing high quality of trays, drives the global market for tray former machines market.

Ease of operations and low operating cost are another factor contributing to the growth of the tray former machines market. The high fixed cost involved in the initial installment of the tray former machines is a key factor hindering the growth of tray former machines market.

The tray former machine requires large inventory size which can increase the working capital of the company. Numerous parts of tray former machines and excessive wear and tear of those parts along with large machine footprint restricts the growth for tray former machines market.

The North America is expected to lead the tray former machines market owing to a well-established modern retail sector in the region. APEJ and Latin America is expected to show rapid growth in the tray former machines market over the forecast period attributed to the changing consumer lifestyle along with increased dispersion of the modern retail format in the region.

The rapid industrialization and the presence of densely populated areas in the APEJ region is expected to support the tray former machines market in the region over the forecast period. Eastern and Western Europe is expected to show moderate growth over the forecast period due to the stagnant growth in the consumption of meat products.

Key players operating in the tray former machines market are Gebo Cermex, Iman Pack Inc., Acmi, Sa, Lantec Uk Ltd, Delta Packaging Industries, Trepko (Uk) Limited, Ixapack Global, Sacmi Packaging S.p.a, Bosch Corporation, Gma Generale De Mecanique Appliquee Sas, Hybernya Industrial, S.a. De c.v., Arpac Group, Meca Systeme Snp, Adco Manufacturing, Wexxar Packaging, Inc., Tecnicam Srl, Lead Technology Ltd., Grandi r. Srl, and Radpak Fabryka Maszyn Pakuj?cych Sp.

The global tray former machines market is estimated to be valued at USD 2.0 billion in 2025.

The market size for the tray former machines market is projected to reach USD 3.2 billion by 2035.

The tray former machines market is expected to grow at a 4.7% CAGR between 2025 and 2035.

The key product types in tray former machines market are automatic and manual.

In terms of end use, agricultural products segment to command 25.2% share in the tray former machines market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Market Share Distribution Among Tray Former Machines Manufacturers

Tray Market Forecast and Outlook 2025 to 2035

Tray Dispensers Market Size and Share Forecast Outlook 2025 to 2035

Tray Liners Market

Tray Packing Machine Market

Tray Loader Market

Tray Sealer Machines Market Size and Share Forecast Outlook 2025 to 2035

Industry Share & Competitive Positioning in Tray Sealer Machines

Tray Sealing Machines Market Size and Share Forecast Outlook 2025 to 2035

Tray and Sleeve Packing Machines Market Size and Share Forecast Outlook 2025 to 2035

ESD Trays Market Size and Share Forecast Outlook 2025 to 2035

Lab Trays Market Size and Share Forecast Outlook 2025 to 2035

Food Tray Market Size and Share Forecast Outlook 2025 to 2035

Meat Trays Market Analysis - Size and Share Forecast Outlook 2025 to 2035

Key Companies & Market Share in the Food Trays Sector

CPET Trays Market

Tilt tray sorter Market

Meal Tray Sealing Machines Market Size and Share Forecast Outlook 2025 to 2035

Cable Tray Market Size and Share Forecast Outlook 2025 to 2035

Sieve Trays Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA