The Elastomeric Bearings Market is estimated to be valued at USD 3.8 billion in 2025 and is projected to reach USD 5.6 billion by 2035, registering a compound annual growth rate (CAGR) of 4.0% over the forecast period.

The 10-year growth comparison of the elastomeric bearings market shows a steady and consistent increase, with market value projected to rise from USD 3.8 billion in 2025 to USD 5.6 billion by 2035, reflecting a compound annual growth rate (CAGR) of 4%. Over this decade, the market is expected to experience incremental growth, with values gradually increasing from USD 3.8 billion in 2025 to USD 3.9 billion in 2026, reaching USD 4.1 billion by 2027. This steady rise indicates an ongoing demand for elastomeric bearings in various industries, including construction, automotive, and infrastructure, where the need for flexible and durable materials continues to grow.

The slow yet consistent growth of the elastomeric bearings market suggests that demand will remain stable over the next decade. By 2035, the market is projected to reach USD 5.6 billion, driven by the increasing use of these bearings in critical infrastructure projects and machinery that require vibration isolation, shock absorption, and long-term durability. The steady market growth underscores the value of elastomeric bearings in sectors where safety and performance are crucial, positioning the market for continued relevance. As global infrastructure projects and manufacturing operations expand, the role of elastomeric bearings in ensuring efficient operations is expected to remain integral.

| Metric | Value |

|---|---|

| Elastomeric Bearings Market Estimated Value in (2025 E) | USD 3.8 billion |

| Elastomeric Bearings Market Forecast Value in (2035 F) | USD 5.6 billion |

| Forecast CAGR (2025 to 2035) | 4.0% |

The elastomeric bearings market is experiencing consistent growth, supported by rising infrastructure development activities and the increasing need for reliable load-bearing and vibration-isolating components in structural applications. Demand is being reinforced by the expanding construction of bridges, highways, and elevated structures, alongside the refurbishment of aging transportation infrastructure. The market is also benefiting from advancements in elastomer compounding and manufacturing technologies, which have enhanced durability, load capacity, and resistance to environmental degradation.

Strict safety and quality standards across regions are driving the adoption of high-performance bearings capable of withstanding heavy loads, temperature fluctuations, and seismic activity. Governments and private contractors are prioritizing materials that offer long service life with minimal maintenance, further supporting the growth trajectory.

Additionally, the increasing use of elastomeric bearings in non-transportation applications such as buildings and industrial machinery is broadening the market scope As global investments in infrastructure projects continue to expand, the market is expected to sustain robust growth, with innovation and material enhancement playing key roles in meeting evolving structural engineering requirements.

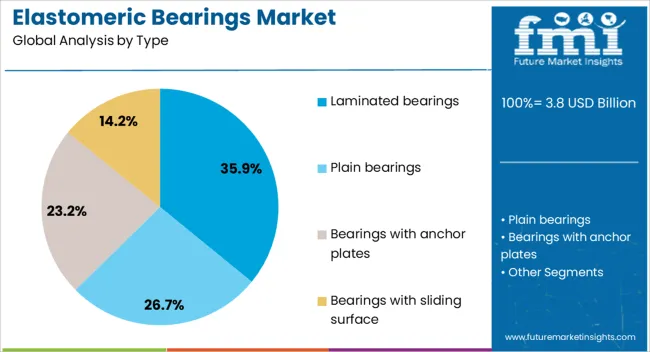

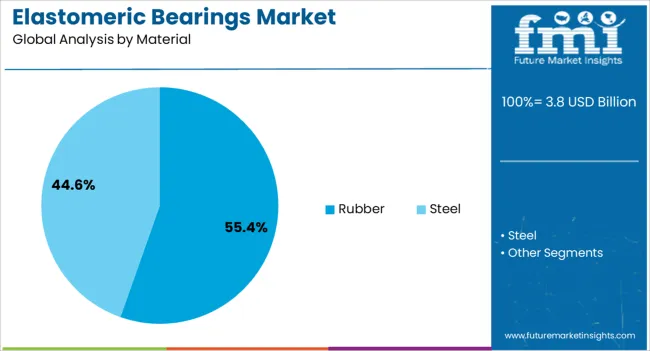

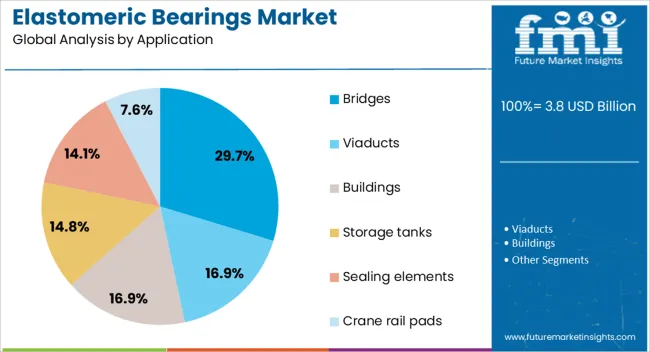

The elastomeric bearings market is segmented by type, material, application, and geographic regions. By type, elastomeric bearings market is divided into Laminated bearings, Plain bearings, Bearings with anchor plates, and Bearings with sliding surface. In terms of material, elastomeric bearings market is classified into Rubber and Steel. Based on application, elastomeric bearings market is segmented into Bridges, Viaducts, Buildings, Storage tanks, Sealing elements, and Crane rail pads. Regionally, the elastomeric bearings industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The laminated bearings segment is projected to hold 35.9% of the elastomeric bearings market revenue share in 2025, establishing itself as the leading product type. Its dominance is driven by the combination of flexibility and load-bearing strength achieved through alternating layers of elastomer and steel plates, enabling superior performance in both vertical load support and horizontal movement accommodation.

These characteristics make laminated bearings suitable for structures requiring high stability and durability, such as bridges and elevated roadways. The segment is benefiting from their long service life, minimal maintenance requirements, and resistance to environmental factors including temperature variation, moisture, and chemical exposure.

Their ability to meet stringent safety and performance standards for infrastructure projects has reinforced their position as the preferred choice among engineers and contractors Growing global infrastructure development, coupled with advancements in precision molding and bonding technologies, is expected to further strengthen demand for laminated bearings in the years ahead.

The rubber material segment is anticipated to account for 55.4% of the elastomeric bearings market revenue share in 2025, making it the largest material category. This leadership is attributed to the inherent flexibility, resilience, and vibration-damping properties of rubber, which make it highly effective for structural load distribution and movement absorption. The segment benefits from the ability of rubber bearings to perform consistently under a variety of environmental and load conditions while requiring minimal maintenance.

Technological advancements in synthetic rubber formulations are improving resistance to ozone, ultraviolet radiation, and temperature fluctuations, extending operational lifespans. The cost-effectiveness of rubber bearings compared to alternative materials is also contributing to their widespread adoption in infrastructure projects.

Their compatibility with a range of structural designs, along with compliance with international engineering standards, has reinforced their dominant position in the market As demand for sustainable and durable infrastructure solutions increases, the rubber segment is expected to remain the preferred material choice.

The bridges application segment is expected to capture 29.7% of the elastomeric bearings market revenue share in 2025, positioning it as the leading application area. Its dominance is supported by the critical role elastomeric bearings play in enhancing bridge safety, durability, and performance under both static and dynamic loads. These bearings help accommodate thermal expansion, seismic activity, and traffic-induced vibrations, ensuring structural integrity over extended periods.

The segment is benefiting from significant investments in bridge construction, rehabilitation, and modernization projects globally, driven by urban development and transportation connectivity needs. The ability of elastomeric bearings to meet strict engineering specifications for load capacity, movement range, and durability has reinforced their preference among civil engineers and project planners.

Advancements in material technology and manufacturing precision are further enhancing performance, enabling longer service intervals and reduced maintenance costs As governments focus on building resilient infrastructure, the demand for high-performance bearings in bridge applications is expected to remain strong.

The elastomeric bearings market is expanding, driven by increasing demand from the construction, transportation, and renewable energy sectors. Opportunities are emerging from infrastructure development, including green energy projects and transport modernization. Product innovation and customization trends are enhancing bearing performance and applications. However, challenges such as raw material price volatility and sourcing difficulties persist. The market outlook remains positive, with growing infrastructure investments and technological advancements driving demand for elastomeric bearings across various industries.

The elastomeric bearings market is experiencing strong demand, driven by the growing need for reliable, cost-effective solutions in infrastructure and construction projects. Elastomeric bearings are essential in bridge and building construction due to their ability to absorb vibrations and accommodate movements in structures. As urbanization and infrastructure development increase globally, the need for durable, low-maintenance bearings continues to rise. This demand is expected to grow further as governments invest in transportation, infrastructure, and renewable energy projects, fueling the market for elastomeric bearings.

Significant opportunities lie in the renewable energy and transportation sectors, where elastomeric bearings play a crucial role in ensuring structural integrity and performance. In wind and solar power installations, elastomeric bearings are used in the foundations of turbines and solar panel frames. Additionally, the growing investment in modern transport infrastructure, including railways, bridges, and tunnels, offers opportunities for elastomeric bearings to improve operational efficiency and longevity. As green energy projects expand and transportation networks modernize, the market is poised for growth.

There is a noticeable trend toward product innovation and customization in the elastomeric bearings market. Manufacturers are developing specialized bearings to meet the increasing demands of various industries. Custom elastomeric bearings tailored to specific project requirements, including varying load capacities, environmental resistance, and vibration-damping capabilities, are becoming more popular. Additionally, advancements in material science are improving the performance of elastomeric bearings, making them more durable and efficient. These trends are supporting the development of high-performance bearings suited for a wider range of applications.

A significant challenge for the elastomeric bearings market is the volatility in raw material prices, particularly rubber and polymers. Price fluctuations due to supply chain disruptions or global demand imbalances can increase production costs, impacting overall market growth. Additionally, sourcing high-quality materials for specific applications remains a challenge, as manufacturers need to ensure that the bearings meet strict durability and performance standards. Overcoming these challenges requires efficient supply chain management, material innovation, and cost control strategies.

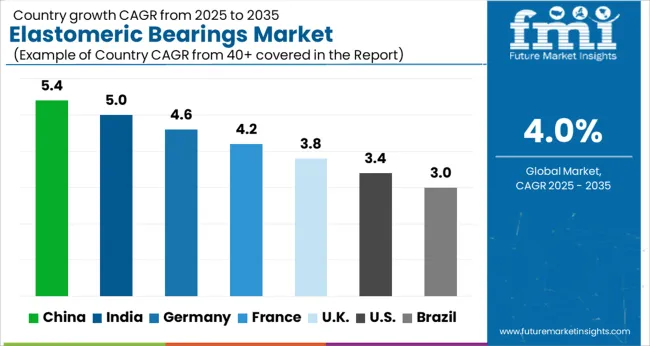

| Country | CAGR |

|---|---|

| China | 5.4% |

| India | 5.0% |

| Germany | 4.6% |

| France | 4.2% |

| UK | 3.8% |

| USA | 3.4% |

| Brazil | 3.0% |

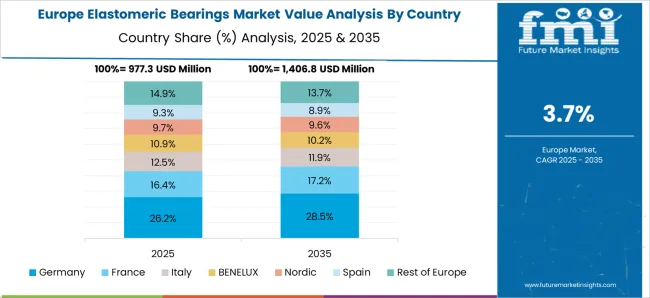

The global elastomeric bearings market is projected to grow at a 4% CAGR from 2025 to 2035. China leads with a growth rate of 5.4%, followed by India at 5% and Germany at 4.6%. The United Kingdom records a growth rate of 3.8%, while the United States shows the slowest growth at 3.4%. The varying growth rates are driven by infrastructure development and modernization needs. China and India, with their rapidly growing construction and transportation sectors, are experiencing higher growth, while more developed markets like the USA and the UK show steady demand due to ongoing infrastructure projects and sustainability initiatives. This report includes insights on 40+ countries; the top markets are shown here for reference.

The elastomeric bearings market in China is projected to grow at a CAGR of 5.4%. China’s rapid infrastructure development, coupled with the increasing demand for road and rail transport, is driving the need for elastomeric bearings in various applications such as bridges, highways, and railways. The government's strong focus on expanding its transportation infrastructure, including high-speed rail projects and large-scale urban development, is further accelerating market growth. Moreover, China’s rising focus on sustainable and cost-effective solutions for infrastructure projects is contributing to the demand for elastomeric bearings, which offer better performance and durability in construction.

The elastomeric bearings market in India is projected to grow at a CAGR of 5%. India’s increasing infrastructure development, including roadways, bridges, and metros, is fueling the demand for elastomeric bearings. The government's focus on building smart cities, enhancing transportation networks, and modernizing railways is pushing the growth of the market. Elastomeric bearings offer cost-effective solutions for transportation infrastructure, and their durability and low maintenance make them ideal for projects across various regions. As India continues to prioritize the development of its infrastructure, the demand for elastomeric bearings is expected to rise in tandem.

The elastomeric bearings market in Germany is projected to grow at a CAGR of 4.6%. Germany’s well-established infrastructure and focus on high-quality engineering standards continue to drive the demand for elastomeric bearings in the construction of bridges, tunnels, and other transportation infrastructure. As a leader in engineering, Germany is investing in long-term, sustainable solutions for its transportation networks, which is boosting the demand for elastomeric bearings. The country’s commitment to improving road and rail connectivity across regions further supports the need for durable, reliable bearings. These materials are particularly important in seismic and heavy-load applications, contributing to their growing adoption.

The elastomeric bearings market in the United Kingdom is projected to grow at a CAGR of 3.8%. The UK has been focused on enhancing its transportation and public infrastructure, including projects such as bridge refurbishments and new road constructions. The demand for elastomeric bearings is growing due to their durability and ability to handle dynamic loads in both road and rail networks. Additionally, the UK government’s investments in upgrading its transportation infrastructure to accommodate increasing traffic and freight movement further contribute to the market growth. Despite slower growth than emerging markets, the UK's established infrastructure ensures steady demand for elastomeric bearings.

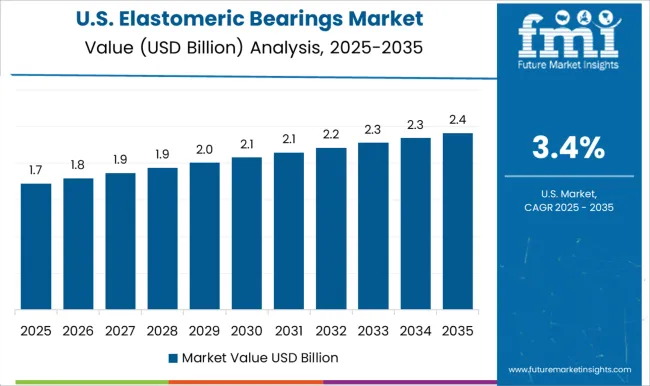

The elastomeric bearings market in the United States is projected to grow at a CAGR of 3.4%. The USA continues to invest in infrastructure projects, particularly in bridges, highways, and railways. As the country modernizes its aging transportation infrastructure, the demand for elastomeric bearings is increasing. Elastomeric bearings are preferred for their ability to withstand heavy loads and seismic activity, making them ideal for USA infrastructure projects, particularly in areas prone to earthquakes. The market growth is supported by federal and state-level investments in infrastructure, as well as a growing focus on sustainable, cost-effective solutions for infrastructure projects.

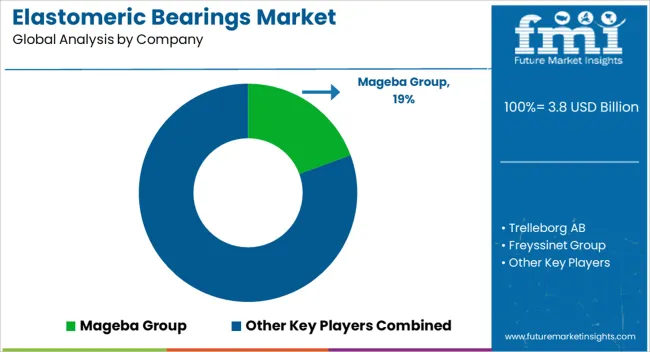

Leading suppliers in the elastomeric bearings market, such as Mageba Group, Trelleborg AB, and Freyssinet Group, are playing a significant role in advancing structural engineering solutions with high-performance elastomeric bearings for bridges, buildings, and other infrastructure projects. These companies focus on providing flexible, durable, and cost-effective bearings that absorb and dissipate loads, ensuring the longevity and stability of critical infrastructure. Mageba and Trelleborg have strengthened their global presence by offering a wide range of elastomeric bearings that are engineered to withstand various environmental conditions, including seismic activity, extreme temperatures, and high traffic loads. Their advanced research and development capabilities enable them to continuously improve the performance of their products, making them key players in the market's expansion.

Companies like Canam Group Inc., RJ Watson, Inc., and Cosmec Inc. are capitalizing on their expertise in engineering and manufacturing elastomeric bearings tailored for specific applications. These suppliers offer customizable solutions designed to meet the unique requirements of each infrastructure project, from roadways and railways to industrial buildings and power plants. VIP-Polymers Ltd. and other regional players are gaining traction by offering specialized elastomeric bearings with enhanced load-bearing capacity and resistance to wear and tear. As the demand for sustainable infrastructure solutions grows, the elastomeric bearings market is becoming more competitive, with companies focusing on innovation, product differentiation, and the ability to deliver reliable, long-lasting performance for the construction and transportation sectors.

| Item | Value |

|---|---|

| Quantitative Units | USD Billion |

| Type | Laminated bearings, Plain bearings, Bearings with anchor plates, and Bearings with sliding surface |

| Material | Rubber and Steel |

| Application | Bridges, Viaducts, Buildings, Storage tanks, Sealing elements, and Crane rail pads |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled | Mageba Group, Trelleborg AB, Freyssinet Group, Canam Group Inc., RJ Watson, Inc., Cosmec Inc., and VIP-Polymers Ltd. |

| Additional Attributes | Dollar sales by bearing type (fixed, sliding, seismic) and material (rubber, thermoplastic, composite) are key metrics. Trends include rising demand for vibration control and seismic protection in construction and infrastructure projects. Regional adoption, advancements in material durability, and government regulations on building safety are shaping market growth. |

The global elastomeric bearings market is estimated to be valued at USD 3.8 billion in 2025.

The market size for the elastomeric bearings market is projected to reach USD 5.6 billion by 2035.

The elastomeric bearings market is expected to grow at a 4.0% CAGR between 2025 and 2035.

The key product types in elastomeric bearings market are laminated bearings, plain bearings, bearings with anchor plates and bearings with sliding surface.

In terms of material, rubber segment to command 55.4% share in the elastomeric bearings market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Elastomeric Coating Market Forecast and Outlook 2025 to 2035

Elastomeric Membrane Market Growth – Trends & Forecast 2024-2034

Elastomeric Couplings Market

Elastomeric Adhesives Market

Sensor Bearings Market Insights - Growth & Forecast 2025 to 2035

Marine Bearings Market Growth - Trends & Forecast 2025 to 2035

Thrust Bearings Market

Linear Bearings Market

Polymer Bearings Market Size and Share Forecast Outlook 2025 to 2035

Camshaft Bearings Market

Miniature Ball Bearings Market Analysis by Type, End-use and Region: Forecast for 2025 to 2035

ASEAN Automotive Bearings Market Size and Share Forecast Outlook 2025 to 2035

Self-Lubricating Bearings Market Size and Share Forecast Outlook 2025 to 2035

Automotive Wheel Bearings Market

Friction Pendulum Bearings Market Size and Share Forecast Outlook 2025 to 2035

Automotive Engine Bearings Market

High Speed Rolling Bearings Market Size and Share Forecast Outlook 2025 to 2035

High Efficiency Rolling Bearings Market Size and Share Forecast Outlook 2025 to 2035

High Precision Heavy Load Bearings Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA