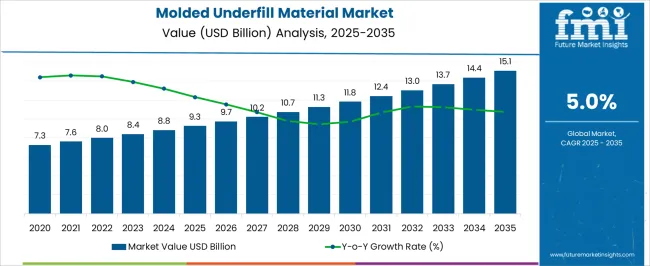

The Molded Underfill Material Market is estimated to be valued at USD 9.3 billion in 2025 and is projected to reach USD 15.1 billion by 2035, registering a compound annual growth rate (CAGR) of 5.0% over the forecast period.

| Metric | Value |

|---|---|

| Molded Underfill Material Market Estimated Value in (2025E) | USD 9.3 billion |

| Molded Underfill Material Market Forecast Value in (2035F) | USD 15.1 billion |

| Forecast CAGR (2025 to 2035) | 5.0% |

The molded underfill material market is gaining traction due to the ongoing evolution in advanced semiconductor packaging, miniaturization trends, and rising demand for high I/O density in consumer and industrial electronics. Molded underfill materials are increasingly being used to enhance mechanical strength, reliability, and thermal cycling performance in microelectronic assemblies.

This surge is supported by the proliferation of mobile devices, automotive electronics, and high-speed computing systems that require improved protection for flip chips, ball grid arrays, and other chip-scale packages. As packaging becomes more complex and form factors more compact, molded underfills are being relied upon for void-free encapsulation and optimized flow characteristics, ensuring superior adhesion and stress absorption.

Environmental durability and reworkability have also emerged as key product features aligned with evolving end-user expectations and sustainability goals With expanding 5G infrastructure, growth in AI-powered devices, and automotive ADAS technologies, the market is expected to witness continued growth, underpinned by advancements in materials engineering and process automation.

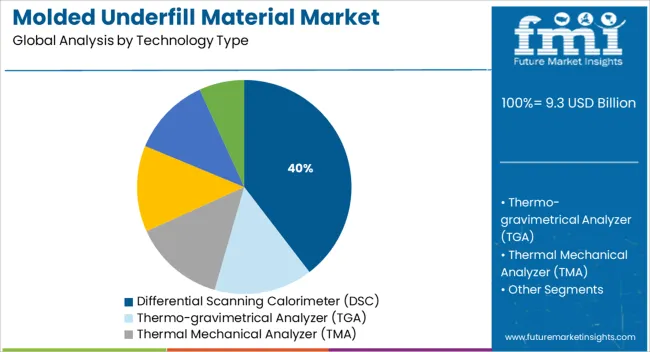

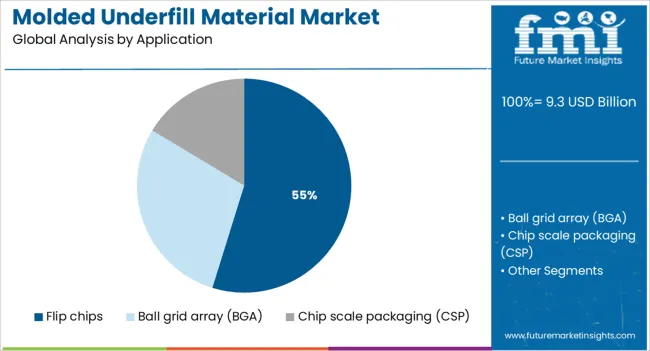

The market is segmented by Technology Type and Application and region. By Technology Type, the market is divided into Differential Scanning Calorimeter (DSC), Thermo-gravimetrical Analyzer (TGA), Thermal Mechanical Analyzer (TMA), Coefficient of Thermal Expansion (CTE), Dynamic Mechanic Analyzer (DMA), and Others. In terms of Application, the market is classified into Flip chips, Ball grid array (BGA), and Chip scale packaging (CSP). Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The differential scanning calorimeter technology type segment is projected to hold 39.6% of the molded underfill material market revenue share in 2025, making it the dominant segment within this category. The adoption of differential scanning calorimetry has been driven by its ability to precisely measure the thermal properties of molded underfill materials during polymerization, cure processes, and end-use temperature cycles.

This capability ensures optimal performance characteristics and helps manufacturers maintain consistency in product quality across high-reliability semiconductor applications. The technology's accuracy in detecting glass transition temperature, melting points, and oxidative stability has made it indispensable in quality control and R&D activities.

Moreover, as underfill material formulations become more sophisticated, especially for advanced node integration, the role of differential scanning calorimetry in ensuring material qualification and process compatibility has increased Its relevance has further grown with the push toward zero-defect packaging in mission-critical applications, where thermal performance margins are closely monitored and controlled.

The flip chips application segment is expected to account for 54.8% of the molded underfill material market’s revenue share in 2025, marking it as the leading application segment. The growth of this segment has been influenced by the increasing use of flip chip interconnects in smartphones, wearables, high-performance computing, and automotive electronics due to their superior electrical and thermal performance.

Molded underfill materials are playing a critical role in enhancing the mechanical robustness of flip chips by providing structural reinforcement and mitigating stress during temperature fluctuations and power cycling. The growing need for finer pitch connections, higher reliability under harsh environmental conditions, and greater thermal conductivity has driven the development of application-specific underfill solutions for flip chip packaging.

Additionally, the compatibility of molded underfill materials with mass production techniques such as transfer molding and their ability to reduce production cycle times have reinforced their preference in this high-volume application As demand for compact, energy-efficient electronics increases, molded underfills are becoming essential in ensuring long-term durability and signal integrity in flip chip assemblies.

Underfill materials are compound formulations of inorganic fillers and organic polymers which are applicable in semiconductor packaging to attain enhanced thermo mechanical enactment. Molded underfill material are mold materials used as over mold compounds in wire bonded or flip chip CSP devices.

Flip chip is a major application for molded underfill material. The growing demand for smaller, lighter, efficient, and cost effective devices has tensed notable consideration towards the molded underfill material. Further, molded underfill is a most significant techniques that is used for the application of underfill materials.

Due to increasing price from end use industry, molded underfill material relatively cost effective technique and being a conventional process technique.

The major factors which are boosting the growth of molded underfill material market are increasing use of molded underfill material in flip chip packages. The prominent trends from consumer side are driving the global molded underfill material market growth. The growing demand for high performing, low cost, small size devices is a key driving factors for global molded underfill material market growth.

Moreover, high usage of molded underfill material from wafer level packaging and flip chip packaging due rising demand in tablets and smart phones is a prominent driving factor for global molded underfill material market demand over the forecast period. Further, advancement and up-gradation in technology for molded underfill material market is directly effect by the innovation and coming advancements in electronic industry. In addition, few molded underfill material manufacturers in the market are offering molded underfill material products with lead free solder paste.

The global underfill material, a parent market for the global molded underfill material market is growing rapidly to continually expand at high CAGR in coming years. Global flip chip market is accounting high growth and is estimated to register significant growth in coming years which in turn increasing the growth of molded underfill material market.

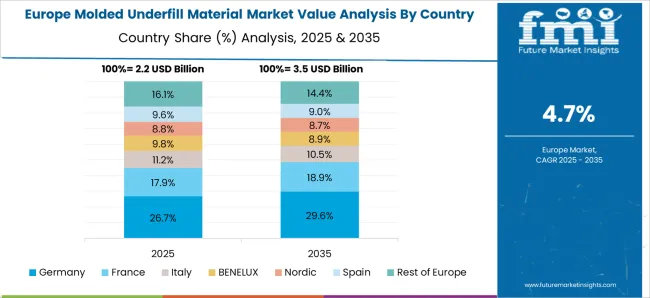

Regarding geography, molded underfill material market has been categorized into seven key regions including North America, Western Europe, Eastern Europe, APEJ, Japan, Latin America, and the Middle East & Africa.

Molded underfill material market is expected to register healthy CAGR during the forecast period due to high demand of molded underfill material in wide range of application such as flip chips, ball grid array (BGA), and chip scale packaging (CSP) across the region.

In terms of regions, North America accounts for significant share for molded underfill material market, owing to the high demand from smart and advanced packaging in the region as related to other developed regions.

In terms of developing region of Asia-Pacific, the growth of the molded underfill material is comparatively high and with high CAGR in forecast period owed to factors such as such as globalization, rapid economic development, and increasing demand of the molded underfill material in packaging industry and its sub-verticals, and high usage of the molded underfill material in media and automotive industry.

In addition, Over the forecast period, Asia-Pacific market for is anticipated to grow significantly owing to the growth of packaging industry in the region. Overall, the global market for molded underfill material is expected to grow significantly by the end of forecast period.

Molded underfill material market for Asia Pacific is also expected to witness rapid growth during the forecast period primarily attributed to the growth of smart packaging market and increasing usage of molded underfill material in different industry verticals, especially in China and India. The molded underfill material market is growing at faster rate and is expected to grow at high CAGR in forecasted years.

Few players identified in molded underfill material market are:-

The research report presents a comprehensive assessment of the market and contains thoughtful insights, facts, historical data, and statistically supported and industry-validated market data. It also contains projections using a suitable set of assumptions and methodologies. The research report provides analysis and information according to categories such as market segments, geographies, type of product and applications.

The global molded underfill material market is estimated to be valued at USD 9.3 billion in 2025.

The market size for the molded underfill material market is projected to reach USD 15.1 billion by 2035.

The molded underfill material market is expected to grow at a 5.0% CAGR between 2025 and 2035.

The key product types in molded underfill material market are differential scanning calorimeter (dsc), thermo-gravimetrical analyzer (tga), thermal mechanical analyzer (tma), coefficient of thermal expansion (cte), dynamic mechanic analyzer (dma) and others.

In terms of application, flip chips segment to command 54.8% share in the molded underfill material market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Molded Fiber Egg Packaging Market Forecast and Outlook 2025 to 2035

Molded Wood Pallets Market Forecast and Outlook 2025 to 2035

Molded Fiber Bowl Market Size and Share Forecast Outlook 2025 to 2035

Molded Fiber Pulp Packaging Industry Analysis in Australia and New Zealand Forecast Outlook 2025 to 2035

Molded Fiber Pulp Packaging Market Size and Share Forecast Outlook 2025 to 2035

Molded Fiber Packaging Market Size and Share Forecast Outlook 2025 to 2035

Molded Fiber Pulp Cap Market Size and Share Forecast Outlook 2025 to 2035

Molded Fiber Pulp Packaging Market Size and Share Forecast Outlook 2025 to 2035

Molded FRP Grating Market Size and Share Forecast Outlook 2025 to 2035

Molded Foam Market Size and Share Forecast Outlook 2025 to 2035

Molded Fiber Cup Market Size and Share Forecast Outlook 2025 to 2035

Molded Pulp Packaging Market Size and Share Forecast Outlook 2025 to 2035

Molded Pulp Basket Market Size and Share Forecast Outlook 2025 to 2035

Molded Fiber Wine Packs Market Size and Share Forecast Outlook 2025 to 2035

Molded Fiber Pulp Edge Protectors Market Size and Share Forecast Outlook 2025 to 2035

Molded Fiber End Caps Market Size and Share Forecast Outlook 2025 to 2035

Molded Fiber Containers Market Size and Share Forecast Outlook 2025 to 2035

Molded Fiber Pulp Packaging industry Analysis in USA and Canada - Size, Share, and Forecast Outlook 2025 to 2035

Molded Pulp Packaging Machines Market Analysis - Growth & Forecast 2025 to 2035

Market Share Breakdown of the Molded Pulp Basket Industry

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA