The induction sealing machines market is experiencing steady growth due to increasing demand for tamper-evident, leak-proof, and secure packaging solutions. There is a strong focus on innovative, high-efficiency sealing technologies offered by vendors to meet global quality standards. Furthermore, increased automation in manufacturing is enhancing efficiency and reducing production costs, further driving market expansion.

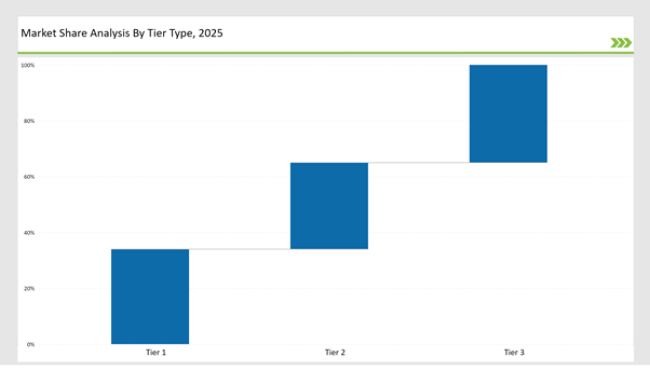

Tier 1 market leaders include Enercon Industries, Pillar Technologies, and Lepel Corporation, which capture 34% of the market share using advanced sealing technologies, extensive distribution networks, and continuous product innovations.

Tier 2 includes companies like Relco, MeRo, and VTOPS, which control 31% of the market. These firms cater to mid-sized consumers by offering customized, high-performance induction sealing solutions, benefiting from cost-effective production and strong regulatory compliance.

Tier 3 players, including regional and niche manufacturers specializing in food, pharmaceuticals, and industrial packaging, constitute the remaining 35% of the market. These players cater to specialized consumer demands with tailored designs and localized distribution networks. They also focus on cost-effective solutions, leveraging flexible production methods to adapt to evolving industry trends.

Global Market Share by Key Players (2025)

| Category | Market Share (%) |

|---|---|

| Top 3 (Enercon Industries, Pillar Technologies, Lepel Corporation) | 15% |

| Rest of Top 5 (Relco, MeRo) | 11% |

| Next 5 of Top 10 (VTOPS, Technopack, Sigma CapSeal, Reltech, Selig Group) | 8% |

The induction sealing machines market caters to various industries, such as packaging security and consumer safety compliance. Emerging markets are also increasing demand, particularly in the food and pharmaceutical sectors.

Companies strive to meet the growing demands of industries by increasing the efficiency of production, reducing environmental impact, and improving product functionality.

Companies are focusing on material innovations that enhance seal integrity, improve energy efficiency, and ensure regulatory compliance.

Technology suppliers should focus on integrating smart packaging solutions that enhance security and traceability. Additionally, fostering collaborations with material suppliers can help in developing cost-effective and innovative induction sealing solutions.

| Tier Type | Example of Key Players |

|---|---|

| Tier 1 | Enercon Industries, Pillar Technologies, Lepel Corporation |

| Tier 2 | Relco, MeRo, VTOPS |

| Tier 3 | Technopack, Sigma CapSeal, Reltech, Selig Group |

Leading manufacturers are focusing on expanding production capabilities, integrating sustainable materials, and enhancing product safety to meet evolving industry demands.

| Manufacturer | Latest Developments |

|---|---|

| Enercon Industries | In March 2024, launched an AI-enabled high-speed induction sealing system. |

| Pillar Technologies | In August 2023, introduced an energy-efficient induction sealer. |

| Lepel Corporation | In May 2024, developed compact, high-performance sealing solutions. |

| Relco | In November 2023, expanded global distribution with new partnerships. |

| MeRo | In February 2024, launched a low-energy induction sealing solution. |

| Technopack | In July 2024, introduced a new range of cost-effective tabletop induction sealers. |

| Sigma CapSeal | In October 2023, developed a next-gen, fully automated induction sealing line. |

| Selig Group | In December 2024, invested in recyclable induction liner technologies to enhance sustainability. |

The competitive landscape in the induction sealing machines market is evolving rapidly, with key players focusing on innovation, sustainability, and advanced manufacturing techniques to maintain a strong market position.

Growth will be driven by automation, material innovations, and sustainability efforts. Companies will integrate smart monitoring systems, invest in energy-efficient induction sealing solutions, and enhance material recycling processes. The demand for high-speed and portable induction sealing machines is expected to rise, further expanding the market. Additionally, advancements in AI-driven predictive maintenance will enhance machine efficiency and reduce downtime, contributing to overall cost savings.

Leading players include Enercon Industries, Pillar Technologies, Lepel Corporation, Relco, and MeRo.

The top 3 players collectively control 15% of the global market.

The market shows medium concentration, with top players holding 34%.

Key drivers include sustainability, automation, material innovation, and regulatory compliance.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Induction Cooktop Market Forecast and Outlook 2025 to 2035

Induction Furnace Market Size and Share Forecast Outlook 2025 to 2035

Induction Hob Market Size and Share Forecast Outlook 2025 to 2035

Induction Motors Market - Growth & Demand 2025 to 2035

Induction Sealing Machines Market Size and Share Forecast Outlook 2025 to 2035

Heat Induction Cap Liner Market Size and Share Forecast Outlook 2025 to 2035

Analysis and Growth Projections for Powder Induction and Dispersion Systems Business

Portable Induction Hobs Market Trends & Forecast 2025 to 2035

Commercial Induction Cooktops Market Growth - Trends & Forecast 2025 to 2035

High Magnetic Induction Grain-Oriented Silicon Steel Market Size and Share Forecast Outlook 2025 to 2035

Sealing & Strapping Packaging Tape Market Size and Share Forecast Outlook 2025 to 2035

Sealing Agent for Gold Market Size and Share Forecast Outlook 2025 to 2035

Sealing And Strapping Packaging Tapes Market Size and Share Forecast Outlook 2025 to 2035

Box Sealing Machines Market Trends – Growth & Forecast 2025 to 2035

Heat Sealing Equipment Market Size and Share Forecast Outlook 2025 to 2035

Heat Sealing Machine Market Size and Share Forecast Outlook 2025 to 2035

Heat Sealing Tape Market Size and Share Forecast Outlook 2025 to 2035

Self-Sealing Bags Market Size and Share Forecast Outlook 2025 to 2035

Self-Sealing Ziplock Bag Market Growth – Demand & Forecast through 2034

Self-Sealing Paper Bands Market

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA