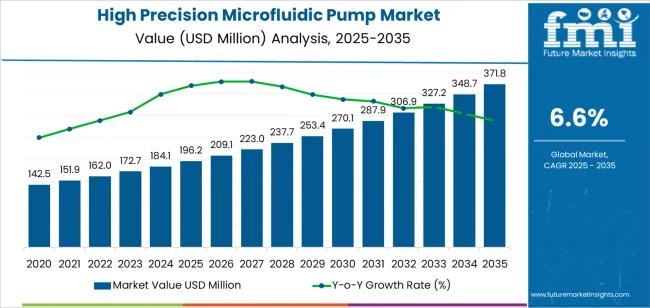

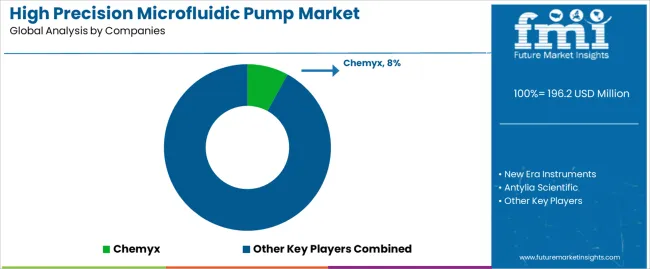

The global high precision microfluidic pump market is projected to grow from USD 196.2 million in 2025 to approximately USD 371.8 million by 2035, recording an absolute increase of USD 175.6 million over the forecast period. This translates into a total growth of 89.5%, with the high precision microfluidic pump market forecast to expand at a compound annual growth rate (CAGR) of 6.6% between 2025 and 2035. The overall market size is expected to grow by nearly 1.9X during the same period, supported by accelerating demand for precision fluid handling systems in pharmaceutical research applications, breakthrough advancements in microfluidic device manufacturing technologies, and expanding adoption of automated laboratory instrumentation across biotechnology research facilities and clinical diagnostic laboratories.

The steady market expansion reflects the transformative potential of high precision microfluidic pump technology in revolutionizing laboratory automation and precision analytical systems. Major pharmaceutical research organizations worldwide are increasingly incorporating advanced microfluidic pumping solutions to enhance experimental accuracy and reduce reagent consumption, while breakthrough developments in personalized medicine research are creating unprecedented demand for ultra-precise fluid delivery systems. The biotechnology sector is experiencing significant growth as cell culture applications and organ-on-chip platforms require advanced pumping solutions that deliver superior flow control characteristics and operational reliability under continuous operation conditions.

Manufacturing capabilities are advancing rapidly as leading producers invest in precision machining facilities and proprietary valve technologies to meet growing market demand for enhanced flow accuracy and reduced pulsation. The technology landscape continues evolving with innovations in pump mechanism design, materials engineering, and control system integration that enhance flow precision while reducing maintenance requirements. Research institutions and commercial manufacturers are collaborating extensively to develop next-generation microfluidic pump products that address specific application requirements across pharmaceutical research, clinical diagnostics, and biotechnology development sectors.

Quality standards are becoming increasingly stringent as applications demand higher precision specifications and greater reliability under extended operational conditions. Industry certification programs and validation protocols ensure consistent product performance while supporting market confidence in microfluidic pump technology adoption across critical research applications and regulated laboratory environments. Regulatory compliance requirements for pharmaceutical and medical device applications are driving investments in comprehensive quality management systems and traceability protocols throughout the manufacturing supply chain.

International collaboration is accelerating market development as major pharmaceutical research programs require coordinated efforts between multiple research institutions and technology suppliers. Global pharmaceutical companies are establishing standardized specifications for microfluidic pump performance that influence worldwide manufacturing standards and create opportunities for specialized suppliers. Academic research institutions are forming strategic partnerships with pump manufacturers to develop application-specific solutions tailored to emerging research methodologies and experimental requirements.

Investment patterns are shifting toward integrated solution development as major end-users seek comprehensive fluid handling systems that combine precision pumping with advanced control software and data analytics capabilities. Pharmaceutical companies are forming joint ventures with technology providers to develop customized laboratory automation platforms, while biotechnology firms are acquiring stakes in specialized pump manufacturers to ensure access to cutting-edge fluid handling technologies for their research and development programs. This trend toward strategic partnerships and technology integration is reshaping competitive dynamics across the precision pumping value chain.

Market maturation is evident in the emergence of specialized application segments that demand unique pump characteristics and performance specifications. Cell culture applications require extremely stable flow conditions and biocompatibility under sterile operating conditions, while chemical synthesis systems need pump solutions that maintain accuracy and reliability when handling aggressive solvents and reagents. These specialized requirements are driving innovation in pump materials, sealing technologies, and control methodologies that extend beyond traditional laboratory and analytical applications.

| Item | Value / Description |

|---|---|

| Market Value (2025) | USD 196.2 million |

| Forecast Value (2035) | USD 371.8 million |

| Forecast CAGR (2025-2035) | 6.6% |

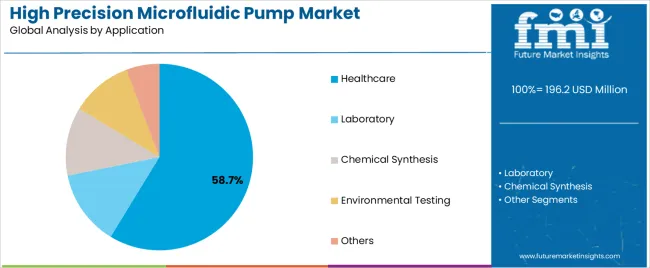

| Leading Application (2025) | Healthcare - 58.7% share |

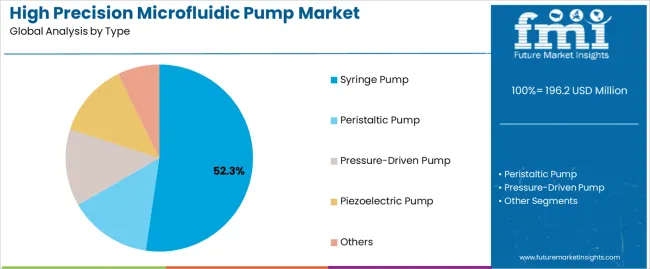

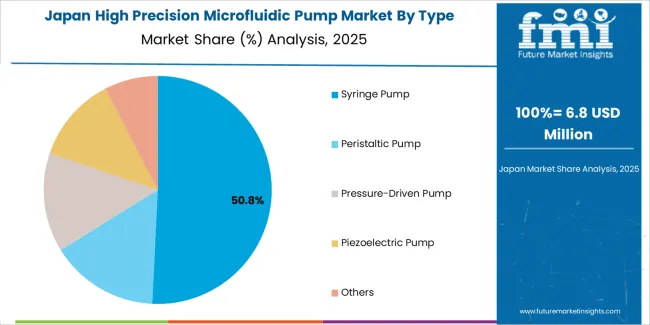

| Leading Type Segment (2025) | Syringe Pump - 52.3% share |

| Leading Distribution Channel (2025) | Direct Sales - 71.2% share |

| Key Growth Regions | Asia Pacific; North America; Europe |

| Top Companies by Market Share | Chemyx; New Era Instruments; Antylia Scientific |

| Metric | Value |

|---|---|

| Market Value (2025) | USD 196.2 million |

| Market Forecast Value (2035) | USD 371.8 million |

| Forecast CAGR (2025-2035) | 6.6% |

| PHARMACEUTICAL RESEARCH ADVANCEMENT | LABORATORY AUTOMATION EXPANSION | BIOTECHNOLOGY DEVELOPMENT |

|---|---|---|

| Drug Discovery Acceleration - Pharmaceutical companies investing in high-throughput screening platforms and precision dosing systems requiring ultra-accurate fluid delivery for compound libraries and biological assays with reduced reagent waste and enhanced experimental reproducibility. | Laboratory Modernization - Research facilities upgrading to automated liquid handling systems and integrated analytical platforms that incorporate precision microfluidic pumps for enhanced workflow efficiency, reduced manual errors, and improved experimental consistency. | Cell Culture Enhancement - Advanced cell culture applications and tissue engineering platforms requiring precision fluid control systems for nutrient delivery, media exchange, and environmental control with superior biocompatibility and sterile operation capabilities. |

| Personalized Medicine Development - Growing focus on precision medicine research requiring microfluidic systems for single-cell analysis, drug screening, and biomarker discovery applications utilizing advanced pump technologies for precise sample manipulation and reagent delivery. | Quality Control Implementation - Analytical laboratories implementing automated quality control systems and method validation protocols that require reliable microfluidic pumping solutions for consistent sample preparation and analytical performance. | Organ-on-Chip Growth - Emerging organ-on-chip research platforms and microphysiological systems requiring sophisticated fluid handling capabilities for simulating physiological conditions and maintaining cellular microenvironments with precision flow control. |

| Clinical Diagnostics Expansion - Point-of-care diagnostic systems and automated clinical analyzers incorporating microfluidic technologies that require precision pumping solutions for sample processing, reagent delivery, and assay automation with regulatory compliance. | Research Productivity Enhancement - Academic and commercial research institutions seeking to improve experimental throughput and data quality through automated fluid handling systems that reduce human error and increase experimental reproducibility. | Bioprocessing Innovation - Biomanufacturing applications and continuous processing systems requiring precision fluid handling for upstream and downstream processing operations with enhanced process control and product quality assurance. |

| Category | Segments / Values |

|---|---|

| By Type | Syringe Pump; Peristaltic Pump; Pressure-Driven Pump; Piezoelectric Pump; Others |

| By Application | Healthcare; Laboratory; Chemical Synthesis; Environmental Testing; Others |

| By End-User | Pharmaceutical Companies; Research Institutions; Biotechnology Firms; Clinical Laboratories; Others |

| By Flow Rate | Nanoliter; Microliter; Milliliter; Others |

| By Distribution Channel | Direct Sales; Specialized Distributors; Online Platforms; Research Partners |

| By Region | North America; Europe; Asia Pacific; Latin America; Middle East & Africa |

| Segment | 2025-2035 Outlook |

|---|---|

| Syringe Pump | Leader in 2025 with 52.3% market share; optimal precision and accuracy for laboratory applications. Widely adopted for pharmaceutical research and analytical chemistry applications requiring precise volume delivery. Momentum: steady growth across research and clinical segments. Watchouts: competition from emerging pump technologies in specialized applications. |

| Peristaltic Pump | Significant segment with 31.7% share, favored for continuous flow applications requiring contamination-free fluid handling and easy maintenance. Momentum: strong growth in biotechnology and environmental testing applications. Watchouts: limited precision compared to syringe pumps in ultra-low flow applications. |

| Pressure-Driven Pump | Specialized segment offering rapid flow changes and precise pressure control for advanced microfluidic applications and chip-based systems. Momentum: growing adoption in organ-on-chip and cell culture applications. Watchouts: higher complexity and system integration requirements. |

| Piezoelectric Pump | Premium segment for ultra-precise applications requiring exceptional accuracy and minimal pulsation for sensitive analytical procedures. Momentum: selective growth in high-end analytical and research applications. Watchouts: higher costs and specialized maintenance requirements. |

| Others | Includes pneumatic pumps and hybrid systems for specialized applications. Momentum: niche growth in custom research platforms and experimental systems. |

| Segment | 2025-2035 Outlook |

|---|---|

| Healthcare | Largest application segment in 2025 at 58.7% share, driven by clinical diagnostics advancement and point-of-care testing systems requiring precision fluid handling. Includes drug delivery research, biomarker analysis, and clinical assay automation. Momentum: robust growth from healthcare digitization and precision medicine development. Watchouts: regulatory approval complexities and validation requirements. |

| Laboratory | Critical segment representing 27.4% share, experiencing strong growth from research automation and analytical method development programs. Momentum: exceptional growth as laboratory automation accelerates across academic and commercial research facilities. Watchouts: budget constraints and technology adoption timelines. |

| Chemical Synthesis | Specialized segment at 8.9% share for flow chemistry applications, microreactor systems, and continuous manufacturing processes requiring precise reagent delivery. Momentum: strong growth from pharmaceutical manufacturing modernization. Watchouts: harsh chemical compatibility and maintenance challenges. |

| Others | Includes environmental testing, food analysis, and emerging applications. Momentum: diverse growth opportunities across multiple analytical sectors. |

| Distribution Channel | Status & Outlook (2025-2035) |

|---|---|

| Direct Sales | Dominant channel in 2025 with 71.2% share for specialized microfluidic applications. Provides technical consultation, application support, and customized solutions for complex research projects. Momentum: strong growth driven by pharmaceutical research and biotechnology projects requiring direct manufacturer engagement. Watchouts: resource constraints and technical support capacity limitations. |

| Specialized Distributors | Technical distribution serving research institutions and analytical laboratories with comprehensive product knowledge and local support capabilities. Momentum: moderate growth as market expands beyond core pharmaceutical applications. Watchouts: inventory investment requirements and technical expertise development. |

| Online Platforms | Digital channel for standard pump configurations and replacement components serving smaller research facilities and educational institutions. Momentum: growing importance as buyers seek convenient procurement and competitive pricing. |

| Research Partners | Collaborative channel for joint development programs and experimental applications with universities and research consortiums. Momentum: strategic growth as biotechnology and pharmaceutical research accelerates. |

| DRIVERS | RESTRAINTS | KEY TRENDS |

|---|---|---|

| Pharmaceutical Research Growth across drug discovery programs and precision medicine development are creating substantial demand for high-precision fluid handling systems supporting automated screening platforms and analytical workflows. | High Initial Costs and complex system integration requirements limit accessibility across smaller research facilities and budget-constrained laboratory environments. | Automation Integration - Advanced laboratory automation systems and robotic platforms are incorporating precision microfluidic pumps for enhanced workflow efficiency and experimental reproducibility. |

| Laboratory Automation Expansion - Global research facility modernization and workflow optimization programs are driving adoption of automated fluid handling systems for improved productivity and data quality. | Technical Complexity - Installation requirements, software integration, and specialized maintenance affect deployment timelines and operational capabilities for smaller research facilities. | Miniaturization Advancement - Innovations in pump design, materials engineering, and control systems are delivering smaller form factors with enhanced precision and reliability characteristics. |

| Biotechnology Development - Next-generation cell culture systems, organ-on-chip platforms, and biomanufacturing applications require precision fluid control solutions for enhanced experimental control and reproducibility. | Limited Technical Expertise - Specialized operational requirements and maintenance procedures constrain adoption among laboratories lacking dedicated technical support and training resources. | Application Diversification - Expanding use cases in environmental analysis, food testing, and quality control are creating new market opportunities beyond traditional pharmaceutical and research applications. |

| Regulatory Compliance Enhancement - Stringent quality standards and validation requirements in pharmaceutical and clinical applications are driving adoption of certified precision pumping solutions with comprehensive documentation and traceability. | Maintenance Challenges - Regular calibration requirements and component replacement procedures create operational complexity and ongoing costs for research facilities. | Digital Integration - Integration with laboratory information management systems and data analytics platforms enabling comprehensive experiment tracking and process optimization. |

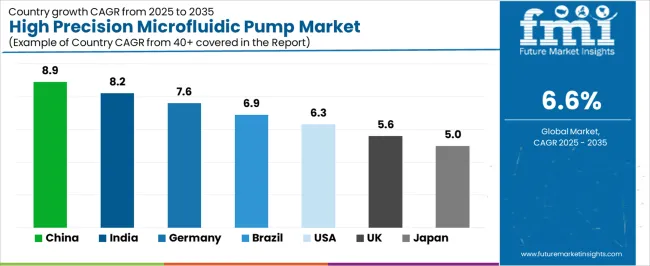

| Country | CAGR (2025-2035) |

|---|---|

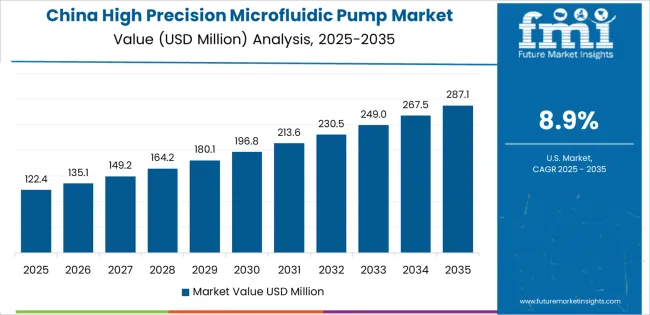

| China | 8.9% |

| India | 8.2% |

| Germany | 7.6% |

| Brazil | 6.9% |

| United States | 6.3% |

| United Kingdom | 5.6% |

| Japan | 5.0% |

Revenue from High Precision Microfluidic Pump in China is projected to exhibit exceptional growth with a market value of USD 67.4 million by 2035, driven by massive pharmaceutical research expansion and comprehensive laboratory modernization initiatives creating substantial opportunities for precision pumping technology suppliers across biotechnology research, clinical diagnostics, and advanced manufacturing sectors. The country's ambitious biotechnology development programs including national research initiatives and commercial pharmaceutical expansion are creating unprecedented demand for high-precision fluid handling systems. Major pharmaceutical companies and research institutions including Beijing Institute of Technology and Tsinghua University are establishing comprehensive microfluidic technology development programs to support large-scale drug discovery and advanced analytical applications.

Revenue from High Precision Microfluidic Pump in India is expanding to reach USD 46.0 million by 2035, supported by extensive pharmaceutical research programs and comprehensive laboratory infrastructure development creating demand for precision pumping solutions across diverse research applications and clinical diagnostic segments. The country's growing biotechnology research capabilities and expanding pharmaceutical manufacturing infrastructure are driving demand for component solutions that provide exceptional accuracy while supporting advanced research technology requirements. Research institutions and pharmaceutical companies are investing in microfluidic technology development to support growing drug discovery operations and analytical testing demand.

Demand for High Precision Microfluidic Pump in Germany is projected to reach USD 31.9 million by 2035, supported by the country's leadership in analytical instrumentation and advanced microfluidic technologies requiring sophisticated precision systems for research and pharmaceutical applications. German research institutions are implementing cutting-edge analytical platforms that support advanced fluid handling capabilities, operational precision, and comprehensive performance protocols. The high precision microfluidic pump market is characterized by focus on engineering excellence, research innovation, and compliance with stringent analytical quality and performance standards.

Revenue from High Precision Microfluidic Pump in Brazil is growing to reach USD 24.2 million by 2035, driven by pharmaceutical research development programs and increasing laboratory capabilities creating opportunities for precision pumping suppliers serving both analytical operations and specialized research contractors. The country's expanding biotechnology sector and growing research infrastructure are creating demand for pumping components that support diverse analytical requirements while maintaining performance standards. Universities and research institutions are developing technology strategies to support operational efficiency and research advancement.

Demand for High Precision Microfluidic Pump in United States is projected to reach USD 22.9 million by 2035, expanding at a CAGR of 6.3%, driven by advanced pharmaceutical research excellence and specialized medical device applications supporting drug discovery development and comprehensive analytical platform applications. The country's established pharmaceutical research tradition including major pharmaceutical companies and biotechnology firms are creating demand for ultra-high precision pumping components that support operational advancement and research standards. Manufacturers and medical device suppliers are maintaining comprehensive development capabilities to support diverse research and clinical requirements.

Revenue from Precision Microfluidic Pump in United Kingdom is growing to reach USD 20.5 million by 2035, supported by pharmaceutical research heritage and established scientific communities driving demand for premium precision pumping solutions across traditional analytical systems and specialized research applications. The country's rich pharmaceutical research heritage including major pharmaceutical companies and established research capabilities create demand for pumping components that support both legacy system advancement and modern research applications.

Demand for High Precision Microfluidic Pump in Japan is projected to reach USD 18.5 million by 2035, driven by precision instrumentation tradition and established technology leadership supporting both domestic analytical markets and export-oriented component production. Japanese companies maintain sophisticated microfluidic development capabilities, with established manufacturers continuing to lead in precision pumping technology and analytical instrumentation standards.

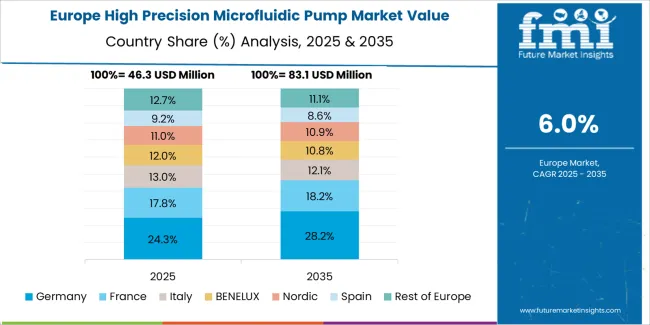

European High Precision Microfluidic Pump operations are increasingly concentrated between German analytical instrumentation excellence and specialized precision manufacturing across multiple countries. German facilities dominate high-performance pump production for pharmaceutical research and advanced analytical applications, leveraging cutting-edge manufacturing technologies and strict quality protocols that command price premiums in global markets. British research institutions maintain leadership in pharmaceutical research and analytical method development, with organizations like pharmaceutical research centers and university laboratories driving technical specifications that suppliers must meet to access major research contracts.

Eastern European operations in Czech Republic and Poland are capturing specialized production contracts through precision manufacturing expertise and EU research compliance, particularly in component fabrication and assembly technologies for analytical applications. These facilities increasingly serve as development partners for Western European research programs while building their own microfluidic technology expertise.

The regulatory environment presents both opportunities and constraints. European research framework requirements create quality standards that favor established European manufacturers and research institutions while ensuring consistent performance specifications for critical pharmaceutical and analytical applications. Brexit has created complexity for UK research collaboration with EU programs, driving opportunities for direct relationships between British institutions and international precision pumping suppliers.

Research collaboration accelerates as institutions seek technological advancement to support major pharmaceutical research milestones and analytical method development timelines. Vertical integration increases, with major research organizations acquiring specialized manufacturing capabilities to secure component supplies and quality control for critical research programs. Smaller research facilities face pressure to specialize in niche applications or risk displacement by larger, more comprehensive operations serving mainstream pharmaceutical research requirements.

South Korean High Precision Microfluidic Pump operations reflect the country's advanced biotechnology research capabilities and export-oriented technology development model. Major research institutions including Korea Institute of Science and Technology and pharmaceutical companies drive component procurement strategies for their research facilities, establishing direct relationships with specialized precision pumping suppliers to secure consistent quality and performance for their analytical research programs and advanced laboratory automation systems targeting both domestic research and international collaboration projects.

The Korean market demonstrates particular strength in integrating microfluidic pump technologies into analytical platforms and advanced laboratory automation configurations, with research teams developing solutions that bridge traditional fluid handling applications and next-generation biotechnology research systems. This integration approach creates demand for specific performance specifications that differ from conventional applications, requiring suppliers to adapt flow accuracy capabilities and system integration characteristics.

Regulatory frameworks emphasize research quality and analytical reliability, with Korean laboratory standards often exceeding international requirements for precision fluid handling systems. This creates barriers for standard component suppliers but benefits established manufacturers who can demonstrate research-grade performance capabilities. The regulatory environment particularly favors suppliers with Korean research facility qualification and comprehensive validation documentation systems.

Supply chain excellence remains critical given Korea's biotechnology research focus and international collaboration dynamics. Research institutions increasingly pursue development partnerships with suppliers in Japan, Germany, and specialized manufacturers to ensure access to cutting-edge precision pumping technologies while managing research risks. Investment in research infrastructure supports performance advancement during extended biotechnology development cycles.

Profit pools are consolidating upstream in advanced pump manufacturing and downstream in application-specific solutions for pharmaceutical research, clinical diagnostics, and biotechnology markets where precision, reliability, and exceptional flow control performance command substantial premiums. Value is migrating from basic pump production to specification-driven, application-ready fluid handling systems where materials engineering expertise, precision manufacturing, and reliable performance characteristics create competitive advantages. Several archetypes define market leadership: established American manufacturers defending share through advanced pump technology and comprehensive application support; German precision equipment companies leveraging manufacturing excellence and engineering capabilities; Japanese instrumentation leaders with analytical equipment expertise and precision manufacturing heritage; and emerging manufacturers pursuing cost-effective production while developing advanced precision capabilities. Switching costs - system integration, application validation, performance qualification - provide stability for established suppliers, while technological advancement requirements and research application growth create opportunities for innovative manufacturers. Consolidation continues as companies seek manufacturing scale; direct research partnerships grow for specialized applications while traditional distribution remains relationship-driven. Focus areas: secure pharmaceutical research and clinical diagnostic market positions with application-specific performance specifications and technical collaboration; develop precision pumping technology and advanced manufacturing capabilities; explore specialized applications including biotechnology and environmental testing requirements.

| Stakeholder Type | Primary Advantage | Repeatable Plays |

|---|---|---|

| American Technology Leaders | Advanced pump expertise; proven reliability; established research relationships | Precision manufacturing; technical innovation; application support |

| German Engineering Companies | Manufacturing excellence; comprehensive development programs; established customer partnerships | Engineering collaboration focus; integrated solutions; technical consultation |

| Japanese Instrumentation Leaders | Analytical expertise; precision technology leadership; trusted by major research programs | Scientific partnerships; application-specific specifications; research collaboration |

| Emerging Technology Producers | Manufacturing efficiency; competitive pricing; rapid technology development | Production scaling; technology advancement; market entry strategies |

| Specialized Distributors | Technical distribution networks; research institution relationships | Research expertise; inventory management; technical support services |

| Item | Value |

|---|---|

| Quantitative Units | USD 196.2 million |

| Type Segments | Syringe Pump; Peristaltic Pump; Pressure-Driven Pump; Piezoelectric Pump; Others |

| Applications | Healthcare; Laboratory; Chemical Synthesis; Environmental Testing; Others |

| End-Users | Pharmaceutical Companies; Research Institutions; Biotechnology Firms; Clinical Laboratories; Others |

| Flow Rate Segments | Nanoliter; Microliter; Milliliter; Others |

| Distribution Channels | Direct Sales; Specialized Distributors; Online Platforms; Research Partners |

| Regions Covered | North America; Latin America; Europe; Asia Pacific; Middle East & Africa |

| Key Countries | China; India; Germany; Brazil; United States; United Kingdom; Japan (+35 additional countries) |

| Key Companies Profiled | Chemyx; New Era Instruments; Antylia Scientific; Harvard Apparatus; Elveflow (Elvesys); Bartels Mikrotechnik; Avantor Masterflex; Dolomite Microfluidics; Burkert; Cellix Ltd.; Longer Pump; Innofluid; HNP Mikrosysteme; Dichbio; Lead Fluid; DK INFUSETEK; Nanjing Runze Fluid Control Equipment; Advanced Microfluidics |

| Additional Attributes | Dollar sales by type and application; Regional demand trends (NA, EU, APAC); Competitive landscape; Direct vs. distributor adoption patterns; Manufacturing and research integration; Advanced precision innovations driving flow accuracy enhancement, operational reliability, and analytical excellence |

The global high precision microfluidic pump market is estimated to be valued at USD 196.2 million in 2025.

The market size for the high precision microfluidic pump market is projected to reach USD 371.8 million by 2035.

The high precision microfluidic pump market is expected to grow at a 6.6% CAGR between 2025 and 2035.

The key product types in high precision microfluidic pump market are syringe pump, peristaltic pump, pressure-driven pump, piezoelectric pump and others.

In terms of application, healthcare segment to command 58.7% share in the high precision microfluidic pump market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

High Voltage Equipment Market Forecast and Outlook 2025 to 2035

High Clear Film Market Size and Share Forecast Outlook 2025 to 2035

High Performance Random Packing Market Forecast Outlook 2025 to 2035

High Performance Composites Market Forecast Outlook 2025 to 2035

High Performance Medical Plastic Market Forecast Outlook 2025 to 2035

High Temperature Fiberglass Filter Media Market Size and Share Forecast Outlook 2025 to 2035

High Purity Tungsten Hexachloride Market Size and Share Forecast Outlook 2025 to 2035

High Purity Nano Aluminum Oxide Powder Market Size and Share Forecast Outlook 2025 to 2035

High Mast Lighting Market Forecast and Outlook 2025 to 2035

High-Protein Pudding Market Forecast and Outlook 2025 to 2035

High Voltage Ceramic Zinc Oxide Surge Arrester Market Size and Share Forecast Outlook 2025 to 2035

High-Power Microwave Source Market Size and Share Forecast Outlook 2025 to 2035

High Performance Epoxy Coating Market Size and Share Forecast Outlook 2025 to 2035

High Molecular Ammonium Polyphosphate Market Size and Share Forecast Outlook 2025 to 2035

High Performance Fluoropolymer Market Size and Share Forecast Outlook 2025 to 2035

High Throughput Screening Market Size and Share Forecast Outlook 2025 to 2035

High Barrier Packaging Films for Pharmaceuticals Market Size and Share Forecast Outlook 2025 to 2035

High Barrier Packaging Films Market Size and Share Forecast Outlook 2025 to 2035

High Purity Carbonyl Iron Powder (CIP) Market Size and Share Forecast Outlook 2025 to 2035

High Voltage PTC Heater Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA