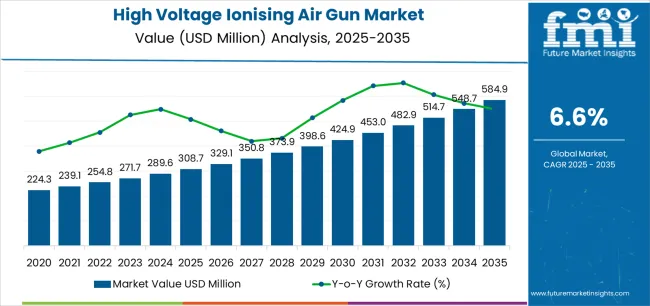

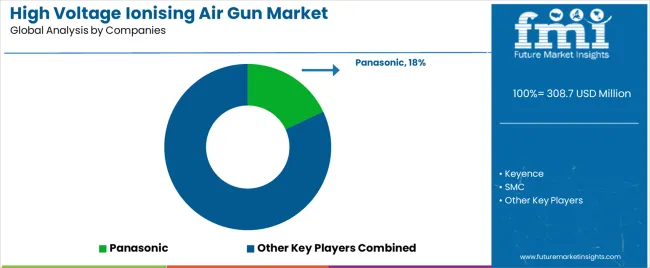

The global high voltage ionising air gun market is valued at USD 308.7 million in 2025. It is slated to reach USD 584.9 million by 2035, recording an absolute increase of USD 276.2 million over the forecast period. This translates into a total growth of 89.5%, with the market forecast to expand at a compound annual growth rate (CAGR) of 6.6% between 2025 and 2035. The overall market size is expected to grow by approximately 1.89 times during the same period, supported by increasing demand for static elimination solutions in electronics manufacturing and cleanroom environments, growing adoption of ionising air guns for precision cleaning and contamination control applications, and rising emphasis on product quality and electrostatic discharge protection across diverse semiconductor fabrication, pharmaceutical manufacturing, consumer electronics assembly, and precision instrument production applications.

Between 2025 and 2030, the high voltage ionising air gun market is projected to expand from USD 308.7 million to USD 424.9 million, resulting in a value increase of USD 116.2 million, which represents 42.1% of the total forecast growth for the decade. This phase of development will be shaped by increasing semiconductor manufacturing capacity and advanced packaging technology adoption, rising demand for contamination control equipment in pharmaceutical cleanrooms and medical device manufacturing, and growing emphasis on electrostatic discharge prevention and quality assurance programs. Electronics manufacturers and cleanroom operators are expanding their ionising air gun capabilities to address the growing demand for reliable and effective solutions that ensure static elimination and surface cleaning performance.

From 2030 to 2035, the market is forecast to grow from USD 424.9 million to USD 584.9 million, adding another USD 160.0 million, which constitutes 57.9% of the overall ten-year expansion. This period is expected to be characterized by the expansion of advanced semiconductor nodes and miniaturized device production, the development of intelligent ionising systems with automated monitoring and feedback control, and the growth of specialized applications for flexible electronics manufacturing and biotechnology production facilities. The growing adoption of Industry 4.0 integration and smart factory technologies will drive demand for ionising air guns with enhanced connectivity and performance verification features.

Between 2020 and 2025, the high voltage ionising air gun market experienced steady growth, driven by increasing electronics manufacturing sophistication and growing recognition of ionising air guns as essential equipment for eliminating static electricity and removing particulate contamination in diverse semiconductor fabrication and precision manufacturing applications. The market developed as production engineers and quality managers recognized the potential for ionising air gun technology to prevent electrostatic damage, improve surface cleanliness, and support yield objectives while meeting stringent quality requirements. Technological advancement in ionisation technology and nozzle design began emphasizing the critical importance of maintaining ion balance and elimination speed in demanding cleanroom environments.

| Metric | Value |

|---|---|

| Estimated Value in (2025E) | USD 308.7 million |

| Forecast Value in (2035F) | USD 584.9 million |

| Forecast CAGR (2025 to 2035) | 6.6% |

Market expansion is being supported by the increasing global demand for electrostatic discharge protection equipment driven by semiconductor device sensitivity and electronics miniaturization trends, alongside the corresponding need for specialized ionisation tools that can enhance static elimination, enable precision cleaning operations, and maintain contamination control across various semiconductor fabrication, pharmaceutical cleanroom, consumer electronics assembly, and precision manufacturing applications. Modern production engineers and cleanroom managers are increasingly focused on implementing ionising air gun solutions that can neutralize static charges, remove surface contaminants, and provide consistent performance in critical manufacturing environments.

The growing emphasis on product quality and yield optimization is driving demand for ionising air guns that can support defect prevention strategies, enable comprehensive electrostatic discharge protection, and ensure effective particulate removal. Equipment manufacturers' preference for ionisation systems that combine static elimination effectiveness with operational safety and energy efficiency is creating opportunities for innovative ionising air gun implementations. The rising influence of advanced packaging technologies and flexible electronics is also contributing to increased adoption of ionising air guns that can provide superior static control without compromising product integrity or manufacturing throughput.

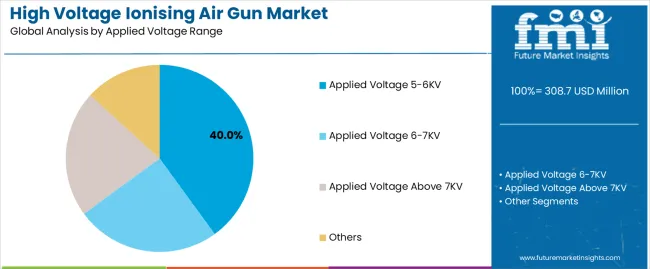

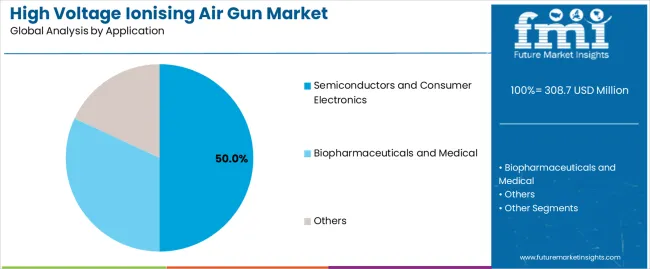

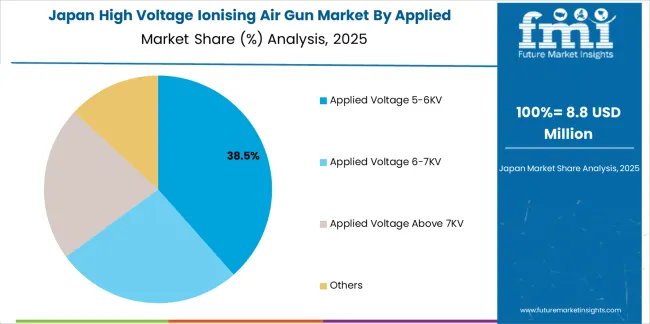

The market is segmented by applied voltage range, application, and region. By applied voltage range, the market is divided into applied voltage 5-6KV, applied voltage 6-7KV, applied voltage above 7KV, and others. Based on application, the market is categorized into semiconductors and consumer electronics, biopharmaceuticals and medical, and others. Regionally, the market is divided into East Asia, Europe, North America, South Asia, Latin America, Middle East & Africa, and Eastern Europe.

The applied voltage 5-6KV segment, projected to represent 40% of the high voltage ionising air gun market in 2025, is set to maintain its leading position. This reaffirms its role as the preferred voltage configuration for general electronics manufacturing and cleanroom static elimination applications. Electronics assembly operators and cleanroom technicians increasingly utilize 5-6KV ionising air guns for their optimal balance of ionisation efficiency, safety characteristics, and proven effectiveness in neutralizing static charges while maintaining operator comfort. Mid-range voltage technology's proven effectiveness and widespread adoption directly address the industry requirements for reliable static elimination and safe operation across diverse manufacturing platforms and cleanroom environments.

This voltage range forms the foundation of modern static control operations, as it represents the specification with the greatest contribution to practical usability and established performance record across multiple electronics applications and cleanroom classes. Manufacturing facility investments in electrostatic discharge control technologies continue to strengthen adoption among electronics manufacturers and pharmaceutical producers. With operational pressures requiring effective static elimination and workplace safety, 5-6KV ionising air guns align with both performance objectives and safety requirements, making them the central component of comprehensive static control strategies.

The semiconductors and consumer electronics application segment, projected to represent 50% of the high voltage ionising air gun market demand in 2025, dominates market demand. This underscores its critical role as the primary driver for ionising air gun adoption across wafer fabrication facilities, assembly operations, and quality inspection stations. Electronics manufacturing managers prefer ionising air guns for static control due to their exceptional electrostatic discharge prevention capabilities, contamination removal benefits, and ability to protect sensitive components while supporting yield improvement and quality assurance objectives. Positioned as essential equipment for modern electronics manufacturing, ionising air guns offer both protection advantages and operational benefits.

The segment is supported by continuous innovation in ionisation technologies and the growing availability of advanced air gun designs that enable superior static elimination with enhanced ion balance and reduced maintenance requirements. Static control equipment manufacturers are investing in comprehensive product development programs to support increasingly miniaturized electronic devices and manufacturing facility requirements for reliable electrostatic discharge protection solutions. As semiconductor device complexity increases and consumer electronics production scales, the semiconductors and consumer electronics application will continue to dominate the market while supporting advanced static control utilization and manufacturing quality optimization strategies.

The high voltage ionising air gun market is advancing steadily due to increasing demand for static elimination equipment driven by electronics device sensitivity and growing adoption of contamination control practices that require specialized ionisation tools providing enhanced electrostatic discharge protection and cleaning efficiency benefits across diverse semiconductor fabrication, pharmaceutical cleanroom, consumer electronics assembly, and precision manufacturing applications. The market faces challenges, including high equipment costs and capital investment requirements, competition from alternative static control methods and automated ionisation systems, and operational constraints related to compressed air consumption and maintenance frequency. Innovation in ionisation technologies and smart monitoring capabilities continues to influence product development and market expansion patterns.

The growing production of advanced semiconductor devices is driving demand for precision static control equipment that addresses electrostatic discharge protection requirements including wafer handling safety, die attach protection, and wire bonding reliability. Modern semiconductor facilities require sophisticated ionising air gun solutions that deliver superior static neutralization across multiple process steps while maintaining cleanroom compatibility and operational efficiency. Electronics equipment suppliers are increasingly recognizing the competitive advantages of ionising air gun integration for yield enhancement and quality assurance, creating opportunities for innovative static control systems specifically developed for next-generation semiconductor manufacturing applications.

Modern ionising air gun manufacturers are incorporating digital monitoring systems and performance verification capabilities to enhance operational assurance, support preventive maintenance, and address comprehensive quality management objectives through real-time ion balance monitoring and elimination speed tracking. Leading equipment manufacturers are developing sensor-equipped air guns with continuous performance verification, implementing data logging systems, and advancing feedback control technologies that improve static elimination effectiveness and operational optimization. These technologies improve operational assurance while enabling new quality benefits, including predictive maintenance scheduling, performance trend analysis, and automated compliance documentation. Advanced monitoring integration also allows operators to support comprehensive quality objectives and manufacturing excellence beyond traditional manual performance checking methods.

The expansion of operator comfort requirements, extended use applications, and workplace safety considerations is driving development of ergonomic ionising air guns with precisely engineered designs and exceptional weight reduction. These advanced systems require specialized engineering with optimized grip configurations that address operator fatigue prevention, creating premium market segments with differentiated value propositions. Manufacturers are investing in advanced materials and ergonomic research to serve emerging long-duration applications while supporting innovation in electronics manufacturing and cleanroom operation industries.

What Are the Key Metrics Impacting the High Voltage Ionising Air Gun Market?

| Metric | Insight |

|---|---|

| Increase in Static Control Requirements | Rising demand for static control in industries such as electronics manufacturing, automotive, and packaging drives adoption of ionising air guns. |

| High Initial Investment | High voltage ionising air guns have a higher upfront cost compared to conventional alternatives, limiting their widespread adoption in price-sensitive markets. |

| Strict Industry Standards | Regulatory requirements for cleanliness and safety in production environments, particularly in the semiconductor and medical device industries, are driving the demand for ionising air guns. |

| Rising Automation in Manufacturing | As manufacturing processes become more automated, the need for precise static charge control using high voltage ionising air guns increases. |

| Increased Electronics and Packaging Production | The growth of consumer electronics and packaging industries, which require static-free environments, boosts demand for high voltage ionising air guns. |

| Maintenance and Operation Costs | The operational and maintenance costs of high voltage ionising air guns can deter some industries from continuous use despite their advantages. |

| Health and Safety Concerns | High voltage systems pose safety risks such as electrical shocks, which may limit adoption without proper safety measures and maintenance protocols. |

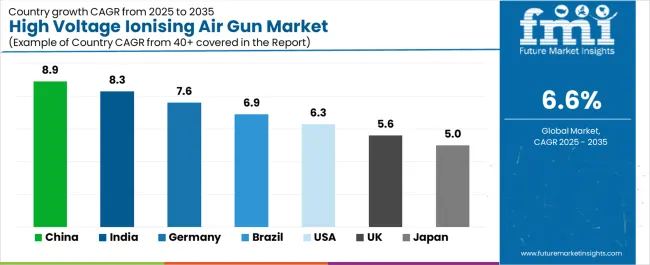

| Country | CAGR (2025-2035) |

|---|---|

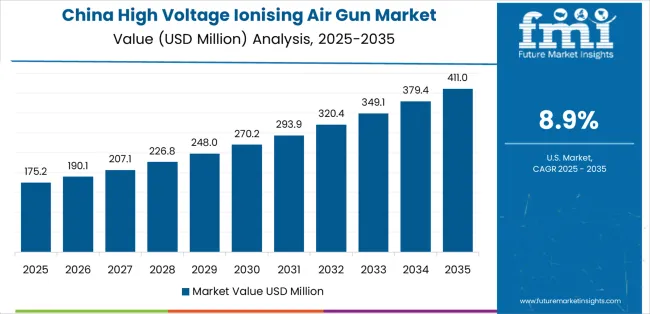

| China | 8.9% |

| India | 8.3% |

| Germany | 7.6% |

| Brazil | 6.9% |

| United States | 6.3% |

| United Kingdom | 5.6% |

| Japan | 5.0% |

The high voltage ionising air gun market is experiencing solid growth globally, with China leading at an 8.9% CAGR through 2035, driven by expanding electronics manufacturing capacity, growing semiconductor fabrication facilities, and increasing adoption of static control equipment in production environments. India follows at 8.3%, supported by electronics manufacturing growth, semiconductor assembly expansion, and rising quality standards adoption. Germany shows growth at 7.6%, emphasizing precision manufacturing excellence, automotive electronics production, and advanced static control technology requirements. Brazil demonstrates 6.9% growth, supported by consumer electronics manufacturing, automotive component production, and industrial automation expansion. The United States records 6.3%, focusing on semiconductor manufacturing leadership, pharmaceutical cleanroom operations, and precision instrument production. The United Kingdom exhibits 5.6% growth, emphasizing electronics assembly and pharmaceutical manufacturing quality. Japan shows 5.0% growth, supported by electronics technology leadership and manufacturing quality control sophistication.

The report covers an in-depth analysis of 20 countries, with top-performing countries highlighted below.

Revenue from high voltage ionising air guns in China is projected to exhibit exceptional growth with a CAGR of 8.9% through 2035, driven by expanding electronics manufacturing capacity and rapidly growing semiconductor fabrication facilities supported by government industrial development initiatives and technology self-sufficiency policies. The country's massive electronics production sector and increasing investment in advanced manufacturing technologies are creating substantial demand for ionising air gun solutions. Major electronics equipment manufacturers and static control suppliers are establishing comprehensive production capabilities to serve both domestic markets and export opportunities.

Demand for high voltage ionising air guns in India is expanding at a CAGR of 8.3%, supported by the country's electronics manufacturing growth, semiconductor assembly expansion, and increasing demand for quality control equipment driven by Make in India initiatives and electronics production requirements. The country's comprehensive industrial development and growing manufacturing sophistication are driving ionising air gun adoption throughout diverse production sectors. Leading industrial equipment distributors and international manufacturers are establishing distribution and technical service facilities to address growing domestic demand.

Revenue from high voltage ionising air guns in Germany is growing at a CAGR of 7.6%, supported by the country's precision manufacturing excellence, automotive electronics production leadership, and strong emphasis on quality control and static elimination technologies. The nation's manufacturing sophistication and quality standards are driving ionising air gun capabilities throughout industrial sectors. Leading equipment manufacturers and automation specialists are investing extensively in advanced static control technologies and specialized applications.

Revenue from high voltage ionising air guns in Brazil is expanding at a CAGR of 6.9%, supported by the country's consumer electronics manufacturing, automotive component production, and growing adoption of industrial automation technologies. The nation's comprehensive industrial development and manufacturing modernization are driving demand for effective ionising air gun solutions. Industrial equipment distributors and manufacturing service providers are investing in capabilities to serve expanding electronics and automotive sectors.

Revenue from high voltage ionising air guns in the United States is expanding at a CAGR of 6.3%, supported by the country's semiconductor manufacturing leadership, established pharmaceutical cleanroom operations, and growing emphasis on domestic electronics production and supply chain resilience. The nation's comprehensive technology infrastructure and manufacturing excellence are driving demand for advanced ionising air gun solutions. Equipment manufacturers and industrial supply companies are investing in technology development and distribution capabilities to serve diverse manufacturing markets.

Revenue from high voltage ionising air guns in the United Kingdom is expanding at a CAGR of 5.6%, driven by the country's electronics assembly operations, pharmaceutical manufacturing excellence, and growing emphasis on quality control and contamination prevention. The nation's manufacturing sector structure and quality frameworks are supporting investment in effective static control technologies. Industrial equipment suppliers and cleanroom service providers are establishing capabilities for equipment supply and technical support programs.

Revenue from high voltage ionising air guns in Japan is expanding at a CAGR of 5.0%, supported by the country's electronics technology leadership, manufacturing quality control sophistication, and strong emphasis on precision production and defect prevention. Japan's technological excellence and quality standards are driving demand for advanced ionising air gun systems. Equipment manufacturers and industrial automation companies are investing in next-generation static control technologies.

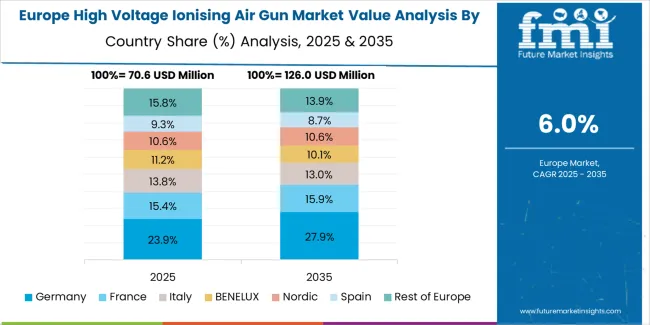

How is the Europe High Voltage Ionising Air Gun Split by Country?

The high voltage ionising air gun market in Europe is projected to grow from USD 104.9 million in 2025 to USD 180.3 million by 2035, registering a CAGR of 5.5% over the forecast period. Germany is expected to maintain leadership with a 28.6% market share in 2025, moderating to 28.3% by 2035, supported by precision manufacturing strength, automotive electronics production, and industrial automation excellence.

France follows with 18.4% in 2025, projected at 18.6% by 2035, driven by electronics manufacturing, pharmaceutical industry, and aerospace component production. The United Kingdom holds 15.7% in 2025, rising to 15.9% by 2035 on the back of electronics assembly operations and pharmaceutical manufacturing requirements. Italy commands 12.9% in 2025, increasing to 13.1% by 2035, while Spain accounts for 9.8% in 2025, reaching 10.0% by 2035 aided by automotive component manufacturing and electronics assembly. Netherlands maintains 6.8% in 2025, up to 7.0% by 2035 due to semiconductor equipment presence and precision manufacturing. The Rest of Europe region, including Switzerland, Nordic countries, Belgium, and other markets, is anticipated to hold 7.8% in 2025 and 7.1% by 2035, reflecting steady development in precision manufacturing, pharmaceutical production, and electronics assembly applications.

The high voltage ionising air gun market is characterized by competition among established industrial automation companies, specialized static control equipment manufacturers, and cleanroom technology suppliers. Companies are investing in ionisation technology development, ergonomic design enhancement, product range expansion, and application-specific optimization to deliver high-performance, reliable, and user-friendly ionising air gun solutions. Innovation in ion generation methods, feedback control systems, and safety features is central to strengthening market position and competitive advantage.

Panasonic leads the market with 18% share with comprehensive industrial automation solutions with a focus on electronics manufacturing applications, quality reliability, and global service capabilities across diverse production and cleanroom environments. Keyence provides precision measurement and automation equipment with emphasis on performance verification and user-friendly operation. SMC delivers pneumatic and automation solutions with comprehensive static control offerings for industrial applications. Simco-ION (ITW Group) specializes in static control technologies with emphasis on ionisation expertise and contamination control. EIKO Group offers cleanroom and static control equipment with focus on Asian market service. TAKK Industries provides static elimination solutions with comprehensive product portfolio. SCS specializes in electrostatic discharge protection and static control technologies. Meech delivers static control and web cleaning systems. AP&T focuses on industrial ionisation equipment. QUICK Intelligent Equipment provides smart manufacturing solutions. Shenzhen Senpum offers static control devices for electronics manufacturing. Shenzhen HORB Technology specializes in ionisation and contamination control equipment.

High voltage ionising air guns represent a specialized static control equipment segment within electronics manufacturing and cleanroom applications, projected to grow from USD 308.7 million in 2025 to USD 584.9 million by 2035 at a 6.6% CAGR. These ionisation devices primarily serve electrostatic discharge protection and contamination removal requirements in semiconductor fabrication facilities, pharmaceutical cleanrooms, consumer electronics assembly operations, and precision manufacturing environments where static elimination, surface cleaning, and product quality protection are essential. Market expansion is driven by increasing electronics manufacturing sophistication, growing semiconductor production capacity, expanding pharmaceutical cleanroom operations, and rising demand for effective static control solutions across diverse technology manufacturing sectors.

How Industrial Standards Organizations Could Strengthen Static Control and Safety Requirements?

How Industry Associations Could Advance Application Standards and Technical Knowledge?

How Ionising Air Gun Manufacturers Could Drive Innovation and Market Leadership?

How Manufacturing Facilities Could Optimize Static Control and Product Quality?

How Electronics and Pharmaceutical Companies Could Enhance Quality Assurance?

How Research Institutions Could Enable Technology Advancement?

How Investors and Financial Enablers Could Support Market Growth and Innovation?

| Items | Values |

|---|---|

| Quantitative Units (2025) | USD 308.7 million |

| Applied Voltage Range | Applied Voltage 5-6KV, Applied Voltage 6-7KV, Applied Voltage Above 7KV, Others |

| Application | Semiconductors and Consumer Electronics, Biopharmaceuticals and Medical, Others |

| Regions Covered | East Asia, Europe, North America, South Asia, Latin America, Middle East & Africa, Eastern Europe |

| Countries Covered | China, India, Germany, Brazil, United States, United Kingdom, Japan, and 20 countries |

| Key Companies Profiled | Panasonic, Keyence, SMC, Simco-ION (ITW Group), EIKO Group, TAKK Industries |

| Additional Attributes | Dollar sales by applied voltage range and application category, regional demand trends, competitive landscape, technological advancements in ionisation technology, smart monitoring integration, ergonomic design development, and static elimination performance optimization |

The global high voltage ionising air gun market is estimated to be valued at USD 308.7 million in 2025.

The market size for the high voltage ionising air gun market is projected to reach USD 584.9 million by 2035.

The high voltage ionising air gun market is expected to grow at a 6.6% CAGR between 2025 and 2035.

The key product types in high voltage ionising air gun market are applied voltage 5-6kv , applied voltage 6-7kv, applied voltage above 7kv and others.

In terms of application, semiconductors and consumer electronics segment to command 50.0% share in the high voltage ionising air gun market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

High Clear Film Market Size and Share Forecast Outlook 2025 to 2035

High Performance Random Packing Market Forecast Outlook 2025 to 2035

High Precision Microfluidic Pump Market Size and Share Forecast Outlook 2025 to 2035

High Performance Composites Market Forecast Outlook 2025 to 2035

High Performance Medical Plastic Market Forecast Outlook 2025 to 2035

High Temperature Heat Pump Dryers Market Size and Share Forecast Outlook 2025 to 2035

High Temperature Fiberglass Filter Media Market Size and Share Forecast Outlook 2025 to 2035

High Purity Tungsten Hexachloride Market Size and Share Forecast Outlook 2025 to 2035

High Purity Nano Aluminum Oxide Powder Market Size and Share Forecast Outlook 2025 to 2035

High Mast Lighting Market Forecast and Outlook 2025 to 2035

High-Protein Pudding Market Forecast and Outlook 2025 to 2035

High-Power Microwave Source Market Size and Share Forecast Outlook 2025 to 2035

High Performance Epoxy Coating Market Size and Share Forecast Outlook 2025 to 2035

High Molecular Ammonium Polyphosphate Market Size and Share Forecast Outlook 2025 to 2035

High Performance Fluoropolymer Market Size and Share Forecast Outlook 2025 to 2035

High Throughput Screening Market Size and Share Forecast Outlook 2025 to 2035

High Barrier Packaging Films for Pharmaceuticals Market Size and Share Forecast Outlook 2025 to 2035

High Barrier Packaging Films Market Size and Share Forecast Outlook 2025 to 2035

High Purity Carbonyl Iron Powder (CIP) Market Size and Share Forecast Outlook 2025 to 2035

High-Performance Fiber Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA