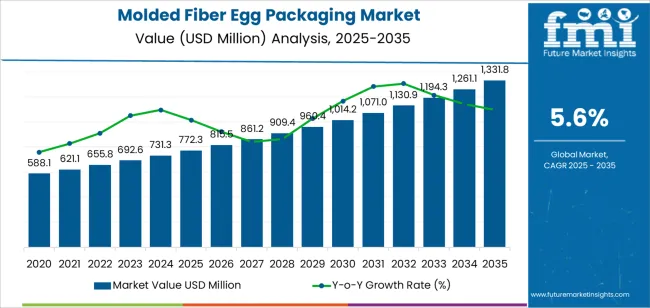

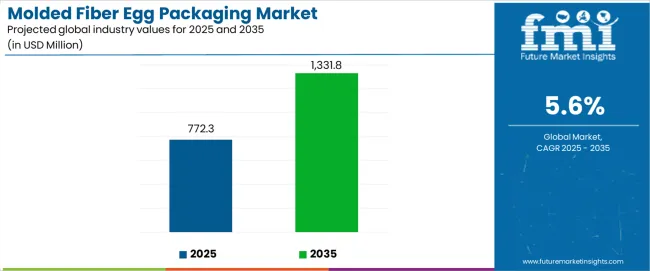

The global molded fiber egg packaging market is valued at USD 772.3 million in 2025 and is set to reach USD 1,331.7 million by 2035, recording an absolute increase of USD 559.4 million over the forecast period. This translates into a total growth of 72.4%, with the market forecast to expand at a compound annual growth rate (CAGR) of 5.60% between 2025 and 2035.

The overall market size is expected to grow by approximately 1.7X during the same period, supported by increasing demand for eco-friendly packaging solutions, growing adoption of biodegradable materials, and rising requirements for protective packaging systems across agricultural, retail, food service, and distribution sectors.

Between 2025 and 2030, the molded fiber egg packaging market is projected to expand from USD 772.3 million to USD 1,024.6 million, resulting in a value increase of USD 252.3 million, which represents 45.1% of the total forecast growth for the decade.

This phase of development will be shaped by increasing demand for biodegradable packaging solutions, rising consumer awareness enabling environmentally conscious purchasing decisions, and growing availability of advanced molding technologies across commercial egg production operations and retail distribution facilities.

Between 2030 and 2035, the market is forecast to grow from USD 1,024.6 million to USD 1,331.7 million, adding another USD 307.1 million, which constitutes 54.9% of the overall ten-year expansion. This period is expected to be characterized by the advancement of smart packaging integration, the development of premium protective features for specialty egg varieties, and the expansion of automated production systems across diverse agricultural applications.

The growing emphasis on circular economy principles and waste reduction will drive demand for advanced molded fiber varieties with enhanced protective capabilities, improved moisture resistance characteristics, and superior cushioning performance profiles.

Between 2020 and 2024, the molded fiber egg packaging market experienced steady growth, driven by increasing consumer preference for eco-friendly packaging and growing recognition of molded fiber technology's effectiveness in delivering superior protection while maintaining cost-effectiveness across agricultural and retail applications.

The market developed as producers recognized the potential for advanced molding processes to deliver operational efficiency while meeting modern requirements for food safety compliance and high-volume packaging operations. Technological advancement in fiber processing and mold design began emphasizing the critical importance of maintaining product integrity while enhancing packaging durability and improving material utilization rates.

| Metric | Value |

|---|---|

| Estimated Value in (2025E) | USD 772.3 million |

| Forecast Value in (2035F) | USD 1,331.7 million |

| Forecast CAGR (2025 to 2035) | 5.60% |

From 2030 to 2035, the market is forecast to grow from USD 1,024.6 million to USD 1,331.7 million, adding another USD 307.1 million, which constitutes 54.9% of the overall ten-year expansion. This period is expected to be characterized by the advancement of digital quality monitoring systems, the integration of automated stacking accessories for distribution efficiency, and the development of specialized surface textures for enhanced grip characteristics. The growing emphasis on packaging optimization and operational precision will drive demand for premium varieties with enhanced structural integrity credentials, improved stackability options, and superior functionality characteristics.

Between 2020 and 2024, the molded fiber egg packaging market experienced robust growth, driven by increasing awareness of environmental benefits and growing recognition of molded fiber systems' effectiveness in supporting efficient distribution operations across agricultural facilities and retail packaging services. The market developed as users recognized the potential for specialized molded fiber solutions to deliver performance advantages while meeting modern requirements for consistent protection quality and reliable packaging performance.

Technological advancement in manufacturing processes and quality assurance systems began emphasizing the critical importance of maintaining dimensional accuracy while extending packaging service life and improving customer satisfaction across diverse egg packaging applications.

Market expansion is being supported by the increasing global demand for environmentally responsible packaging solutions and the corresponding shift toward high-performance molded fiber packages that can provide superior protective characteristics while meeting user requirements for packaging reliability and cost-effective distribution processes. Modern egg producers are increasingly focused on incorporating packaging systems that can enhance product protection while satisfying demands for consistent, precisely molded containers and optimized material consumption practices.

Molded fiber egg packaging's proven ability to deliver protective excellence, product freshness preservation, and diverse application possibilities makes them essential components for agricultural producers and quality-conscious packaging professionals.

The growing emphasis on environmental responsibility and packaging optimization is driving demand for high-performance molded fiber systems that can support distinctive protective outcomes and comprehensive product preservation across organic egg production, specialty farming operations, and premium retail applications.

User preference for packaging that combines functional excellence with environmental compatibility is creating opportunities for innovative implementations in both traditional and emerging egg distribution applications. The rising influence of automated packaging processes and advanced production technologies is also contributing to increased adoption of specialized molded fiber solutions that can provide authentic performance benefits and reliable protective characteristics.

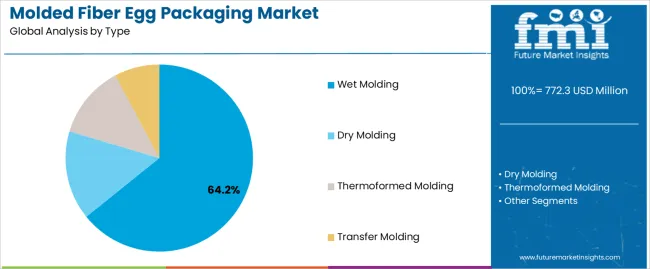

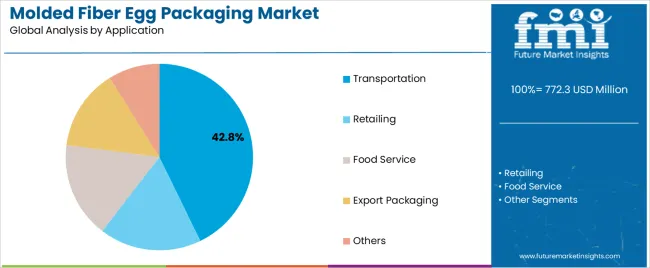

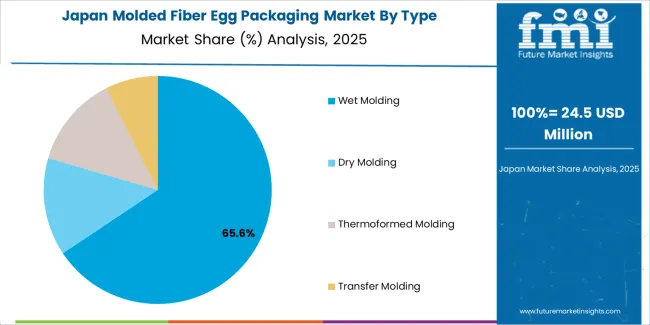

The market is segmented by type, application, capacity, surface treatment, and region. By type, the market is divided into wet molding, dry molding, thermoformed molding, and transfer molding. Based on application, the market is categorized into transportation, retailing, food service, export packaging, and others.

By capacity, the market includes 6-egg capacity, 12-egg capacity, 18-egg capacity, 24-egg capacity, and 30-egg capacity. By surface treatment, the market encompasses standard finish, water-resistant coating, anti-microbial treatment, and premium surface enhancement. Regionally, the market is divided into North America, Europe, Asia Pacific, Latin America, Middle East & Africa, and other regions.

The wet molding segment is projected to account for 64.2% of the molded fiber egg packaging market in 2025, reaffirming its position as the leading type category. Producers and packaging professionals increasingly utilize wet molding for its superior forming characteristics, established production standards, and essential functionality in diverse packaging applications across multiple egg production types. Wet molding's proven performance characteristics and established cost-effectiveness directly address user requirements for reliable packaging formation and optimal protective precision in commercial applications.

This type segment forms the foundation of modern molded fiber packaging performance patterns, as it represents the manufacturing category with the greatest production efficiency potential and established compatibility across multiple packaging systems.

Business investments in advanced molding technology and performance optimization continue to strengthen adoption among efficiency-conscious producers. With users prioritizing packaging consistency and production reliability, wet molding aligns with both productivity objectives and quality requirements, making them the central component of comprehensive packaging strategies.

Transportation is projected to represent 42.8% of the molded fiber egg packaging market in 2025, underscoring its critical role as the primary application for quality-focused distributors seeking superior protective efficiency benefits and enhanced logistics completion credentials. Commercial distributors and transportation professionals prefer transportation applications for their established volume requirements, proven market demand, and ability to maintain exceptional product protection while supporting versatile handling requirements during diverse distribution operations. Positioned as essential applications for performance-conscious distributors, transportation offerings provide both operational excellence and competitive positioning advantages.

The segment is supported by continuous improvement in logistics technology and the widespread availability of established distribution standards that enable quality assurance and premium positioning at the distributor level. Transportation companies are optimizing packaging selections to support route differentiation and competitive handling strategies. As logistics technology continues to advance and distributors seek efficient protection methods, transportation applications will continue to drive market growth while supporting business development and customer satisfaction strategies.

The molded fiber egg packaging market is advancing rapidly due to increasing environmental packaging consciousness and growing need for protective packaging solutions that emphasize superior performance outcomes across agricultural segments and retail applications. The market faces challenges, including competition from alternative packaging technologies, production complexity considerations, and material cost pressures affecting operational economics. Innovation in smart packaging integration and advanced fiber materials continues to influence market development and expansion patterns.

Expansion of Organic and Premium Egg Market Applications

The growing adoption of molded fiber egg packaging in organic egg production and premium retail segments is enabling producers to develop packaging strategies that provide distinctive protection benefits while commanding competitive positioning and enhanced product presentation characteristics. Organic applications provide superior protection consistency while allowing more sophisticated branding features across various product categories. Users are increasingly recognizing the operational advantages of molded fiber positioning for premium packaging outcomes and environmentally-conscious product integration.

Integration of Digital Tracking and Smart Package Systems

Modern molded fiber egg packaging manufacturers are incorporating advanced tracking technologies, digital identification systems, and automated inventory management to enhance distribution precision, improve product traceability, and meet commercial demands for intelligent packaging solutions. These systems improve operational effectiveness while enabling new applications, including supply chain optimization programs and freshness monitoring protocols. Advanced tracking integration also allows producers to support quality leadership positioning and performance assurance beyond traditional packaging operations.

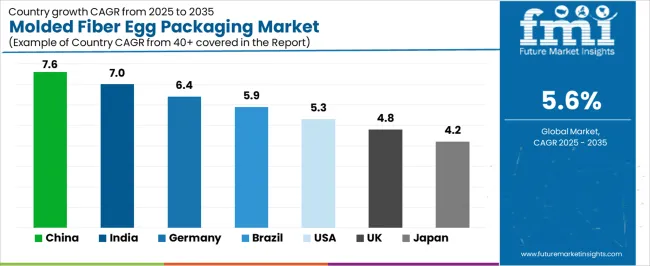

| Country | CAGR (2025 to 2035) |

|---|---|

| China | 7.6% |

| India | 7.0% |

| Germany | 6.4% |

| Brazil | 5.9% |

| USA | 5.3% |

| UK | 4.8% |

| Japan | 4.2% |

The molded fiber egg packaging market is experiencing robust growth globally, with China leading at a 7.6% CAGR through 2035, driven by the expanding egg production industry, growing environmental awareness requirements, and increasing adoption of mechanized packaging systems. India follows at 7.0%, supported by rising agricultural modernization, expanding retail infrastructure, and growing acceptance of protective packaging solutions.

Germany shows growth at 6.4%, emphasizing established manufacturing capabilities and comprehensive packaging technology development. Brazil records 5.9%, focusing on agricultural expansion and export market growth. The USA demonstrates 5.3% growth, prioritizing advanced packaging technologies and production optimization.

The report covers an in-depth analysis of 40+ countries, Top-performing countries are highlighted below.

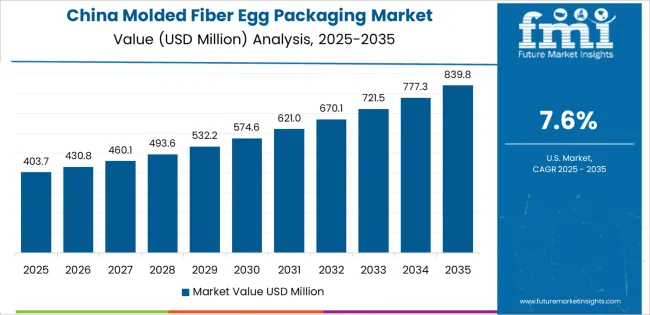

Revenue from molded fiber egg packaging consumption and sales in China is projected to exhibit exceptional growth with a CAGR of 7.6% through 2035, driven by the country's rapidly expanding egg production sector, favorable government policies toward agricultural modernization, and initiatives promoting environmentally responsible packaging technologies across major agricultural regions.

China's position as a leading egg production hub and increasing focus on food safety systems are creating substantial demand for high-quality molded fiber egg packaging in both domestic and export markets. Major agricultural companies and packaging distributors are establishing comprehensive packaging capabilities to serve growing demand and emerging market opportunities.

Revenue from molded fiber egg packaging products in India is expanding at a CAGR of 7.0%, supported by rising agricultural investment, growing rural development, and expanding packaging distributor capabilities. The country's developing agricultural sector and increasing commercial investment in modern packaging technologies are driving demand for molded fiber egg packaging across both traditional and modern production applications. International packaging companies and domestic distributors are establishing comprehensive operational networks to address growing market demand for quality packaging and efficient protective solutions.

Revenue from molded fiber egg packaging products in Germany is projected to grow at a CAGR of 6.4% through 2035, supported by the country's mature agricultural sector, established packaging standards, and leadership in production technology. Germany's sophisticated food processing infrastructure and strong support for advanced packaging systems are creating steady demand for both traditional and innovative molded fiber varieties. Leading packaging manufacturers and specialty distributors are establishing comprehensive operational strategies to serve both domestic markets and growing export opportunities.

Revenue from molded fiber egg packaging products in Brazil is projected to grow at a CAGR of 5.9% through 2035, driven by the country's emphasis on agricultural expansion, rural development, and growing packaging distributor capabilities. Brazilian producers and agricultural companies consistently seek commercial-grade packaging that enhances product protection and supports operational excellence for both traditional and modern egg production applications. The country's position as a Latin American agricultural leader continues to drive innovation in specialized packaging applications and commercial production standards.

Revenue from molded fiber egg packaging products in the USA is projected to grow at a CAGR of 5.3% through 2035, supported by the country's emphasis on packaging technology advancement, production optimization, and advanced automation integration requiring efficient packaging solutions. American producers and food processing users prioritize performance reliability and operational precision, making specialized molded fiber packaging essential components for both traditional and modern egg distribution applications. The country's comprehensive technology leadership and advancing packaging patterns support continued market expansion.

Revenue from molded fiber egg packaging products in the UK is projected to grow at a CAGR of 4.8% through 2035, supported by established food safety standards, mature producer markets, and emphasis on packaging reliability across commercial and retail sectors. British producers and food processing professionals prioritize quality performance and operational consistency, creating steady demand for premium packaging solutions. The country's comprehensive market maturity and established food safety practices support continued development in specialized applications.

Revenue from molded fiber egg packaging products in Japan is projected to grow at a CAGR of 4.2% through 2035, supported by the country's emphasis on precision manufacturing, quality excellence, and advanced technology integration requiring efficient packaging solutions. Japanese businesses and food processing users prioritize technical performance and manufacturing precision, making specialized molded fiber packaging essential components for both traditional and modern egg distribution applications. The country's comprehensive quality leadership and advancing packaging patterns support continued market expansion.

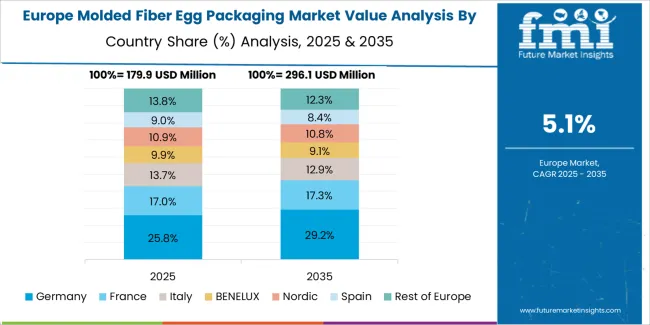

The Europe molded fiber egg packaging market is projected to grow from USD 268.4 million in 2025 to USD 442.8 million by 2035, recording a CAGR of 5.1% over the forecast period. Germany leads the region with a 36.2% share in 2025, moderating slightly to 35.6% by 2035, supported by its strong food processing base and demand for premium, technically advanced packaging solutions. The United Kingdom follows with 23.8% in 2025, easing to 23.4% by 2035, driven by a mature food retail market and emphasis on packaging reliability and environmental performance.

France accounts for 17.2% in 2025, rising to 17.8% by 2035, reflecting steady adoption of eco-friendly packaging solutions and operational efficiency enhancement. Italy holds 11.6% in 2025, expanding to 12.4% by 2035 as agricultural modernization and specialty food packaging applications grow.

Spain contributes 6.4% in 2025, growing to 6.9% by 2035, supported by expanding poultry sector and packaging modernization. The Nordic countries rise from 3.5% in 2025 to 3.7% by 2035 on the back of strong environmental consciousness and advanced packaging methodologies. BENELUX remains at 1.3% share across both 2025 and 2035, reflecting mature, efficiency-focused food processing markets.

The molded fiber egg packaging market is characterized by competition among established packaging manufacturers, specialized molding companies, and integrated agricultural solution providers. Companies are investing in precision manufacturing technologies, advanced fiber processing systems, product innovation capabilities, and comprehensive distribution networks to deliver consistent, high-quality, and reliable molded fiber egg packaging systems. Innovation in structural enhancement, moisture resistance optimization, and application-specific product development is central to strengthening market position and customer satisfaction.

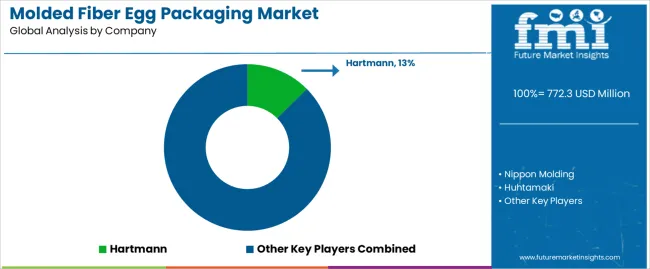

Hartmann leads the market with a strong focus on packaging innovation and comprehensive molded fiber egg packaging solutions, offering commercial packaging systems with emphasis on manufacturing excellence and technological heritage. Nippon Molding provides specialized molded packaging with a focus on Asian market applications and precision engineering networks.

Huhtamaki delivers integrated packaging solutions with a focus on producer positioning and operational efficiency. Tekni-Plex specializes in comprehensive protective packaging with an emphasis on food safety applications. Dispak focuses on comprehensive agricultural packaging with advanced design and premium positioning capabilities.

The success of molded fiber egg packaging in meeting commercial agricultural demands, producer-driven efficiency requirements, and environmental integration will not only enhance food safety outcomes but also strengthen global packaging manufacturing capabilities. It will consolidate emerging regions' positions as hubs for efficient packaging production and align advanced economies with commercial agricultural systems. This calls for a concerted effort by all stakeholders -- governments, industry bodies, manufacturers, distributors, and investors. Each can be a crucial enabler in preparing the market for its next phase of growth.

| Items | Values |

|---|---|

| Quantitative Units (2025) | USD 772.3 million |

| Type | Wet Molding, Dry Molding, Thermoformed Molding, Transfer Molding |

| Application | Transportation, Retailing, Food Service, Export Packaging, Others |

| Capacity | 6-Egg Capacity, 12-Egg Capacity, 18-Egg Capacity, 24-Egg Capacity, 30-Egg Capacity |

| Surface Treatment | Standard Finish, Water-Resistant Coating, Anti-Microbial Treatment, Premium Surface Enhancement |

| Regions Covered | North America, Europe, Asia Pacific, Latin America, Middle East & Africa, Other Regions |

| Countries Covered | China, India, Germany, Brazil, United States, United Kingdom, Japan, and 40+ countries |

| Key Companies Profiled | Hartmann, Nippon Molding, Huhtamaki, Tekni-Plex, Dispak, and other leading molded fiber egg packaging companies |

| Additional Attributes | Dollar sales by type, application, capacity, surface treatment, and region; regional demand trends, competitive landscape, technological advancements in molding engineering, precision manufacturing initiatives, protection enhancement programs, and premium product development strategies |

The global molded fiber egg packaging market is estimated to be valued at USD 772.3 million in 2025.

The market size for the molded fiber egg packaging market is projected to reach USD 1,331.8 million by 2035.

The molded fiber egg packaging market is expected to grow at a 5.6% CAGR between 2025 and 2035.

The key product types in molded fiber egg packaging market are wet molding, dry molding, thermoformed molding and transfer molding.

In terms of application, transportation segment to command 42.8% share in the molded fiber egg packaging market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Molded Wood Pallets Market Forecast and Outlook 2025 to 2035

Molded FRP Grating Market Size and Share Forecast Outlook 2025 to 2035

Molded Foam Market Size and Share Forecast Outlook 2025 to 2035

Molded Pulp Basket Market Size and Share Forecast Outlook 2025 to 2035

Molded Underfill Material Market Size and Share Forecast Outlook 2025 to 2035

Market Share Breakdown of the Molded Pulp Basket Industry

Competitive Overview of Molded Wood Pallets Market Share

Molded Case Circuit Breaker (MCCB) Market Growth – Trends & Forecast 2023-2033

Molded Interconnect Devices (MID) Market

Molded Pulp Packaging Market Size and Share Forecast Outlook 2025 to 2035

Molded Pulp Packaging Machines Market Analysis - Growth & Forecast 2025 to 2035

Molded Fiber Bowl Market Size and Share Forecast Outlook 2025 to 2035

Molded Fiber Pulp Cap Market Size and Share Forecast Outlook 2025 to 2035

Molded Fiber Cup Market Size and Share Forecast Outlook 2025 to 2035

Molded Fiber Wine Packs Market Size and Share Forecast Outlook 2025 to 2035

Molded Fiber Pulp Edge Protectors Market Size and Share Forecast Outlook 2025 to 2035

Molded Fiber End Caps Market Size and Share Forecast Outlook 2025 to 2035

Molded Fiber Containers Market Size and Share Forecast Outlook 2025 to 2035

Molded Fiber Tray Market Trends – Growth & Forecast 2024-2034

Molded Fiber Packaging Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA