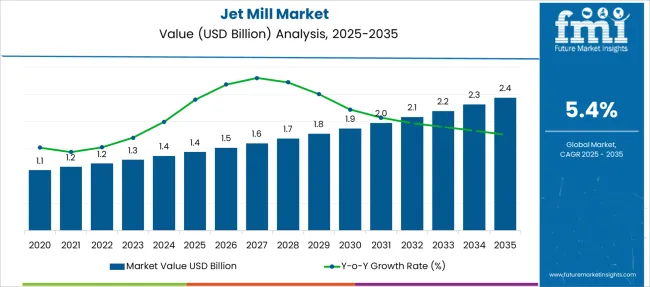

The Jet Mill Market is estimated to be valued at USD 1.4 billion in 2025 and is projected to reach USD 2.4 billion by 2035, registering a compound annual growth rate (CAGR) of 5.4% over the forecast period.

| Metric | Value |

|---|---|

| Jet Mill Market Estimated Value in (2025 E) | USD 1.4 billion |

| Jet Mill Market Forecast Value in (2035 F) | USD 2.4 billion |

| Forecast CAGR (2025 to 2035) | 5.4% |

The Jet Mill market is experiencing steady growth due to rising demand for ultra-fine particle size reduction across high-precision industries. Current market trends indicate increased usage in pharmaceuticals, chemicals, and materials engineering where particle uniformity and contamination-free processing are critical. Industry-specific publications and company press releases have emphasized the advantages of jet milling technologies in achieving micron-level grinding without heat generation, which is essential for temperature-sensitive compounds.

Growing regulatory emphasis on cleanroom-compatible manufacturing and sterile production environments has further supported adoption. Investor updates from technology providers have highlighted strategic capacity expansions, especially in emerging markets, to meet evolving quality standards.

In addition, technological innovations such as automation, integration with pneumatic conveying systems, and easier cleaning protocols have enhanced the efficiency and hygiene of jet mills These advancements are expected to drive deeper market penetration across sectors, positioning jet mills as a preferred solution for precision milling applications globally.

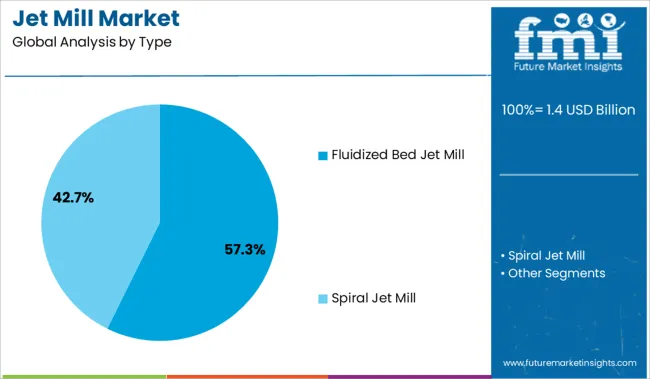

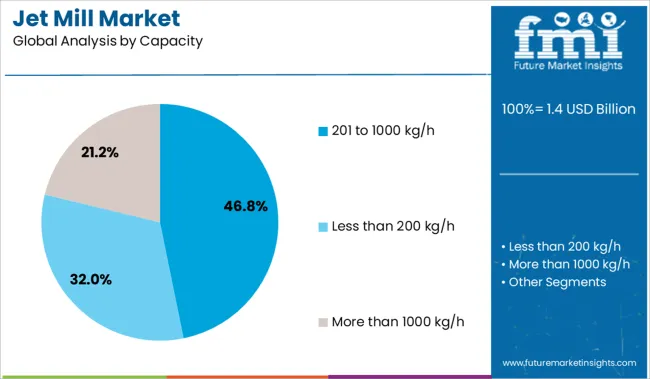

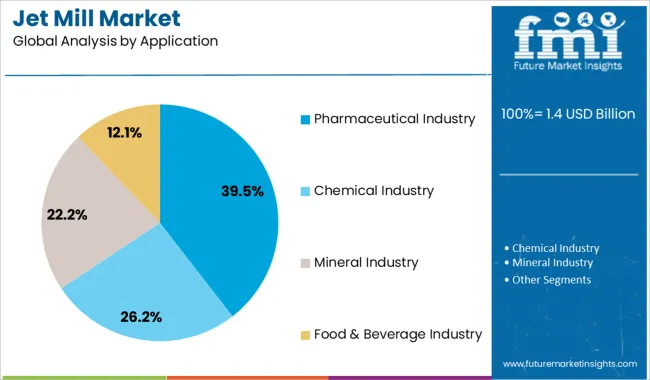

The market is segmented by Type, Capacity, Application, and Sales Channel and region. By Type, the market is divided into Fluidized Bed Jet Mill and Spiral Jet Mill. In terms of Capacity, the market is classified into 201 to 1000 kg/h, Less than 200 kg/h, and More than 1000 kg/h. Based on Application, the market is segmented into Pharmaceutical Industry, Chemical Industry, Mineral Industry, and Food & Beverage Industry. By Sales Channel, the market is divided into Offline and Online. Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The fluidized bed jet mill type is projected to account for 57.3% of the Jet Mill market revenue share in 2025, making it the dominant technology segment. Its leadership has been attributed to its ability to achieve uniform particle size distribution and high throughput while maintaining thermal stability during the milling process.

Industry engineering journals and corporate product releases have noted that the fluidized bed configuration reduces wear and contamination, making it ideal for handling sensitive or reactive materials. The segment’s prominence has also been supported by the rising demand for scalable, energy-efficient milling solutions in sectors requiring strict compliance with purity standards.

Process optimization, low maintenance requirements, and adaptability to a wide range of feed materials have reinforced its market position The continued preference for fluidized bed systems in pharmaceutical and specialty chemical processing has further strengthened its adoption across both established and emerging regions.

The 201 to 1000 kg/h capacity range is anticipated to contribute 46.8% of the Jet Mill market revenue share in 2025, emerging as the leading capacity segment. Its dominance has been supported by its suitability for mid-scale production lines that demand both flexibility and cost-efficiency.

Equipment specifications and operational reports from manufacturers have shown that this capacity range offers a balance between throughput and control, which is essential for industries like pharmaceuticals and fine chemicals where product quality is critical. The segment's growth has been further enabled by modular system designs that allow for integration into both batch and continuous processing environments.

Regulatory shifts requiring smaller, more controlled production environments have also favored this capacity band With increasing demand for formulation customization and product-specific milling requirements, this capacity segment has become a strategic choice for many manufacturers optimizing process reliability and cost across medium-scale operations.

The pharmaceutical industry application segment is expected to hold 39.5% of the Jet Mill market revenue share in 2025, establishing itself as the leading application area. Its prominence has been driven by the industry's strict requirement for particle size control, sterility, and non-contaminating milling processes.

Jet mills have become increasingly favored in the production of active pharmaceutical ingredients, where precise particle distribution significantly impacts bioavailability and drug performance. Product documentation and pharma equipment supplier statements have emphasized the benefits of jet mills in supporting cleanroom compliance, ease of validation, and suitability for potent compounds.

The ability to process heat-sensitive ingredients without degradation has also contributed to the segment’s strength In addition, global pharmaceutical expansions and increasing generic drug production have intensified the need for reliable and consistent micronization equipment, securing the segment's sustained growth.

As per FMI, the worldwide market for jet mills expanded from USD 1,001.1 Million in 2020 to USD 1,230.8 Million in 2025. The market observed a CAGR of 5.3% during the historical period (2020 to 2025).

However, with a growing end-user preference for jet mills over other traditional grinding solutions, the overall jet mill demand is slated to grow at 5.4% CAGR throughout the assessment period (2025 to 2035).

One of the main reasons influencing the market's expansion is the rising demand for high-end skin care and cosmetic goods among the general public. To give cosmetic items a fine and smooth texture, manufacturers of products crush crystalline and thermal ingredients in jet mills.

Similarly, the pharmaceutical sector's widespread product usage is boosting the market's expansion. To increase the potency and bioavailability of pharmaceutical components, jet mills are often employed for processing pigments and micronizing pharmaceuticals. Accordingly, the market is expanding due to the growing use of fluidized bed jet mills for the vertical and cylindrical milling of hard materials.

Several key factors have been identified by FMI that is likely to aid in the expansion of the global market for jet mills during the assessment period (2025 to 2035). Further, FMI analysts have also analyzed the restraining elements, upcoming threats, and lucrative opportunities that can somehow influence the sales of jet mills.

The drivers, restraints, opportunities, and threats (DROTs) identified are as follows:

DRIVERS

RESTRAINTS

OPPORTUNITIES

THREATS

The usage of alternative milling technologies may hamper the growth in the global market.

Booming Pharmaceutical Industry Propelling Jet Mill Demand in the USA

The jet mill industry in North America is developing rapidly with the US leading at the forefront. This is attributed to the rapid growth of the pharmaceutical industry, advancements in nanotechnology, and the growing adoption of highly efficient grinding technologies.

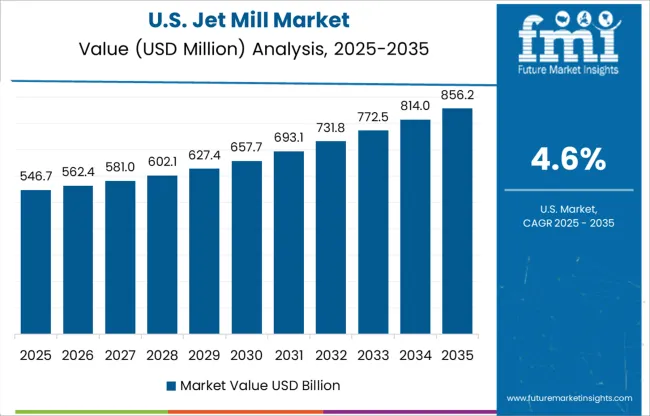

As per FMI, the worldwide jet mill market receives 32.1% of its total income from the United States. The country’s thriving pharmaceutical industry plays a key role in driving demand for jet mills.

Similarly, the number of companies manufacturing and selling jet mills is increasing every year. The competition among these companies is also increasing. This is leading to a decrease in the prices of jet mills.

The quality of jet mills is also improving. The new models are more efficient and have better performance than the older ones. This is attracting more customers to buy jet mills, which in turn will eventually fuel jet mill sales in the US during the forecast period.

Rising End User Preference Towards Better Grinding Technologies Boosting Market in Europe

There are several reasons for the growing demand for jet mills in Europe. First, the continent has a large manufacturing base that is constantly looking for ways to improve its competitiveness. Second, jet mills offer several advantages over traditional grinding methods, including higher productivity and lower energy consumption.

Third, European countries like Germany and the UK are increasingly investing in research and development activities related to jet mills. This is resulting in the development of new and improved jet milling technologies that are being commercialized by leading companies in the region.

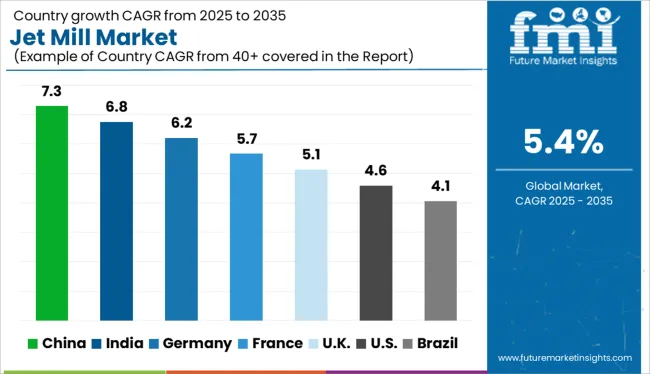

Thanks to these aforementioned factors, Germany holds around 25.1% of the global Jet Mill market, while the UK market is projected to expand at 6.0% CAGR over the projection period.

Rapid Growth of End-Use Industries Fostering Jet Mill Sales Across China and India

The market for jet mills is expanding rapidly in the Asia Pacific. This is due to the increasing demand for jet mills from various industries including chemical, pharmaceuticals, food processing, and cosmetics. Jet mills are also being used increasingly in the manufacturing of nanomaterials.

Asia Pacific is home to some of the world’s largest jet mill manufacturers, such as China, Japan, and South Korea. The market for jet mills is predicted to grow even further in the coming years, due to the increasing demand from countries like China and India. Jet mills are very efficient and provide a high-quality product. They are also easy to operate and maintain.

India and China are the market leaders in the Asia Pacific owing to the rapid expansion of pharmaceutical, chemical, and cosmetics industries in these countries. FMI has predicted CAGRs of 5.9% and 6.1% for the Indian and China markets respectively.

Various Advantages Offered by Fluidized Bed Jet Mills Making Them Highly SoughtAfter Types

Based on type, demand is expected to remain high for fluidized bed jet mills due to their ability to achieve smaller particle sizes and reduce material loss.

A fluidized bed jet mill is a type of mill that uses a fluidized bed to pulverize material. The material is placed in a chamber and then injected with a gas or air stream. The material is then ground by the force of the fluidized bed.

Fluidized bed jet mills are used for a variety of applications, including the grinding of pharmaceuticals, chemicals, and minerals. They can be used to grind both dry and wet materials. The mills are also capable of grinding materials to very fine particle sizes.

Furthermore, these mills possess features like low energy consumption, less pollution, uniform distribution, etc., making them highly sought-after jet mill types.

Pharmaceutical and Chemical Industries to Generate Maximum Revenues Through 2035

Based on application, the pharmaceutical industry, and chemical industry segments together hold the largest share of the global jet mill industry, and the trend is expected to continue over the projection period. This is attributed to the rising usage of jet mills across these target industries coupled with the growing demand for chemicals and pharmaceuticals worldwide.

Jet mills have been used in the pharmaceutical industry for decades and are increasingly being used in the industry as new drugs are developed. These mills work by using high-pressure air to grind particles down to a size that can be easily inhaled.

The mills can be used to create both dry and wet powders, which makes them versatile for use in different manufacturing processes. Jet mills are also very efficient, meaning that they use less energy and produce less waste than other types of grinding machines.

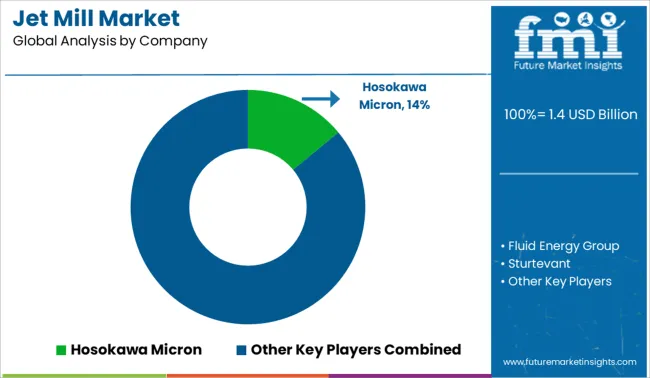

The jet mill market is highly competitive with the presence of several large and small vendors. Key manufacturers of jet mills are focused on expanding their product portfolios and geographical footprints to gain a larger share of the market.

Fluid Energy Group, Hosokawa Micron, Sturtevant, British Rema, and Continental Biomass Industries are some of the leading players in this market space. These companies hold a significant share of the jet mill industry due to their strong product portfolio and brand recognition.

Recent Developments:

| Attribute | Details |

|---|---|

| Estimated Market Size (2025) | USD 1.4 billion |

| Projected Market Size (2035) | USD 2.4 billion |

| Anticipated Growth Rate (2025 to 2035) | 5.4% CAGR |

| Forecast Period | 2025 to 2035 |

| Historical Data Available for | 2020 to 2025 |

| Market Analysis | USD Million for Value and Units for Volume |

| Key Regions Covered | North America; Europe; Asia Pacific; Latin America; Middle East & Africa (MEA); RoW |

| Key Countries Covered | The USA, Canada, Mexico, Germany, The UK, France, Russia, Brazil, Argentina, Japan, Australia, China, India, Indonesia, South Korea |

| Key Segments Covered | Type, Capacity, Application, Sales Channel, Region |

| Key Companies Profiled | Fluid Energy Group; Midas Microtech Engineering Private Limited; Hosokawa Micron; Sturtevant; British Rema; Continental Biomass Industries; FREUND Corporation; Erich NETZSCH GmbH & Co.; Loesche GmbH; Kunshan Unique Machinery Co. Ltd.; Kurimoto Ltd.; The Jet Pulverizer Co. Inc.; Tecnologia Meccanica; Promas Engineers Private Limited |

| Report Coverage | DROT Analysis, Market Forecast, Company Share Analysis, Market Dynamics and Challenges, Competitive Landscape, and Strategic Growth Initiatives |

The global jet mill market is estimated to be valued at USD 1.4 billion in 2025.

The market size for the jet mill market is projected to reach USD 2.4 billion by 2035.

The jet mill market is expected to grow at a 5.4% CAGR between 2025 and 2035.

The key product types in jet mill market are fluidized bed jet mill and spiral jet mill.

In terms of capacity, 201 to 1000 kg/h segment to command 46.8% share in the jet mill market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Jet Needle-free Injectors Market Size and Share Forecast Outlook 2025 to 2035

Jetting Pumps Market

Inkjet Printers Market Size and Share Forecast Outlook 2025 to 2035

Inkjet Printer Market in Korea – Growth & Demand Forecast through 2035

Inkjet Coders Market Growth - Trends & Outlook 2025 to 2035

Key Players & Market Share in the Inkjet Printers Industry

Inkjet Paper Market Trends & Industry Growth Forecast 2024-2034

Inkjet Label Market Trends & Industry Growth Forecast 2024-2034

Gas Jet Compressor Market Size and Share Forecast Outlook 2025 to 2035

Steam Jet Ejector Market

Binder Jet Market

MEMS Inkjet Heads Market Growth – Trends and Forecast 2025-2035

Business Jet Market Size and Share Forecast Outlook 2025 to 2035

Japan Inkjet Printer Market - Industry Trends & Forecast 2025 to 2035

Thermal Inkjet Printer Market Size and Share Forecast Outlook 2025 to 2035

Thermal Inkjet Inks Market Size and Share Forecast Outlook 2025 to 2035

Examining Market Share Trends in the Thermal Inkjet Printer Industry

Thermal & Inkjet Disc Printers Market Analysis by Ribbon Type, Supplier, Technology, and Region Through 2035

Continuous Inkjet Inks Market Forecast and Outlook 2025 to 2035

Continuous Inkjet Printers Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA