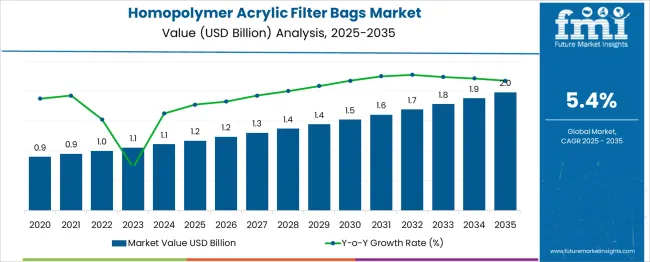

The Homopolymer Acrylic Filter Bags Market is estimated to be valued at USD 1.2 billion in 2025 and is projected to reach USD 2.0 billion by 2035, registering a compound annual growth rate (CAGR) of 5.4% over the forecast period. A Growth Contribution Index (GCI) analysis shows steady and consistent growth across the forecast period. Between 2025 and 2030, the market grows from USD 1.2 billion to USD 1.5 billion, contributing USD 0.3 billion in growth, which accounts for approximately 30% of the total market growth over the 10 years. This early-stage growth is driven by increasing demand for efficient filtration solutions across various industries such as pharmaceuticals, chemicals, and manufacturing, where homopolymer acrylic filter bags offer superior resistance to high temperatures and chemicals.

From 2030 to 2035, the market is expected to continue expanding from USD 1.5 billion to USD 2.0 billion, contributing USD 0.5 billion in growth, with a higher contribution of approximately 40% to the overall growth. This phase is characterized by steady demand, driven by the expansion of industrial production, particularly in emerging markets, as well as innovations in filtration technology that enhance performance and durability. The GCI highlights a steady contribution from both periods, with the market accelerating in the latter years as the adoption of advanced filtration solutions becomes more widespread across diverse sectors, ensuring sustained market growth.

| Metric | Value |

|---|---|

| Homopolymer Acrylic Filter Bags Market Estimated Value in (2025 E) | USD 1.2 billion |

| Homopolymer Acrylic Filter Bags Market Forecast Value in (2035 F) | USD 2.0 billion |

| Forecast CAGR (2025 to 2035) | 5.4% |

The homopolymer acrylic filter bags market is gaining momentum as industries intensify their focus on high-efficiency filtration systems that withstand aggressive operating conditions. The growing importance of maintaining emission control in compliance with tightening environmental regulations has created sustained demand for temperature and chemical-resistant filter media.

Homopolymer acrylic materials are being increasingly preferred for their superior performance in dry filtration, corrosion resistance, and extended service life, particularly in flue gas treatment and industrial dust collection applications. These properties have made them suitable for use in power plants, cement kilns, incinerators, and chemical manufacturing facilities where particulate emissions must be tightly regulated.

The market is also benefitting from innovation in bag design, installation compatibility, and process optimization using software-aided filtration control. As decarbonization goals accelerate, the reliance on efficient and durable filtration solutions is expected to grow, supporting the long-term expansion of homopolymer acrylic filter bags across heavy-duty industrial verticals.

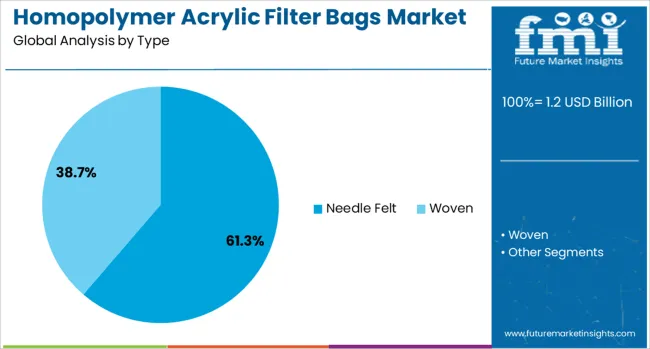

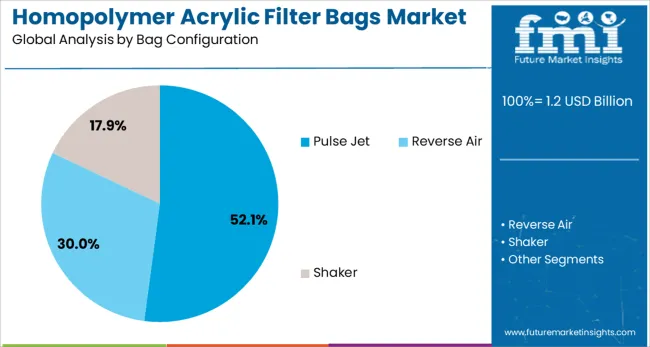

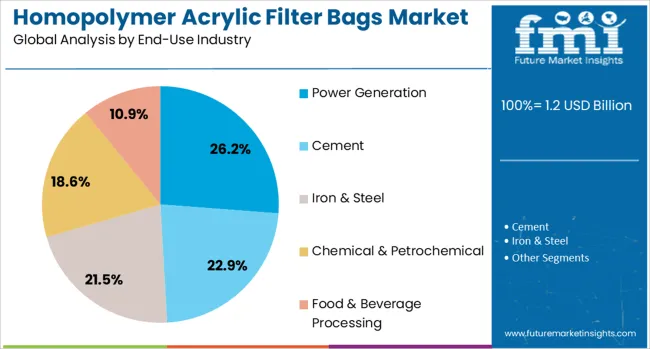

The homopolymer acrylic filter bags market is segmented by type, bag, configuration, end-use industry, application, and geographic regions. By type, the homopolymer acrylic filter bags market is divided into Needle Felt and Woven. In terms of bag configuration, the homopolymer acrylic filter bags market is classified into Pulse Jet and Reverse AirShaker. Based on end-use industry, the homopolymer acrylic filter bags market is segmented into Power Generation, Cement, Iron & Steel, Chemical & Petrochemical, and Food & Beverage Processing. By application, the homopolymer acrylic filter bags market is segmented into Dust Collection, Fume Filtration, Product Recovery, and Emission Control. Regionally, the homopolymer acrylic filter bags industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The needle felt type is projected to account for 61.3% of the total revenue share in the homopolymer acrylic filter bags market in 2025, maintaining its position as the leading segment. The high adoption of needle felt is being driven by its ability to provide consistent filtration efficiency under high temperature and chemically aggressive conditions.

This material configuration has been widely integrated into filtration systems due to its depth filtration characteristics, dimensional stability, and resistance to hydrolysis and chemical degradation. Its dense fiber structure allows for higher dust-holding capacity and prolonged operational cycles, reducing the need for frequent bag replacements.

These features are critical in applications where uninterrupted plant performance and low maintenance are essential, such as in waste incineration, metallurgy, and cement industries. Additionally, advancements in surface treatments and membrane coatings have further enhanced the dust release efficiency and lifecycle of needle felt bags, solidifying their dominance in medium- to high-temperature industrial environments.

The pulse jet bag configuration is expected to hold 52.1% of the overall market revenue in 2025, emerging as the most widely used configuration in the homopolymer acrylic filter bags industry. This segment’s growth is being influenced by its high filtration efficiency, compact design, and capability for continuous operation without interrupting system airflow.

Pulse jet systems operate with high-frequency cleaning pulses that maintain low pressure drop and optimal airflow through the bags, extending their service life and performance stability. The configuration has gained widespread acceptance across industries where space constraints and process uptime are critical.

The ability to automate cleaning cycles and reduce manual intervention has also contributed to the rising deployment of pulse jet systems in modern industrial filtration setups. Furthermore, compatibility with a broad range of filter media including homopolymer acrylic has enabled versatile use across varying temperature and particulate conditions, reinforcing its status as a preferred bag configuration.

The power generation end-use industry is projected to represent 26.2% of the homopolymer acrylic filter bags market revenue in 2025, securing its position as the dominant consumer segment. This growth is being driven by stringent environmental regulations on particulate emissions and the need for efficient fly ash handling in thermal power plants. Homopolymer acrylic filter bags have been increasingly used in baghouse systems within coal-fired power stations due to their excellent chemical resistance and thermal durability.

These bags are suited for capturing fine particulates in flue gases, where stable performance is required under varying load conditions. The segment has also benefited from efforts to upgrade existing emission control systems to meet revised pollution control standards and operational efficiency targets.

As older plants continue to retrofit or replace outdated filtration components with modern solutions, the demand for reliable, long-lasting filter bags has grown. With power utilities prioritizing cleaner operations, the role of advanced filtration technologies in power generation is expected to expand further.

The demand for homopolymer acrylic filter bags is rising due to their high filtration efficiency and durability in various industries such as cement, mining, and chemical processing. These filter bags are valued for their ability to withstand harsh conditions like high temperatures, moisture, and chemicals, making them ideal for industrial dust collection systems. The increasing focus on improving air quality and regulatory compliance is boosting the demand for reliable filtration solutions. Despite challenges like high production costs, innovations in manufacturing processes are providing opportunities for market growth.

The primary driver of the homopolymer acrylic filter bag market is the increasing stringency of environmental regulations that require industries to control emissions and maintain air quality standards. Industries such as cement, mining, and power generation, which produce significant amounts of dust and particulate matter, are adopting efficient filtration systems to comply with environmental standards. Homopolymer acrylic filter bags, known for their superior dust collection capabilities, are widely used in these industries.The rise in industrialization and urbanization, combined with the increasing demand for high-efficiency filtration systems, continues to drive the market for homopolymer acrylic filter bags as industries strive to meet regulatory requirements and improve operational efficiency.

One of the main challenges faced by the homopolymer acrylic filter bag market is the high production cost associated with manufacturing these bags. The materials used in producing homopolymer acrylic filter bags are more expensive than other alternatives, which can increase the cost for end users. Additionally, there is intense competition from alternative filtration materials such as polyester and polypropylene, which are more cost-effective. While homopolymer acrylic bags offer superior performance in specific applications, their higher cost can deter smaller companies or those operating in cost-sensitive industries from adopting them. This price sensitivity can limit market penetration, particularly in emerging economies.

Opportunities in the homopolymer acrylic filter bag market driven by ongoing innovations in filter bag technology and expanding applications across industries. Manufacturers are focusing on enhancing the performance of filter bags by improving filtration efficiency, lifespan, and resistance to chemicals, extreme temperatures, and moisture. The integration of advanced features, such as anti-static properties and self-cleaning mechanisms, offers new growth opportunities. As industries in emerging markets continue to expand, particularly in Asia-Pacific and Latin America, the demand for high-efficiency filtration systems is expected to rise. This presents significant opportunities for the adoption of homopolymer acrylic filter bags in industries that prioritize environmental compliance and air quality.

Emerging trends include production of ultra-thin CCL grades that support multilayer stacks with compact inter-trace spacing and controlled impedance. Advanced surface treatments such as micro-etch or proprietary foil texturing are being applied to reduce signal loss and improve copper bonding. Use of digital twin modeling for predicting dielectric behavior under signal load and thermal stress is gaining traction. Multi-source multilayer core architectures and selective foil plating techniques are improving yield in high-speed PCB fabrication. Collaboration between lamination material providers and CAD tool developers to embed material property libraries supports faster PCB stack-up design cycles. Automated quality analytics such as in-line dielectric constant scanning are being introduced for real-time process control.

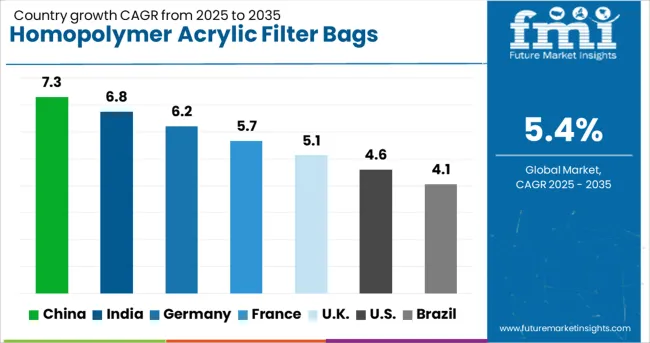

| Country | CAGR |

|---|---|

| China | 7.3% |

| India | 6.8% |

| Germany | 6.2% |

| France | 5.7% |

| UK | 5.1% |

| USA | 4.6% |

| Brazil | 4.1% |

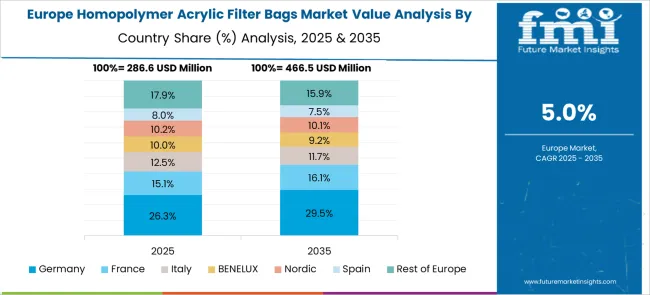

The global homopolymer acrylic filter bags market is expected to grow at a CAGR of 5.4% from 2025 to 2035. China leads the market with a growth rate of 7.3%, followed by India at 6.8%. Germany and France are experiencing steady growth at 6.2% and 6.0%, respectively. Developed markets like the UK and USA are seeing more moderate growth rates of 5.1% and 4.6%, respectively. The increasing demand for filtration solutions across various industries such as chemicals, pharmaceuticals, and food processing, combined with the growing need for environmentally friendly and efficient filtration systems, is driving the market. The analysis includes over 40 countries, with the top five detailed below.

The homopolymer acrylic filter bags market in China is expanding rapidly, with a projected CAGR of 7.3%. The growth is largely driven by the country’s increasing industrial activities, particularly in sectors like chemicals, automotive, and textiles. As industries face heightened pressure to meet stricter environmental regulations and improve efficiency, the demand for advanced filtration systems rises. Additionally, China’s rising focus on sustainability and reducing pollution contributes to the growing adoption of high-performance filtration solutions. The increasing need for air and water quality control in manufacturing and other sectors further accelerates the market demand.

The homopolymer acrylic filter bags market in India is expected to grow steadily with a CAGR of 6.8%. The rapid growth of India’s industrial base, particularly in the automotive, chemicals, and pharmaceuticals sectors, is driving the demand for efficient filtration systems. As the country continues to industrialize, the need for advanced filtration solutions to handle waste management and pollution control becomes critical. Government regulations on air and water quality are encouraging industries to adopt high-efficiency filter bags, making them essential in a wide range of applications, from manufacturing to energy production.

The homopolymer acrylic filter bags market in Germany is projected to grow at a CAGR of 6.2%. The demand for filtration solutions is driven by the country’s emphasis on clean manufacturing processes and strict environmental regulations. As industries like automotive, pharmaceuticals, and chemicals increasingly focus on sustainability, the need for effective filtration systems to maintain air and water quality is growing. Germany’s commitment to renewable energy and waste management practices further fuels the demand for high-efficiency filter bags, ensuring better production processes and reducing environmental impact.

Sales of homopolymer acrylic filter bags in the United Kingdom are growing at a moderate CAGR of 5.4%. The demand is driven by the need for better waste management solutions in the automotive, pharmaceutical, and chemical industries. The country’s commitment to reducing industrial emissions and improving air and water quality is pushing industries to adopt high-performance filtration systems. Moreover, the growing adoption of smart manufacturing and sustainable production practices is leading to an increase in the use of efficient filtration technologies, which is contributing to the market’s steady growth.

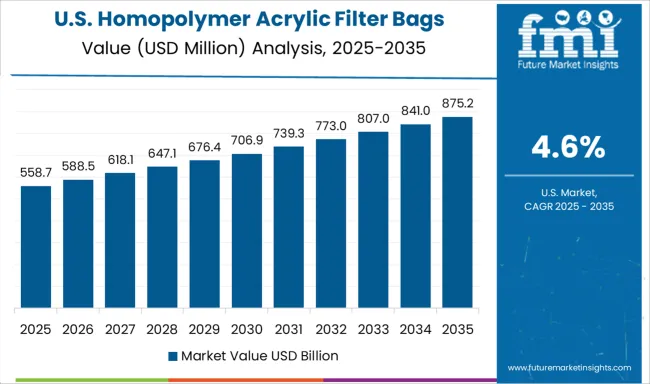

The USA homopolymer acrylic filter bags market is projected to grow at a CAGR of 4.8%. The demand is supported by the country’s industrial growth and the need for efficient filtration systems in various sectors, including manufacturing, automotive, and food processing. As the USA continues to focus on environmental compliance and sustainability, the adoption of high-efficiency filtration systems increases. The push for cleaner production processes and stricter government regulations on emissions and waste management further accelerates the growth of the filter bag market, especially in industries where air and water quality are critical.

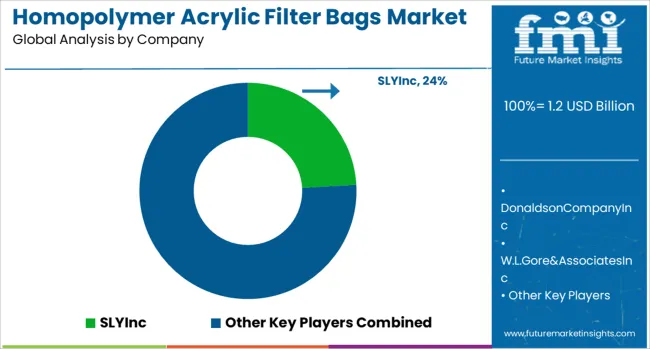

The homopolymer acrylic filter bag market is defined by specialized manufacturers delivering high-performance filtration solutions for industrial applications, including cement, steel, power generation, chemicals, and pharmaceuticals. Dominant global players, including Donaldson Company, Inc., Ahlstrom-Munksjö, and Parker Hannifin, maintain market leadership through product reliability, extended bag life, and resistance to high temperatures and corrosive environments. These companies leverage advanced nonwoven fiber technologies, precise pore size control, and customized bag designs to meet stringent industrial emission and filtration standards.

Regional leaders such as Filtration Group Corporation, Filtros Polimex, and W. L. Gore & Associates focus on market penetration through tailored solutions for local industries, emphasizing ease of installation, maintenance, and compatibility with existing baghouse systems. Emerging manufacturers, including Hangzhou Anri Filtration, Shijiazhuang Zexin Filtration, and Henan Xinda Filter Materials, differentiate through cost-effective production, rapid lead times, and application-specific formulations.

Historically, strategies have concentrated on developing high-temperature-resistant fabrics, extending bag service life, and strengthening distribution networks. Forecast strategies emphasize innovations in electrostatic treatments, hybrid fiber blends, and modular bag designs to enhance dust collection efficiency, energy savings, and environmental compliance. Differentiation levers include fabric composition, filtration efficiency, thermal and chemical resistance, and operational durability. Growth opportunities are pronounced in the cement, steel, power, and chemical industries, especially in emerging economies, where industrial output expansion drives demand for filtration systems. Strategic partnerships with industrial equipment suppliers, retrofit projects, and aftermarket service contracts are leveraged to enhance market reach, brand loyalty, and recurring revenue streams.

| Item | Value |

|---|---|

| Quantitative Units | USD 1.2 Billion |

| Type | Needle Felt and Woven |

| Bag Configuration | Pulse Jet, Reverse Air, and Shaker |

| End-Use Industry | Power Generation, Cement, Iron & Steel, Chemical & Petrochemical, and Food & Beverage Processing |

| Application | Dust Collection, Fume Filtration, Product Recovery, and Emission Control |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled | SLYInc, DonaldsonCompanyInc, W.L.Gore&AssociatesInc, HLFilterUSALLC, ZonelFiltech, and AmritFilter |

| Additional Attributes | Dollar sales by filter bag type (air filters, liquid filters) and end-use segments (chemical processing, power generation, cement industry, textiles). Demand dynamics are influenced by the growing need for efficient filtration solutions, increasing regulatory standards for air and liquid quality, and the rising adoption of advanced filtration technologies. Regional trends show strong growth in North America and Europe, driven by industries such as power generation and chemical processing, while Asia-Pacific is expanding due to rapid industrialization and the growing demand for industrial filtration solutions. |

The global homopolymer acrylic filter bags market is estimated to be valued at USD 1.2 billion in 2025.

The market size for the homopolymer acrylic filter bags market is projected to reach USD 2.0 billion by 2035.

The homopolymer acrylic filter bags market is expected to grow at a 5.4% CAGR between 2025 and 2035.

The key product types in homopolymer acrylic filter bags market are needle felt and woven.

In terms of bag configuration, pulse jet segment to command 52.1% share in the homopolymer acrylic filter bags market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

PP Homopolymer Market Report - Demand, Growth & Industry Outlook 2025 to 2035

Vinyl Acetate Homopolymer Market Size and Share Forecast Outlook 2025 to 2035

Acrylic Fibre Market Size and Share Forecast Outlook 2025 to 2035

Acrylic Emulsions Market Size and Share Forecast Outlook 2025 to 2035

Acrylic Polymer Market Size and Share Forecast Outlook 2025 to 2035

Acrylic Resin Market Size and Share Forecast Outlook 2025 to 2035

Acrylic Fine Particle Market Size and Share Forecast Outlook 2025 to 2035

Acrylic Boxes Market Size and Share Forecast Outlook 2025 to 2035

Acrylic Paper Market Size and Share Forecast Outlook 2025 to 2035

Acrylic Pad Market Size and Share Forecast Outlook 2025 to 2035

Acrylic Adhesives Market Growth - Trends & Forecast 2025 to 2035

Acrylic Teeth Market Trends and Assessment for 2025 to 2035

Acrylic Styrene Acrylonitrile (ASA) Resin Market- Growth & Demand 2025 to 2035

Key Companies & Market Share in the Acrylic Airless Bottle Sector

Analyzing Acrylic Boxes Market Share & Industry Leaders

Acrylic Acid Market Growth - Trends & Forecast 2024 to 2034

Acrylic Airless Bottle Market Trends - Demand & Forecast 2024 to 2034

Acrylic Paint Market Growth – Trends & Forecast 2024-2034

Acrylic Colors Market

Acrylic Container Market

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA