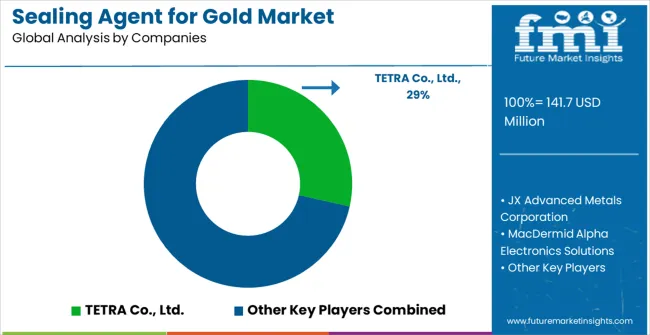

The sealing agent for gold market is forecasted to reach USD 141.7 million in 2025 and is expected to expand to USD 249 million by 2035, registering a CAGR of 5.8%. Early-stage adoption from USD 106.9 million in 2020 to USD 141.7 million in 2025 reflects initial market penetration, primarily driven by growing demand in jewelry, electronics, and precision manufacturing. During this period, manufacturers are investing in high-performance sealing agents to improve durability, corrosion resistance, and product quality. The adoption curve indicates the market is transitioning from an introduction phase into early growth, with increasing awareness among end-users of the benefits of specialized gold sealing solutions.

| Metric | Value |

|---|---|

| Estimated Value in (2025E) | USD 141.7 million |

| Forecast Value in (2035F) | USD 249.0 million |

| Forecast CAGR (2025 to 2035) | 5.8% |

Between 2025 and 2030, the market rises from USD 141.7 million to USD 187.9 million, representing a phase of accelerated adoption. This period reflects mid-stage market growth as sealing agents for gold become standard across multiple applications, including fine jewelry production and high-value electronic components. Industrial and consumer demand is reinforced by consistent quality requirements and regulatory compliance, prompting manufacturers to integrate advanced sealing agents into production processes. Revenue gains during this phase indicate a gradual maturity in adoption, with market participants increasingly relying on established products and trusted suppliers to meet operational and performance expectations.

From 2030 to 2035, the market grows from USD 187.9 million to USD 249.0 million, marking the mature adoption stage of the curve. Growth during this period is supported by widespread acceptance of sealing agents as a critical component in gold protection, process standardization, and product longevity. Manufacturers are focused on optimizing formulations and expanding production capacity to meet consistent demand. The adoption curve demonstrates a leveling trend where new entrants are fewer, and incremental growth is driven by replacement cycles, geographic expansion, and incremental technological refinements. By 2035, the market reaches full maturity, characterized by stable growth and high penetration across target applications.

Market expansion is being supported by the increasing use of gold in high-performance electronic and aerospace applications and the corresponding demand for surface protection solutions that can maintain gold's superior electrical and thermal properties while preventing oxidation and corrosion. Modern electronics and aerospace industries are increasingly focused on materials that can provide reliable performance in demanding environments while maintaining long-term stability and functionality. The proven capability of sealing agents to preserve gold surface integrity, prevent contamination, and ensure consistent electrical performance makes them essential components of advanced manufacturing processes.

The growing emphasis on miniaturization and performance optimization in electronic devices is driving demand for specialized surface protection technologies that can support reduced component sizes while maintaining enhanced reliability and performance characteristics. Industry preference for protection solutions that can integrate seamlessly with existing manufacturing processes while providing superior long-term protection is creating opportunities for advanced sealing agent development. The rising influence of quality and reliability requirements in aerospace and medical applications is also contributing to increased adoption of premium surface protection technologies across different high-performance sectors.

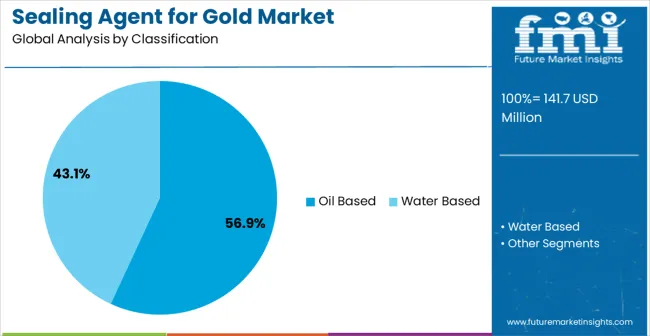

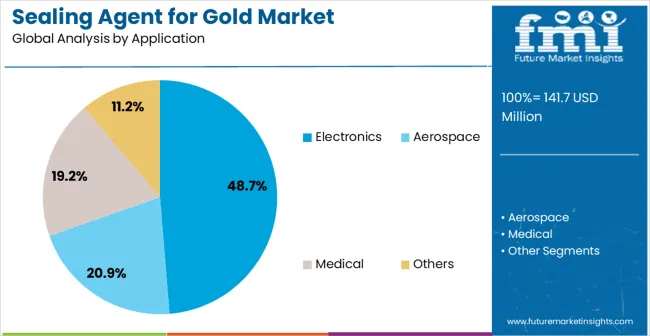

The market is segmented by classification, application, and region. By classification, the market is divided into oil-based, water-based, and others. Based on application, the market is categorized into electronics, aerospace, medical, and others. Regionally, the market is divided into Asia Pacific, North America, Europe, Latin America, and Middle East & Africa.

The oil-based classification is projected to account for 56.9% of the sealing agent for gold market in 2025, reaffirming its position as the dominant formulation type. This segment’s leadership is driven by its superior penetration, durability, and protective characteristics, making it ideal for gold surface applications that require long-term reliability. Oil-based sealing agents provide resistance to environmental stressors such as moisture, oxidation, and temperature variations, ensuring sustained protection of delicate gold coatings. Manufacturers increasingly adopt this classification due to its proven performance in critical industrial and electronic applications. Continuous innovation in formulation technology, combined with extensive testing and quality validation, reinforces confidence in oil-based solutions. Their versatility across multiple application scenarios, along with long-lasting surface protection and ease of use, ensures sustained market dominance. Oil-based sealing agents are expected to continue as the preferred choice for high-performance gold surface protection through the forecast period.

Electronics applications are projected to represent 48.7% of sealing agent for gold demand in 2025, making them the largest application segment. Gold-plated components used in electronics require reliable surface protection to maintain conductivity and prevent corrosion or degradation in high-performance and miniaturized devices. The increasing complexity of electronic systems, including microchips, connectors, and precision circuits, drives demand for advanced sealing agents that safeguard component functionality and extend product lifespan. Manufacturers prioritize formulations that ensure consistent coating integrity, electrical reliability, and resistance to environmental stressors. Additionally, the electronics industry’s focus on yield optimization, reduced failure rates, and high-quality standards further supports adoption. Continuous innovation in sealing technologies, combined with precision application methods, allows electronics producers to maintain performance across increasingly demanding operating environments. The segment is expected to sustain leadership due to the rising deployment of gold-based components across consumer electronics, industrial electronics, and high-reliability systems globally.

The sealing agent for gold market is advancing steadily due to increasing demand for high-performance electronics and growing need for gold surface protection in critical applications. However, the market faces challenges including high-value substrate sensitivity, application complexity, and environmental regulations affecting solvent-based formulations. Innovation in formulation chemistry and application methods continue to influence product development and market expansion patterns.

The growing development of advanced electronics and miniaturization technologies is creating enhanced opportunities for specialized gold sealing agent applications in high-density electronic assemblies and micro-components. Advanced electronics manufacturing requires precise surface protection solutions that can maintain gold functionality while supporting increasingly small component geometries. Miniaturization trends provide opportunities for specialized sealing technologies that can deliver protection without compromising electrical or mechanical properties.

The sealing agent for gold market is growing due to rising consumption of gold in jewelry, electronics, and decorative applications. Sealing agents protect gold surfaces from tarnish, scratches, and corrosion, enhancing durability and aesthetic appeal. Jewelry manufacturers, luxury watchmakers, and electronics producers increasingly adopt sealing agents to maintain surface integrity and premium finish. Rising disposable income, luxury product consumption, and industrial adoption in emerging economies are further boosting market growth and driving demand for advanced sealing solutions.

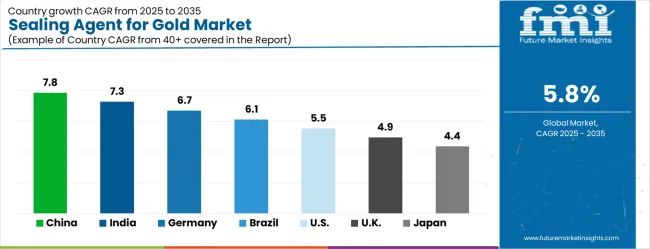

| Country | CAGR (2025-2035) |

|---|---|

| China | 7.8% |

| India | 7.3% |

| Germany | 6.7% |

| Brazil | 6.1% |

| USA | 5.5% |

| UK | 4.9% |

| Japan | 4.4% |

The sealing agent for gold market is experiencing solid growth globally, with China leading at a 7.8% CAGR through 2035, driven by massive electronics manufacturing expansion, growing aerospace industry development, and increasing adoption of advanced surface protection technologies. India follows at 7.3%, supported by expanding electronics manufacturing capabilities, growing aerospace sector development, and increasing investment in high-technology industries. Germany shows growth at 6.7%, emphasizing precision manufacturing excellence and comprehensive quality standards. Brazil records 6.1% growth, focusing on expanding industrial manufacturing and growing adoption of advanced specialty chemicals. The USA shows 5.5% growth, representing steady demand from established electronics and aerospace industries.

The report covers an in-depth analysis of 40+ countries top-performing countries are highlighted below.

The sealing agent for gold market in China is projected to grow at a CAGR of 7.8% through 2035, driven by rapid electronics manufacturing expansion, aerospace industry growth, and increased medical device production. Government-supported high-technology initiatives and infrastructure investments are facilitating widespread adoption of advanced surface protection solutions across manufacturing hubs. Domestic and international specialty chemical companies are expanding production and distribution networks to meet the rising demand. The proliferation of high-precision electronics assembly and gold-coated component applications is creating a sustained need for reliable sealing agents, while large-scale manufacturers are integrating surface protection into product quality assurance programs.

The sealing agent for gold market in India is expected to expand at a CAGR of 7.3% through 2035, supported by the growing electronics manufacturing sector, emerging aerospace projects, and high-technology investment initiatives. Increasing domestic production of high-precision components is creating demand for advanced surface protection solutions. International specialty chemical suppliers and domestic manufacturers are strengthening partnerships and local production capabilities to address rising requirements. Urban industrial zones and technology clusters are adopting sealing agents to ensure gold-coated components maintain quality standards. Continuous growth in electronic device assembly and aerospace production is driving manufacturers to integrate advanced chemical solutions into assembly lines and preventive maintenance programs.

The sealing agent for gold market in Germany is projected to grow at a CAGR of 6.7% through 2035, supported by the country’s precision manufacturing expertise, advanced chemical technology adoption, and well-established quality standards. Leading electronics and aerospace manufacturers are continuously investing in high-performance sealing agents to enhance product reliability and maintain competitive advantages. Research collaborations between industrial companies and chemical technology institutes are facilitating innovation and ensuring superior surface protection performance. Germany’s robust industrial framework, combined with extensive experience in precision chemical application, is supporting widespread integration of sealing agents for gold into critical components, including high-end electronics and aerospace assemblies.

The sealing agent for gold market in Brazil is projected to grow at a CAGR of 6.1% through 2035, supported by industrial modernization, electronics sector growth, and increasing adoption of surface protection solutions. Manufacturers in the country are investing in advanced sealing technologies to enhance product reliability and meet quality standards. Partnerships between international chemical companies and local producers are strengthening the domestic market and facilitating knowledge transfer. Expanding industrial infrastructure and increasing electronics assembly projects are generating demand for high-performance chemical solutions. Surface protection integration into manufacturing processes is becoming standard practice to reduce component failure and improve product consistency.

The sealing agent for gold market in the United States is projected to grow at a CAGR of 5.5% through 2035, driven by established electronics and aerospace industries, advanced manufacturing technologies, and high-performance surface protection adoption. Manufacturers are incorporating sealing agents to ensure product longevity, reliability, and compliance with stringent quality standards. Specialty chemical suppliers are innovating formulations to meet the specific needs of precision electronics, aerospace, and medical device sectors. Established industrial infrastructure, combined with research and development capabilities, is facilitating widespread adoption of sealing agents for gold. High-value component production is increasingly dependent on these chemical solutions to maintain operational reliability and prevent corrosion-related failures.

The sealing agent for gold market in the United Kingdom is expected to grow at a CAGR of 4.9% through 2035, supported by mature aerospace and electronics industries, quality-focused manufacturing, and investment in advanced chemical technologies. British manufacturers are emphasizing high-performance surface protection solutions to ensure product reliability and maintain industrial competitiveness. Specialty chemical companies are strengthening service and distribution networks to meet demand across critical manufacturing sectors. Widespread use of precision assembly and gold-coated components in electronics and aerospace applications is driving the adoption of sealing agents for gold.

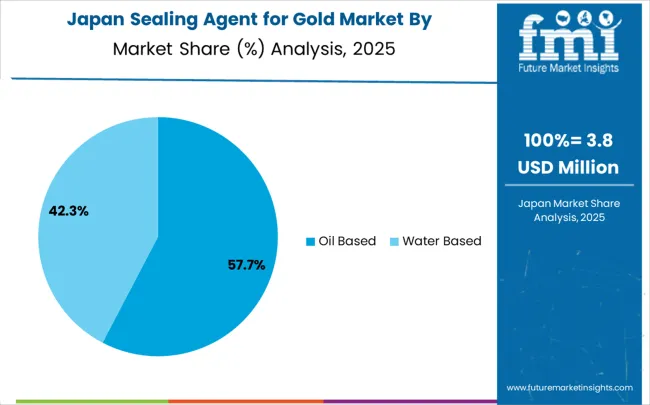

The sealing agent for gold market in Japan is projected to grow at a CAGR of 4.4% through 2035, driven by the country’s focus on precision manufacturing, advanced chemical technology integration, and high-quality component production. Japanese electronics and aerospace manufacturers are adopting specialized sealing agents to enhance reliability, ensure compliance, and extend product service life. Investments in research, automated application methods, and high-precision production lines are supporting widespread adoption. Surface protection technologies are being integrated into assembly workflows to maintain gold-coated component performance and meet industrial quality benchmarks.

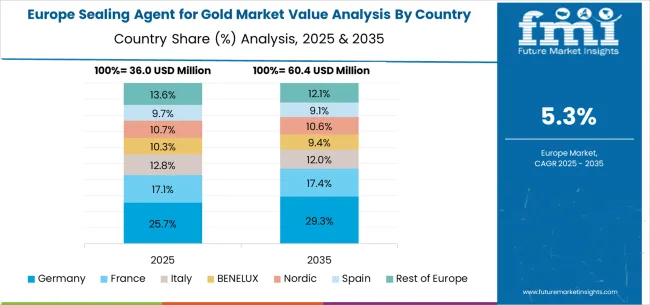

The sealing agent for gold market in Europe is projected to grow from USD 36.0 million in 2025 to USD 60.4 million by 2035, at a CAGR of 5.3%. Germany will lead, increasing from 28.9% in 2025 to 29.6% by 2035, supported by precision manufacturing capabilities, advanced chemical technology infrastructure, and stringent quality frameworks. The United Kingdom will follow with 19.4% in 2025, rising to 19.7% in 2035, reflecting its aerospace and electronics industry expertise. France will account for 16.7% in 2025, edging up to 17.0% by 2035, supported by advanced manufacturing and high-technology surface protection demand.

Italy contributes 12.8% in 2025, stabilizing at 13.0% by 2035, underpinned by specialized chemical production. Spain will hold 9.6% in 2025, slightly improving to 9.7% by 2035, reflecting gradual industrial adoption. Nordic countries will increase from 10.3% to 12.0%, showing stronger uptake in advanced chemical applications, while BENELUX remains stable at 10.7% in 2025 and 9.4% in 2035. The Rest of Europe will decline from 13.6% to 12.1%, showing slower growth compared to the core Western European countries.

The sealing agent for gold market is characterized by competition among specialized chemical companies, established precious metals processors, and innovative surface protection technology providers. Companies are investing in advanced formulation chemistry, application technology development, strategic partnerships, and technical support to deliver high-performance, reliable, and cost-effective gold sealing solutions. Technology development, quality assurance, and customer support strategies are central to strengthening competitive advantages and market presence.

TETRA CO., LTD. leads the market with significant expertise in specialty chemical solutions, offering comprehensive sealing agent products with focus on performance optimization and application reliability. JX Advanced Metals Corporation provides established precious metals processing capabilities with emphasis on advanced chemical technologies and manufacturing integration. MacDermid Alpha Electronics Solutions focuses on specialty chemical solutions with comprehensive surface treatment and protection expertise.

Tanaka Precious Metals Co., Ltd. delivers advanced precious metals technologies with strong focus on high-performance applications and quality assurance. These companies provide diverse technological approaches and specialized expertise to enhance overall market development and surface protection capability advancement across multiple high-technology application sectors.

| Items | Values |

|---|---|

| Quantitative Units (2025) | USD 141.7 million |

| Classification | Oil Based, Water Based, Others |

| Application | Electronics, Aerospace, Medical, Others |

| Regions Covered | Asia Pacific, North America, Europe, Latin America, Middle East & Africa |

| Countries Covered | China, India, Germany, Brazil, United States, United Kingdom, Japan and 40+ countries |

| Key Companies Profiled | TETRA CO., LTD., JX Advanced Metals Corporation, MacDermid Alpha Electronics Solutions, Tanaka Precious Metals Co., Ltd. |

| Additional Attributes | Dollar sales by agent type and application, regional adoption trends, competitive landscape, manufacturing partnerships, integration with production processes, innovations in formulation chemistry and application methods, performance analysis, and reliability optimization strategies |

The global sealing agent for gold market is estimated to be valued at USD 141.7 million in 2025.

The market size for the sealing agent for gold market is projected to reach USD 249.0 million by 2035.

The sealing agent for gold market is expected to grow at a 5.8% CAGR between 2025 and 2035.

The key product types in sealing agent for gold market are oil based and water based.

In terms of application, electronics segment to command 48.7% share in the sealing agent for gold market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Sealing & Strapping Packaging Tape Market Size and Share Forecast Outlook 2025 to 2035

Sealing And Strapping Packaging Tapes Market Size and Share Forecast Outlook 2025 to 2035

Box Sealing Machines Market Trends – Growth & Forecast 2025 to 2035

Self-sealing Ziplock Bag Market Size and Share Forecast Outlook 2025 to 2035

Tray Sealing Machines Market Size and Share Forecast Outlook 2025 to 2035

Heat Sealing Equipment Market Size and Share Forecast Outlook 2025 to 2035

Heat Sealing Machine Market Size and Share Forecast Outlook 2025 to 2035

Heat Sealing Tape Market Size and Share Forecast Outlook 2025 to 2035

Self-Sealing Bags Market Size and Share Forecast Outlook 2025 to 2035

Tube Sealing Machines Market Analysis by Tube type, Technology type, End User, and Region through 2025 to 2035

Competitive Breakdown of Tube Sealing Machines Providers

Industry Share Analysis for Self-Sealing Bags Companies

Self-Sealing Paper Bands Market

Heat Sealing Tester Market

Heat Sealing Bags Market

Pouch Sealing Machine Market

Hybrid Sealing-Cut Machines Market Analysis - Size and Share Forecast Outlook 2025 to 2035

Bottle Sealing Wax Market Size and Share Forecast Outlook 2025 to 2035

Vacuum Sealing Machine Market Size and Share Forecast Outlook 2025 to 2035

Vessel-sealing Devices Market Trends - Growth & Forecast 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA