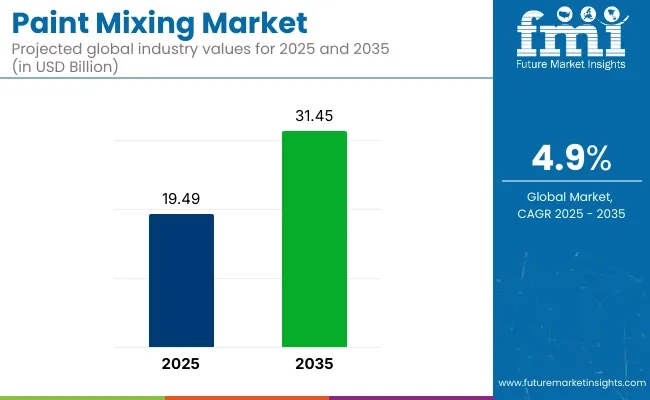

The global paint mixing market is projected to witness substantial expansion, as its value is expected to increase from USD 19.49 billion in 2025 to USD 31.45 billion by 2035, reflecting a CAGR of 4.9% during the forecast period.

This growth trajectory is being supported by heightened demand for customized paint colors, ongoing technological advancements in paint mixing equipment, and the consistent expansion of industries such as construction and automotive. Across residential, commercial, and industrial segments, paint mixing systems are being leveraged to ensure precise color formulations and enhanced product quality.

Several factors are influencing this market’s positive outlook. A significant increase in consumer demand for personalized paint solutions is driving the adoption of advanced paint mixing technologies. Moreover, a global shift towards sustainability is encouraging the use of eco-friendly paints, with low-VOC (volatile organic compound) formulations gaining traction.

As a result, paint mixing equipment is being engineered to accommodate these newer, sustainable product types. Additionally, automation, artificial intelligence (AI), and machine learning are being integrated into paint mixing processes. This integration is leading to improvements in operational efficiency, color accuracy, and a reduction in production time, thereby making such technologies essential to the future competitiveness of the paint mixing industry.

Recent innovations and strategic advancements continue to reshape the market. Notably, PPG Industries’ MOONWALK automated paint mixing system was adopted across body shops in all 50 USA states by November 2025, leading to a productivity gain of over 10 percent. Furthermore, Sherwin-Williams reported an expected low-single-digit percentage increase in net sales for 2025, driven by efficiency improvements and cost-control strategies.

AkzoNobel’s CEO, Greg Poux-Guillaume, highlighted the company’s proactive efforts in conducting strategic reviews and implementing cost-saving measures to maintain its market leadership amid economic uncertainties. These strategic initiatives and innovations reflect a market that is being shaped by adaptability, technological progress, and evolving consumer preferences. As a result, the paint mixing market is expected to maintain its robust growth trajectory through 2035.

| Attribute | Value |

|---|---|

| Market Size in 2025 | USD 19.49 billion |

| Market Size in 2035 | USD 31.45 billion |

| CAGR (2025 to 2035) | 4.9% |

The paint mixing market is expected to see significant growth, driven by key segments such as water-based paints and paint manufacturers. Water-based paints are projected to dominate the market, while paint manufacturers will remain the primary end-users. These segments are expected to drive innovation and expansion in the paint mixing industry.

Water-based paints are projected to capture 45% of the paint mixing market share by 2025. These paints are becoming increasingly popular due to their eco-friendly characteristics, including low volatile organic compound (VOC) emissions and easy cleanup with water. Water-based paints are widely used in both residential and commercial applications due to their durability, ease of application, and improved performance in terms of color retention and resistance to wear.

Companies like PPG Industries, Sherwin-Williams, and AkzoNobel have been leading the development of water-based paints, incorporating advanced mixing technologies to enhance product quality and performance. As environmental concerns continue to rise and regulations on VOC emissions become stricter, the demand for water-based paints is expected to increase.

This will drive the growth of the paint mixing market, as manufacturers continue to focus on developing high-performance, environmentally friendly paint solutions that meet consumer demand for sustainability and health-conscious products.

Paint manufacturers are expected to capture 30% of the paint mixing market share by 2025. These companies are the largest end-users of paint mixing technologies, as they rely on advanced mixing processes to ensure consistent and high-quality paint production. With growing demand for customized colors, textures, and finishes, paint manufacturers are increasingly adopting sophisticated mixing systems to improve production efficiency and meet specific customer requirements.

Leading companies such as Benjamin Moore, Dulux, and Behr Paint are investing in modern mixing technologies to streamline operations, reduce waste, and enhance the overall quality of their products. The need for paint manufacturers to deliver superior products, along with the rising demand for both industrial and consumer-grade paints, is expected to fuel the continued demand for advanced paint mixing solutions. As manufacturers seek to improve their operational effectiveness and keep up with growing market demand, the paint manufacturing segment will remain a key driver of growth in the paint mixing market.

People all around the world are altering the appearance of their homes, businesses, and other establishments, which is driving the growth of interior design and décor. Using the use of paint mixers, users may create the precise color for their area, changing the aesthetic appeal of a room effectively with paints. Since they have no smell and have less of an impact on the environment, eco-friendly paints are in more demand. People are moving to eco-friendly products, which is accelerating market expansion.

The DIY and color experimentation trend, which is frequently pushed on social media, is fuelling the expansion of the paint mixer industry. Many users are experimenting with unusual color combinations, textures, and even fragrances that may be mixed into their paint using efficient paint mixers.

Today, paint mixers are among the most lucrative industries. Numerous facets of the economy need a lot of paint. Future growth is anticipated to be boosted by technology developments as well as the release of novel goods like automated paint mixers and other products. Manufacturers have developed automatic paint mixers due to technological advancements to lessen labor-intensive paint mixing processes. Powders and pigments are combined with polyurethane, epoxy, polyester, and acrylic resins in the newly created and highly advanced automated mixer without the need for air.

Different types of paint mixers are used by paint manufacturers to properly and effectively mix dry paints. Using these machines, manufacturers may create a variety of mixtures, such as pigment with resin or binder, liquid (solvent), pigment with solvent, etc. A high mix quality and flawless mixing are necessary at several phases of the paint production process. Automatic paint mixers are used for this by paint factories. blending different elements to create a consistent combination that produces a finish that is smooth and free of streaks and lumps for a better look. For small-batch mixing, paint manufacturers employ manual paint mixers.

| Attribute | Details |

|---|---|

| Paint Mixing Market Size (2025) | USD 17,712.7 million |

| Paint Mixing Market Forecast Value (2035) | USD 28,578.5 million |

| Paint Mixing Market Growth Rate (2025 to 2035) | 4.9% CAGR |

| Forecast Period | 2025 to 2035 |

| USA Paint Mixing Market Share | 32.7% |

The market for paint mixing is likely to remain lucrative in the United States. In 2023, this region is anticipated to account for more than 22% of the global market. The presence of major companies and the rising demand for vehicles in this region are projected to expand the region's dominance in the industry. The United States is a popular site for businesses to establish manufacturing operations due to the expanding middle class, low labour costs, and low operational expenses. As a result, there are now more industrial facilities in the area, which has led to an increase in construction work and, ultimately, a predicted rise in demand for paint mixing.

India is a country with a rich culture and history. The art of painting has been prevalent in India since ancient times. Indian paintings are known for their bright colours and intricate designs. There is a great demand for paint mixing in India. This is because there are many opportunities for paint mixers in India. Many painting companies in India need skilled paint mixers. In addition, there are many art galleries and museums in India that require paint mixers to create the perfect colours for their paintings.

Germany is the world's largest paint producer and has a strong grip on the European paint mixing market. German companies have been able to dominate the market due to their efficient production processes and economies of scale. German firms have also been able to benefit from lower raw material costs and favourable government policies. As a result of these factors, German companies have been able to gain a significant competitive advantage over their rivals in other European countries. This has allowed them to increase their market share and control a large percentage of the European paint mixing industry.

China is the world’s most populous country and its economy is rapidly growing. China is an attractive market for paint companies due to its large population, rapid economic growth, and improving standard of living. The Chinese government’s 'Made in China 2025' initiative is expected to boost the demand for paints and coatings as it aims to increase the manufacturing output of high-quality products in the country. The Chinese paint market presents a great opportunity for foreign paint companies looking to expand their operations into Asia. Key challenges for foreign companies doing business in China include intellectual property protection, regulatory compliance, and local competition.

The color of the paint is determined by the type and number of pigments added to the binder. The binder is the liquid portion of the paint that suspends the pigment and gives the paint its adhesion. Some binders are natural while others are synthetic. Many different types of pigments can be used to make paint, including both inorganic and organic compounds.

Inorganic pigments are often minerals that have been ground into a fine powder, while organic pigments are usually derived from plants or animals. The same principles that apply to making paint also apply to creating food and beverage colorants. Just as many different types of pigments can be used to make paint, many different types of colorants can be used in food and beverages.

Due to rising market demand for eco-friendly products, start-ups are putting paint mixing in the spotlight. In addition to offering non-synthetic paint and coatings on the market, these consumer products start-up enterprises are also involved in a broad variety of production, distribution, and marketing operations. The automotive and construction sectors use the majority of environmentally friendly and sustainable paint components since they are used in a wide range of metal and wood coatings.

Currently, the market is dominated by a few large companies that have established themselves as leaders in the space. However, with the increasing popularity of do-it-yourself (DIY) home improvement projects, more consumers are looking for ways to mix their paint at home. This has created an opportunity for new companies to enter the market and offer products and services that cater to this growing trend. As the competitive landscape evolves, it will be important for companies to differentiate themselves to stand out from the crowd.

Some players in the market are opting for a semi-automatic paint mixer that mixes paints and varnishes. This semi-automatic paint mixer is most commonly employed by vendors in industrial settings, such as manufacturing facilities and warehouses, where vast volumes of coatings such as glosses and primers are produced or utilized. These are low-cost equipment used to manually mix pigment with thinner or water before adding it to the primary substance, such as lacquer thinner, paint thinner oil, and so on. They can be utilized in tiny amounts but not in big numbers.

B&Q uses Hullabalook technology to provide an online paint-mixing experience. Hullabaloo, in addition to 2000+ hues, allows customers to order online, mix on demand, and provide the product ready for purchase. For the first time, B&Q now sells a large selection of Valspar mixed-to-order paints online.

COAT was founded in London, England in 2020. This internet-only company provides paints and painting supplies. As part of the offering, there are sustainable peel-and-stick swatches, chosen color sets of paints, and a variety of painting supplies like bamboo rollers, colorful tapes, sugarcane trays, and more.

| Report Attributes | Details |

|---|---|

| Market Size in 2025 | USD 19.49 billion |

| Market Size in 2035 | USD 31.45 billion |

| CAGR (2025 to 2035) | 4.9% |

| Base Year for Estimation | 2024 |

| Historical Period | 2020 to 2024 |

| Projections Period | 2025 to 2035 |

| Quantitative Units | USD billion for value |

| Types Analyzed | Water-Based, Oil-Based, Others |

| Applications Analyzed | Paint Manufacturers, Paint Users, Commercial, Food and Equipment Machinery, Manufacturing Industry |

| Regions Covered | North America, Latin America, Europe, East Asia, South Asia, Oceania, MEA |

| Countries Covered | United States, Canada, Mexico, Brazil, Argentina, Germany, France, United Kingdom, Italy, Spain, Netherlands, China, India, Japan, South Korea, Australia, GCC Countries, South Africa |

| Key Players influencing the Market | Sherwin-Williams, DYNAMIX AGITATORS, Marshalltown, Alloway Tools, Pacer Industrial Mixers, Bosch, Allway Tools, Wal-Board Tools, Husky |

| Additional Attributes | Dollar sales by type (water-based, oil-based), Dollar sales by application (paint manufacturers, food and equipment machinery), Growth trends in paint mixing equipment demand across commercial and manufacturing sectors, Regional adoption trends in key markets across North America, Europe, and Asia-Pacific |

The paint mixing market size is estimated to be valued at USD 19.49 billion in 2025.

The paint mixing industry is expected to rise at a CAGR of 4.9% during the forecast period.

The North American paint mixing industry is expected to register a 4.9% CAGR between 2025 and 2035.

China's paint mixing industry is projected to grow at a CAGR of 5.7% during the forecast period.

The United Kingdom paint mixing industry is projected to grow at a CAGR of 5.3% during the forecast period.

India's paint-mixing industry is projected to grow at a CAGR of 6.3% during the forecast period.

The demand for the paint mixing industry in the USA is expected to grow at 32.7% in 2025.

The demand for the paint mixing industry in Japan is expected to grow at 8.0 % in 2025.

The demand for the paint mixing industry in Australia is expected to grow at 2.7% in 2025.

The global paint mixing industry is forecasted to surpass USD 31.45 billion by 2035.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Paint Cans Market Size and Share Forecast Outlook 2025 to 2035

Painting Robots Market Size and Share Forecast Outlook 2025 to 2035

Paint Curing Lamp Market Size and Share Forecast Outlook 2025 to 2035

Paint Booth Market Size and Share Forecast Outlook 2025 to 2035

Painting Tool Market Size and Share Forecast Outlook 2025 to 2035

Paint Rollers Market Size and Share Forecast Outlook 2025 to 2035

Paint Ingredient Market Size and Share Forecast Outlook 2025 to 2035

Paint Tester Market Size and Share Forecast Outlook 2025 to 2035

Paint Knife Market Size and Share Forecast Outlook 2025 to 2035

Paint Buckets Market Size, Share & Forecast 2025 to 2035

Market Share Insights of Paint Can Manufacturers

Market Share Breakdown of Paint Protection Film Manufacturers

Paint Additives Market Growth 2024-2034

Faux Paints And Coatings Market Size and Share Forecast Outlook 2025 to 2035

Spray Painting Machine Market Size and Share Forecast Outlook 2025 to 2035

Small Paint Pail Market Size and Share Forecast Outlook 2025 to 2035

Metal Paint Tray Market Size and Share Forecast Outlook 2025 to 2035

Epoxy Paint Thinner Market Growth - Trends & Forecast 2025 to 2035

Epoxy Paint Market Growth – Trends & Forecast 2024-2034

Metal Paint Can Market Trends & Industry Growth Forecast 2024-2034

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA