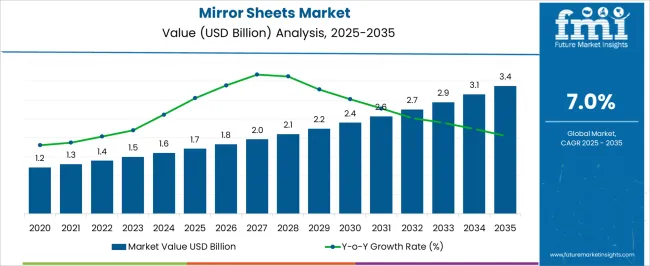

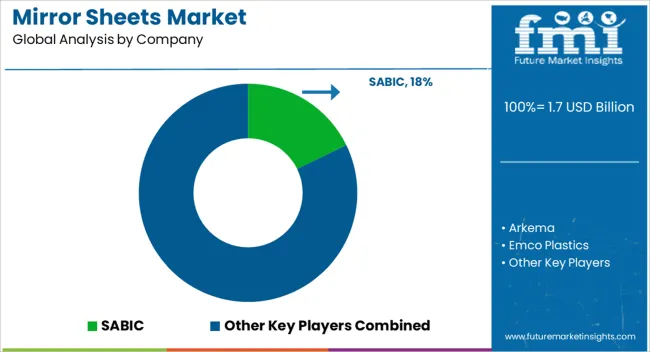

The mirror sheets market, estimated at USD 1.7 billion in 2025 and projected to reach USD 3.4 billion by 2035 at a CAGR of 7.0%, exhibits notable regional growth imbalances driven by industrial activity, construction demand, and manufacturing capabilities across Asia-Pacific, Europe, and North America. Asia-Pacific is expected to dominate growth due to large-scale infrastructure projects, expanding automotive production, and increasing adoption in interior and decorative applications.

Countries such as China and India benefit from high-volume glass production and low-cost manufacturing, enabling rapid scaling of mirror sheet output. This regional strength in production capacity supports competitive pricing and accelerated market penetration. Europe demonstrates steady but moderate growth, fueled by stringent quality standards, specialized applications, and regulatory compliance in the architectural and automotive segments.

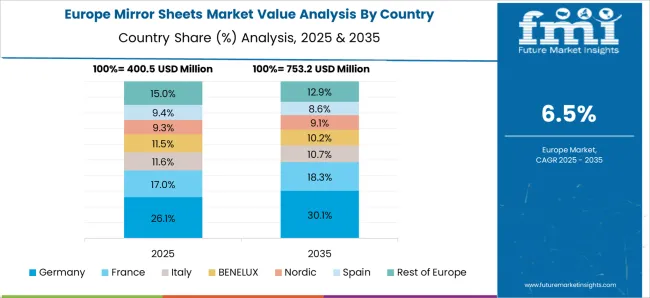

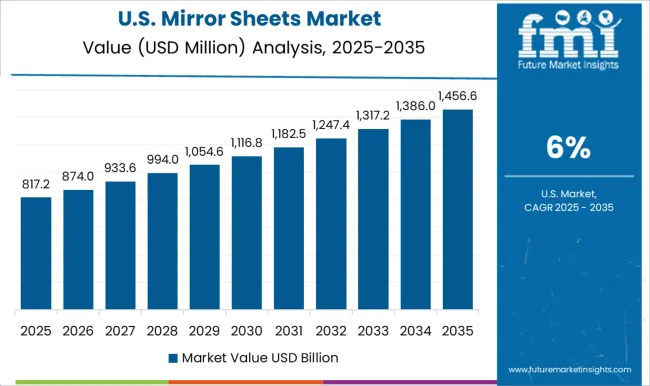

Advanced manufacturing technologies and strong brand presence provide value addition, yet relatively mature markets constrain the pace of expansion. North America maintains moderate growth, with industrial demand in automotive, commercial construction, and consumer electronics driving adoption. The higher production costs and concentrated manufacturing centers create supply chain limitations, slowing market growth compared to the Asia-Pacific. The regional disparities in production capacity, labor costs, industrial development, and regulatory frameworks result in an imbalanced market landscape. Asia-Pacific’s aggressive expansion contrasts with Europe’s stable growth and North America’s moderate adoption, shaping competitive dynamics and investment priorities throughout the forecast period.

| Metric | Value |

|---|---|

| Mirror Sheets Market Estimated Value in (2025 E) | USD 1.7 billion |

| Mirror Sheets Market Forecast Value in (2035 F) | USD 3.4 billion |

| Forecast CAGR (2025 to 2035) | 7.0% |

The mirror sheets market is regarded as a specialized segment within decorative, construction, and industrial applications. It is estimated to hold 5.3% of the decorative and interior materials market, driven by use in home, commercial, and hospitality spaces. Within glass and glazing products, a 4.1% share is observed, reflecting adoption in partitions, windows, and paneling. The furniture and home decor sector contributes 3.7%, supported by integration in cabinets, wardrobes, and decorative panels. Automotive components and accessories account for 2.9%, primarily in interior design and cosmetic enhancements.

Construction and building materials represent 3.2%, reflecting installation in walls, ceilings, and feature spaces for aesthetic and functional purposes. Lightweight, shatterproof, and eco-friendly mirror sheet designs have shaped recent industry trends. Groundbreaking developments include reflective acrylic and polycarbonate sheets, anti-fog and anti-scratch coatings, and laser-cut, customizable designs for residential and commercial use. Key players are implementing strategies involving partnerships with interior designers, furniture manufacturers, and automotive OEMs to expand application reach. Digital printing and decorative laminates are enhancing aesthetic appeal, while safety enhancements such as laminated or tempered substrates are driving adoption in high-traffic areas. The Asia Pacific leads regional growth due to construction and interior design demand, while Europe focuses on premium and sustainable mirror sheet solutions.

The mirror sheets market is witnessing consistent growth, underpinned by rising applications in residential, commercial, and industrial environments. Demand has been supported by expansion in the interior design and construction sectors, where mirror sheets are increasingly valued for both functional and aesthetic purposes. Advancements in manufacturing technologies have improved product quality, durability, and optical clarity, thereby enhancing market acceptance.

Raw material optimization and efficient supply chain strategies have contributed to cost competitiveness, while customization in size, shape, and finish has broadened consumer appeal. Regional demand is being shaped by urbanization, rising disposable incomes, and increasing investments in real estate projects.

The integration of mirrors in furniture, architectural projects, and decorative installations is driving sustained adoption. Over the forecast period, ongoing innovation in coating and lamination processes, coupled with strategic market expansion into developing economies, is expected to support steady volume growth, strengthen competitive positioning, and create new opportunities for high-margin, specialty product lines.

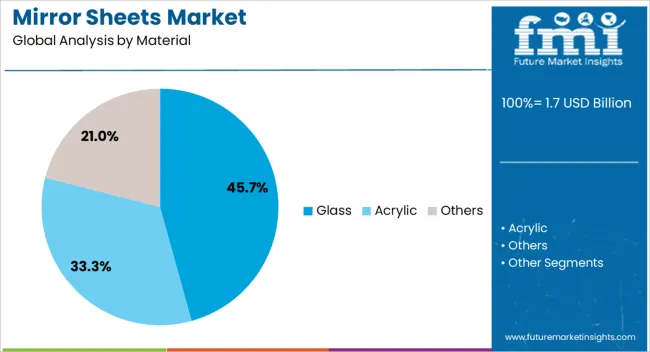

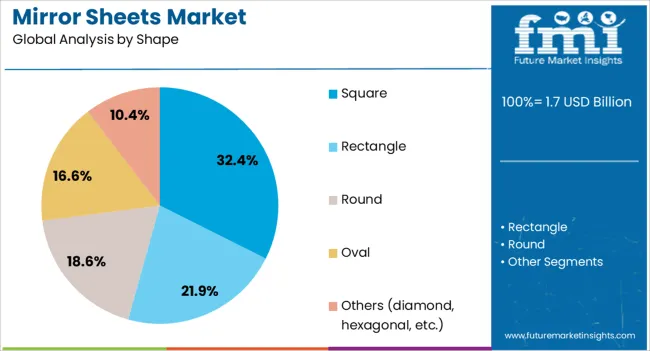

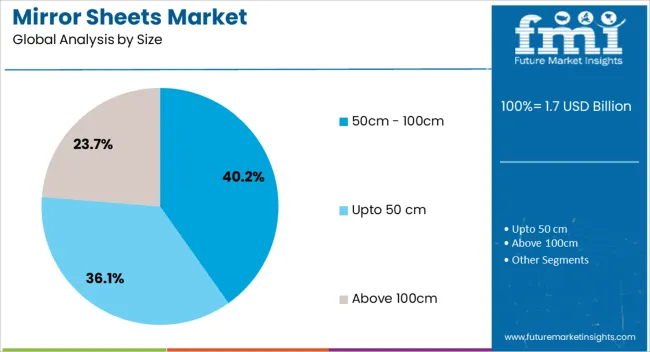

The mirror sheets market is segmented by material, shape, size, price range, end use, distribution channel, and geographic regions. By material, mirror sheets market is divided into Glass, Acrylic, and Others. In terms of shape, mirror sheets market is classified into Square, Rectangle, Round, Oval, and Others (diamond, hexagonal, etc.). Based on size, mirror sheets market is segmented into 50cm - 100cm, Upto 50 cm, and Above 100cm.

By price range, mirror sheets market is segmented into Mid, Low, and High. By end use, mirror sheets market is segmented into Commercial and Individual. By distribution channel, mirror sheets market is segmented into Offline and Online. Regionally, the mirror sheets industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The glass segment, accounting for 45.70% of the material category, has retained its leadership owing to its superior reflective quality, structural stability, and long-standing presence in mirror manufacturing. Market dominance has been maintained through continuous improvements in float glass production and coating technologies, which have enhanced resistance to corrosion and surface degradation.

The segment benefits from the wide availability of raw materials, efficient processing infrastructure, and established supply networks. Consumer preference for glass mirrors in both decorative and functional applications has remained stable, supported by high optical precision and ease of maintenance.

The scalability of glass production allows for competitive pricing, while design versatility enables its integration into diverse architectural and interior applications. Regulatory compliance in safety glazing and environmental standards has been addressed through the adoption of eco-friendly coatings and recycling practices, ensuring continued acceptance in both domestic and export markets.

The square shape segment, representing 32.40% of the shape category, has maintained a strong market position due to its adaptability in varied installation settings and cost-efficient manufacturing process. The uniform geometry of square mirrors facilitates easier cutting, handling, and transportation, leading to reduced production waste and optimized material utilization. Demand has been sustained by its popularity in modular wall designs, tiled mirror layouts, and standard furniture integration.

The segment benefits from standardized sizing, which simplifies installation for both commercial and residential projects. Market resilience is supported by widespread availability across retail channels, complemented by strong demand from bulk procurement for hospitality, office spaces, and public infrastructure.

Improved finishing techniques have enhanced surface smoothness and edge quality, reinforcing consumer perception of value and durability. These factors collectively ensure that square-shaped mirror sheets remain a preferred choice in the market’s shape category.

The 50cm–100cm size range, holding 40.20% of the size category, has emerged as the leading preference due to its balance between aesthetic appeal and practical usability. This size range offers versatility for a broad spectrum of applications, from home décor and bathroom mirrors to retail and commercial installations. Production efficiency is achieved through compatibility with standard manufacturing and packaging formats, reducing costs while ensuring consistent quality.

Demand growth is reinforced by the size’s suitability for both standalone and multi-panel arrangements, enabling flexible design possibilities. Market adoption has been further supported by its optimal weight-to-durability ratio, allowing for ease of transportation and installation without compromising stability.

Retailers and distributors favor this range for its strong consumer demand, leading to widespread stock availability. With expanding customization trends, the 50cm–100cm segment is expected to maintain its dominance, supported by ongoing innovations in framing, mounting systems, and surface treatments.

The market has witnessed significant expansion due to growing demand in construction, interior decoration, automotive, and consumer goods sectors. Mirror sheets, available in acrylic, polycarbonate, and glass-based varieties, are increasingly preferred for their lightweight, shatter-resistant, and aesthetically versatile properties. Applications include decorative panels, furniture inserts, signage, safety mirrors, and vehicle components. The rising need for innovative interior designs, home renovations, and automotive customization drives market growth. Technological improvements in coatings, surface finishing, and laser-cutting techniques have enhanced durability, reflectivity, and precision.

The construction and interior design industries are major consumers of mirror sheets due to their ability to enhance visual appeal, light reflection, and space perception. Architects and interior designers increasingly use acrylic and polycarbonate mirror sheets as alternatives to traditional glass mirrors because they are lightweight, easy to install, and safer in high-traffic areas. Commercial spaces, hotels, and residential projects utilize mirror sheets for wall cladding, partitions, and ceiling designs. Furniture manufacturers incorporate mirror sheets into cabinets, shelves, and decorative panels to add aesthetic value. The combination of durability, low maintenance, and design flexibility has reinforced their adoption in both new constructions and renovation projects, driving consistent demand globally.

Advancements in manufacturing processes, coatings, and surface finishing have enhanced the performance and versatility of mirror sheets. Anti-scratch coatings, UV-resistant layers, and shatterproof treatments extend lifespan and maintain optical clarity. Laser-cutting, engraving, and digital printing enable precise customization for decorative, commercial, and automotive applications.

Acrylic and polycarbonate mirrors are being engineered for enhanced reflectivity and chemical resistance, expanding their usability in industrial environments and outdoor installations. Integration of lightweight materials with improved rigidity allows easier handling and installation without compromising safety. These technological innovations have made mirror sheets more competitive, reliable, and preferred over traditional glass mirrors in a wide range of applications.

Mirror sheets are increasingly used in the automotive and transportation sectors for rearview mirrors, interior panels, and reflective safety components. Lightweight and shatter-resistant properties make acrylic and polycarbonate sheets suitable for vehicle interiors and exterior safety applications. Bus, truck, and passenger vehicle manufacturers are adopting these materials to reduce weight, enhance fuel efficiency, and improve passenger safety.

Mirror sheets are also employed in public transport systems, airports, and train stations for security and surveillance purposes, where impact resistance and optical clarity are crucial. Growing automotive production, fleet modernization, and focus on vehicle aesthetics are contributing to steady market growth in this sector.

Regional construction activity, urbanization, and lifestyle trends significantly influence mirror sheet adoption. Asia Pacific, particularly China and India, has witnessed high demand due to rapid urban development, commercial projects, and rising disposable incomes. Europe focuses on sustainable, high-quality materials with aesthetic appeal for commercial and residential projects. North America emphasizes safety, innovation, and industrial applications, while emerging regions are gradually adopting mirror sheets in construction and automotive segments. Government regulations for building safety, fire resistance, and material standards also affect product selection. Regional dynamics reflect how construction, consumer preferences, and industrial requirements collectively drive market growth and innovation.

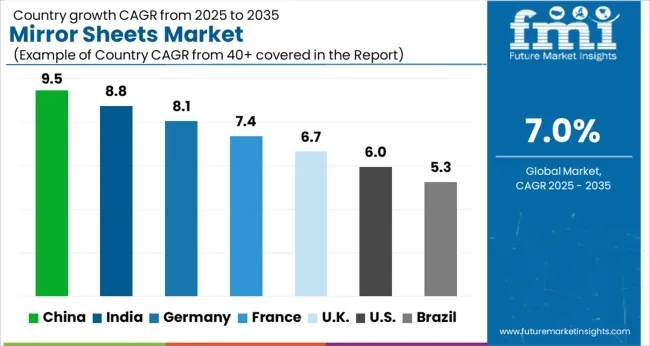

| Country | CAGR |

|---|---|

| China | 9.5% |

| India | 8.8% |

| Germany | 8.1% |

| France | 7.4% |

| UK | 6.7% |

| USA | 6.0% |

| Brazil | 5.3% |

China leads the market with a forecast CAGR of 9.5%, driven by extensive glass manufacturing, high demand in construction, and interior décor applications. India follows at 8.8%, supported by growing urban infrastructure, rising commercial projects, and increased adoption in residential interiors. Germany records 8.1%, benefiting from advanced manufacturing technologies and precision glass processing for automotive and architectural applications. The United Kingdom posts 6.7%, where innovation in decorative and functional mirror products contributes to steady growth. The United States registers 6.0%, sustained by demand across commercial, residential, and industrial segments. This report includes insights on 40+ countries; the top markets are shown here for reference.

China is expected to experience steady growth in the market with a CAGR of 9.5% due to increasing construction, interior decoration, and furniture manufacturing activities. Rising demand for aesthetically appealing and durable mirror sheets in residential and commercial spaces is contributing to market expansion. The use of high-quality reflective materials and tempered glass products is gaining traction. Industrial applications, including automotive and electronics sectors, are also driving adoption. Continuous technological advancements, such as lightweight and shatterproof mirror solutions, are encouraging manufacturers to offer versatile options. Increasing urban development projects and investment in commercial infrastructures further reinforce the market growth in China.

India is projected to grow at a CAGR of 8.8% in the market, fueled by rapid urbanization, commercial development, and demand for modern interiors. Residential and hospitality sectors are increasingly opting for decorative mirror solutions to improve aesthetics and spatial perception. Manufacturers are focusing on durable, shatter-resistant, and lightweight mirror sheets suitable for diverse applications. Growth in retail and automotive industries is also driving demand. Adoption of innovative coatings and anti-fog technologies enhances product functionality, boosting market acceptance. Increasing infrastructure investment and rising consumer preference for premium interior finishes provide a conducive environment for market expansion across India.

Germany is expected to witness a CAGR of 8.1% in the market, supported by a strong construction sector, modern architecture, and automotive applications. The trend toward sustainable and energy-efficient interiors is driving demand for advanced reflective materials. Manufacturers are supplying mirror sheets with enhanced durability, safety features, and innovative finishes suitable for both commercial and residential applications. The automotive sector is increasingly integrating decorative and functional mirrors, while interior design trends favor versatile and aesthetically pleasing solutions. Technological advancements and regulatory compliance ensure high-quality production standards, reinforcing steady growth in the German market.

The United Kingdom is projected to grow at a CAGR of 6.7% in the market due to increased focus on home renovation, retail interior design, and commercial infrastructure development. Premium and lightweight mirror sheets with safety features are being adopted to meet aesthetic and functional requirements. Trends in decorative applications, including furniture and hospitality interiors, are expanding market opportunities. Sustainable manufacturing practices and environmentally friendly coatings are influencing consumer preference. Integration of energy-efficient and shatterproof mirror sheets across modern architecture and commercial buildings supports steady market growth throughout the UK.

The United States is expected to grow at a CAGR of 6.0% in the market, driven by increasing residential construction, retail space development, and automotive applications. Demand for decorative, high-strength, and shatter-resistant mirror sheets is rising in both commercial and residential sectors. Manufacturers are focusing on advanced coatings, anti-fog solutions, and lightweight designs to meet functional and aesthetic requirements. Industrial adoption in automotive, electronics, and furniture manufacturing further strengthens market growth. Continuous innovation, sustainable production practices, and rising consumer awareness contribute to a favorable outlook for the mirror sheets market across the US.

The market is characterized by a diverse set of global and regional players delivering innovative, high-performance reflective sheet solutions for industrial, architectural, automotive, and decorative applications. SABIC and Arkema remain at the forefront with advanced polymer-based technologies, providing lightweight, impact-resistant sheets that combine optical clarity with durability for both indoor and outdoor usage. These products are widely adopted in signage, interior design, and protective surfaces where both aesthetics and functionality are critical. Emco Plastics and Plaskolite complement the market with thermoplastic sheets that offer superior flexibility, ease of fabrication, and resilience against physical stress, making them suitable for complex applications such as industrial panels and consumer goods.

Evonik and Mitsubishi focus on high-performance engineered materials, emphasizing chemical and UV resistance to ensure long-term reliability in challenging environments. Fabback and Reynolds Polymer Technology deliver highly customizable mirror sheets in varied thicknesses, finishes, and colors, catering to bespoke architectural and design requirements. Rohm GmbH and Tap Plastics provide cost-effective solutions without compromising optical performance, targeting a mix of commercial, industrial, and consumer applications. These providers drive market growth by continually enhancing product durability, visual appeal, and application versatility, ensuring that mirror sheets remain an essential material across multiple sectors globally.

| Item | Value |

|---|---|

| Quantitative Units | USD 1.7 Billion |

| Material | Glass, Acrylic, and Others |

| Shape | Square, Rectangle, Round, Oval, and Others (diamond, hexagonal, etc.) |

| Size | 50cm - 100cm, Upto 50 cm, and Above 100cm |

| Price Range | Mid, Low, and High |

| End Use | Commercial and Individual |

| Distribution Channel | Offline and Online |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled | SABIC, Arkema, Emco Plastics, Evonik, Fabback, Mitsubishi, Plaskolite, Reynolds Polymer Technology, Rohm Gmbh, and Tap Plastics |

| Additional Attributes | Dollar sales by sheet type and application, demand dynamics across construction, interior design, and automotive sectors, regional trends in decorative and functional mirror adoption, innovation in reflective quality, lightweight materials, and safety coatings, environmental impact of production and recycling, and emerging use cases in smart interiors and specialized architectural applications. |

The global mirror sheets market is estimated to be valued at USD 1.7 billion in 2025.

The market size for the mirror sheets market is projected to reach USD 3.4 billion by 2035.

The mirror sheets market is expected to grow at a 7.0% CAGR between 2025 and 2035.

The key product types in mirror sheets market are glass, acrylic and others.

In terms of shape, square segment to command 32.4% share in the mirror sheets market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Mirrored Glass Market

Smart Mirror Market Size and Share Forecast Outlook 2025 to 2035

Safety Mirrors Market - Growth & Forecast 2025 to 2035

Polygon Mirror Scanner Motor Market Size and Share Forecast Outlook 2025 to 2035

Fogless Mirror Market Growth - Trends & Industry Outlook 2025 to 2035

Bathroom Mirror Wiper Market Size and Share Forecast Outlook 2025 to 2035

Fog Free Mirrors Market Size and Share Forecast Outlook 2025 to 2035

Auto-Dimming Mirror Market Size and Share Forecast Outlook 2025 to 2035

Digital Micromirror Device (DMD) market Size and Share Forecast Outlook 2025 to 2035

Smart Fitness Mirror Market Size and Share Forecast Outlook 2025 to 2035

Convex Safety Mirrors Market Growth - Demand & Forecast 2025 to 2035

Automotive Rear View Mirror Market

Telescopic Inspection Mirror Market Size and Share Forecast Outlook 2025 to 2035

Automotive Auto Dimming Mirror Market Size and Share Forecast Outlook 2025 to 2035

Slip Sheets Market Insights – Growth & Demand 2025 to 2035

Dryer Sheets Market Size and Share Forecast Outlook 2025 to 2035

Veneer Sheets Market Size and Share Forecast Outlook 2025 to 2035

Aluminum Sheets and Coils Market Size and Share Forecast Outlook 2025 to 2035

Tarpaulin Sheets Market Size and Share Forecast Outlook 2025 to 2035

Evaluating Tarpaulin Sheets Market Share & Provider Insights

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA