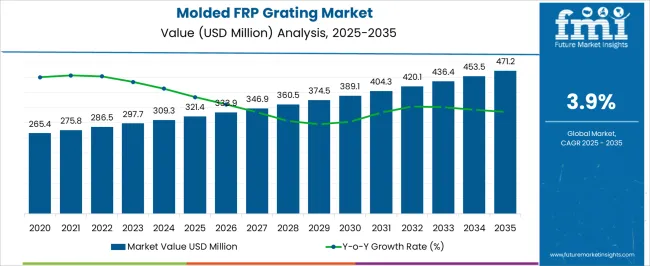

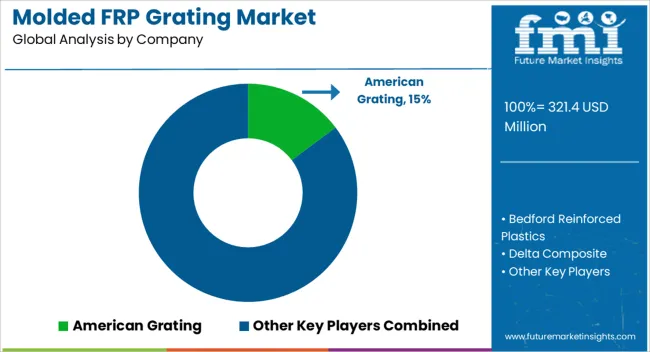

The molded FRP grating market is estimated to be valued at USD 321.4 million in 2025 and is projected to reach USD 471.2 million by 2035, registering a compound annual growth rate (CAGR) of 3.9% over the forecast period. The demand for molded FRP grating is expected to rise across various industries, including construction, oil and gas, and chemical processing, where the need for lightweight, durable, and corrosion-resistant materials is increasing. This growth is attributed to the grating’s ability to withstand harsh environments while providing an efficient and cost-effective solution for flooring, platforms, and walkways.

The market’s expansion is driven by the growing recognition of FRP grating’s advantages over traditional materials like steel, especially in terms of longevity and low maintenance requirements. The molded FRP grating market is anticipated to maintain a stable growth trajectory as end-users increasingly opt for lightweight, durable, and corrosion-resistant materials. This shift is largely being influenced by industries that prioritize operational efficiency and long-term cost savings.

By 2030, molded FRP grating is expected to become more prevalent in both new constructions and renovation projects, as it offers an advantageous alternative to metal grating, which is prone to rust and high maintenance costs. With continued investment in infrastructure and an expanding global construction sector, molded FRP grating is well-positioned to meet the growing demand for resilient and low-maintenance solutions.

| Metric | Value |

|---|---|

| Molded FRP Grating Market Estimated Value in (2025 E) | USD 321.4 million |

| Molded FRP Grating Market Forecast Value in (2035 F) | USD 471.2 million |

| Forecast CAGR (2025 to 2035) | 3.9% |

The molded FRP grating market is estimated to hold a notable proportion within its parent markets, representing approximately 10-12% of the FRP grating market, around 8-9% of the composite materials market, close to 6-7% of the industrial flooring market, about 5-6% of the construction materials market, and roughly 4-5% of the chemical and corrosion-resistant materials market. Collectively, the cumulative share across these parent segments is observed in the range of 33-39%, reflecting a growing role of molded FRP grating solutions in industrial, construction, and corrosion-resistant applications.

The market has been influenced by the demand for durable, lightweight, and maintenance-free flooring solutions, where corrosion resistance, strength, and ease of installation are highly prioritized. Adoption is guided by procurement decisions that emphasize long-term operational performance, cost-effectiveness, and resistance to harsh environmental conditions.

Market participants have focused on expanding product variations, improving load-bearing capacity, and enhancing chemical resistance to meet diverse industry requirements. As a result, the molded FRP grating market has not only captured a substantial share within the composite materials and industrial flooring domains but has also influenced construction materials and chemical-resistant solutions, highlighting its strategic role in improving the safety, durability, and operational reliability of industrial and infrastructure projects.

The molded FRP grating market is witnessing consistent growth due to its superior corrosion resistance, lightweight nature, and long service life, making it a preferred alternative to traditional materials in industrial and commercial applications. Growing awareness of safety standards, along with the need for cost-effective and durable construction materials in harsh environments, is driving adoption across sectors such as water treatment, chemical processing, and marine infrastructure. Increasing investments in public infrastructure, particularly in water and wastewater management systems, are further expanding the market’s growth potential.

Molded FRP gratings are being adopted for their non-conductive, fire-retardant, and slip-resistant properties, which enhance worker safety and operational efficiency in demanding settings. Technological advancements in resin formulations and manufacturing processes are enabling manufacturers to offer customized solutions that meet diverse performance requirements.

As sustainability and maintenance efficiency become increasingly important across industrial applications, the demand for molded FRP gratings is expected to rise steadily. The market outlook remains positive, supported by the need for high-performance, low-maintenance materials in infrastructure development projects worldwide.

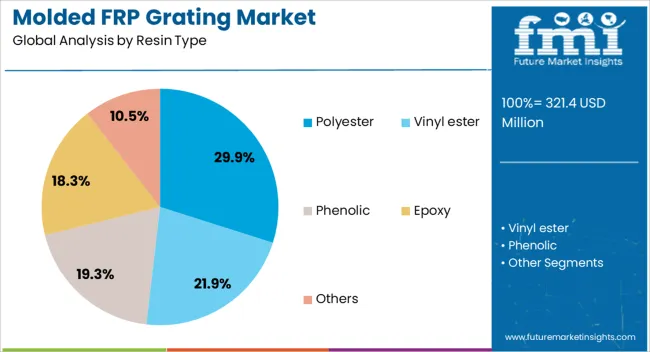

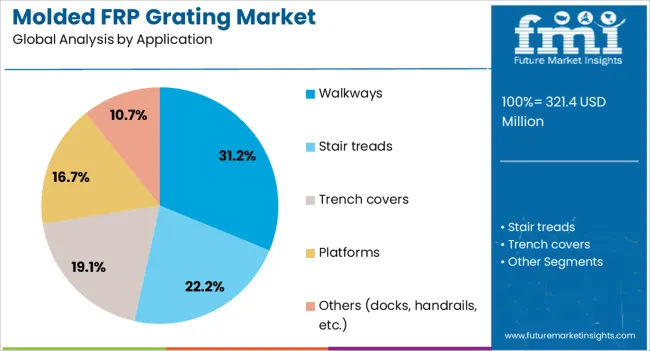

The molded FRP grating market is segmented by resin type, application, end-use industry, and geographic regions. By resin type, the molded FRP grating market is divided into Polyester, Vinyl ester, Phenolic, Epoxy, and Others. In terms of application, molded frp grating market is classified into Walkways, Stair treads, Trench covers, Platforms, and Others (docks, handrails, etc.).

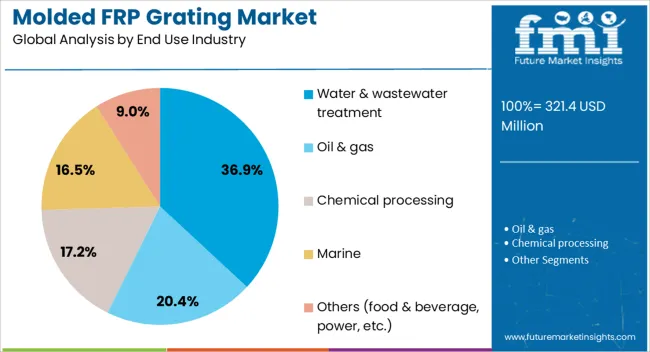

Based on end-use industry, the molded FRP grating market is segmented into Water & wastewater treatment, Oil & gas, Chemical processing, Marine, and Others (food & beverage, power, etc.). Regionally, the molded FRP grating industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The polyester segment is projected to account for 29.9% of the molded FRP grating market revenue share in 2025, establishing itself as the leading resin type. This leadership is attributed to its balanced performance characteristics, cost-effectiveness, and chemical resistance, which make it suitable for a wide range of general-purpose applications. Polyester-based gratings are being widely adopted in industries where moderate corrosion protection is sufficient, such as commercial walkways, platforms, and industrial flooring.

The resin’s affordability, ease of molding, and compatibility with various fillers and reinforcements enable efficient manufacturing and widespread customization. Polyester gratings also provide good mechanical strength and dimensional stability, which meet the operational requirements of most standard industrial environments.

Their acceptance is further reinforced by compliance with fire retardancy and safety standards, particularly in moderately corrosive or outdoor conditions. As industrial and municipal infrastructure projects continue to expand, the versatility and economic advantage of polyester resin are expected to sustain its dominance in the resin type segment of the molded FRP grating market.

The walkways segment is anticipated to hold 31.2% of the molded FRP grating market revenue share in 2025, making it the dominant application segment. This leadership is driven by the increasing need for durable, slip-resistant, and maintenance-free surfaces in industrial, commercial, and public infrastructure environments. Molded FRP gratings are being favored for walkway installations due to their ability to withstand exposure to corrosive chemicals, moisture, and UV radiation without deteriorating over time.

Their lightweight nature enables faster installation and reduces structural load, making them ideal for elevated platforms and catwalks. Enhanced safety features, such as anti-slip surfaces and non-conductive properties, are supporting their use in high-risk environments like processing plants, treatment facilities, and power stations.

The long operational life and minimal maintenance requirements of FRP walkways are also reducing total lifecycle costs for end users. As safety regulations become more stringent and infrastructure expansion continues globally, molded FRP gratings are expected to retain their prominent role in walkway applications across various industries.

The water and wastewater treatment segment is projected to represent 36.9% of the molded FRP grating market revenue share in 2025, positioning it as the leading end-use industry. This dominance is being driven by the need for corrosion-resistant and low-maintenance materials that can withstand continuous exposure to moisture, chemicals, and biological agents. Molded FRP gratings are being widely adopted in treatment plants for use in walkways, trenches, platforms, and cover panels due to their ability to resist rust, degradation, and microbial growth.

Their non-conductive and slip-resistant properties make them ideal for ensuring safety in wet and hazardous operating environments. The rising global emphasis on water conservation, sanitation infrastructure, and environmental compliance is encouraging municipalities and private operators to invest in reliable, long-lasting materials.

FRP gratings also contribute to reduced operational costs by minimizing downtime and eliminating the need for frequent replacements or surface treatments. As governments increase funding for sustainable infrastructure and modernize aging facilities, the adoption of molded FRP gratings in water and wastewater treatment is expected to remain a key growth driver for the market.

The molded FRP grating market is growing as demand for corrosion-resistant, durable materials increases in industrial sectors. Its expanded applications across various industries, coupled with the trend toward customized solutions, are driving market growth. However, the higher initial cost of FRP grating and challenges with market penetration remain significant hurdles. The market’s growth will largely depend on overcoming these challenges and continuing to demonstrate the long-term value that molded FRP grating offers to industries worldwide.

The molded FRP grating market is seeing an increase in demand due to the growing need for corrosion-resistant materials. Industries like chemical processing, wastewater treatment, and oil & gas are turning to FRP grating for its durability and resistance to harsh environments. The market is benefiting from industries looking for alternatives to traditional metal gratings that are prone to rust and deterioration. As companies focus on improving the lifespan of their infrastructure, molded FRP grating offers a strong solution.

Molded FRP grating’s expanding applications in industrial sectors is opening up new market opportunities. The lightweight yet strong properties of FRP grating make it ideal for use in flooring, walkways, and platforms in a variety of industries, including pharmaceuticals, food processing, and energy. As industries continue to realize the value of using molded FRP grating in tough and demanding environments, its market potential grows. The increased adoption of FRP grating across diverse sectors is helping boost overall demand.

A notable trend in the molded FRP grating market is the growing demand for customizable and aesthetically pleasing grating solutions. As industries aim to improve both the functional and visual aspects of their infrastructure, FRP grating manufacturers are offering more customization options. These include different colors, designs, and surface textures to meet specific client requirements. This trend is particularly evident in commercial and residential projects, where visual appeal and performance are equally important.

Despite its many advantages, the molded FRP grating market faces challenges related to price and market penetration. The initial cost of molded FRP grating tends to be higher than that of traditional metal gratings, limiting its adoption in some cost-sensitive sectors. Additionally, although the material offers long-term benefits, it may still be overlooked in favor of conventional materials that are perceived as more affordable or readily available. Overcoming these pricing challenges will be essential for expanding the market further.

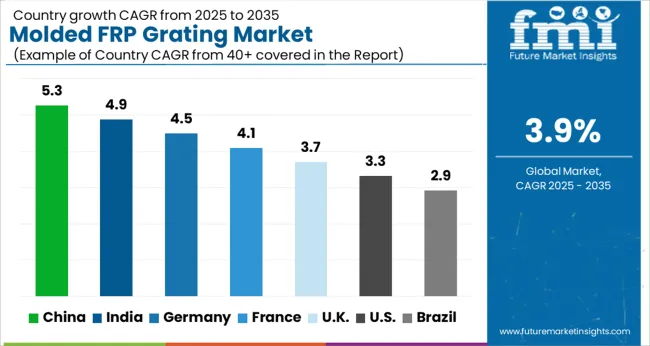

| Country | CAGR |

|---|---|

| China | 5.3% |

| India | 4.9% |

| Germany | 4.5% |

| France | 4.1% |

| UK | 3.7% |

| USA | 3.3% |

| Brazil | 2.9% |

The global molded FRP grating market is projected to grow at a CAGR of 3.9% from 2025 to 2035. China leads with a growth rate of 5.3%, followed by India at 4.9%, and Germany at 4.5%. The United Kingdom records a growth rate of 3.7%, while the United States shows the slowest growth at 3.3%. This expansion is driven by the increasing demand for corrosion-resistant materials in various industries, such as construction, marine, and industrial applications. Emerging markets like China and India are experiencing faster growth due to industrialization and infrastructure development, while developed markets like the USA and UK focus on adopting eco-friendly, durable, and high-performance materials. This report includes insights on 40+ countries; the top markets are shown here for reference.

The molded FRP grating market in China is expected to grow at a rate of 5.3%, supported by the country’s rapid industrialization, infrastructure growth, and the increasing demand for durable and corrosion-resistant materials. With a large manufacturing base, the need for moldable and lightweight materials in construction and industrial applications is accelerating, particularly in sectors like energy, water treatment, and chemical processing. As the country emphasizes sustainability and high-quality building materials, molded FRP grating’s resistance to environmental factors such as chemicals, moisture, and extreme temperatures makes it an attractive option for a wide range of applications. China’s growing industrial production and infrastructural development are expected to continue fueling the demand for these materials.

The molded FRP grating market in India is projected to grow at 4.9%, supported by the country’s rapid urbanization, growing infrastructure development, and increasing industrial activities. With expanding sectors like energy, manufacturing, and construction, the demand for high-performance and durable materials is on the rise. Molded FRP grating’s corrosion resistance and long-lasting properties are particularly appealing in industries such as water treatment, chemical processing, and oil and gas. The Indian government’s initiatives to boost industrial infrastructure and expand manufacturing capabilities further drive the demand for molded FRP grating. Additionally, as the country focuses on green building solutions, the lightweight and eco-friendly nature of FRP materials positions them as an ideal choice for various applications.

The molded FRP grating market in Germany is expected to grow at a rate of 4.5%, driven by the country’s advanced manufacturing base and the increasing emphasis on sustainable infrastructure. With a strong industrial sector and a focus on renewable energy projects, Germany is witnessing a surge in demand for durable materials like FRP grating, which offer resistance to harsh environments. The chemical, marine, and energy industries are key sectors driving adoption, where safety, corrosion resistance, and lightweight properties are crucial. Germany’s robust focus on industrial automation and digitalization also contributes to the demand for high-performance, cost-effective materials that meet strict environmental standards.

The molded FRP grating market in the United Kingdom is projected to grow at a rate of 3.7%, with demand driven by infrastructure development, particularly in the energy, chemical, and water treatment sectors. As the UK increasingly focuses on eco-friendly and efficient building materials, molded FRP grating’s resistance to corrosion and ease of maintenance have made it an attractive solution for various industrial applications. The need for durable materials in the water treatment and wastewater management sectors, combined with the growing demand for sustainable construction solutions, is expected to support the market’s growth. Additionally, the UK’s aging infrastructure and its need for reliable and long-lasting materials further contribute to the demand for molded FRP grating.

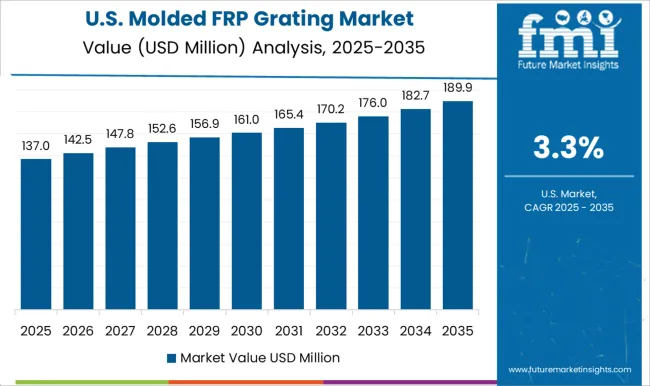

The molded FRP grating market in the United States is expected to grow at a rate of 3.3%, supported by the increasing need for high-performance materials in various industries, including construction, oil and gas, and wastewater management. USA companies are increasingly adopting molded FRP grating due to its cost-effectiveness, low maintenance requirements, and excellent resistance to corrosion. As industries in the USA continue to modernize, especially in water treatment and infrastructure development, the demand for durable and eco-friendly materials is rising. The market is also benefiting from increasing regulatory pressure to adopt sustainable materials and improve the safety and longevity of infrastructure.

The molded FRP (Fiberglass Reinforced Plastic) grating market is poised for steady growth due to its superior performance, durability, and versatility in a variety of industrial applications. Key players such as American Grating, Bedford Reinforced Plastics, and Delta Composite are leading the market by providing high-quality FRP grating products that are corrosion-resistant, lightweight, and easy to maintain. Fibergrate Composite Structures and Fibrolux offer a range of molded grating solutions designed for industries like chemical, oil and gas, and water treatment, where traditional materials like metal would corrode or degrade quickly under harsh conditions. The global demand for molded FRP gratings is also driven by increasing safety standards in industrial settings, where these products help ensure non-slip surfaces and robust support for heavy machinery and equipment.

Indiana Group, Liberty Pultrusions, and Meiser Grating are capitalizing on this trend by offering innovative designs, while ensuring that their products meet stringent quality and environmental standards. As the market expands, companies like National Grating, Peabody Engineering, and Seasafe are focusing on providing customized solutions that cater to specific customer needs in various sectors, including marine, infrastructure, and manufacturing. Strongwell Corporation, a major player in the molded FRP grating sector, is investing heavily in R&D to develop advanced products that deliver greater load-bearing capacities and longer service lives. Additionally, with the growing emphasis on sustainability, manufacturers are designing eco-friendly FRP grating materials that contribute to reducing environmental impact.

| Item | Value |

|---|---|

| Quantitative Units | USD 321.4 Million |

| Resin Type | Polyester, Vinyl ester, Phenolic, Epoxy, and Others |

| Application | Walkways, Stair treads, Trench covers, Platforms, and Others (docks, handrails, etc.) |

| End Use Industry | Water & wastewater treatment, Oil & gas, Chemical processing, Marine, and Others (food & beverage, power, etc.) |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled | American Grating, Bedford Reinforced Plastics, Delta Composite, Fibergrate Composite Structures, Fibrolux, Higoal, Indiana Group, Liberty Pultrusions, Meiser Grating, National Grating, Peabody Engineering, Seasafe, and Strongwell Corporation |

| Additional Attributes | Dollar sales by material type (glass fiber reinforced plastic, carbon fiber reinforced plastic) and application (industrial, marine, chemical, wastewater) are key metrics. Trends include rising demand for corrosion-resistant, lightweight grating solutions, growth in industrial and infrastructure projects, and adoption in hazardous environments. Regional adoption, technological advancements, and regulatory compliance are driving market growth. |

The global molded frp grating market is estimated to be valued at USD 321.4 million in 2025.

The market size for the molded frp grating market is projected to reach USD 471.2 million by 2035.

The molded frp grating market is expected to grow at a 3.9% CAGR between 2025 and 2035.

The key product types in molded frp grating market are polyester, vinyl ester, phenolic, epoxy and others.

In terms of application, walkways segment to command 31.2% share in the molded frp grating market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Molded Fiber Egg Packaging Market Forecast and Outlook 2025 to 2035

Molded Wood Pallets Market Forecast and Outlook 2025 to 2035

Molded Fiber Bowl Market Size and Share Forecast Outlook 2025 to 2035

Molded Fiber Pulp Packaging Industry Analysis in Australia and New Zealand Forecast Outlook 2025 to 2035

Molded Fiber Pulp Packaging Market Size and Share Forecast Outlook 2025 to 2035

Molded Fiber Packaging Market Size and Share Forecast Outlook 2025 to 2035

Molded Fiber Pulp Cap Market Size and Share Forecast Outlook 2025 to 2035

Molded Fiber Pulp Packaging Market Size and Share Forecast Outlook 2025 to 2035

Molded Foam Market Size and Share Forecast Outlook 2025 to 2035

Molded Fiber Cup Market Size and Share Forecast Outlook 2025 to 2035

Molded Pulp Packaging Market Size and Share Forecast Outlook 2025 to 2035

Molded Pulp Basket Market Size and Share Forecast Outlook 2025 to 2035

Molded Fiber Wine Packs Market Size and Share Forecast Outlook 2025 to 2035

Molded Underfill Material Market Size and Share Forecast Outlook 2025 to 2035

Molded Fiber Pulp Edge Protectors Market Size and Share Forecast Outlook 2025 to 2035

Molded Fiber End Caps Market Size and Share Forecast Outlook 2025 to 2035

Molded Fiber Containers Market Size and Share Forecast Outlook 2025 to 2035

Molded Fiber Pulp Packaging industry Analysis in USA and Canada - Size, Share, and Forecast Outlook 2025 to 2035

Molded Pulp Packaging Machines Market Analysis - Growth & Forecast 2025 to 2035

Competitive Overview of Molded Wood Pallets Market Share

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA