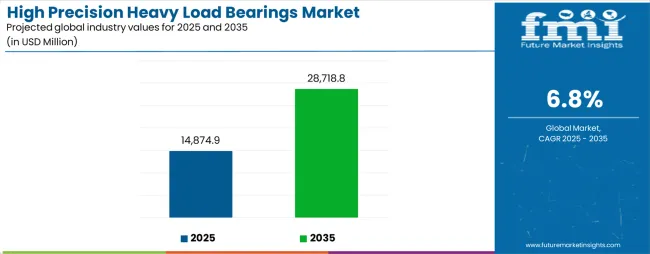

The high precision heavy load bearings market is projected to expand significantly from USD 14,874.9 million in 2025 to USD 28,718.8 million by 2035, reflecting a CAGR of 6.8%. This growth is primarily attributed to increasing demand across industries requiring high precision and load-bearing capabilities, such as heavy machinery, aerospace, automotive, and industrial equipment. The year-on-year growth trajectory demonstrates consistent acceleration, driven by a heightened focus on improving the efficiency and durability of bearings, which is essential in sectors with stringent performance and safety requirements.

As industries such as construction, mining, and energy see increasing demand for machinery capable of handling more significant loads, the reliance on high-precision heavy-load bearings is expected to rise. Market growth is further influenced by a focus on minimizing downtime and optimizing operational costs, which is pushing manufacturers to innovate and produce bearings with enhanced performance and longevity.

The demand for high precision heavy load bearings is linked to the broader trends in automation and high-capacity equipment deployment. Industries are investing in equipment that can manage larger loads while maintaining precision and reliability. As automation in manufacturing and construction accelerates, the need for robust and efficient bearings has grown, with particular focus on components capable of withstanding extreme operating conditions. Growing interest in renewable energy infrastructure, such as wind turbines and heavy-duty transport systems, has also provided a catalyst for demand. The market is expected to continue on its upward trajectory, driven by these key industry shifts. The forecasted market expansion aligns with rising industrialization and automation trends, positioning the high precision heavy load bearings market as an essential component of modern machinery and equipment systems throughout the 2025-2035 period.

The high precision heavy load bearings market has been analyzed within several key industrial sectors, contributing around 7.2% of the bearing market, 6.9% of the industrial machinery market, 5.3% of the automotive components market, 4.8% of the aerospace components market, and 3.9% of the heavy equipment market. Combined, this results in a total market share of approximately 28.1% across these parent industries.

This highlights the increasing need for high precision bearings in applications that require superior load-bearing capacity and operational reliability. These bearings are being sought after in industries such as manufacturing, automotive, and aerospace, where equipment performance is crucial. As industries demand higher levels of efficiency, the role of these precision components has been elevated, driving growth in the market.

| Metric | Value |

|---|---|

| Estimated Value in (2025E) | USD 14,874.9 million |

| Forecast Value in (2035F) | USD 28,718.8 million |

| Forecast CAGR (2025 to 2035) | 6.8% |

Market expansion is being supported by the increasing global demand for precision-engineered industrial components and the corresponding shift toward advanced bearing technologies that can provide superior performance while meeting stringent specifications for critical applications. Modern manufacturing facilities and industrial equipment manufacturers are increasingly focused on incorporating high-precision bearings to enhance operational reliability while satisfying demands for extended service life and proven performance in demanding environments. High precision heavy load bearings' proven ability to deliver superior load capacity, operational longevity, and precision performance makes them essential components for advanced manufacturing operations and critical industrial applications.

The growing emphasis on industrial automation and smart manufacturing is driving demand for high-quality bearing systems that can support distinctive performance characteristics and mission-critical applications across machinery, energy, and aerospace categories. Manufacturer preference for components that combine performance excellence with proven reliability credentials is creating opportunities for innovative bearing implementations in both traditional and emerging industrial applications. The rising influence of predictive maintenance technologies and operational optimization is also contributing to increased adoption of intelligent bearing systems that can provide real-time performance monitoring and operational insights.

The market is segmented by bearing type, application, and region. By bearing type, the market is divided into deep groove ball bearings, angular contact ball bearings, cylindrical roller bearings, and other bearing types. Based on application, the market is categorised into heavy machinery, energy, aerospace, and other applications. Regionally, the market is divided into North America, Europe, East Asia, South Asia & Pacific, Latin America, and the Middle East & Africa.

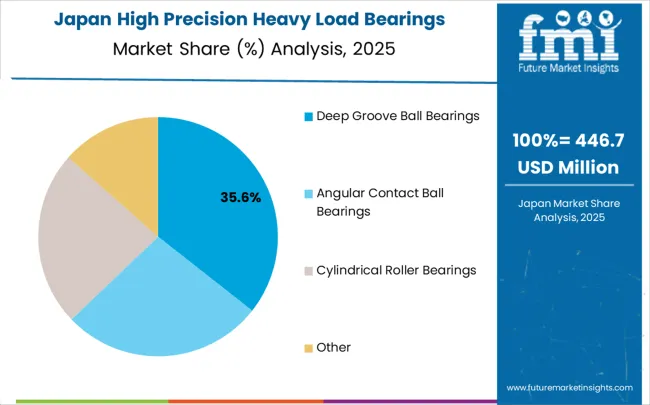

The deep groove ball bearings segment is projected to account for 36% of the high-precision heavy-load bearings market in 2025, reaffirming its position as the leading bearing type category. Industrial manufacturers and equipment designers increasingly utilise deep groove ball bearings for their operational versatility, superior load distribution characteristics, and ease of integration in complex mechanical systems across diverse industrial applications. This bearing type's proven design directly addresses industrial requirements for reliable performance and efficient operation in high-load applications.

This segment forms the foundation of modern precision bearing applications, as it represents the configuration with the greatest adaptability and established compatibility across multiple industrial systems. Manufacturer investments in design optimisation and precision manufacturing continue to strengthen adoption among industrial equipment producers. With manufacturing companies prioritizing operational reliability and consistent performance characteristics, deep groove ball bearings align with both efficiency objectives and durability requirements, making them the central component of comprehensive precision bearing strategies.

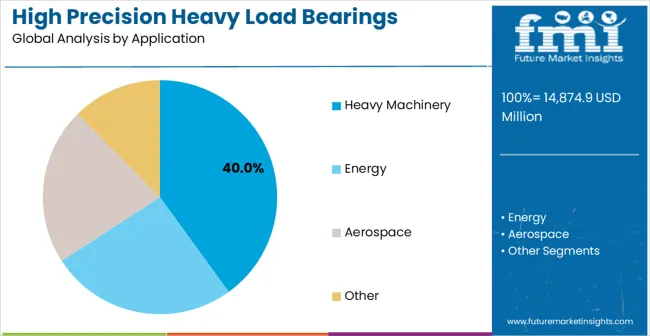

Heavy machinery applications represent the dominant segment of high-precision heavy-load bearing demand in 2025, accounting for 40% of the market, underscoring their critical role as essential components for industrial equipment operations. Manufacturing companies prefer precision bearing systems for their operational reliability, load-carrying capacity, and ability to support both standard operations and specialised applications while offering proven effectiveness in demanding industrial environments. Positioned as essential components for heavy machinery, precision bearings offer both operational capability and competitive advantages.

The segment is supported by continuous growth in industrial automation programs and the growing availability of specialized bearing variants that enable equipment differentiation and operational effectiveness at the machinery level. Additionally, equipment manufacturers are investing in advanced bearing technologies to support precision machinery positioning and operational accessibility. As industrial automation continues to gain priority and manufacturers seek reliable components, heavy machinery applications will continue to dominate the market landscape while supporting operational excellence and equipment reliability strategies.

The high-precision heavy-load bearings market is advancing robustly due to increasing industrial preference for precision-engineered components and growing demand for high-performance bearings that emphasise reliable operation across manufacturing and infrastructure applications. However, the market faces challenges, including raw material price fluctuations due to steel and specialty alloy costs, technical complexity from advanced engineering requirements, and competition from alternative bearing technologies. Innovation in smart bearing systems and predictive maintenance integration continues to influence market development and expansion patterns.

The growing adoption of high precision heavy load bearings in advanced manufacturing systems and automated applications is enabling equipment manufacturers to develop machinery that provides distinctive operational capabilities while commanding premium positioning and enhanced performance characteristics. Automated applications provide superior operational differentiation while allowing more sophisticated equipment development across various industrial categories and manufacturing segments. Manufacturers are increasingly recognizing the competitive advantages of precision bearing integration for advanced machinery development and industrial automation penetration.

Modern bearing manufacturers are incorporating IoT sensors, condition monitoring systems, and predictive maintenance capabilities to enhance bearing performance, improve operational insights, and meet industrial demands for intelligent component solutions. These technologies enhance operational efficiency while enabling new applications, including predictive maintenance and smart manufacturing systems for bearings. Advanced technology integration also allows suppliers to support premium market positioning and industrial trust building beyond traditional bearing supply relationships.

| Country | CAGR (2025-2035) |

|---|---|

| China | 9.2% |

| India | 8.5% |

| Germany | 7.8% |

| Brazil | 7.1% |

| United States | 6.5% |

| United Kingdom | 5.8% |

| Japan | 5.1% |

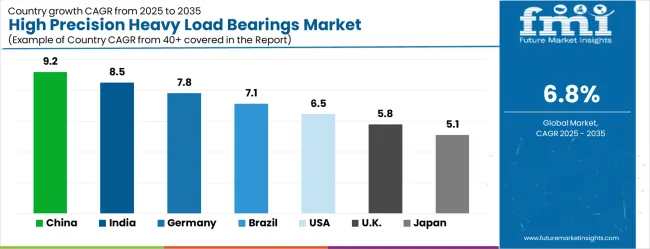

The high precision heavy load bearings market is experiencing robust growth globally, with China leading at a 9.2% CAGR through 2035, driven by the expanding manufacturing sector, growing industrial automation adoption, and increasing infrastructure development across heavy industries. India follows at 8.5%, supported by rapid industrialization, rising manufacturing investments, and increasing demand for precision components in emerging industrial sectors. The USA shows growth at 6.5%, emphasizing advanced manufacturing applications and aerospace industry requirements. Germany records 7.8%, focusing on precision engineering excellence and industrial equipment manufacturing. Brazil demonstrates 7.1% growth, prioritizing industrial modernization and infrastructure development. The U.K. exhibits 5.8% growth, supported by advanced manufacturing capabilities and precision engineering expertise. Japan shows 5.1% growth, emphasizing high-precision manufacturing and technological innovation.

The report covers an in-depth analysis of 40+ countries, the top-performing countries are highlighted below.

The high precision heavy load bearings market in China is projected to exhibit exceptional growth with a CAGR of 9.2% through 2035, driven by the rapidly expanding manufacturing sector and increasing industrial automation adoption across factories seeking advanced precision components. The country's growing industrial base and strategic manufacturing development are creating substantial demand for high-performance bearings in both traditional and advanced manufacturing applications. Major bearing manufacturers and industrial suppliers are establishing comprehensive production and distribution capabilities to serve both domestic industrial requirements and export markets.

The high precision heavy load bearings market in India is expanding at a CAGR of 8.5%, supported by rapid industrialisation, increasing manufacturing investments, and growing focus on infrastructure development requiring precision components. The country's developing industrial sector and expanding manufacturing infrastructure are driving demand for quality bearing systems across both traditional and modern industrial applications. International bearing companies and domestic manufacturers are establishing comprehensive distribution and production capabilities to address growing market demand for reliable precision components.

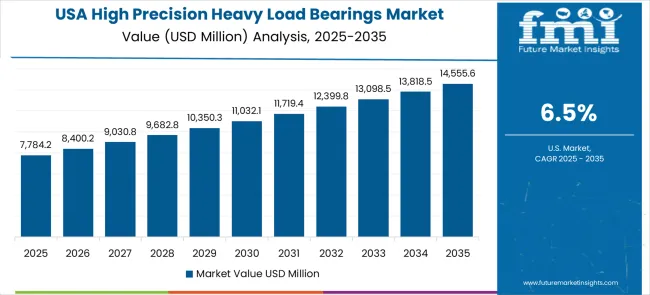

The high precision heavy load bearings market in the United States is projected to grow at a CAGR of 6.5% through 2035, driven by the country's advanced manufacturing capabilities, aerospace industry requirements, and continued focus on precision components for critical applications. The USA's sophisticated industrial base and willingness to invest in high-performance bearing systems are creating substantial demand for both standard and specialised bearing variants. Leading industrial companies and equipment suppliers are establishing comprehensive sourcing strategies to serve both manufacturing operations and specialised industrial markets.

The high precision heavy load bearings market in Germany is projected to grow at a CAGR of 7.8% through 2035, supported by the country's advanced precision engineering industry, industrial equipment manufacturing sector, and established tradition of engineering excellence requiring high-quality bearing components. German manufacturers and industrial producers consistently demand superior bearing systems that meet exacting quality standards for both domestic production and export markets. The country's position as an industrial technology leader continues to drive innovation in bearing applications and quality standards.

The high precision heavy load bearings market in Brazil is projected to grow at a CAGR of 7.1% through 2035, supported by the country's industrial modernization programs, expanding manufacturing capabilities, and focus on infrastructure development requiring precision components. Brazilian industrial facilities prioritise operational effectiveness, equipment reliability, and manufacturing capability enhancement, making precision bearings essential components for both domestic operations and regional industrial applications. The country's comprehensive industrial development programs and strategic emphasis support continued bearing market development.

The high precision heavy load bearings market in the U.K. is projected to grow at a CAGR of 5.8% through 2035, supported by the country's advanced manufacturing industry, expertise in precision engineering, and established industrial tradition requiring high-quality bearing components. British industrial organizations' focus on operational excellence and proven components creates steady demand for reliable bearing systems and specialized variants. The country's attention to component quality and operational effectiveness drives consistent adoption across both traditional and specialised industrial applications.

The high precision heavy load bearings market in Japan is projected to grow at a CAGR of 5.1% through 2035, supported by the country's advanced manufacturing capabilities, precision engineering expertise, and focus on developing high-quality industrial components. Japan's industrial sector continues to benefit from its reputation for producing superior precision products while working to address evolving manufacturing requirements and develop advanced bearing technologies through continuous innovation.

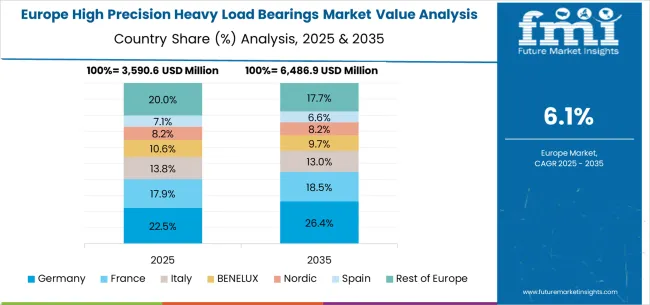

The high precision heavy load bearings market in Europe is projected to grow from USD 3,287.3 million in 2025 to USD 6,345.6 million by 2035, registering a CAGR of 6.8% over the forecast period. Germany is expected to maintain its leadership position with a 32.5% market share in 2025, declining slightly to 31.8% by 2035, supported by its advanced precision engineering sector and industrial equipment manufacturing capabilities serving European and international markets.

The United Kingdom follows with a 18.7% share in 2025, projected to reach 18.4% by 2035, driven by established industrial expertise and precision manufacturing capabilities. France holds a 16.2% share in 2025, expected to reach 16.8% by 2035, supported by growing industrial automation programs and manufacturing technology development. Italy commands a 13.8% share in 2025, projected to reach 14.2% by 2035, while Spain accounts for 9.6% in 2025, expected to reach 10.1% by 2035. The Netherlands maintains a 3.4% share in 2025, growing to 3.6% by 2035. The Rest of Europe region, including Nordic countries, Eastern Europe, Belgium, Switzerland, Austria, and other European nations, is anticipated to hold 5.8% in 2025, declining to 5.1% by 2035, attributed to mixed growth patterns with steady expansion in some Eastern European markets balanced by slower growth in smaller Western European countries implementing industrial modernization programs.

The high-precision heavy-load bearings market is characterised by competition among established bearing manufacturers, specialised precision component producers, and integrated industrial equipment suppliers. Companies are investing in advanced manufacturing technologies, precision engineering systems, quality enhancement processes, and comprehensive testing protocols to deliver consistent, high-performance, and reliable bearing solutions. Innovation in materials science, smart bearing technologies, and specialised applications is central to strengthening market position and industrial confidence.

SKF leads the market with a strong focus on bearing innovation and precision manufacturing, offering comprehensive bearing solutions that emphasise quality assurance and operational reliability. Schaeffler provides integrated bearing and mechanical component capabilities with a focus on advanced engineering and global distribution networks. ROLLON delivers precision linear motion and bearing systems with a focus on industrial excellence and specialised applications. Emerson Bearing specialises in high-performance bearing solutions with emphasis on industrial-grade quality and critical applications. NSK focuses on precision bearing technology and global market development. NTN emphasises advanced bearing manufacturing with a focus on industrial applications and quality standardisation.

The global high precision heavy load bearings market represents a critical component segment within industrial machinery and precision engineering, projected to grow from USD 14,874.9 million in 2025 to USD 28,718.8 million by 2035 at a CAGR of 6.8%. Deep groove ball bearings dominate with 36% market share, serving primarily heavy machinery applications that demand exceptional load capacity, operational precision, and extended service life. The market's expansion is driven by industrial automation adoption, advanced manufacturing requirements, and growing emphasis on predictive maintenance across critical industrial applications. Achieving sustained growth requires coordinated efforts across industrial policy makers, standards organisations, bearing manufacturers, equipment integrators, and capital providers.

Manufacturing Infrastructure Investment: Establish dedicated industrial zones and manufacturing hubs with specialised facilities for precision bearing production, including advanced machining centres, quality testing laboratories, and skilled workforce training institutes to support domestic bearing manufacturing capabilities.

R&D and Innovation Support: Fund research programs focused on advanced bearing materials, smart bearing technologies with IoT integration, and predictive maintenance systems. Support collaborative projects between universities, research institutes, and bearing manufacturers to develop next-generation precision bearing solutions.

Skills Development Programs: Invest in technical education and vocational training programs that develop expertise in precision manufacturing, quality control, materials science, and advanced machining techniques required for high-precision bearing production and maintenance.

Export Promotion & Trade Facilitation: Create export incentive schemes for precision bearing manufacturers, establish trade promotion councils to support international market development, and negotiate favourable trade agreements that reduce barriers for bearing component imports and exports.

Industrial Standards & Certification: Develop national quality standards aligned with international specifications (ISO, ANSI, DIN) and establish accredited testing facilities that enable domestic bearing manufacturers to compete in global markets with certified quality credentials.

Technical Standards Development: Establish comprehensive quality standards for precision bearings covering load ratings, dimensional tolerances, material specifications, and performance criteria that ensure consistent quality across manufacturers and enable reliable product comparisons.

Testing and Certification Protocols: Develop standardized testing methodologies for bearing performance evaluation including fatigue life testing, load capacity validation, precision measurement procedures, and quality assurance frameworks that support procurement decisions.

Best Practices Documentation: Create technical guidelines for bearing selection, installation procedures, maintenance protocols, and troubleshooting methodologies that help end-users optimize bearing performance and extend operational life across diverse applications.

Professional Certification Programs: Establish technical certification courses for bearing specialists, maintenance engineers, and quality control personnel to ensure industry-wide competency in precision bearing technology and application expertise.

Market Intelligence & Analytics: Provide regular industry reports covering technology trends, market dynamics, competitive analysis, and emerging applications to guide strategic planning for manufacturers, distributors, and end-users across global markets.

Advanced Manufacturing Technologies: Develop precision manufacturing capabilities including ultra-precision machining, advanced heat treatment processes, surface engineering technologies, and automated quality control systems that ensure consistent production of high-performance bearings meeting stringent specifications.

Smart Bearing Integration: Incorporate IoT sensors, condition monitoring capabilities, and predictive analytics into bearing designs to enable real-time performance monitoring, predictive maintenance scheduling, and operational optimization for industrial equipment manufacturers.

Material Science Innovation: Advanced bearing materials, including high-performance steels, ceramic components, advanced lubricants, and surface coatings that improve load capacity, reduce friction, extend service life, and enhance performance in demanding operating environments.

Modular Design Platforms: Create standardized bearing families and modular design systems that enable rapid customization for specific applications while maintaining economies of scale in manufacturing and reducing development costs for specialized requirements.

Technical Support Infrastructure: Establish comprehensive customer support networks, including application engineering services, on-site technical assistance, training programs, and digital tools that help customers select, install, and maintain optimal bearing solutions.

Integrated Design Strategies: Develop bearing integration approaches that optimise equipment design around precision bearing capabilities, including load distribution analysis, vibration mitigation, and thermal management to maximise bearing performance and equipment reliability.

Supplier Partnership Development: Build strategic relationships with bearing manufacturers that provide early access to new technologies, collaborative product development opportunities, and guaranteed supply security for critical applications requiring specialised bearing solutions.

Predictive Maintenance Integration: Implement condition monitoring systems and predictive maintenance capabilities that leverage smart bearing technologies to optimize equipment uptime, reduce maintenance costs, and improve overall operational effectiveness.

Application-Specific Solutions: Develop specialized bearing requirements for specific industrial applications including renewable energy systems, aerospace applications, heavy construction equipment, and precision manufacturing tools that require unique performance characteristics.

Quality Assurance Programs: Establish comprehensive bearing qualification procedures including performance validation, reliability testing, and supplier auditing processes that ensure consistent quality and performance across bearing supply chains.

Manufacturing Capacity Expansion: Finance advanced production facilities, automated manufacturing systems, and precision equipment investments that enable bearing manufacturers to scale production capabilities and meet growing global demand for high-precision components.

Technology Innovation Funding: Provide venture capital and growth funding for bearing technology startups developing smart bearing systems, advanced materials, innovative manufacturing processes, and digital solutions that advance bearing performance and capabilities.

Market Expansion Capital: Support international market development initiatives, including regional manufacturing facilities, distribution networks, technical support infrastructure, and local partnerships in high-growth markets like Asia-Pacific and emerging economies.

Supply Chain Integration: Finance vertical integration strategies that combine bearing manufacturing with steel production, precision machining, and distribution capabilities to create more efficient and competitive bearing supply chains.

Industry Consolidation Support: Facilitate strategic mergers and acquisitions that create larger, more capable bearing organizations with enhanced R&D capabilities, broader product portfolios, and global market reach necessary to serve major industrial equipment manufacturers effectively.

| Items | Values |

|---|---|

| Quantitative Units (2025) | USD 14,874.9 million |

| Bearing Type | Deep Groove Ball Bearings, Angular Contact Ball Bearings, Cylindrical Roller Bearings, Other |

| Application | Heavy Machinery, Energy, Aerospace, Other |

| Regions Covered | North America, Europe, East Asia, South Asia & Pacific, Latin America, Middle East & Africa |

| Countries Covered | China, India, Germany, Brazil, the United States, the United Kingdom, Japan and 40+ countries |

| Key Companies Profiled | SKF, Schaeffler, ROLLON, Emerson Bearing, NSK, NTN, Koyo, RBC Bearings Incorporated, HQW Precision GmbH, FHD Bearings, IBC INDUSTRIAL BEARINGS AND COMPONENTS AG, New Hampshire Ball Bearings Inc., TPI BEARINGS, NACHI EUROPE GmbH, American Roller Bearing |

| Additional Attributes | Dollar sales by bearing type and application, regional demand trends, competitive landscape, technological advancements in bearing design, smart bearing integration, precision manufacturing programs, and industrial automation strategies |

The global high precision heavy load bearings market is estimated to be valued at USD 14,874.9 million in 2025.

The market size for the high precision heavy load bearings market is projected to reach USD 28,718.8 million by 2035.

The high precision heavy load bearings market is expected to grow at a 6.8% CAGR between 2025 and 2035.

The key product types in high precision heavy load bearings market are deep groove ball bearings, angular contact ball bearings, cylindrical roller bearings and other.

In terms of application, heavy machinery segment to command 40.0% share in the high precision heavy load bearings market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

High Voltage Porcelain Bushing Market Size and Share Forecast Outlook 2025 to 2035

High Purity Process Systems for Semiconductor Market Size and Share Forecast Outlook 2025 to 2035

High Octane Racing Fuel Market Size and Share Forecast Outlook 2025 to 2035

High Voltage Air-cooled Battery Compartment Market Size and Share Forecast Outlook 2025 to 2035

High Temperature NiMH Battery Market Size and Share Forecast Outlook 2025 to 2035

High Current Power Supply for Electrophoresis Market Size and Share Forecast Outlook 2025 to 2035

High Voltage Cable Termination Market Size and Share Forecast Outlook 2025 to 2035

High Security Wedge Barricades Market Size and Share Forecast Outlook 2025 to 2035

High Purity Chemical Filters Market Size and Share Forecast Outlook 2025 to 2035

High Performance Liquid Chromatography-Tandem Mass Spectrometry System Market Size and Share Forecast Outlook 2025 to 2035

High-vacuum Fiber Feedthrough Flanges Market Size and Share Forecast Outlook 2025 to 2035

High Pressure Grease Hose Market Size and Share Forecast Outlook 2025 to 2035

High Performing Matting Agent Market Size and Share Forecast Outlook 2025 to 2035

High Reliability Oscillators Market Size and Share Forecast Outlook 2025 to 2035

High-performance Dual-core Processor Market Size and Share Forecast Outlook 2025 to 2035

High Purity Magnesium Citrate Market Size and Share Forecast Outlook 2025 to 2035

High Performance Magnet Market Size and Share Forecast Outlook 2025 to 2035

High-frequency RF Evaluation Board Market Size and Share Forecast Outlook 2025 to 2035

High Viscosity Mixer Market Size and Share Forecast Outlook 2025 to 2035

High Voltage Ionising Air Gun Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA