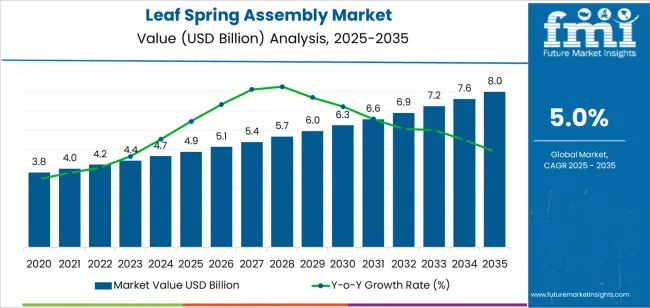

The leaf spring assembly market is valued at USD 4.9 billion in 2025 and is projected to reach USD 8.0 billion by 2035, growing at a CAGR of 5.0% over the forecast period. The expansion traces rising global demand for commercial trucks, trailers, buses, and off-highway equipment that require suspension systems with high load-bearing strength, reliable shock absorption, durability under continuous use, and maintenance-friendly configurations. Between 2025 and 2030, the market increases to USD 6.3 billion, accounting for 43.9% of the decade growth as freight transport networks expand, logistics fleets scale up, and new vehicle production accelerates in China, India, and North America.

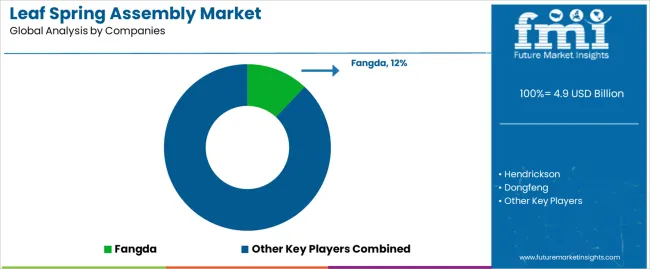

The period from 2030 to 2035 contributes USD 1.7 billion in additional growth as electric commercial vehicle platforms mature, chassis lightweighting intensifies, and manufacturers adopt advanced spring steels and composite reinforcement to optimize strength-to-weight performance. Multi-leaf springs hold the majority share due to proven reliability in heavy-load environments, while mono-leaf designs gain gradual traction in pickup trucks and emerging EV utility platforms where weight reduction is prioritized. Automotive applications account for approximately 70% of total demand, supported by commercial truck production cycles and aftermarket replacement volumes, while machinery applications benefit from agricultural, mining, and construction equipment deployment. East Asia and South Asia lead regional adoption due to manufacturing scale, while Europe and North America sustain steady replacement-driven demand. Key players such as Fangda, Hendrickson, Jamna Auto Industries, Fawer, Dongfeng, and San Luis Rassini reinforce competitive positioning through metallurgy improvements, process automation, and OEM integration partnerships.

Commercial vehicle manufacturers and equipment producers are expanding their leaf spring assembly capabilities to address the growing demand for durable and high-performance suspension solutions that ensure vehicle stability and operational reliability.

From 2030 to 2035, the market is forecast to grow from USD 6.3 billion to USD 8.0 billion, adding another USD 1.7 billion, which constitutes 56.1% of the ten-year expansion. This period is expected to be characterized by the expansion of electric commercial vehicle platforms and lightweight suspension technologies, the development of composite material integration and advanced coating systems, and the growth of specialized applications for autonomous vehicle chassis and next-generation mobility solutions. The growing adoption of weight optimization strategies and advanced manufacturing technologies will drive demand for leaf spring assemblies with enhanced performance and reduced environmental impact characteristics.

Between 2020 and 2025, the leaf spring assembly market experienced steady growth, driven by increasing commercial vehicle demand and growing recognition of leaf springs as essential suspension components for heavy-load applications across diverse vehicle platforms. The market developed as vehicle engineers and chassis designers recognized the potential for leaf spring technology to provide superior load-carrying capacity, deliver cost-effective suspension solutions, and support operational objectives while meeting stringent performance requirements. Technological advancement in spring steel metallurgy and heat treatment processes began emphasizing the critical importance of maintaining fatigue resistance and dimensional stability in challenging operating environments.

| Metric | Value |

|---|---|

| Estimated Value in (2025E) | USD 4.9 billion |

| Forecast Value in (2035F) | USD 8.0 billion |

| Forecast CAGR (2025 to 2035) | 5.0% |

Market expansion is being supported by the increasing global demand for commercial vehicles and heavy-duty transportation solutions driven by infrastructure development and logistics sector growth, alongside the corresponding need for reliable suspension components that can deliver superior load-carrying capacity, ensure vehicle stability, and maintain operational efficiency across various truck, trailer, and off-highway equipment applications. Modern vehicle manufacturers and equipment producers are increasingly focused on implementing leaf spring assembly solutions that can withstand heavy loads, provide consistent performance, and deliver reliable operation in demanding service conditions.

The growing emphasis on transportation efficiency and vehicle durability is driving demand for suspension components that can support payload optimization, enable extended service life, and ensure comprehensive operational reliability. Commercial vehicle operators' preference for suspension systems that combine load capacity with installation simplicity and maintenance efficiency is creating opportunities for innovative leaf spring assembly implementations. The rising influence of e-commerce logistics and infrastructure development projects is also contributing to increased adoption of leaf spring assemblies that can provide superior durability characteristics without compromising vehicle performance or operational economics.

The market is segmented by spring type, application, and region. By spring type, the market is divided into multi-leaf spring, mono-leaf spring, and others. Based on application, the market is categorized into automotive and machinery. Regionally, the market is analyzed across East Asia, South Asia, Europe, North America, Latin America, United Kingdom, and Japan.

The multi-leaf spring segment is projected to maintain its leading position in the leaf spring assembly market in 2025, holding a 55% market share. This segment reaffirms its role as the preferred product category for heavy-duty commercial vehicles and industrial equipment applications. Vehicle manufacturers and equipment producers increasingly utilize multi-leaf springs for their exceptional load-carrying capacity, proven durability characteristics, and reliable performance across diverse operating conditions. Multi-leaf spring technology's proven effectiveness and application versatility directly address the industry requirements for heavy payload support and cost-effective suspension solutions across diverse commercial vehicle platforms and equipment categories.

This product segment forms the foundation of commercial vehicle suspension systems, as it represents the spring configuration with the greatest combination of load capacity and established performance record across multiple vehicle types and duty cycles. Commercial transportation investments continue to strengthen adoption among vehicle manufacturers and fleet operators. With regulatory pressures requiring enhanced vehicle safety and improved payload efficiency, multi-leaf spring assemblies align with both operational objectives and economic requirements, making them the central component of comprehensive commercial vehicle suspension strategies.

The automotive application segment is projected to represent the largest share of leaf spring assembly demand in 2025, capturing around 70% of the market share. This underscores its critical role as the primary driver for leaf spring adoption across commercial trucks, pickup trucks, and sport utility vehicles. Vehicle manufacturers prefer leaf spring assemblies for suspension systems due to their exceptional load-carrying capabilities, durability under stress, and ability to provide reliable performance while supporting vehicle stability and regulatory compliance. Positioned as essential components for commercial and utility vehicle platforms, leaf spring assemblies offer both performance advantages and economic benefits.

The segment is supported by continuous growth in commercial vehicle production and the growing availability of advanced spring materials that enable superior suspension performance with enhanced fatigue resistance and reduced maintenance requirements. Vehicle manufacturers are investing in comprehensive suspension system programs to support increasingly stringent safety regulations and customer demand for reliable transportation solutions. As commercial vehicle demand increases and performance standards evolve, the automotive application will continue to dominate the market while supporting advanced leaf spring utilization and suspension optimization strategies.

The leaf spring assembly market is advancing steadily due to increasing demand for commercial vehicle suspension solutions driven by freight transportation growth and growing adoption of heavy-duty equipment that requires specialized suspension technologies providing superior load capacity and durability benefits across diverse truck, trailer, and machinery applications. The market faces challenges, including competition from alternative suspension technologies including air suspension and coil spring systems, price pressure from cost-conscious commercial vehicle segments, and supply chain constraints related to steel raw material availability and manufacturing capacity limitations. Innovation in material technologies and manufacturing process optimization continues to influence product development and market expansion patterns.

The growing freight transportation industry is driving demand for specialized commercial vehicle suspension systems that address payload requirements including heavy load capacity, reliable performance under continuous operation, and optimized vehicle stability for safety compliance. Commercial trucks and trailers require advanced leaf spring assemblies that deliver superior performance across multiple operational parameters while maintaining cost-effectiveness and service life. Vehicle manufacturers are increasingly recognizing the competitive advantages of leaf spring integration for commercial vehicle development and payload optimization, creating opportunities for innovative spring designs specifically engineered for modern logistics applications.

Modern leaf spring manufacturers are incorporating advanced spring steel alloys and precision manufacturing processes to enhance fatigue resistance, improve dimensional accuracy, and support comprehensive quality objectives through optimized heat treatment procedures and surface finishing technologies. Leading companies are developing high-strength steel formulations, implementing automated production systems, and advancing manufacturing technologies that enhance product consistency and performance reliability. These technologies improve durability credentials while enabling new market opportunities, including lightweight vehicle applications, extended service interval requirements, and high-performance suspension systems. Advanced manufacturing integration also allows producers to support comprehensive quality assurance objectives and market differentiation beyond traditional product attributes.

The expansion of fuel efficiency regulations and vehicle weight reduction initiatives is driving demand for lightweight suspension components with optimized strength-to-weight ratios and advanced material compositions. These weight optimization requirements are creating specialized spring configurations with composite material integration and advanced design methodologies that support efficiency objectives, creating premium market segments with differentiated performance propositions. Manufacturers are investing in composite material development and hybrid spring systems to serve emerging lightweight vehicle markets while supporting innovation in commercial vehicle and equipment industries.

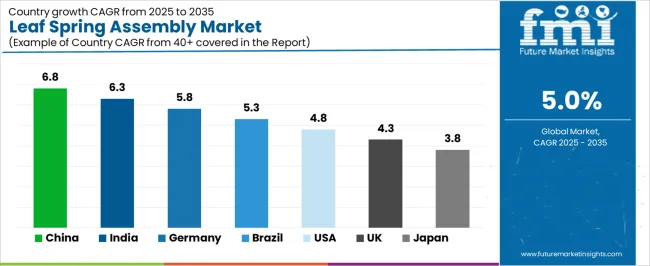

| Country | CAGR (2025-2035) |

|---|---|

| China | 6.8% |

| India | 6.3% |

| Germany | 5.8% |

| Brazil | 5.3% |

| United States | 4.8% |

| United Kingdom | 4.3% |

| Japan | 3.8% |

The leaf spring assembly market is experiencing solid growth globally, with China leading at a 6.8% CAGR through 2035, driven by massive commercial vehicle production, expanding logistics infrastructure, and growing construction equipment manufacturing. India follows at 6.3%, supported by increasing commercial vehicle demand, expanding manufacturing sector, and government infrastructure development initiatives. Germany shows growth at 5.8%, emphasizing commercial vehicle engineering, advanced manufacturing technologies, and export-oriented production. Brazil demonstrates 5.3% growth, supported by agricultural equipment demand, commercial vehicle market expansion, and infrastructure development programs. The United States records 4.8%, focusing on pickup truck production, commercial trailer manufacturing, and heavy-duty equipment applications. The United Kingdom exhibits 4.3% growth, driven by commercial vehicle production and aftermarket replacement demand. Japan shows 3.8% growth, emphasizing quality manufacturing and specialized vehicle applications.

The report covers an in-depth analysis of major markets, with top-performing countries are highlighted below.

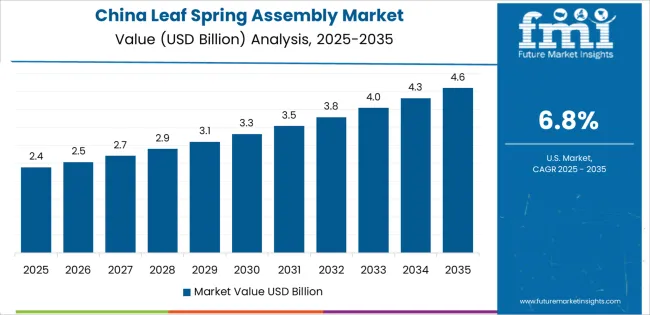

Revenue from leaf spring assemblies in China is projected to exhibit exceptional growth with a CAGR of 6.8% through 2035, driven by massive commercial vehicle manufacturing capacity and rapidly expanding logistics infrastructure supported by government Belt and Road initiatives and construction sector development programs. The country's comprehensive transportation infrastructure expansion and increasing investment in commercial vehicle technologies are creating substantial demand for leaf spring assembly solutions. Major automotive component manufacturers and spring producers are establishing comprehensive production capabilities to serve both domestic markets and export opportunities.

Demand for leaf spring assemblies in India is expanding at a CAGR of 6.3%, supported by the country's rapidly growing commercial vehicle sector, expanding manufacturing industry, and increasing government investment in road infrastructure and logistics development. The country's comprehensive automotive manufacturing programs and infrastructure modernization initiatives are driving sophisticated leaf spring assembly capabilities throughout diverse application sectors. Leading automotive component suppliers and manufacturers are establishing production and assembly facilities to address growing domestic demand.

Revenue from leaf spring assemblies in Germany is growing at a CAGR of 5.8%, supported by the country's premium commercial vehicle sector, advanced manufacturing technologies, and engineering expertise supporting specialized suspension development for high-performance applications. Germany's automotive engineering excellence and component manufacturing leadership are driving advanced leaf spring capabilities throughout commercial vehicle sectors. Leading automotive suppliers and component manufacturers are establishing comprehensive development programs for specialized suspension technologies.

Demand for leaf spring assemblies in Brazil is anticipated to expand at a CAGR of 5.3%, supported by agricultural equipment manufacturing, commercial vehicle market growth, and increasing infrastructure development activities. The nation's agricultural sector importance and commercial vehicle demand are driving requirements for reliable suspension components. Component suppliers and manufacturers are investing in production capabilities and distribution networks to serve growing regional demand.

Revenue from leaf spring assemblies in the United States is projected to grow at a CAGR of 4.8%, supported by strong pickup truck production, commercial trailer manufacturing, and heavy-duty equipment applications across construction and agricultural sectors. The nation's mature automotive market and specialized vehicle production are driving demand for reliable leaf spring solutions. Component manufacturers and suppliers are maintaining production capabilities and distribution networks to serve diverse market requirements.

Demand for leaf spring assemblies in the United Kingdom is expanding at a CAGR of 4.3%, driven by commercial vehicle manufacturing, trailer production activities, and aftermarket replacement demand for aging vehicle fleets. The country's commercial vehicle sector and component distribution networks are supporting leaf spring assembly capabilities throughout automotive sectors. Component suppliers and distributors are establishing service programs for original equipment and replacement markets.

Revenue from leaf spring assemblies in Japan is growing at a CAGR of 3.8%, supported by the country's quality manufacturing standards, specialized commercial vehicle applications, and emphasis on precision component production and durability. Japan's technological sophistication and manufacturing excellence are driving demand for high-specification leaf spring products. Leading component manufacturers and automotive suppliers are maintaining specialized capabilities for quality suspension component production.

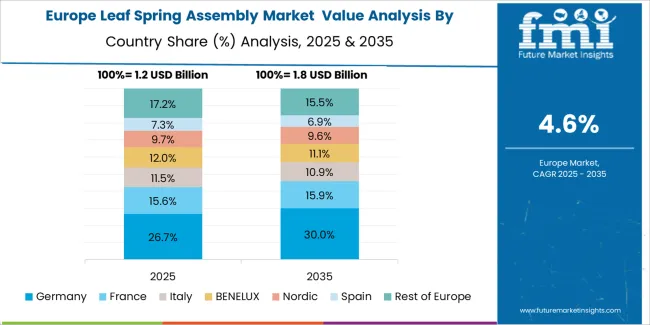

The leaf spring assembly market in Europe is projected to grow from USD 968.5 million in 2025 to USD 1,564.3 million by 2035, registering a CAGR of 4.9% over the forecast period. Germany is expected to maintain leadership with a 32.6% market share in 2025, moderating to 31.9% by 2035, supported by commercial vehicle engineering excellence, advanced manufacturing capabilities, and strong export-oriented production.

France follows with 16.4% in 2025, projected at 16.8% by 2035, driven by commercial vehicle production, agricultural equipment manufacturing, and automotive component sector development. The United Kingdom holds 14.7% in 2025, declining slightly to 14.3% by 2035 due to market maturation and production adjustments. Italy commands 11.9% in 2025, rising to 12.3% by 2035, while Spain accounts for 9.2% in 2025, reaching 9.6% by 2035 aided by commercial vehicle assembly and component production. The Netherlands maintains 5.8% in 2025, up to 6.1% by 2035 due to trailer manufacturing and logistics equipment demand. The Rest of Europe region, including Nordic countries, Central and Eastern Europe, and other markets, is anticipated to hold 9.4% in 2025 and 9.0% by 2035, reflecting steady development in commercial vehicle component manufacturing and equipment production.

The leaf spring assembly market is characterized by competition among established automotive component manufacturers, specialized spring producers, and integrated automotive suppliers. Companies are investing in advanced steel material development, manufacturing process optimization, product quality enhancement, and global distribution network expansion to deliver reliable, cost-effective, and high-performance leaf spring assembly solutions. Innovation in spring steel metallurgy, heat treatment processes, and coating technologies is central to strengthening market position and competitive advantage.

Fangda leads the market with comprehensive leaf spring assembly solutions with a focus on commercial vehicle applications, advanced manufacturing capabilities, and extensive product range across diverse suspension requirements. Hendrickson provides innovative suspension systems with emphasis on heavy-duty truck applications and engineered suspension solutions. Dongfeng delivers automotive components with focus on commercial vehicle integration and original equipment supply. Jamna Auto Industries offers specialized leaf spring products with emphasis on commercial vehicle and automotive applications across domestic and export markets. Fawer provides integrated automotive component solutions with comprehensive suspension system offerings. San Luis Rassini delivers suspension components with focus on commercial vehicle and light truck applications across North American and global markets.

Additional market participants include Shuaichai focusing on commercial vehicle components, Eaton Detroit Spring offering specialized suspension products, Chongqing Hongqi providing regional manufacturing capabilities, Hubei Shenfeng emphasizing commercial vehicle applications, NHK Spring delivering precision spring products, Leopord focusing on automotive suspension components, Mitsubishi Steel offering advanced steel materials and spring products, Shuangli Banhuang providing commercial vehicle components, Standens emphasizing agricultural and commercial equipment, Owen Springs offering specialized spring solutions, Hayward focusing on aftermarket and original equipment supply, Hunan Yitong providing regional manufacturing capabilities, Sogefi delivering integrated automotive components, Anhui Anhuang emphasizing domestic market supply, Shandong Fangcheng focusing on commercial vehicle applications, Zhengzhou Xinjiaotong providing regional component manufacturing, Jiangxi Automobile Leaf Spring offering specialized production capabilities, and Eagle Suspensions delivering aftermarket suspension solutions.

Leaf spring assemblies represent a specialized automotive component segment within commercial vehicle and machinery applications, projected to grow from USD 4,899.9 million in 2025 to USD 7,981.4 million by 2035 at a 5.0% CAGR. These suspension components serve as critical mechanical elements in commercial trucks, trailers, and off-highway equipment where superior load-carrying capacity, durability under stress, and reliable vehicle stability are essential. Market expansion is driven by increasing commercial vehicle production, growing freight transportation demand, expanding construction and agricultural equipment sectors, and rising requirements for durable suspension solutions across diverse automotive and machinery applications.

How Automotive Regulators Could Strengthen Component Standards and Vehicle Safety?

How Industry Associations Could Advance Technology Standards and Market Development?

How Leaf Spring Manufacturers Could Drive Innovation and Market Leadership?

How End-User Industries Could Optimize Component Performance and Vehicle Reliability?

How Research Institutions Could Enable Technology Advancement?

How Investors and Financial Enablers Could Support Market Growth and Innovation?

| Items | Values |

|---|---|

| Quantitative Units (2025) | USD 4.9 billion |

| Spring Type | Multi-Leaf Spring, Mono-Leaf Spring, Others |

| Application | Automotive, Machinery |

| Countries Covered | China, India, Germany, Brazil, United States, United Kingdom, Japan |

| Key Companies Profiled | Fangda, Hendrickson, Dongfeng, Jamna Auto Industries, Fawer, San Luis Rassini |

| Additional Attributes | Dollar sales by spring type and application category, regional demand trends, competitive landscape, technological advancements in spring steel materials, manufacturing process optimization, and suspension performance enhancement |

The global leaf spring assembly market is estimated to be valued at USD 4.9 billion in 2025.

The market size for the leaf spring assembly market is projected to reach USD 8.0 billion by 2035.

The leaf spring assembly market is expected to grow at a 5.0% CAGR between 2025 and 2035.

The key product types in leaf spring assembly market are multi-leaf spring .

In terms of application, automotive segment to command 70.0% share in the leaf spring assembly market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Leaf Rolling Machine Market Size and Share Forecast Outlook 2025 to 2035

Bay Leaf Oil Market Size and Share Forecast Outlook 2025 to 2035

Bay Leaf Market Size and Share Forecast Outlook 2025 to 2035

Olive Leaf Extract Market

Mullein Leaf Market Size and Share Forecast Outlook 2025 to 2035

Eucommia Leaf Extract Market Size and Share Forecast Outlook 2025 to 2035

Red Vine Leaf Extract Market Size and Share Forecast Outlook 2025 to 2035

Lawn and Leaf Bags Market Size and Share Forecast Outlook 2025 to 2035

Peppermint Leaf Powder Market

Abies Alba (Fir) Leaf Oil Market – Growth & Demand 2025 to 2035

Camellia Sinensis Leaf Extract Market

Non-Selective Broadleaf Herbicides Market Size and Share Forecast Outlook 2025 to 2035

Automotive Composite Leaf Springs Market Growth - Trends & Forecast 2025 to 2035

Platycladus Orientalis Leaf Extract Market Size and Share Forecast Outlook 2025 to 2035

USA Automotive Composite Leaf Springs Market Analysis – Size & Industry Trends 2025-2035

China Automotive Composite Leaf Springs Market Trends – Size, Share & Growth 2025-2035

Japan Automotive Composite Leaf Springs Market Insights – Growth & Demand 2025-2035

India Automotive Composite Leaf Springs Market Trends – Size, Share & Growth 2025-2035

Germany Automotive Composite Leaf Springs Market Report – Demand & Forecast 2025-2035

Spring Applied Clutches Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA