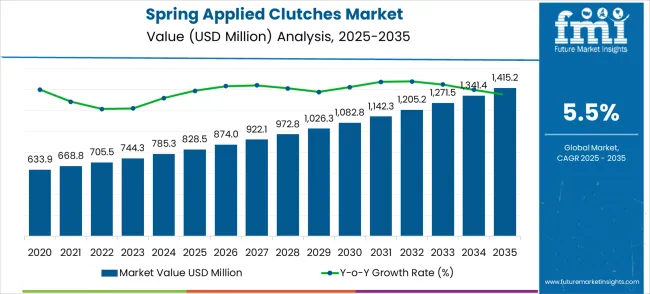

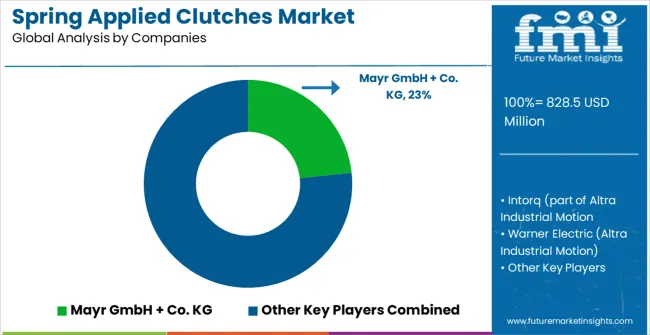

The spring applied clutches market is anticipated to advance from USD 828.5 million in 2025 to USD 1,415.2 million by 2035, reflecting a CAGR of 5.5% and a multiplication factor of nearly 1.7X over the decade. Elasticity of growth in this market is closely tied to manufacturing output, capital investment cycles, and demand for industrial automation. When macroeconomic conditions such as GDP expansion, growth in construction activity, and increased machinery production strengthen, demand for spring applied clutches accelerates. These clutches are widely used in heavy equipment, packaging systems, and industrial machinery, making them directly responsive to business investment trends and industrial productivity levels.

In periods of macroeconomic slowdown or reduced capital expenditure, elasticity demonstrates its counter-effect as demand for machinery components contracts. The resilience in sectors like food processing, logistics, and renewable energy supports baseline growth, cushioning the market against volatility. As economies invest more in automated systems and energy-efficient machinery, the demand elasticity strengthens, reflecting higher responsiveness to positive economic indicators. Additionally, long-term adoption in emerging regions provides an extended buffer, as industrialization and infrastructure development create consistent growth opportunities. This interplay between macroeconomic drivers and elasticity highlights a balanced trajectory, where the market sustains progress while adapting to cyclical economic pressures.

| Metric | Value |

|---|---|

| Estimated Value in (2025E) | USD 828.5 million |

| Forecast Value in (2035F) | USD 1,415.2 million |

| Forecast CAGR (2025 to 2035) | 5.5% |

The spring applied clutches market is structured across automation and industrial machinery (34%), automotive systems (26%), material handling equipment (18%), robotics (12%), and aerospace and defense applications (10%). Automation and machinery lead adoption as these clutches ensure safety braking and torque transmission in heavy-duty operations. Automotive use is rising due to growing demand for reliable braking systems and energy efficiency. Material handling equipment utilizes spring applied clutches for controlled stopping and load management, while robotics depends on precise torque control and fail-safe braking.

Aerospace and defense sectors apply these clutches in mission-critical systems requiring reliability under demanding conditions. Recent advancements include integration with smart sensors for predictive maintenance, compact lightweight designs for energy savings, and enhanced friction materials for durability. Collaboration between clutch manufacturers and automation providers is producing tailored solutions. Rising focus on safety, operational efficiency, and high-performance motion control is fueling adoption across multiple sectors worldwide.

Market expansion is being supported by the increasing global demand for reliable power transmission components and the corresponding need for safety-critical clutch systems that can provide emergency braking and precise positioning across various industrial applications. Modern machinery operators and equipment manufacturers are increasingly focused on implementing clutch solutions that can ensure operational safety, provide accurate torque control, and maintain reliable performance under demanding operating conditions. Spring applied clutches' proven ability to deliver fail-safe operation, emergency braking capabilities, and precise positioning control make them essential components for contemporary industrial machinery and automotive applications.

The growing emphasis on workplace safety and operational reliability is driving demand for spring-applied clutches that can support safety regulations, provide emergency stopping capabilities, and enable predictable machinery control without compromising operational efficiency or equipment performance. Industrial operators' preference for components that combine safety features with operational precision and maintenance convenience is creating opportunities for innovative clutch implementations. The rising influence of automation technologies and electric vehicle adoption is also contributing to increased demand for spring-applied clutches that can provide precise control and safety benefits in advanced mechanical systems.

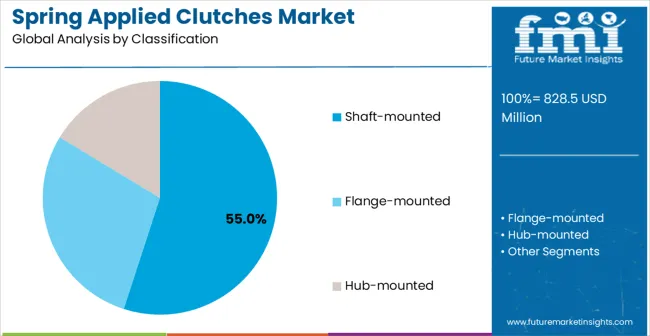

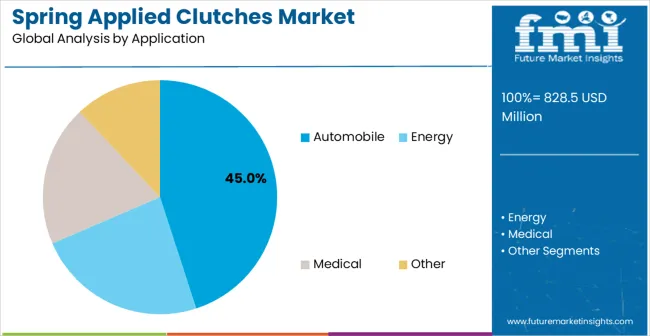

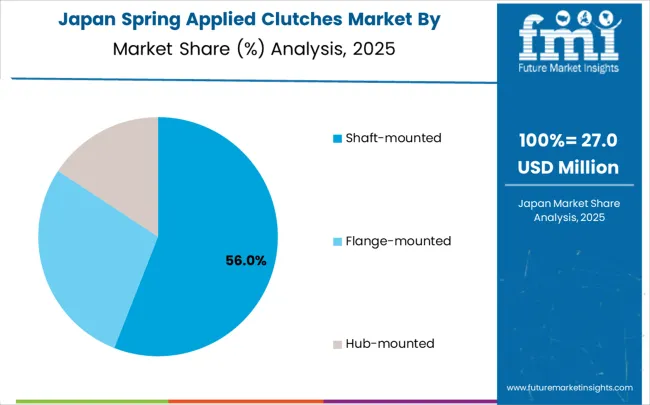

The spring applied clutches market is growing steadily, supported by demand from power transmission applications across industries. Shaft-mounted clutches dominate the mounting type segment with approximately 55% of the market share, widely preferred for their compact design, easy installation, and reliable torque transmission. On the application side, the automobile sector leads with about 45% of the market, driven by the rising need for efficient braking and transmission systems in passenger and commercial vehicles.

Shaft-mounted clutches account for nearly 55% of the mounting type segment, making them the most widely adopted option. Their direct mounting on drive shafts simplifies installation while minimizing alignment issues. These clutches typically provide torque capacity in the range of 50–1,000 Nm, with high response reliability under repeated engagement cycles. Leading manufacturers include Warner Electric, KEB Automation, Ortlinghaus, and Nexen Group. Shaft-mounted designs are favored in machinery requiring compact power transmission solutions, ensuring smooth operation while reducing system downtime.

The automobile sector represents around 45% of the application market, making it the leading user of spring applied clutches. They are extensively used in braking systems, powertrains, and auxiliary vehicle mechanisms to ensure safety and efficiency. Automobiles demand clutches with consistent torque control, quick response times, and durability under high operating temperatures and vibrations. Key suppliers such as Warner Electric, KEB Automation, Ortlinghaus, and Nexen Group provide models tailored to automotive applications. Growth is driven by rising global vehicle production and the need for advanced safety systems in both passenger and commercial vehicles.

The spring-applied clutches market is advancing steadily due to increasing demand for safety-critical power transmission components and growing adoption of automated machinery that requires reliable torque control and emergency braking capabilities across diverse industrial applications. The market faces challenges, including competition from alternative clutch technologies, the complexity of system integration requirements, and the need for specialized maintenance expertise. Innovation in smart control systems and advanced materials continues to influence product development and market expansion patterns.

The growing adoption of industrial automation and robotic systems is driving demand for spring-applied clutches that can support precise positioning control, emergency stopping capabilities, and reliable power transmission in automated manufacturing environments. Advanced automation systems require specialized clutch solutions while enabling more efficient production processes and enhanced operational safety across various industrial applications and equipment configurations. Manufacturers are increasingly recognizing the competitive advantages of automation-compatible clutch capabilities for industrial market expansion and technology leadership.

Modern spring-applied clutch producers are incorporating smart control systems and sensor technologies to enable real-time performance monitoring, predictive maintenance capabilities, and enhanced operational intelligence for industrial and automotive applications. These technologies improve system reliability while enabling new applications, including remote monitoring systems and automated maintenance scheduling. Advanced sensor integration also allows operators to support sophisticated control strategies and operational optimization beyond traditional clutch performance metrics.

| Country | CAGR (2025-2035) |

|---|---|

| China | 7.4% |

| India | 6.9% |

| Germany | 6.3% |

| Brazil | 5.8% |

| USA | 5.2% |

| UK | 4.7% |

| Japan | 4.1% |

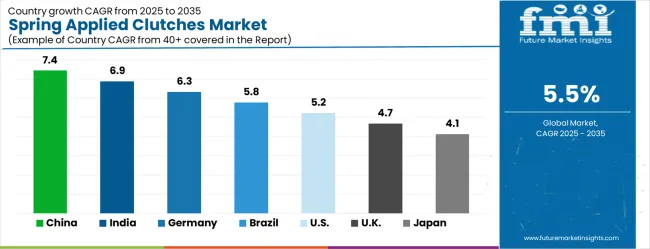

The spring-applied clutches market is experiencing strong growth globally, with China leading at a 7.4% CAGR through 2035, driven by the expanding manufacturing sector, growing automotive production, and significant investment in industrial automation technologies. India follows at 6.9%, supported by rapid industrialization, increasing automotive manufacturing, and growing emphasis on manufacturing safety and operational efficiency. Germany shows growth at 6.3%, emphasizing technological innovation and advanced precision engineering solutions. Brazil records 5.8%, focusing on automotive industry expansion and industrial modernization programs. The USA demonstrates 5.2% growth, driven by manufacturing sector recovery and advanced automation adoption. The UK exhibits 4.7% growth, supported by industrial modernization and automotive technology development. Japan shows 4.1% growth, emphasizing precision manufacturing and advanced mechanical component technologies.

The report covers an in-depth analysis of 40+ countries, Top-performing countries are highlighted below.

The spring-applied clutches market in China is projected to exhibit exceptional growth with a CAGR of 7.4% through 2035, driven by expanding manufacturing infrastructure and rapidly growing automotive production supported by government industrial modernization initiatives. The country's massive industrial sector and increasing investment in automation technology are creating substantial demand for advanced clutch solutions. Major automotive manufacturers and industrial equipment producers are establishing comprehensive clutch capabilities to serve both domestic and international markets.

The spring-applied clutches market in India is expanding at a CAGR of 6.9%, supported by the country's rapid industrialization, growing automotive manufacturing sector, and increasing emphasis on manufacturing safety and operational efficiency in industrial operations. The country's expanding industrial infrastructure and increasing manufacturing capabilities are driving demand for advanced clutch technologies. International clutch manufacturers and domestic distributors are establishing extensive distribution networks to address the growing demand for precision mechanical components.

The spring-applied clutches market in Germany is expanding at a CAGR of 6.3%, supported by the country's advanced manufacturing industry, strong emphasis on technological innovation, and robust demand for precision engineering solutions among leading automotive and industrial manufacturers. The nation's established automotive sector and focus on engineering excellence are driving sophisticated clutch capabilities throughout the industrial supply chain. Leading manufacturers are investing extensively in advanced clutch development and precision manufacturing methods to serve both domestic and export markets.

The demand for spring-applied clutches in Brazil is growing at a CAGR of 5.8%, driven by expanding automotive industry activities, increasing industrial modernization programs, and growing investment in manufacturing safety and operational efficiency enhancement. The country's growing automotive sector and modernization of industrial facilities are supporting demand for advanced clutch solutions across major production regions. Automotive manufacturers and industrial companies are establishing comprehensive clutch capabilities to serve both domestic and export market requirements.

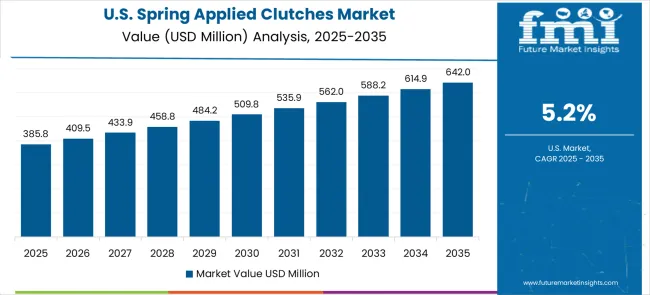

The spring-applied clutches market in the USA is expanding at a CAGR of 5.2%, supported by the country's manufacturing sector recovery, established automotive industry, and strong emphasis on advanced technology adoption and operational safety enhancement. The nation's mature industrial base and focus on manufacturing competitiveness are driving demand for advanced clutch technologies, focusing on safety and reliability performance. Manufacturers are investing in comprehensive clutch solutions to serve both automotive and industrial markets with proven safety-critical components.

Demand for spring-applied clutches in the UK is growing at a CAGR of 4.7%, driven by the country's industrial modernization initiatives, automotive technology development programs, and emphasis on manufacturing safety and operational efficiency across industrial sectors. The UK's established manufacturing sector and focus on operational excellence are supporting investment in advanced clutch technologies throughout major industrial centers. Leading manufacturers are establishing comprehensive clutch capabilities to serve both automotive and industrial markets with reliable safety-critical solutions.

The spring applied clutches market in Japan is expanding at a CAGR of 4.1%, supported by the country's focus on precision manufacturing, emphasis on advanced technology development, and strong preference for high-quality mechanical components with superior performance characteristics. Japan's sophisticated manufacturing industry and focus on engineering excellence are driving demand for advanced clutch technologies, including precision-engineered solutions and smart control systems. Leading manufacturers are investing in specialized capabilities to serve automotive, industrial, and machinery segments with premium clutch solutions.

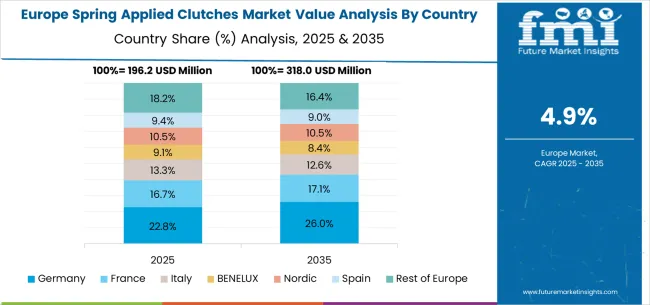

The spring-applied clutches market in Europe is projected to grow from USD 192.4 million in 2025 to USD 328.8 million by 2035, registering a CAGR of 5.5% over the forecast period. Germany is expected to maintain its leadership position with a 33.7% market share in 2025, moderating slightly to 33.4% by 2035, supported by its strong automotive industry, advanced manufacturing capabilities, and comprehensive precision engineering networks serving major European markets.

The United Kingdom follows with a 20.1% share in 2025, projected to reach 20.3% by 2035, driven by robust industrial modernization initiatives, an established automotive sector, and strong demand for advanced clutch solutions across manufacturing and automotive applications. France holds a 16.8% share in 2025, rising to 17.0% by 2035, supported by automotive industry development and increasing adoption of safety-critical manufacturing technologies in industrial operations. Italy records 12.4% in 2025, inching to 12.5% by 2035, with growth underpinned by manufacturing sector modernization and increasing emphasis on operational safety in industrial facilities. Spain contributes 9.2% in 2025, moving to 9.3% by 2035, supported by expanding automotive activities and industrial development programs. The Netherlands maintains a 3.1% share in 2025, growing to 3.2% by 2035. The Rest of Europe region, including Nordic countries, Eastern Europe, Belgium, Switzerland, and Austria, is anticipated to gain momentum, expanding its collective share from 4.7% to 4.3% by 2035, attributed to increasing adoption of advanced manufacturing technologies in Nordic countries and growing industrial activities across Eastern European markets implementing modernization programs.

The spring-applied clutches market is characterized by competition among established mechanical component manufacturers, specialized clutch technology providers, and integrated power transmission solution companies. Companies are investing in advanced materials research, precision manufacturing enhancement, smart control system integration, and comprehensive product portfolios to deliver consistent, high-performance, and reliable clutch solutions. Innovation in spring mechanisms, control technologies, and sensor integration is central to strengthening market position and competitive advantage.

Mayr GmbH + Co. KG leads the market with a strong market share, offering comprehensive clutch solutions with a focus on advanced engineering and safety-critical applications. Intorq provides specialized clutch products with an emphasis on industrial automation and precision control systems. Warner Electric delivers innovative clutch technologies with a focus on automotive and industrial markets. Kendrion N.V. specializes in electromagnetic clutch solutions with emphasis on advanced control and automation applications. Ortlinghaus-Werke GmbH focuses on precision clutch systems and specialized engineering solutions for demanding applications. SINFONIA Technology Co., Ltd. offers comprehensive clutch products with emphasis on the industrial and automotive sectors.

Spring-applied clutches represent a safety-critical power transmission segment within industrial machinery and automotive systems, projected to grow from USD 828.5 million in 2025 to USD 1,415.2 million by 2035 at a 5.5% CAGR. These fail-safe mechanical components—primarily shaft-mounted configurations for versatile installation—provide emergency braking and precise torque control across automobile applications (USD 286.7 million in 2025), energy systems, and medical equipment requiring reliable safety mechanisms. Market expansion is driven by increasing industrial automation demands, growing automotive safety requirements, rising workplace safety regulations, and expanding electric vehicle technologies requiring precise power transmission control and fail-safe operation capabilities.

How Industrial Safety Organizations Could Strengthen Safety Standards and Compliance?

How Automotive Manufacturers Could Optimize Safety Systems and Performance?

How Component Manufacturers Could Drive Innovation and Market Leadership?

How Industrial Equipment Manufacturers Could Enhance Machine Safety and Performance?

How Industrial Maintenance Organizations Could Optimize Equipment Reliability and Safety?

How Investors and Financial Enablers Could Support Market Development and Safety Innovation?

| Items | Values |

|---|---|

| Quantitative Units (2025) | USD 828.5 million |

| Mounting Type | Shaft-mounted, Flange-mounted, Hub-mounted, Others |

| Application | Automobile, Energy, Medical |

| Regions Covered | North America, Europe, East Asia, South Asia & Pacific, Latin America, Middle East & Africa |

| Countries Covered | United States, Canada, United Kingdom, Germany, France, China, Japan, South Korea, India, Brazil, Australia and 40+ countries |

| Key Companies Profiled | Mayr GmbH + Co. KG, Intorq, Warner Electric, Kendrion N.V., Ortlinghaus-Werke GmbH and SINFONIA Technology Co., Ltd. |

| Additional Attributes | Dollar sales by mounting type and application category, regional demand trends, competitive landscape, technological advancements in clutch systems, control innovation, smart technology integration, and performance optimization |

North America

Europe

East Asia

South Asia & Pacific

Latin America

Middle East & Africa

The global spring applied clutches market is estimated to be valued at USD 828.5 million in 2025.

The market size for the spring applied clutches market is projected to reach USD 1,415.2 million by 2035.

The spring applied clutches market is expected to grow at a 5.5% CAGR between 2025 and 2035.

The key product types in spring applied clutches market are shaft-mounted, flange-mounted and hub-mounted.

In terms of application, automobile segment to command 45.0% share in the spring applied clutches market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Spring Shackles Market

Leaf Spring Assembly Market Size and Share Forecast Outlook 2025 to 2035

Innerspring Mattresses Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Clutch Spring Wires Market

Thermal Spring Market Size and Share Forecast Outlook 2025 to 2035

Automotive Spring Market Size and Share Forecast Outlook 2025 to 2035

Nitrogen Gas Springs Market

Compression Gas Spring Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Automotive Coil Spring Market

Automotive Valve Spring Market Size and Share Forecast Outlook 2025 to 2035

China Nitrogen Gas Spring Market Report - Trends, Growth & Forecast 2025 to 2035

Leading Providers & Market Share in China Nitrogen Gas Springs

Automotive Composite Leaf Springs Market Growth - Trends & Forecast 2025 to 2035

USA Automotive Composite Leaf Springs Market Analysis – Size & Industry Trends 2025-2035

China Automotive Composite Leaf Springs Market Trends – Size, Share & Growth 2025-2035

India Automotive Composite Leaf Springs Market Trends – Size, Share & Growth 2025-2035

Japan Automotive Composite Leaf Springs Market Insights – Growth & Demand 2025-2035

Germany Automotive Composite Leaf Springs Market Report – Demand & Forecast 2025-2035

Industrial Brakes and Clutches Market Growth – Trends & Forecast 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA