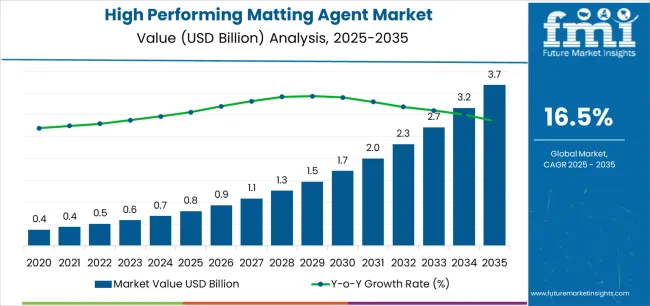

The global high performing matting agent market is projected to reach USD 3.7 billion by 2035, recording an absolute increase of USD 2,869.0 million over the forecast period. The market is valued at USD 0.8 billion in 2025 and is set to rise at a CAGR of 16.5% during the assessment period. The overall market size is expected to grow by nearly 4.5 times during the same period, supported by increasing demand for high-quality surface finishes across industrial, electronics, and building materials applications worldwide, driving demand for efficient matting solutions and increasing investments in advanced coating technology projects globally.

High performing matting agents represent specialized additives that reduce gloss levels in coatings, inks, and paints while maintaining excellent transparency and mechanical properties. These materials create controlled surface roughness at the microscopic level, scattering incident light to produce matte or satin finishes desired in modern manufacturing. Industrial applications require matting agents that deliver consistent performance across diverse substrate materials, from metal components to plastic housings. Electronics manufacturing demands ultra-fine particle distributions that prevent interference with delicate circuitry while providing anti-glare properties on display surfaces. Building materials incorporate matting agents to achieve aesthetic finishes that resist fingerprints and maintain appearance durability in high-traffic environments.

The market expansion reflects fundamental shifts in consumer preferences toward premium matte finishes across product categories. Automotive interior components increasingly feature soft-touch surfaces with precisely controlled gloss levels, requiring matting agents that maintain tactile properties throughout vehicle service life. Consumer electronics manufacturers adopt matte screen protectors and device housings that reduce reflective glare while conveying premium brand positioning through sophisticated surface treatments. Architectural coatings for commercial and residential applications specify matting agents that deliver uniform appearance across large surface areas while meeting stringent VOC emission standards and durability requirements.

Technology advancement in particle engineering enables next-generation matting agents with improved efficiency and performance characteristics. Silica-based inorganic matting agents benefit from precipitation and spray-drying innovations that produce narrower particle size distributions, reducing the loading levels required to achieve target gloss values. Organic matting agents incorporating polymer microspheres offer advantages in specific coating systems where inorganic materials create compatibility challenges. Hybrid formulations combining multiple matting mechanisms provide formulators with tools to optimize performance across competing requirements including transparency, scratch resistance, and chemical durability.

Industrial production processes demand matting agents that integrate seamlessly with high-speed coating operations without creating application defects. Powder coatings for metal finishing require matting agents with thermal stability sufficient to withstand curing temperatures while maintaining particle dispersion throughout the coating matrix. UV-curable systems used in wood finishing and graphic arts applications need matting agents compatible with radical polymerization mechanisms that occur within milliseconds of UV exposure. Waterborne coating formulations growing in market share due to environmental regulations require matting agents with appropriate surface treatments to ensure stable dispersion in aqueous systems without agglomeration during storage.

Government regulations promoting sustainable manufacturing and reduced environmental impact accelerate demand for matting agents that enable compliance with evolving standards. European Union restrictions on hazardous substances in electronics drive adoption of matting agents free from heavy metals and substances of very high concern. Building product certifications including LEED and environmental product declarations create preference for matting agents with documented low emissions profiles and renewable raw material content. Industrial coating specifications increasingly mandate sustainable sourcing and circular economy principles, favoring matting agent suppliers with established environmental management systems and transparent supply chain documentation.

Between 2025 and 2030, the high performing matting agent market is projected to expand from USD 0.8 billion to USD 1,986.2 million, resulting in a value increase of USD 1,176.8 million, which represents 41.0% of the total forecast growth for the decade. This phase of development will be shaped by rising demand for premium surface finishes in automotive and electronics applications, product innovation in silica precipitation technologies and organic polymer formulations, as well as expanding integration with waterborne coating systems and UV-curable formulations. Companies are establishing competitive positions through investment in particle engineering capabilities, surface treatment technologies, and strategic partnerships with coating manufacturers and industrial end users.

From 2030 to 2035, the market is forecast to grow from USD 1,986.2 million to USD 3.7 billion, adding another USD 1,692.2 million, which constitutes 59.0% of the overall ten-year expansion. This period is expected to be characterized by the expansion of specialized matting solutions, including ultra-fine particle grades for electronics applications and bio-based organic matting agents tailored for sustainable coating formulations, strategic collaborations between matting agent producers and coatings formulators, and an enhanced focus on transparency maintenance and mechanical property optimization. The growing emphasis on sustainable manufacturing and circular economy principles will drive demand for advanced, high-performance matting agent solutions across diverse industrial coating applications.

| Metric | Value |

|---|---|

| Market Value (2025) | USD 0.8 billion |

| Market Forecast Value (2035) | USD 3.7 billion |

| Forecast CAGR (2025-2035) | 16.5% |

The high performing matting agent market grows by enabling coating manufacturers to achieve superior surface aesthetics and functional performance while meeting demanding application requirements across industrial sectors. Coatings formulators face mounting pressure to deliver premium matte finishes with excellent durability characteristics, with matting agent solutions typically providing 30-40% improvement in gloss reduction efficiency compared to conventional alternatives, making advanced matting technologies essential for competitive product positioning. The premium surface finish movement creates demand for specialized matting agents that can deliver consistent appearance across diverse coating systems while maintaining transparency, scratch resistance, and chemical durability.

Government initiatives promoting sustainable coatings and reduced VOC emissions drive adoption in industrial, electronics, and building materials applications, where matting agent performance has a direct impact on coating formulation flexibility and environmental compliance. The global shift toward waterborne and high-solids coating technologies accelerates matting agent demand as manufacturers seek solutions compatible with environmentally responsible formulations that maintain performance parity with legacy solventborne systems. However, high material costs compared to commodity extenders and technical complexity in optimizing matting agent dispersion may limit adoption rates among small-scale coating producers and price-sensitive market segments operating with constrained formulation budgets.

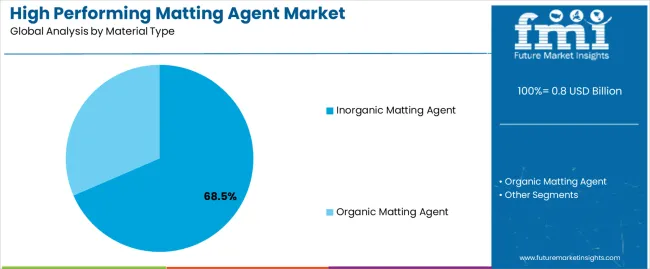

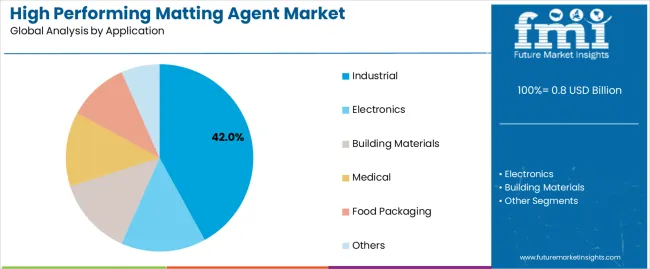

The market is segmented by material type, application, and region. By material type, the market is divided into inorganic matting agent and organic matting agent. Based on application, the market is categorized into industrial, electronics, building materials, medical, food packaging, and others. Regionally, the market is divided into Asia Pacific, Europe, North America, Latin America, and Middle East & Africa.

The inorganic matting agent segment represents the dominant force in the high performing matting agent market, capturing approximately 68.5% of total market share in 2025. This advanced category encompasses formulations featuring precipitated silica, fumed silica, silica gel, and synthetic silicate materials, delivering comprehensive matting performance with excellent transparency and durability characteristics. The inorganic matting agent segment leads through its exceptional efficiency in gloss reduction, proven compatibility across diverse coating chemistries, and cost-effectiveness compared to organic alternatives in high-volume applications.

The organic matting agent segment maintains a substantial 31.5% market share, serving formulators who require specialized performance characteristics through wax-based systems, polymer microspheres, and cellulose derivatives. Key advantages driving the inorganic matting agent segment include broad compatibility with solventborne, waterborne, and UV-curable coating systems, superior thermal stability enabling use in powder coatings and high-temperature applications, excellent transparency maintenance in clear coating formulations critical for wood finishing and automotive applications, and established manufacturing infrastructure supporting cost-competitive pricing in high-volume industrial markets.

Industrial applications dominate the high performing matting agent market with approximately 42% market share in 2025, reflecting the extensive deployment across metal finishing, machinery coatings, and general industrial coating systems requiring durable matte finishes. The industrial segment leads through deployment in powder coatings for appliances and architectural metal, liquid coatings for equipment and machinery, and protective coatings for infrastructure applications requiring long-term performance under demanding environmental exposure.

The electronics segment represents 23.0% market share through applications in display coatings, device housings, and circuit board protective finishes. Building materials account for 18.0% market share, while medical holds 8.0%, food packaging represents 5.0%, and other applications collectively account for 4.0% market share. Key market dynamics supporting application preferences include industrial coatings requiring robust matting performance with excellent mechanical properties across diverse substrates, electronics applications demanding ultra-fine particle distributions that maintain optical clarity while reducing glare, building materials emphasizing fingerprint resistance and appearance retention in architectural coatings, and specialized segments including medical and food packaging requiring regulatory compliance and chemical resistance in addition to aesthetic performance.

The market is driven by three concrete demand factors tied to surface finish requirements and performance optimization. First, premium product positioning creates increasing requirements for sophisticated matte finishes, with automotive and consumer electronics markets demanding precise gloss control between 5-20 gloss units that requires advanced matting agent formulations with optimized particle size distributions. Second, sustainability mandates drive formulation transitions toward waterborne and high-solids coating systems, with matting agents requiring specialized surface treatments and dispersion technologies to maintain performance in environmentally compliant formulations. Third, functional performance requirements including scratch resistance and chemical durability demand matting agents that reduce gloss without compromising mechanical properties, with coating manufacturers targeting 15-25% improvement in surface hardness through optimized matting agent selection and loading optimization.

Market restraints include cost premiums of 40-60% compared to commodity extender materials affecting adoption in price-sensitive coating segments, particularly in architectural paints and industrial maintenance coatings where material cost pressures limit formulation flexibility. Technical complexity in achieving ultra-low gloss levels while maintaining transparency poses formulation challenges, as matting agent loading increases required to reach gloss targets below 5 units can create haze and reduce coating clarity unacceptable in clear wood finishes and automotive clearcoats. Dispersion stability challenges in waterborne systems create additional barriers, since inadequate matting agent surface treatment can lead to agglomeration during storage or application defects including cratering and surface roughness.

Key trends indicate accelerated adoption in Asia Pacific markets, particularly China where government programs support advanced manufacturing and electronics production requiring premium surface finishes with documented quality standards. Technology advancement trends toward nano-structured silica particles with controlled porosity, hybrid organic-inorganic matting systems optimizing multiple performance characteristics, and bio-based organic matting agents from renewable raw materials enable next-generation product development. However, the market faces potential disruption if surface texturing technologies including laser ablation or chemical etching achieve cost-effectiveness sufficient to compete with conventional matting agents in high-volume coating applications.

| Country | CAGR (2025-2035) |

|---|---|

| China | 18.1% |

| India | 16.9% |

| Germany | 15.5% |

| Brazil | 14.2% |

| USA | 12.8% |

| UK | 11.5% |

| Japan | 10.1% |

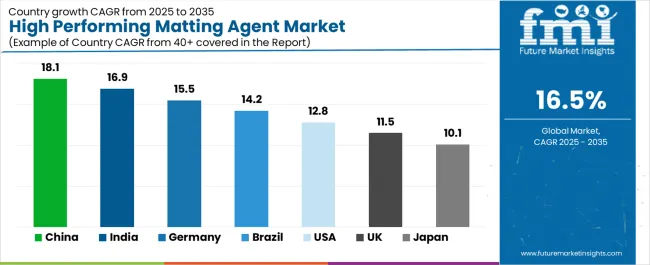

The high performing matting agent market is gaining momentum worldwide, with China taking the lead thanks to aggressive manufacturing expansion programs and electronics production growth. Close behind, India benefits from industrial development initiatives and coating industry modernization, positioning itself as a strategic growth hub in the Asia Pacific region. Germany shows strong advancement, where established coatings industry and chemical manufacturing expertise strengthen its role in European specialty chemicals supply chains.

The USA demonstrates robust growth through advanced coating technology development and premium product demand, signaling continued investment in surface finishing innovation. Meanwhile, Japan stands out for its electronics manufacturing focus and precision coating applications with quality emphasis, while UK continues to record consistent progress driven by specialty coatings development and industrial manufacturing. Together, China and India anchor the global expansion story, while established markets build stability and technical sophistication into the market growth path.

The report covers an in-depth analysis of 40+ countries top-performing countries are highlighted below.

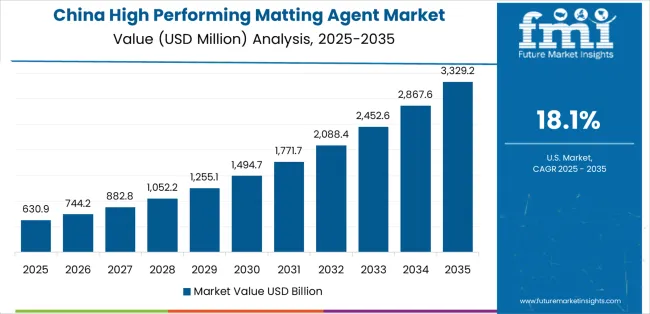

China demonstrates the strongest growth potential in the High Performing Matting Agent Market with a CAGR of 18.1% through 2035. The country leads through comprehensive manufacturing expansion programs, electronics production growth, and industrial coating development driving adoption of advanced matting technologies. Growth is concentrated in major industrial regions, including Guangdong, Jiangsu, Zhejiang, and Shandong, where coating manufacturers and electronics producers are implementing premium surface finish programs for domestic consumption and export markets.

Distribution channels through chemical distributors, direct manufacturer relationships, and industrial coating formulators expand deployment across furniture finishing, electronics manufacturing, and industrial equipment coating applications. The country's Made in China 2025 initiative provides policy support for specialty chemicals development, including support for domestic matting agent production and advanced coating technology adoption.

Key market factors:

In the Maharashtra, Gujarat, Tamil Nadu, and Karnataka industrial regions, the adoption of high performing matting agent systems is accelerating across automotive component finishing, consumer durables coating, and building materials applications, driven by industrial expansion initiatives and increasing quality standards for manufactured goods. The market demonstrates strong growth momentum with a CAGR of 16.9% through 2035, linked to comprehensive manufacturing development and increasing focus on premium product positioning.

Indian coating manufacturers are implementing advanced matting agent formulations and quality control systems to improve surface finish quality while meeting international standards for export markets including North America, Europe, and Middle East. The country's National Manufacturing Policy creates sustained demand for specialty coating additives, while increasing emphasis on sustainable production drives adoption of waterborne coating systems requiring compatible matting solutions.

Germany's advanced chemical industry demonstrates sophisticated implementation of high performing matting agent systems, with documented case studies showing 25-30% efficiency improvements in coating formulations through optimized silica technology selection. The country's chemical manufacturing infrastructure in major production regions, including North Rhine-Westphalia, Bavaria, Baden-Württemberg, and Hesse, showcases integration of matting technologies with existing coating production systems, leveraging expertise in specialty chemicals and precision formulation.

German coating manufacturers emphasize technical performance and sustainability compliance, creating demand for reliable matting agent sources that support environmental commitments and premium product positioning. The market maintains strong growth through focus on innovation and international market service, with a CAGR of 15.5% through 2035.

Key development areas:

The Brazilian market leads in coating industry modernization based on integration with furniture manufacturing and building materials production driving demand for premium surface finishes. The country shows solid potential with a CAGR of 14.2% through 2035, driven by construction sector growth and manufacturing expansion across major industrial regions, including São Paulo, Rio de Janeiro, Minas Gerais, and Rio Grande do Sul. Brazilian coating producers are adopting advanced matting agents for compliance with quality standards in furniture export markets, particularly in applications requiring durability and appearance retention under tropical climate conditions. Technology deployment channels through chemical distributors, technical service providers, and direct coating manufacturer relationships expand coverage across diverse industrial coating operations.

Leading market segments:

The UK market leads in advanced matting agent development based on integration with high-performance coating systems and sophisticated formulation technologies for enhanced surface properties. The country shows solid potential with a CAGR of 12.8% through 2035, driven by automotive coating requirements and premium industrial coating demand across major manufacturing regions, including the Midwest industrial corridor, Southeast automotive clusters, and Gulf Coast chemical production centers. American coating manufacturers are adopting specialized matting agents for compliance with performance standards in demanding applications, particularly in automotive refinishing requiring excellent appearance and durability, and industrial equipment coatings operating under harsh environmental conditions. Technology deployment channels through specialty chemical distributors, technical service partnerships, and direct formulator relationships expand coverage across diverse coating market segments.

Leading market segments:

The UK market demonstrates sophisticated implementation focused on specialty coating applications and premium product segments, with documented integration of matting agent technologies achieving differentiated performance in industrial and decorative coating systems. The country maintains steady growth momentum with a CAGR of 11.5% through 2035, driven by specialty coatings development and manufacturing quality emphasis aligned with export market requirements. Major chemical manufacturing regions, including Northwest England, Yorkshire, and Scotland, showcase advanced coating formulation capabilities where matting agent programs integrate seamlessly with existing production infrastructure and quality management systems.

Key market characteristics:

In Tokyo, Osaka, and Nagoya industrial regions, coating manufacturers are implementing high performing matting agent programs to enhance electronics surface finishes and meet precision coating requirements, with documented case studies showing integration in display manufacturing and consumer electronics assembly operations. The market shows solid growth potential with a CAGR of 10.1% through 2035, linked to Japanese electronics industry quality standards, precision manufacturing capabilities, and emphasis on surface finish excellence. Japanese coating producers are adopting specialized matting formulations and advanced dispersion technologies to maintain optical clarity standards while achieving target gloss levels in demanding electronics applications.

Market development factors:

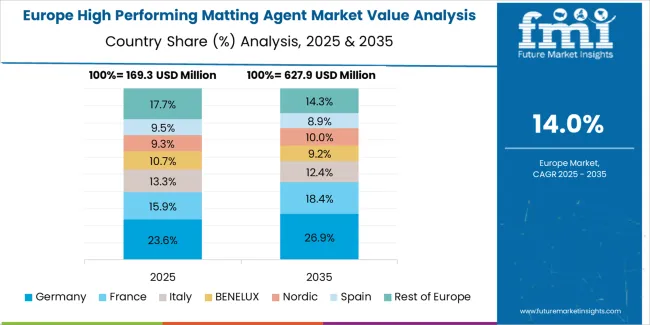

The high performing matting agent market in Europe is projected to grow from USD 189.4 million in 2025 to USD 780.2 million by 2035, registering a CAGR of 15.2% over the forecast period. Germany is expected to maintain its leadership position with a 28.5% market share in 2025, declining slightly to 27.8% by 2035, supported by its advanced chemical industry and major production centers including Ruhr Valley and Rhine industrial clusters. France follows with a 19.2% share in 2025, projected to reach 19.5% by 2035, driven by comprehensive coatings industry infrastructure and automotive sector coating demand.

The United Kingdom holds a 16.8% share in 2025, expected to decrease to 16.3% by 2035 through established specialty chemicals production and industrial coating applications. Italy commands a 13.5% share, while Spain accounts for 10.5% in 2025. The Rest of Europe region is anticipated to gain momentum, expanding its collective share from 11.5% to 12.1% by 2035, attributed to increasing matting agent adoption in Nordic countries and emerging Central & Eastern European coating production implementing premium surface finish programs.

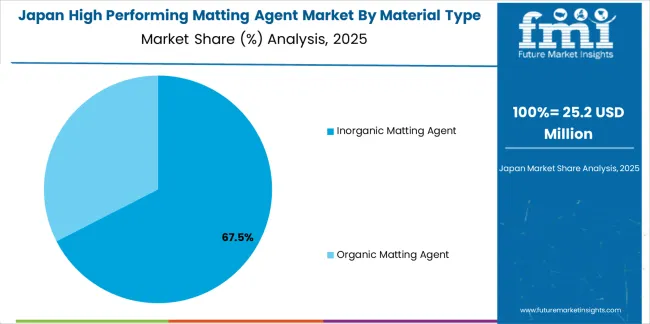

The Japanese high performing matting agent market demonstrates a mature and quality-focused landscape, characterized by sophisticated integration of ultra-fine silica particles and precision coating systems with existing electronics manufacturing infrastructure across display production, consumer electronics assembly, and precision industrial coating applications. Japan's emphasis on surface finish excellence and optical performance drives demand for advanced matting solutions that support electronics quality standards and consumer expectations in premium product categories.

The market benefits from strong partnerships between international silica producers and domestic coating manufacturers including major chemical companies, creating comprehensive technology ecosystems that prioritize particle size control and dispersion stability. Manufacturing centers in Tokyo, Osaka, Nagoya, and other major industrial areas showcase advanced coating implementations where matting agent programs achieve precise gloss control while maintaining transparency requirements essential for electronics applications.

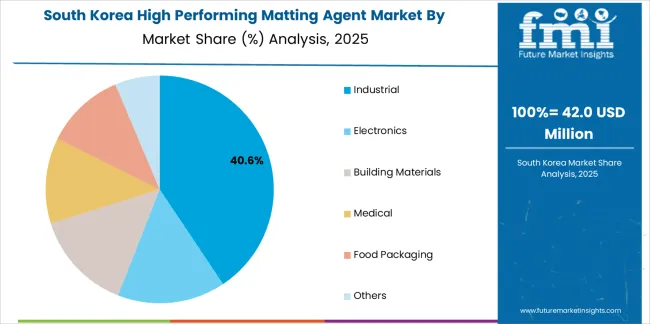

The South Korean high performing matting agent market is characterized by growing international technology provider presence, with companies maintaining significant positions through comprehensive technical service and formulation support capabilities for electronics and industrial coating applications. The market demonstrates increasing emphasis on premium surface finishes and display coating quality, as Korean electronics manufacturers increasingly demand advanced matting agents that integrate with domestic coating production and sophisticated quality control systems deployed across major manufacturing complexes.

Regional coating producers are gaining market share through strategic partnerships with international silica suppliers, offering specialized services including Korean regulatory compliance support and application-specific formulation programs for electronics and automotive coating operations. The competitive landscape shows increasing collaboration between multinational specialty chemical companies and Korean coating technology specialists, creating hybrid service models that combine international matting agent expertise with local formulation knowledge and manufacturing integration capabilities.

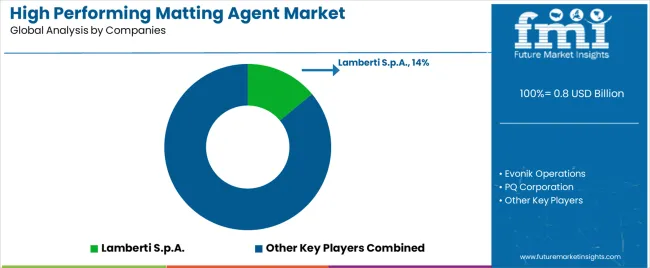

The high performing matting agent market features approximately 30-35 meaningful players with moderate fragmentation, where the top three companies control roughly 35-40% of global market share through established production infrastructure and comprehensive product portfolios. Competition centers on particle engineering capabilities, technical service quality, and formulation support rather than price competition alone. Lamberti S.p.A. leads with approximately 14.0% market share through its comprehensive silica-based matting agent portfolio spanning diverse coating applications.

Market leaders include Lamberti S.p.A., Evonik Operations, and PQ Corporation, which maintain competitive advantages through decades of silica production experience, established technical service infrastructure supporting coating formulators worldwide, and deep expertise in particle surface modification technologies, creating trust and reliability advantages with industrial coating producers. These companies leverage research capabilities in precipitation technology and surface chemistry alongside ongoing formulation support relationships to defend market positions while expanding into waterborne coating systems and specialty application segments.

Challengers encompass Mitsubishi Chemical and EuroMinerals, which compete through specialized matting technologies and strong regional presence in key coating markets. Product specialists, including Honeywell, Imerys, and Ishihara Sangyo Kaisha, focus on specific matting mechanisms or application segments, offering differentiated capabilities in organic matting systems, mineral-based solutions, and ultra-fine particle technologies.

Regional players and emerging specialty chemical producers create competitive pressure through localized production advantages and rapid response capabilities, particularly in high-growth markets including China and India, where proximity to coating manufacturers provides advantages in logistics costs and technical service delivery. Market dynamics favor companies that combine reliable product quality with comprehensive technical support offerings that address the complete coating formulation cycle from initial development through production scale-up and quality optimization.

High performing matting agents represent critical functional additives that enable coating manufacturers to achieve 30-40% improvement in gloss reduction efficiency compared to conventional alternatives, delivering superior surface aesthetics and functional performance with maintained transparency and mechanical properties in demanding industrial applications. With the market projected to grow from USD 0.8 billion in 2025 to USD 3.7 billion by 2035 at a 16.5% CAGR, these specialty chemicals offer compelling advantages for industrial applications (42.0% market share), electronics (23.0% share), and coating systems seeking premium matte finishes with excellent durability characteristics. Scaling market adoption and technology advancement requires coordinated action across specialty chemical producers, coating manufacturers, end-use industries, research institutions, and sustainable chemistry investment capital.

How Governments Could Spur Local Production and Adoption?

How Industry Bodies Could Support Market Development?

How OEMs and Technology Players Could Strengthen the Ecosystem?

How Suppliers Could Navigate the Shift?

How Investors and Financial Enablers Could Unlock Value?

| Item | Value |

|---|---|

| Quantitative Units | USD 0.8 billion |

| Material Type | Inorganic Matting Agent, Organic Matting Agent |

| Application | Industrial, Electronics, Building Materials, Medical, Food Packaging, Others |

| Regions Covered | Asia Pacific, Europe, North America, Latin America, Middle East & Africa |

| Country Covered | China, India, Germany, Brazil, USA, UK, Japan, and 40+ countries |

| Key Companies Profiled | Lamberti S.p.A., Evonik Operations, PQ Corporation, Mitsubishi Chemical, EuroMinerals, Honeywell, Imerys, Ishihara Sangyo Kaisha, Grace, Tosoh Silica Corporation |

| Additional Attributes | Dollar sales by material type and application categories, regional adoption trends across Asia Pacific, Europe, and North America, competitive landscape with specialty chemical manufacturers and coating industry partnerships, production facility requirements and specifications, integration with coating formulation development programs and sustainable chemistry initiatives, innovations in particle engineering and surface treatment technologies, and development of specialized matting agents with enhanced transparency and durability capabilities. |

The global high performing matting agent market is estimated to be valued at USD 0.8 billion in 2025.

The market size for the high performing matting agent market is projected to reach USD 3.7 billion by 2035.

The high performing matting agent market is expected to grow at a 16.5% CAGR between 2025 and 2035.

The key product types in high performing matting agent market are inorganic matting agent and organic matting agent.

In terms of application, industrial segment to command 42.0% share in the high performing matting agent market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

High Reliability Oscillators Market Size and Share Forecast Outlook 2025 to 2035

High-performance Dual-core Processor Market Size and Share Forecast Outlook 2025 to 2035

High Purity Magnesium Citrate Market Size and Share Forecast Outlook 2025 to 2035

High Performance Magnet Market Size and Share Forecast Outlook 2025 to 2035

High-frequency RF Evaluation Board Market Size and Share Forecast Outlook 2025 to 2035

High Viscosity Mixer Market Size and Share Forecast Outlook 2025 to 2035

High Voltage Ionising Air Gun Market Size and Share Forecast Outlook 2025 to 2035

High Voltage Equipment Market Forecast and Outlook 2025 to 2035

High Clear Film Market Size and Share Forecast Outlook 2025 to 2035

High Performance Random Packing Market Forecast Outlook 2025 to 2035

High Precision Microfluidic Pump Market Size and Share Forecast Outlook 2025 to 2035

High Performance Composites Market Forecast Outlook 2025 to 2035

High Performance Medical Plastic Market Forecast Outlook 2025 to 2035

High Temperature Heat Pump Dryers Market Size and Share Forecast Outlook 2025 to 2035

High Temperature Fiberglass Filter Media Market Size and Share Forecast Outlook 2025 to 2035

High Purity Tungsten Hexachloride Market Size and Share Forecast Outlook 2025 to 2035

High Purity Nano Aluminum Oxide Powder Market Size and Share Forecast Outlook 2025 to 2035

High Mast Lighting Market Forecast and Outlook 2025 to 2035

High-Protein Pudding Market Forecast and Outlook 2025 to 2035

High Voltage Ceramic Zinc Oxide Surge Arrester Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA