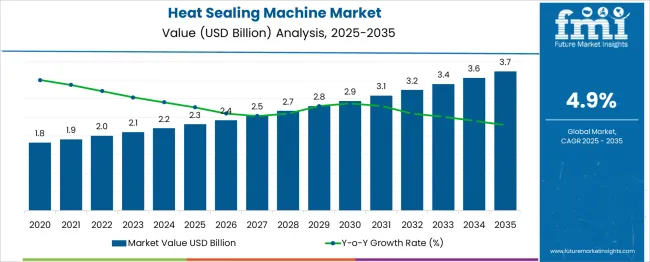

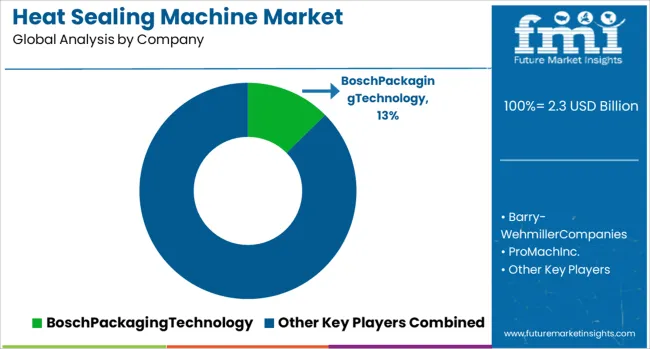

The Heat Sealing Machine Market is estimated to be valued at USD 2.3 billion in 2025 and is projected to reach USD 3.7 billion by 2035, registering a compound annual growth rate (CAGR) of 4.9% over the forecast period. A market growth curve shape analysis reveals a steady, consistent upward trajectory throughout the forecast period. Between 2025 and 2030, the market grows from USD 2.3 billion to USD 2.9 billion, contributing USD 0.6 billion in growth, with a CAGR of 4.9%. This early-stage growth is driven by increasing demand across industries such as packaging, food and beverages, and pharmaceuticals, where efficient sealing processes are critical for maintaining product quality and extending shelf life.

As automation and production speed become more important, heat sealing machines are increasingly adopted to improve manufacturing efficiency and packaging reliability. From 2030 to 2035, the market continues to grow at a more stable rate, expanding from USD 2.9 billion to USD 3.7 billion, contributing USD 0.8 billion in growth, with a slightly lower CAGR of 4.6%. This phase indicates a deceleration in growth as the market matures, but the continued adoption of advanced sealing technologies, such as those focused on sustainability and energy efficiency, supports steady growth. The overall growth curve indicates a gradual increase in demand, with early-stage acceleration followed by stable expansion as the market matures.

| Metric | Value |

|---|---|

| Heat Sealing Machine Market Estimated Value in (2025 E) | USD 2.3 billion |

| Heat Sealing Machine Market Forecast Value in (2035 F) | USD 3.7 billion |

| Forecast CAGR (2025 to 2035) | 4.9% |

The heat sealing machine market is gaining considerable traction due to the growing need for reliable and efficient packaging solutions across food, pharmaceutical, and consumer goods industries. The transition toward sustainable and hermetically sealed flexible packaging has necessitated the integration of advanced sealing technologies capable of maintaining product integrity and safety.

Increased focus on automation, quality assurance, and energy efficiency in production lines has elevated the demand for heat sealing machines that deliver consistent performance at scale. Government regulations regarding hygiene, tamper-proof packaging, and reduced material waste are also supporting the deployment of precision-driven sealing systems.

As e-commerce and fast-moving consumer goods sectors expand, the necessity for high-speed sealing equipment with minimum downtime and adaptive sealing profiles has become increasingly apparent. The market outlook remains optimistic, driven by growing investments in smart manufacturing infrastructure and innovations in sealing materials, as manufacturers seek to enhance throughput without compromising on packaging quality and sustainability.

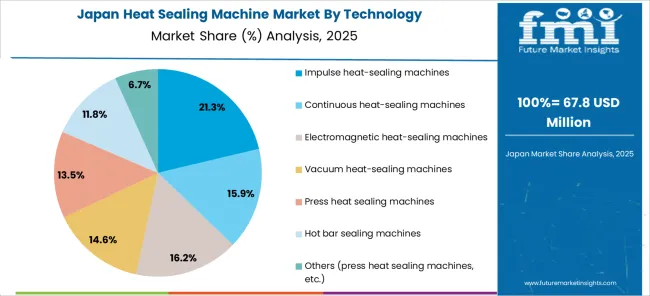

The heat sealing machine market is segmented by technology, installation, speed, end use, and geographic regions. By technology, the heat sealing machine market is divided into Impulse heat-sealing machines, Continuous heat-sealing machines, Electromagnetic heat-sealing machines, Vacuum heat-sealing machines, Press heat-sealing machines, Hot bar sealing machines, and others (press heat-sealing machines, etc.). In terms of installation, the heat sealing machine market is classified into fixed and portable. Based on speed, the heat sealing machine market is segmented into between 200-500 Seals per minute, More than 500 seals per minute, and less than 200 seals per minute. By end use, the heat sealing machine market is segmented into Industrial, Residential, and Commercial. Regionally, the heat sealing machine industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

Impulse heat-sealing machines are expected to account for 21.4% of the total revenue share in the heat sealing machine market by 2025, indicating their growing preference in energy-sensitive and thermally controlled sealing applications. The segment's growth has been driven by the intermittent heating functionality of impulse systems, which ensures energy is used only during active sealing cycles, thus reducing operational costs and improving safety.

These machines have been widely implemented in environments where controlled heat distribution and minimal thermal distortion are critical, particularly in packaging materials that are heat-sensitive or require consistent seal integrity. The ability to deliver high precision seals with uniform temperature distribution has enabled their use in sectors requiring cleanroom compliance and low material wastage.

With growing emphasis on machine uptime and energy conservation, impulse sealing machines are increasingly being integrated into automated production lines that demand reliability and repeatability. Enhanced compatibility with programmable controllers and diagnostic features has also contributed to the strong uptake of this technology across industrial packaging setups.

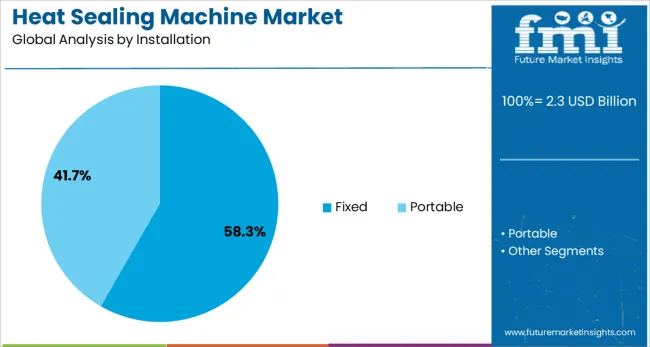

The fixed installation segment is projected to account for 58.3% of the total heat sealing machine market revenue in 2025, reflecting its dominant role in high-volume and continuous production environments. The segment’s prominence is supported by its robust construction, stability during operations, and capability to deliver consistent sealing performance over prolonged periods.

Fixed machines are typically deployed in manufacturing plants and industrial settings where line integration, throughput consistency, and maintenance efficiency are prioritized. Their design facilitates permanent alignment with conveyors, fillers, and labeling units, making them essential in fully automated packaging processes.

The adoption of fixed installation systems has been further strengthened by the demand for centralized control systems, predictive maintenance capabilities, and modular upgrades, which improve overall operational efficiency. The segment’s growth is also influenced by the increasing focus on lean manufacturing and quality assurance, where fixed machines help reduce variability and ensure compliance with industry-specific packaging standards.

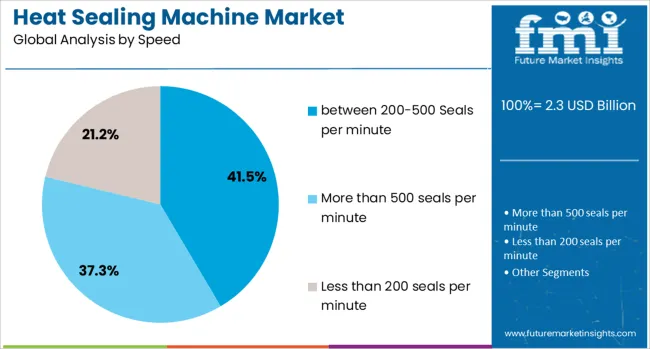

Machines operating at speeds between 200 and 500 seals per minute are anticipated to capture 41.5% of the revenue share in the heat sealing machine market in 2025, making this the leading speed category. This performance range has gained traction due to its suitability for medium to high-speed production environments that demand a balance between output and precision.

The segment’s growth has been supported by the need for efficient throughput without compromising on seal quality, particularly in sectors such as food packaging, pharmaceuticals, and personal care products. The ability of these machines to maintain seal consistency at high speeds while minimizing downtime has enhanced their adoption in fully automated lines.

Advanced servo control systems, improved sealing bar technology, and reduced thermal cycle times have further enabled this speed category to become a cost-effective choice for manufacturers. With the rise of customized packaging formats and fluctuating batch sizes, sealing machines in this speed range offer the flexibility and productivity needed to meet evolving market demands.

The heat sealing machine market is expanding as demand increases across various industries for reliable, efficient, and cost-effective sealing solutions. These machines are crucial in packaging, particularly in food and beverage, pharmaceuticals, and consumer goods, where maintaining product freshness and security is vital. The versatility of heat sealing machines in packaging various materials, including plastic, foil, and paper, is contributing to their widespread adoption. With technological advancements improving sealing speed and accuracy, the market is set to grow, despite challenges related to initial costs and machinery maintenance.

The growth of the heat sealing machine market is primarily driven by the increasing demand for packaging solutions across multiple industries. In sectors like food and beverage, pharmaceuticals, and consumer goods, packaging plays a critical role in preserving product quality, extending shelf life, and ensuring product safety. Heat sealing machines are essential in providing an airtight and tamper-evident seal that helps maintain product integrity. As the global packaging industry expands with the rise in consumer goods demand and e-commerce, there is a strong need for efficient, high-quality packaging systems, further driving the adoption of heat sealing machines. Moreover, growing awareness of the need for packaging sustainability is pushing manufacturers to create packaging that is not only functional but also eco-friendly.

One of the key challenges in the heat sealing machine market is the high initial investment required for purchasing and installing the machinery. The cost of advanced machines with enhanced features such as automatic feeding systems, customizable sealing temperature control, and integration with production lines can be significant. For small and medium-sized enterprises, the high upfront costs can limit their ability to adopt these machines. The ongoing maintenance and repair costs can pose challenges, particularly with complex machinery that requires specialized technicians and spare parts. Downtime caused by malfunctions or maintenance issues can affect production schedules and increase operational costs, making the management of these machines a critical concern for manufacturers.

The heat sealing machine market offers substantial opportunities driven by technological advancements and the growing demand for eco-friendly packaging solutions. Innovations such as ultrasonic sealing and digital control systems are improving the efficiency, precision, and speed of heat sealing machines, making them more attractive to industries focused on high-throughput production. Additionally, the shift toward biodegradable and recyclable materials in packaging is opening new avenues for heat sealing machines, as manufacturers seek machines capable of sealing more sustainable materials. Furthermore, the increasing demand for customized and high-quality packaging in food, pharmaceuticals, and personal care products offers opportunities for the development of versatile sealing solutions that can meet the specific requirements of these industries.

A significant trend in the heat sealing machine market is the growing adoption of automation and smart packaging solutions. Manufacturers are increasingly integrating automated features into heat sealing machines to improve production efficiency, reduce labor costs, and minimize human error. Automated systems allow for faster setup times, better quality control, and seamless integration with production lines. The rise of smart packaging, where packaging materials are embedded with sensors for real-time monitoring of product conditions, is driving demand for advanced heat sealing machines. These machines are being designed to work with intelligent packaging materials, ensuring better traceability and improved consumer safety. The trend towards automation and smart packaging is transforming the industry, driving further growth in the heat sealing machine market.

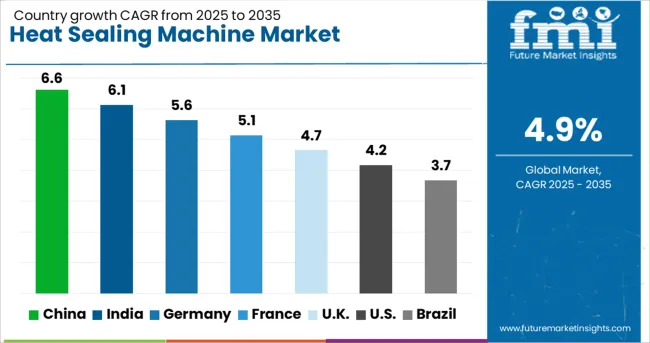

| Country | CAGR |

|---|---|

| China | 6.6% |

| India | 6.1% |

| Germany | 5.6% |

| France | 5.1% |

| UK | 4.7% |

| USA | 4.2% |

| Brazil | 3.7% |

The global heat sealing machine market is anticipated to grow at a CAGR of 4.9%, with substantial contributions from both OECD countries and BRICS nations. China leads the market with a growth rate of 6.6% through 2035, followed by India at 6.1% during the same period. France records a growth rate of 5.1%, while the UK and USA show growth rates of 4.7% and 4.2%, respectively. The increasing demand for energy-efficient solutions in packaging, driven by awareness of hygiene and waste reduction, is fueling growth in both emerging and developed markets. The analysis includes over 40 countries, with the leading markets shown below.

China is set to lead the global heat sealing machine market with a growth rate of 6.6% through 2035. The country’s rapid industrial growth, particularly in the packaging, food, and electronics sectors, significantly contributes to this expansion. The increasing need for automation in packaging processes, driven by cost reduction and efficiency, supports the adoption of advanced heat sealing machines. Strong focus on manufacturing innovation and the expansion of consumer goods production further accelerate the demand. Government policies supporting industrial growth and modernization also play a vital role in fostering the demand for high-performance heat sealing machines.

The heat sealing machine market in India is expected to grow at a CAGR of 6.1% through 2035. With the rapid industrialization of sectors such as packaging, food processing, and pharmaceuticals, demand for efficient sealing solutions is on the rise. The government’s push for infrastructure development and modernization of production lines in both small and large-scale industries further supports the demand. Additionally, as India’s manufacturing industry expands, the need for high-quality, durable, and cost-effective packaging solutions becomes more critical, driving the adoption of heat sealing machines.

France is expected to see a growth rate of 5.1% through 2035 in the heat sealing machine market. The country’s strong industrial base, particularly in food processing, packaging, and pharmaceuticals, contributes to the steady demand for advanced sealing solutions. As consumer preferences evolve and packaging requirements become more complex, French companies are increasingly adopting high-performance heat sealing machines. France’s focus on innovation, coupled with regulatory requirements for packaging efficiency, is also driving the demand for machines that offer greater efficiency and reduced environmental impact.

The UK is expected to grow at a CAGR of 4.7% through 2035 in the heat sealing machine market. The demand in the UK is primarily driven by the food and beverage packaging sector, where advanced packaging solutions are required to ensure product safety, extend shelf life, and comply with stringent regulations. With a rising focus on automation and labor cost reduction in manufacturing, companies are increasingly adopting high-quality heat sealing machines. The growing preference for efficient packaging solutions also drives the demand for machines that meet sustainability goals while maintaining efficiency.

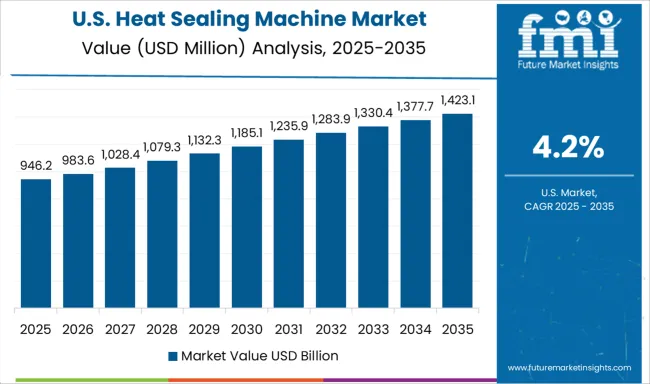

The USA is expected to see a growth rate of 4.2% through 2035 in the heat sealing machine market. The steady growth is fueled by advancements in packaging technologies across industries like food, medical, and consumer goods. With increasing demand for high-quality packaging solutions that ensure safety and compliance with regulations, USA manufacturers are adopting advanced heat sealing machines. The market is further supported by the rise in consumer preference for eco-conscious packaging, pushing companies to invest in more sustainable and energy-efficient sealing technologies.

Bosch Packaging Technology leads through high-performance, energy-efficient sealing machines with modular designs that support diverse packaging formats and automation levels. Barry-Wehmiller Companies and ProMach Inc. distinguish themselves by integrating cost-effective automation with operational flexibility, enabling manufacturers to optimize production throughput while reducing downtime. Krones AG is recognized for integrated packaging solutions, combining precise sealing performance with broader packaging system offerings, while Illinois Tool Works Inc. and GEA Group focus on industrial-scale reliability, compliance with regulatory standards, and long-term operational efficiency.

Control system specialists Omron Corporation and Audion Elektro provide high-precision automation, enhancing performance monitoring and predictive maintenance. Sonoco Products Company and PAC Machinery Group offer durable, flexible solutions for industrial and medical applications, emphasizing sealing consistency under high-volume production. Hayssen Flexible Systems and Tokyo Automatic Machinery Works Ltd. focus on automated, high-speed operations, whereas Starview Packaging Machinery and Wenzhou Ruizhi Packaging Machinery address custom packaging requirements for small and mid-sized enterprises. Packrite targets SMEs with user-friendly, affordable machines, emphasizing quick installation and simplified operation.

Historically, companies invested in automation, energy efficiency, and integrated production systems. Forecast strategies indicate a shift toward intelligent sealing solutions with IoT-enabled monitoring, predictive maintenance, hybrid packaging formats, and environmentally friendly sealing technologies. Differentiation levers include sealing speed, temperature control precision, machine modularity, energy consumption, and compatibility with diverse packaging materials. Growth opportunities exist in the food, pharmaceutical, and e-commerce packaging sectors of emerging economies, as well as in retrofitting existing production lines and providing aftermarket services for predictive maintenance, process optimization, and product lifecycle management.

| Item | Value |

|---|---|

| Quantitative Units | USD 2.3 Billion |

| Technology | Impulse heat-sealing machines, Continuous heat-sealing machines, Electromagnetic heat-sealing machines, Vacuum heat-sealing machines, Press heat sealing machines, Hot bar sealing machines, and Others (press heat sealing machines, etc.) |

| Installation | Fixed and Portable |

| Speed | between 200-500 Seals per minute, More than 500 seals per minute, and Less than 200 seals per minute |

| End Use | Industrial, Residential, and Commercial |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled | BoschPackagingTechnology, Barry-WehmillerCompanies, ProMachInc., KronesAG, IllinoisToolWorksInc., GEAGroup, OmronCorporation, AudionElektro, SonocoProductsCompany, PACMachineryGroup, HayssenFlexibleSystems, TokyoAutomaticMachineryWorksLtd., StarviewPackagingMachinery, WenzhouRuizhiPackagingMachinery, and Packrite |

| Additional Attributes | Dollar sales by machine type (vertical form-fill-seal machines, horizontal form-fill-seal machines, rotary sealing machines) and end-use segments (food and beverage, pharmaceuticals, consumer goods, industrial applications). Demand dynamics are driven by the increasing adoption of automated packaging solutions, the growing demand for sustainable packaging, and the need for high-quality sealing in industries such as food and pharmaceuticals. Regional trends show strong growth in North America and Europe due to the adoption of advanced packaging technologies, while Asia-Pacific is expanding due to increasing industrialization and the rising demand for packaged goods. |

The global heat sealing machine market is estimated to be valued at USD 2.3 billion in 2025.

The market size for the heat sealing machine market is projected to reach USD 3.7 billion by 2035.

The heat sealing machine market is expected to grow at a 4.9% CAGR between 2025 and 2035.

The key product types in heat sealing machine market are impulse heat-sealing machines, continuous heat-sealing machines, electromagnetic heat-sealing machines, vacuum heat-sealing machines, press heat sealing machines, hot bar sealing machines and others (press heat sealing machines, etc.).

In terms of installation, fixed segment to command 58.3% share in the heat sealing machine market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Second Lid Heat Sealing Machine Market Size and Share Forecast Outlook 2025 to 2035

Heat Sealing Equipment Market Size and Share Forecast Outlook 2025 to 2035

Heat Sealing Tape Market Size and Share Forecast Outlook 2025 to 2035

Heat Sealing Tester Market

Heat Sealing Bags Market

Wheat Milling Machine Market Size and Share Forecast Outlook 2025 to 2035

Box Sealing Machines Market Trends – Growth & Forecast 2025 to 2035

Tray Sealing Machines Market Size and Share Forecast Outlook 2025 to 2035

Tube Sealing Machines Market Analysis by Tube type, Technology type, End User, and Region through 2025 to 2035

Competitive Breakdown of Tube Sealing Machines Providers

Heat Shrink Fitting Machines Market Size and Share Forecast Outlook 2025 to 2035

Pouch Sealing Machine Market

Vacuum Sealing Machine Market Size and Share Forecast Outlook 2025 to 2035

Market Share Distribution Among Vacuum Sealing Machine Providers

Hybrid Sealing-Cut Machines Market Analysis - Size and Share Forecast Outlook 2025 to 2035

Portable Sealing Machine Market Size and Share Forecast Outlook 2025 to 2035

Envelope Sealing Machines Market Trends - Growth & Forecast 2025 to 2035

Induction Sealing Machines Market Size and Share Forecast Outlook 2025 to 2035

Meal Tray Sealing Machines Market Size and Share Forecast Outlook 2025 to 2035

Packaging Machine Heaters Market Growth – Trends & Forecast 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA