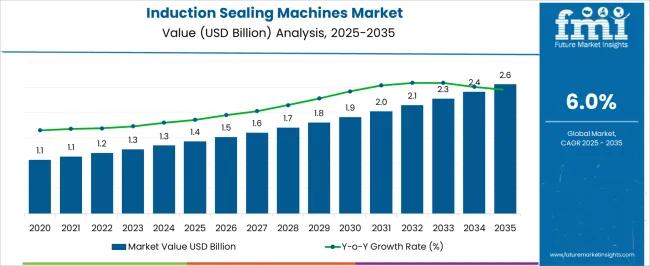

The Induction Sealing Machines Market is estimated to be valued at USD 1.4 billion in 2025 and is projected to reach USD 2.6 billion by 2035, registering a compound annual growth rate (CAGR) of 6.0% over the forecast period.

| Metric | Value |

|---|---|

| Induction Sealing Machines Market Estimated Value in (2025 E) | USD 1.4 billion |

| Induction Sealing Machines Market Forecast Value in (2035 F) | USD 2.6 billion |

| Forecast CAGR (2025 to 2035) | 6.0% |

The induction sealing machines market is gaining strong traction globally as industries prioritize packaging integrity, contamination prevention, and automation-driven productivity. The shift toward contactless sealing solutions that enable leak-proof, secure closures has been instrumental in improving the operational efficiency of packaging lines. Key drivers include rising regulatory emphasis on food safety, pharmaceutical integrity, and consumer protection, particularly in emerging markets where industrial automation is accelerating.

Induction sealing technology has become increasingly favored for its ability to provide hermetic seals without direct contact, reducing risks of contamination and preserving product quality over extended periods. Technological innovations such as capless induction sealing, energy-efficient systems, and modular machine designs are further expanding its relevance across diverse sectors.

Additionally, the need to reduce waste, enhance sustainability, and comply with industry-specific labeling and safety requirements has led to broader adoption of induction sealing solutions As end-users focus on flexible, high-throughput machinery that supports digital control and seamless integration with automated lines, the market is expected to witness steady growth in the years ahead.

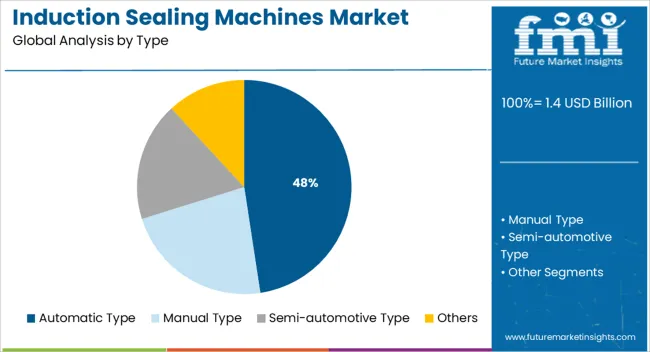

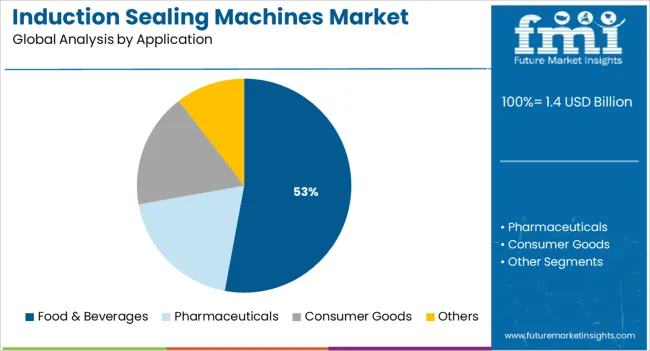

The market is segmented by Type and Application and region. By Type, the market is divided into Automatic Type, Manual Type, Semi-automotive Type, and Others. In terms of Application, the market is classified into Food & Beverages, Pharmaceuticals, Consumer Goods, and Others. Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

Automatic type induction sealing machines are projected to contribute 47.6% of the overall revenue share in the induction sealing machines market by 2025. This segment’s dominance is being supported by the rising need for high-speed sealing operations in large-scale manufacturing environments. Automatic systems have gained preference due to their ability to minimize manual intervention while ensuring consistent seal quality and operational efficiency.

The demand has been further reinforced by the integration of programmable logic controllers, digital monitoring interfaces, and IoT-enabled performance analytics, which have enabled manufacturers to streamline production workflows and reduce downtime. Industries with high output demands, such as pharmaceuticals, food processing, and chemicals, have increasingly adopted automatic systems to maintain quality assurance under stringent regulatory environments.

The capability of these machines to handle varying cap sizes, container types, and line speeds without compromising sealing performance has strengthened their utility across continuous operations The need for scalable packaging solutions with minimal human error has positioned automatic type machines as a critical component in modern packaging infrastructures.

The food and beverages segment is expected to account for 52.9% of the revenue share in the induction sealing machines market in 2025, making it the largest application segment. This growth is being driven by the increasing focus on shelf-life extension, product safety, and contamination prevention in the packaged food and beverage sector. Induction sealing has become essential for ensuring tamper-evidence, leak prevention, and airtight packaging in consumables, especially under growing consumer awareness about hygiene and safety.

The technology’s ability to seal diverse container materials such as glass, PET, and HDPE with varying lid types has facilitated its broad adoption across sauces, dairy products, juices, and nutritional supplements. Automation trends in food processing plants and the growing demand for high-speed, error-free sealing solutions have further supported the segment’s expansion.

Moreover, compliance with food safety regulations and the pressure to maintain freshness in long-haul supply chains have prompted manufacturers to adopt induction sealing as a critical control point This has reinforced its role in ensuring brand protection and consumer trust.

Packaging industry is technology driven. In today’s highly competitive and dynamic marketplace, to achieve the highest revenue, growth packaging manufacturers are embracing the technology, especially filling, forming, sealing, labelling and inspection solutions.

Induction sealing, which is widely known as heat sealing uses electromagnetic induction principle. The sealant under cap foil liner automatically gets heated and attached to neck of the bottle.

These machines are extensively used in personal care & cosmetics, food & beverages, homecare, pharmaceuticals industries. Growing demand for bottle sealing from pharmaceuticals, personal care & cosmetics and food & beverages sectors to drive the global demand for induction sealing machines market. Induction sealing machines market is highly dominated by small scale manufacturers, whose annual revenues falls within USD 20 to 25 Million.

Europe & North America has large number of manufacturers. The trend of shifting manufacturing from Europe & North America to Asia Pacific (APAC) region, especially to India, Bangladesh, Thailand, Malaysia and China is expected to influence the dynamics of the global induction sealing machines market.

Due to their counterfeit protection, tamper evidence and leak-proof features, induction sealing machines are creating their space in majority of packaging and converting companies. Overall the global induction sealing machine market is expected to grow at a healthy CAGR, during forecast period.

Induction sealing machines helps in counterfeit protective packaging for pharmaceuticals, cosmetics and food & beverages. A statistics show that annually approx. one million people die from consumption of counterfeit medicines. Counterfeit protection is also a major problem in cosmetics where counterfeiting can cause loss of brand equity.

Induction sealing is very eco-friendly, because it requires less energy and uses less foil & sealant material compared to conductive sealers. Induction liners in cap sealing acts as hermetic seals, which will not allow oxygen, dust, moisture and other foreign material into the bottles. So, the product shelf-life can be extended up to 10 to 12 weeks.

Induction sealers get heated as soon as power on, no wastage of time in heating & cooling. The high speed sealing and less changeover times, no touching or handling will increase packaging productivity. Induction sealing also helps in leak prevention, because they use air tight sealing, which can withstand high pressures.

These aforementioned features make induction sealing machines, top choice of packaging manufacturers and converters. Rising intolerance towards plastic is expected to hamper the growth of induction sealing machines market. Overall the market is expected to grow at a healthy CAGR over forecast period.

The global induction sealing machines market is segmented on the basis of technology, throughput and end-use. On the basis of technology, the global induction sealing machines market is segmented into manual, semiautomatic and automatic.

On the basis of end use, the global induction sealing machines market is segmented into pharmaceuticals, food & beverages, cosmetics & personal care, home care & toiletries, sealants & adhesives and others. Food & beverages and pharmaceuticals together is expected to dominate the overall global induction sealing machines market. Cosmetics is expected to grow at a highest growth during the forecast period.

Key players

Some of the players in the global Induction sealing machines market are Enercon Industries Corporation, Pillar Technologies, Inc., Zhejiang Brother Packing Machinery Co., Ltd, me.ro S.p.a., Lepel Corporation, KWT Machine Systems Co., Ltd., Relco UK, Y-Fang Sealing Machine Ltd. and others.

The research report presents a comprehensive assessment of the market and contains thoughtful insights, facts, historical data, and statistically supported and industry-validated market data. It also contains projections using a suitable set of assumptions and methodologies. The research report provides analysis and information according to market segments such as geographies, application, and industry.

The report is a compilation of first-hand information, qualitative and quantitative assessment by industry analysts, inputs from industry experts and industry participants across the value chain.

The report provides in-depth analysis of parent market trends, macro-economic indicators and governing factors along with market attractiveness as per segments. The report also maps the qualitative impact of various market factors on market segments and geographies.

The global induction sealing machines market is estimated to be valued at USD 1.4 billion in 2025.

The market size for the induction sealing machines market is projected to reach USD 2.6 billion by 2035.

The induction sealing machines market is expected to grow at a 6.0% CAGR between 2025 and 2035.

The key product types in induction sealing machines market are automatic type, manual type, semi-automotive type and others.

In terms of application, food & beverages segment to command 52.9% share in the induction sealing machines market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Market Share Breakdown of Induction Sealing Machines Manufacturers

Induction Cooktop Market Forecast and Outlook 2025 to 2035

Induction Furnace Market Size and Share Forecast Outlook 2025 to 2035

Induction Hob Market Size and Share Forecast Outlook 2025 to 2035

Induction Motors Market - Growth & Demand 2025 to 2035

Heat Induction Cap Liner Market Size and Share Forecast Outlook 2025 to 2035

Analysis and Growth Projections for Powder Induction and Dispersion Systems Business

Vertical Induction Hardening System Market Size and Share Forecast Outlook 2025 to 2035

Portable Induction Hobs Market Trends & Forecast 2025 to 2035

Commercial Induction Cooktops Market Growth - Trends & Forecast 2025 to 2035

High Magnetic Induction Grain-Oriented Silicon Steel Market Size and Share Forecast Outlook 2025 to 2035

Sealing & Strapping Packaging Tape Market Size and Share Forecast Outlook 2025 to 2035

Sealing Agent for Gold Market Size and Share Forecast Outlook 2025 to 2035

Sealing And Strapping Packaging Tapes Market Size and Share Forecast Outlook 2025 to 2035

Box Sealing Machines Market Trends – Growth & Forecast 2025 to 2035

Self-sealing Ziplock Bag Market Size and Share Forecast Outlook 2025 to 2035

Heat Sealing Equipment Market Size and Share Forecast Outlook 2025 to 2035

Heat Sealing Machine Market Size and Share Forecast Outlook 2025 to 2035

Heat Sealing Tape Market Size and Share Forecast Outlook 2025 to 2035

Self-Sealing Bags Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA