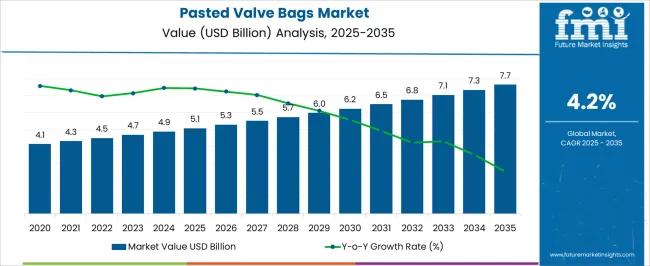

The Pasted Valve Bags Market is estimated to be valued at USD 5.1 billion in 2025 and is projected to reach USD 7.7 billion by 2035, registering a compound annual growth rate (CAGR) of 4.2% over the forecast period.

| Metric | Value |

|---|---|

| Pasted Valve Bags Market Estimated Value in (2025E) | USD 5.1 billion |

| Pasted Valve Bags Market Forecast Value in (2035F) | USD 7.7 billion |

| Forecast CAGR (2025 to 2035) | 4.2% |

The pasted valve bags market is experiencing strong growth due to increasing demand for sustainable, durable, and efficient packaging solutions across construction, chemical, and food industries. The adoption of valve bags has been driven by their superior sealing capability, reduced leakage risk, and ease of stacking, which enhance operational efficiency in bulk material handling.

With industries shifting toward paper-based alternatives to meet environmental regulations and consumer preferences, paper valve bags have emerged as a preferred solution. Growing investments in cement production, agrochemicals, and industrial minerals, particularly in emerging economies, are contributing to expanded application of pasted valve bags in high-volume packaging.

Technological advancements in high-barrier paper films and improved moisture resistance have further boosted the reliability of these bags under diverse transport and storage conditions As companies across sectors prioritize eco-friendly and recyclable packaging solutions, the pasted valve bags market is poised for consistent growth, supported by ongoing innovations in bag construction, closure systems, and material layering for strength and durability.

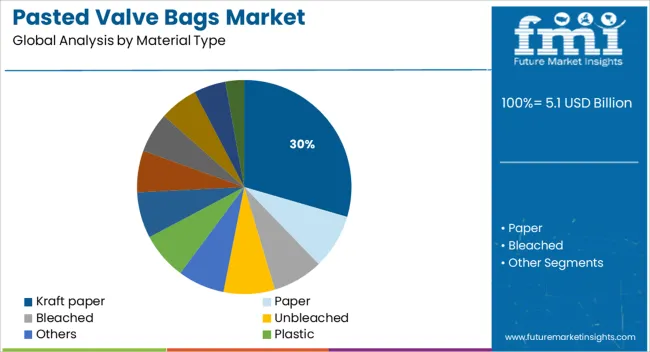

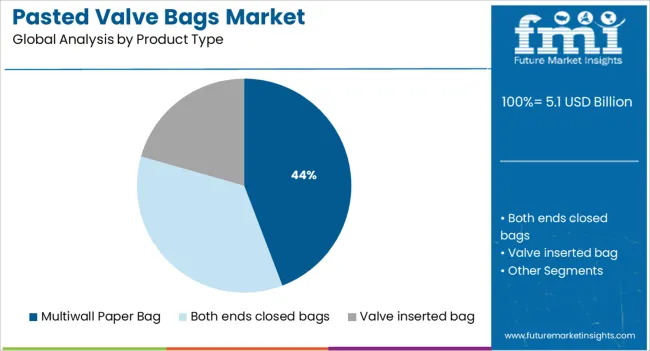

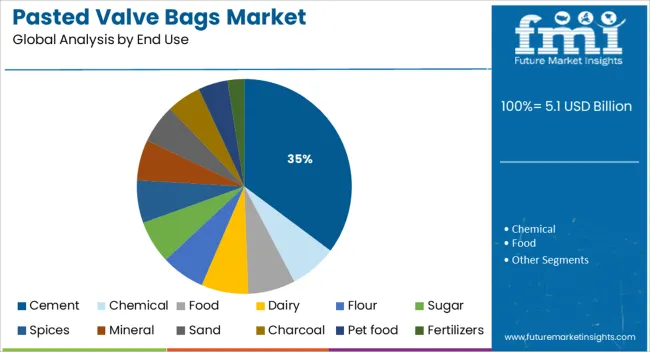

The market is segmented by Material Type, Product Type, and End Use and region. By Material Type, the market is divided into Kraft paper, Paper, Bleached, Unbleached, Others, Plastic, PP, PE, Others, Coating, Low-density polyethylene (LDPE), and High-density polyethylene (HDPE). In terms of Product Type, the market is classified into Multiwall Paper Bag, Both ends closed bags, and Valve inserted bag. Based on End Use, the market is segmented into Cement, Chemical, Food, Dairy, Flour, Sugar, Spices, Mineral, Sand, Charcoal, Pet food, and Fertilizers. Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The kraft paper segment is projected to account for 29.5% of the total revenue share in the pasted valve bags market in 2025, emerging as a key material type due to its high tensile strength and recyclability. The segment’s growth has been reinforced by increasing demand for biodegradable packaging alternatives and regulatory support for phasing out plastic-based industrial bags.

Kraft paper offers durability, resistance to tearing, and compatibility with various printing technologies, making it suitable for branding and compliance labeling. The enhanced barrier properties and moisture control capabilities of multi-ply kraft paper structures have made them favorable for bulk storage and long-haul transportation.

The ability to withstand high filling speeds without compromising on structural integrity has encouraged its use in automated bagging systems, especially in cement and chemical packaging In addition, its renewable source origin and lower environmental footprint have positioned kraft paper as a preferred substrate among manufacturers aiming to meet sustainability targets while ensuring performance and safety.

The multiwall paper bag segment is expected to contribute 44.2% of the total revenue share in the pasted valve bags market by 2025, reflecting its leading role in industrial packaging applications. This segment’s dominance is driven by its superior strength, flexibility in barrier layering, and compatibility with valve-sealed filling processes. Multiwall paper bags provide enhanced product protection against environmental factors such as humidity and dust, making them ideal for transporting materials like cement, fertilizer, and fine powders.

These bags also offer improved stacking strength and reduced breakage during handling, supporting efficiency in logistics and storage. The growing shift toward paper-based packaging for industrial bulk goods, coupled with the need for high-speed filling compatibility, has increased adoption of multiwall constructions.

Manufacturers have been increasingly opting for custom barrier combinations using high GSM kraft papers and functional coatings to tailor performance The rising demand for sustainable and high-performance packaging has reinforced the market appeal of multiwall paper bags across multiple industries.

The cement segment is projected to hold 35.2% of the total revenue share in the pasted valve bags market in 2025, making it the leading end-use segment. The segment’s leadership is driven by the rising global demand for infrastructure development, housing, and urban construction activities. Cement manufacturers have widely adopted pasted valve bags due to their dust-proof sealing, automated filling compatibility, and superior moisture protection.

These features have significantly minimized material loss and ensured compliance with international transport and safety standards. Valve bags made for cement packaging are designed to withstand rough handling, extended storage, and exposure to varied climates, ensuring the product maintains quality from plant to end-user. Additionally, the use of recyclable and biodegradable kraft-based materials has aligned with the construction industry’s push for greener procurement practices.

The integration of efficient filling systems and stackable formats has further optimized supply chain performance As cement consumption continues to rise in emerging and developing economies, the demand for reliable pasted valve bags is expected to remain robust.

The need for efficient resource packaging of granular products such as grains, cement, pet food, fertilizers and pharmaceutical products has led to the innovation of pasted valve bag.

Pasted valve bags are closed from both ends while incorporating an opening to allow for filling of the bag; sometimes these bags are often provided with micro perforation for escaping of air.

These bags are commonly made of virgin or recycled Kraft paper. The use of such bags reduces the cost of packaging significantly which makes them an attractive choice for manufacturers. Area for printing provided by these bags is overwhelming, and the quality of the print is cleaner than the traditional sacks.

To increase the area of application of pasted valve bag different coating are also used by manufacturers to enhance its barrier properties against gasses and water vapors.

The convenience provided by posted valve bags for the handling of granular products is the key driver for pasted valve bag market. The use of pasted valve bag decreases the input of raw material in packaging and increases the speed for filling of product hence improving the operational efficiency and profitability of the company.

Use of such bags not only reduces the use of plastic but also decreases the carbon footprint of the company. Ease in customization of the bags according to the need and convenience of the customers is another factor favoring pasted valve bags market.

Printable surface offered by pasted valve bag helps the manufacturer to communicate with and build its brand image among consumers. However, increasing market penetration of bulk containers due to recent technological advancements may eliminate the need for such bags which can hamper pasted valve bag market.

Being a sustainable packaging form pasted valve bag packaging market is expected to gain support from regulatory authorities across the globe which can open new opportunities for pasted valve bag market over the forecast period.

On the backdrop of increased area of application with the use of liners for altering the barrier properties of the pasted valve bags, pasted valve bag market is expected to see significant growth in future

Regionally global pasted valve bags market is segmented into

APEJ is expected to lead pasted valve bags market over the forecast period due to rapid industrialization in the region. Being the biggest consumption based economy, North America is projected to follow APEJ region concerning value share in pasted valve bags market.

MEA is expected to exhibit significant growth in pasted valve bag market. Eastern and Western Europe are projected to grow moderately while Japan is expected to contribute significant value share in pasted valve bags market.

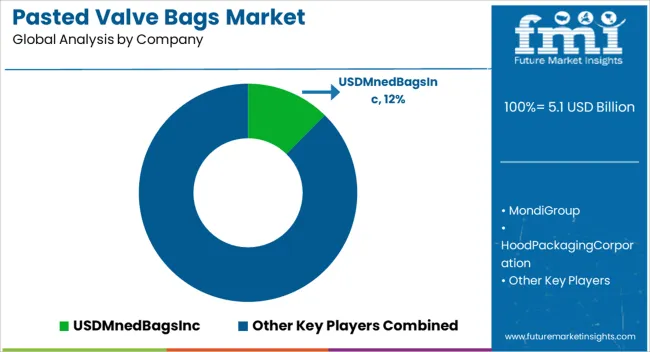

Some key players in pasted valve bags market are Groupe Gelpac Inc, United Bags Inc, Mondi Group, Hood Packaging Corporation, Dairyland Packaging USA, LLC., Southern Packaging, LP, Coveris Holdings S.A., Novey Bag Co., Langston Companies, Inc., El Dorado Packaging, Central Bag Company, National Paper Products Company Ltd, Bag Supply Company, Inc., Industrial Bags inc. and Apack Manufacturing Sdn Bhd.

The research report presents a comprehensive assessment of the market and contains thoughtful insights, facts, historical data, and statistically supported and industry-validated market data. It also contains projections using a suitable set of assumptions and methodologies.

The research report provides analysis and information according to categories such as market segments, geographies, type of product and applications.

The report is a compilation of first-hand information, qualitative and quantitative assessment by industry analysts, inputs from industry experts and industry participants across the value chain.

The report provides in-depth analysis of parent market trends, macro-economic indicators and governing factors along with market attractiveness as per segments. The report also maps the qualitative impact of various market factors on market segments and geographies.

The global pasted valve bags market is estimated to be valued at USD 5.1 billion in 2025.

The market size for the pasted valve bags market is projected to reach USD 7.7 billion by 2035.

The pasted valve bags market is expected to grow at a 4.2% CAGR between 2025 and 2035.

The key product types in pasted valve bags market are kraft paper, paper, bleached, unbleached, others, plastic, pp, pe, others, coating, low-density polyethylene (ldpe) and high-density polyethylene (hdpe).

In terms of product type, multiwall paper bag segment to command 44.2% share in the pasted valve bags market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Valve Grinder Market Size and Share Forecast Outlook 2025 to 2035

Valve Seat Inserts Market Size and Share Forecast Outlook 2025 to 2035

Valve Driver Market Size and Share Forecast Outlook 2025 to 2035

Valve Remote Control Systems Market Analysis by Type, Application and Region - Forecast for 2025 to 2035

Valve Positioner Market Growth – Trends & Forecast (2024-2034)

Valve Cover Gasket Market

Valve Sack Market

ESD Valve Market Forecast and Outlook 2025 to 2035

EGR Valve Market

HVAC Valve Market Size and Share Forecast Outlook 2025 to 2035

Flat Valve Caps And Closures Market Size and Share Forecast Outlook 2025 to 2035

Gate Valve Market Growth – Trends & Forecast 2023-2033

Korea Valve Seat Insert Market Trend Analysis Based on Sales, Material, Engine, End-Use, and Provinces 2025 to 2035

Japan Valve Seat Inserts Market Trend Analysis Based on Sales Channel, Material, Engine, End-Use and Provinces 2025 to 2035

Lined Valve Market Growth – Trends & Forecast 2024-2034

Remote Valve Tissue Expanders Market Size and Share Forecast Outlook 2025 to 2035

Bag On Valve Product Market Size and Share Forecast Outlook 2025 to 2035

Engine Valve Market Size and Share Forecast Outlook 2025 to 2035

Slurry Valves Market Analysis - Size, Share, and Forecast 2025 to 2035

Safety Valve Market Size, Growth, and Forecast 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA