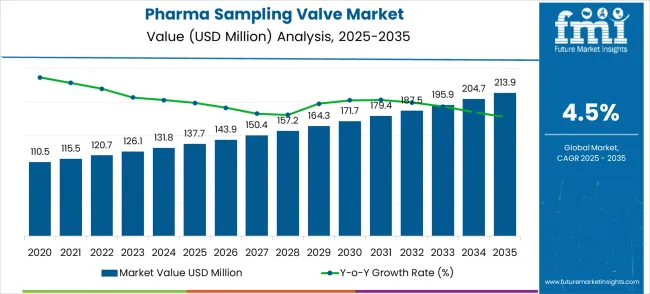

The pharma sampling valve market is expected to witness a steady annual growth rate from 2025 to 2035, driven by the increasing demand for precision in pharmaceutical manufacturing and quality control. Starting at USD 137.7 million in 2025 and projected to reach USD 213.9 million by 2035, this market exhibits a compound annual growth rate (CAGR) of 4.5%.

Each year, the market is expected to experience consistent increases, reflecting the growing importance of accurate sampling and high-quality production standards. With each successive year, the market’s growth rate shows incremental acceleration, a trend likely linked to the pharmaceutical industry's ongoing efforts to improve safety standards, product quality, and regulatory compliance. These factors are expected to drive up the need for more advanced, reliable sampling valves, thus fueling the market’s expansion.

The acceleration in demand can also be attributed to the growing adoption of stringent regulations surrounding pharmaceutical product testing and packaging. Pharma sampling valves play a crucial role in meeting these requirements, ensuring that samples are taken without contamination and with minimal error.

As the market continues to expand, the focus will likely remain on enhancing the precision, reliability, and efficiency of these valves. This is likely to result in increased competition among suppliers and innovations aimed at enhancing functionality and cost-effectiveness. As a result, the pharmaceutical sampling valve market is poised for sustained, steady growth over the next decade, meeting the increasing demands of the pharmaceutical manufacturing sector.

The pharma sampling valve market accounts for approximately 8% of the share within the pharmaceutical equipment market, driven by the increasing demand for reliable and precise sampling systems in pharmaceutical production. In the valves market, it holds about 6%, as pharma sampling valves play a critical role in fluid and material management within the industry.

Within the industrial automation market, the market share is around 7%, reflecting the growing trend of automated pharmaceutical production processes. The healthcare manufacturing market sees about 5%, as these valves are used in drug production lines to maintain hygiene and prevent contamination.

In the process control equipment market, the pharma sampling valve market captures roughly 4%, as these valves are key components in ensuring efficient and accurate process monitoring. These figures underline the importance of pharma sampling valves in maintaining the integrity and quality of pharmaceutical production systems.

| Metric | Value |

|---|---|

| Market Value (2025) | USD 137.7 million |

| Market Forecast Value (2035) | USD 213.9 million |

| Market Forecast CAGR | 4.5% |

Market expansion is being supported by the steady increase in pharmaceutical manufacturing regulations worldwide and the corresponding need for validated sampling systems that provide contamination-free sample collection and superior sample integrity in critical pharmaceutical production environments.

Modern pharmaceutical facilities rely on sampling valves to deliver consistent quality control and comprehensive compliance documentation including sterile manufacturing, bioprocessing, and analytical testing operations. Even minor sampling contamination can require comprehensive quality investigation procedures to maintain optimal product quality and regulatory compliance.

The growing complexity of pharmaceutical manufacturing requirements and increasing demand for automated sampling solutions are driving demand for sampling valves from certified pharmaceutical equipment manufacturers with appropriate cGMP capabilities and regulatory expertise.

Pharmaceutical companies and contract manufacturers are increasingly requiring documented sampling system validation and sterility assurance to maintain product quality and regulatory approval. Industry specifications and pharmaceutical regulations are establishing standardized sampling procedures that require specialized pharmaceutical technologies and trained quality control personnel.

The Pharma Sampling Valve market is entering a new phase of steady growth, driven by demand for pharmaceutical quality control, manufacturing compliance, and evolving cGMP standards. By 2035, these pathways together can unlock USD 25-35 million in incremental revenue opportunities beyond baseline growth.

Pathway A - Stainless Steel Excellence (Premium Materials)

Pathway B - Liquid Application Leadership (Process Sampling)

Pathway C - Single-Use Technology Innovation (Disposable Systems)

Pathway D - Biotechnology Manufacturing Expansion (Bioprocessing)

Pathway E - Process Analytical Technology Integration (PAT Systems)

Pathway F - Emerging Market Penetration (Global Pharma Growth)

Pathway G - Powder and Granule Applications (Solid Dosage)

Pathway H - Digital Integration and Industry 4.0

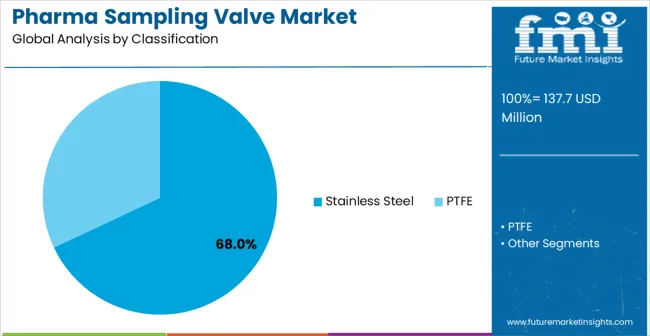

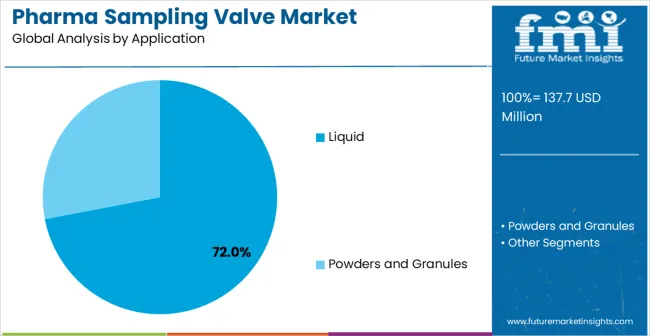

The market is segmented by material type, application, and region. By material type, the market is divided into stainless steel, PTFE, and others. Based on application, the market is categorized into liquid and powders and granules. Regionally, the market is divided into North America, Europe, East Asia, South Asia & Pacific, Latin America, and Middle East & Africa.

In 2025, the stainless steel pharma sampling valve segment is projected to capture around 68% of the total market share, making it the leading material category. This dominance is largely driven by the widespread adoption of corrosion-resistant materials that provide superior durability and regulatory compliance characteristics, catering to a wide variety of pharmaceutical manufacturing environments with stringent cleanliness requirements.

Stainless steel sampling valve technology is particularly favored for its ability to withstand aggressive cleaning and sterilization procedures while maintaining structural integrity and surface smoothness essential for pharmaceutical applications.

Pharmaceutical manufacturers, biotechnology companies, contract manufacturing organizations, and quality control laboratories increasingly prefer stainless steel construction, as it meets stringent FDA and cGMP requirements without imposing material compatibility concerns or surface contamination risks.

The availability of well-established stainless steel grades, along with comprehensive material certifications and technical documentation from leading pharmaceutical equipment manufacturers, further reinforces the segment's market position.

Additionally, this material category benefits from consistent demand across regions, as it is considered a practical high-performance solution for facilities requiring validated pharmaceutical equipment. The combination of regulatory compliance, material durability, and cleanability makes stainless steel pharma sampling valves a preferred choice, ensuring their continued popularity in the pharmaceutical manufacturing equipment market.

The liquid segment is expected to represent 72% of pharma sampling valve demand in 2025, highlighting its position as the most significant application sector. This dominance stems from the unique operational needs of pharmaceutical liquid processing, where precise sample collection and contamination prevention are critical to product quality and regulatory compliance.

Pharmaceutical liquid manufacturing often features complex process streams that require frequent sampling throughout extended production campaigns, demanding reliable and sterile sampling equipment. Pharma sampling valves are particularly well-suited to these environments due to their ability to provide representative samples without compromising process integrity or introducing contamination, even during continuous manufacturing operations.

As pharmaceutical companies globally advance toward liquid formulation complexity and sterile manufacturing requirements, the demand for specialized sampling solutions continues to rise. The segment also benefits from increased investment in biopharmaceutical manufacturing and liquid drug development programs, where manufacturers are increasingly prioritizing sample integrity and sterility assurance as essential quality control measures.

With pharmaceutical companies investing in advanced liquid processing systems and quality enhancement programs, sampling valves provide an essential solution to maintain superior product quality. The growth of injectable drug manufacturing, bioprocessing applications, and sterile liquid formulations, coupled with increased focus on process analytical technology, ensures that liquid applications will remain the largest and most stable demand driver for pharma sampling valves in the forecast period.

The Pharma Sampling Valve market is advancing steadily due to increasing pharmaceutical manufacturing regulations and growing recognition of sterile sampling advantages over traditional sampling methods in pharmaceutical production.

However, the market faces challenges including high initial validation costs compared to conventional sampling equipment, complex sterilization requirements for pharmaceutical applications, and varying regulatory standards across different geographic regions. Performance optimization efforts and pharmaceutical technology advancement programs continue to influence valve design and market adoption patterns.

The growing development of disposable sampling systems is enabling enhanced contamination prevention with simplified validation procedures and reduced cross-contamination risks. Advanced single-use technologies and sterile connection systems provide superior sampling integrity while maintaining cost-effective operational procedures.

These technologies are particularly valuable for pharmaceutical manufacturers and biotechnology companies who require reliable sampling systems that can support diverse production requirements with minimal contamination risk.

Modern pharma sampling valve manufacturers are incorporating advanced PAT integration capabilities and real-time monitoring systems that enhance sampling accuracy and process understanding. Integration of automated sampling sequences and data collection enables superior process control and comprehensive quality documentation capabilities. Advanced PAT features support operation in diverse pharmaceutical environments while meeting various regulatory requirements and validation specifications.

| Country | CAGR (2025-2035) |

|---|---|

| China | 6.1% |

| India | 5.6% |

| Germany | 5.2% |

| Brazil | 4.7% |

| United States | 4.3% |

| United Kingdom | 3.8% |

| Japan | 3.4% |

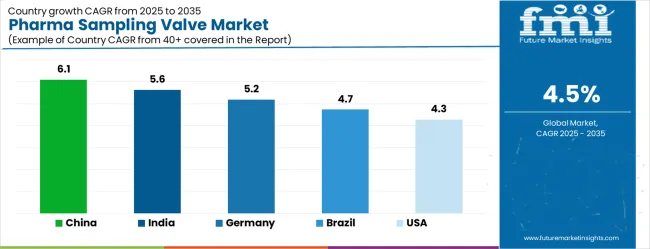

The pharma sampling valve market is experiencing moderate growth, with China leading at a 6.1% CAGR through 2035, driven by rapid pharmaceutical industry expansion and increasing adoption of cGMP-compliant manufacturing equipment across generic drug production, biotechnology manufacturing, and pharmaceutical quality control sectors. India follows at 5.6%, supported by rising pharmaceutical manufacturing industry growth and growing demand for regulatory compliance solutions for domestic and export pharmaceutical markets.

Germany grows steadily at 5.2%, integrating sampling valve technology into its established pharmaceutical manufacturing and biotechnology infrastructure. Brazil records 4.7%, emphasizing pharmaceutical industry modernization and quality control enhancement initiatives.

The United States shows solid growth at 4.3%, focusing on biopharmaceutical development and advanced pharmaceutical manufacturing innovation. The United Kingdom demonstrates steady progress at 3.8%, maintaining established pharmaceutical manufacturing applications and biotechnology research leadership. Japan records 3.4% growth, concentrating on precision pharmaceutical manufacturing and ultra-high quality production standards.

The report covers an in-depth analysis of 40+ countries, the top-performing countries are highlighted below.

The pharma sampling valve market in China is projected to exhibit the highest growth rate with a CAGR of 6.1% through 2035, driven by extensive pharmaceutical industry expansion programs and increasing demand for cGMP-compliant manufacturing equipment across generic drug production, biotechnology manufacturing, and pharmaceutical quality control operations. The country's aggressive pharmaceutical modernization and growing domestic drug development capabilities are creating significant demand for advanced sampling valve systems. Major pharmaceutical companies and contract manufacturers are establishing comprehensive quality control systems to support the increasing requirements of regulatory agencies and international pharmaceutical markets across major pharmaceutical development zones.

National pharmaceutical development initiatives are supporting establishment of world-class pharmaceutical manufacturing facilities and biotechnology centers, driving demand for advanced sampling equipment throughout major pharmaceutical industrial parks. Pharmaceutical industry modernization programs are facilitating adoption of validated sampling technologies that enhance quality control capabilities and international regulatory compliance across pharmaceutical supply chains.

The pharma sampling valve market in India is expanding at a CAGR of 5.6%, supported by increasing pharmaceutical manufacturing industry development and growing awareness of regulatory compliance advantages for global pharmaceutical markets. The country's expanding generic drug manufacturing sector and rising international quality standards are driving demand for advanced sampling valve solutions. Pharmaceutical companies and contract manufacturing organizations are gradually implementing professional-grade sampling equipment to maintain international compliance and export competitiveness.

Pharmaceutical manufacturing industry growth and global market integration are creating opportunities for equipment suppliers that can support diverse regulatory requirements and international quality specifications. Professional training and development programs are building technical expertise among pharmaceutical quality professionals, enabling effective utilization of sampling valve technology that meets international standards and regulatory requirements.

The pharma sampling valve market in Germany is projected to grow at a CAGR of 5.2%, supported by the country's emphasis on pharmaceutical manufacturing quality standards and advanced biotechnology production adoption. German pharmaceutical companies and biotechnology manufacturers are implementing cutting-edge sampling valve systems that meet stringent regulatory requirements and international quality specifications. The market is characterized by focus on system validation, cGMP compliance, and integration with comprehensive pharmaceutical engineering standards.

Pharmaceutical manufacturing industry investments are prioritizing advanced sampling technology that demonstrates superior regulatory compliance and operational reliability while meeting German quality and international pharmaceutical standards. Professional certification programs are ensuring comprehensive technical expertise among pharmaceutical quality engineers and biotechnology specialists, enabling specialized sampling system capabilities that support diverse pharmaceutical applications and regulatory requirements.

The pharma sampling valve market in Brazil is growing at a CAGR of 4.7%, driven by increasing pharmaceutical facility modernization and growing recognition of advanced quality control advantages for pharmaceutical production and regulatory compliance. The country's expanding pharmaceutical sector is gradually integrating advanced sampling equipment to enhance quality control capabilities and international market access. Pharmaceutical companies and manufacturing organizations are investing in sampling valve technology to address evolving regulatory expectations and export competitiveness.

Pharmaceutical modernization is facilitating adoption of advanced quality control technologies that support comprehensive pharmaceutical manufacturing capabilities across production regions. Professional development programs are enhancing technical capabilities among pharmaceutical quality professionals, enabling effective sampling valve utilization that meets evolving regulatory standards and international requirements.

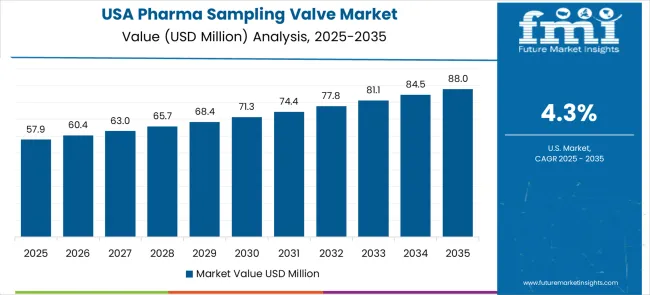

The pharma sampling valve market in the USA is expanding at a CAGR of 4.3%, driven by established pharmaceutical industry leadership and growing emphasis on biopharmaceutical development and advanced pharmaceutical manufacturing innovation. Large pharmaceutical companies and biotechnology firms are implementing comprehensive sampling valve capabilities to serve diverse drug development and manufacturing quality requirements. The market benefits from established pharmaceutical equipment networks and professional training programs that support various pharmaceutical and biotechnology applications.

Pharmaceutical industry leadership is enabling standardized sampling technology utilization across multiple production types, providing consistent quality control and comprehensive regulatory coverage throughout regional pharmaceutical markets. Professional development and certification programs are building specialized technical expertise among pharmaceutical and biotechnology quality professionals, enabling effective sampling valve utilization that supports evolving pharmaceutical production requirements.

The pharma sampling valve market in the UK is projected to grow at a CAGR of 3.8%, supported by established pharmaceutical technology sectors and growing emphasis on biotechnology manufacturing capabilities. British pharmaceutical companies and biotechnology providers are implementing sampling valve equipment that meets industry regulatory standards and international quality requirements. The market benefits from established pharmaceutical infrastructure and comprehensive training programs for pharmaceutical professionals.

Pharmaceutical technology investments are prioritizing advanced sampling systems that support diverse pharmaceutical applications while maintaining established regulatory and technical standards. Professional development programs are building pharmaceutical expertise among technology personnel, enabling specialized sampling valve operation capabilities that meet evolving institutional requirements and pharmaceutical technology standards.

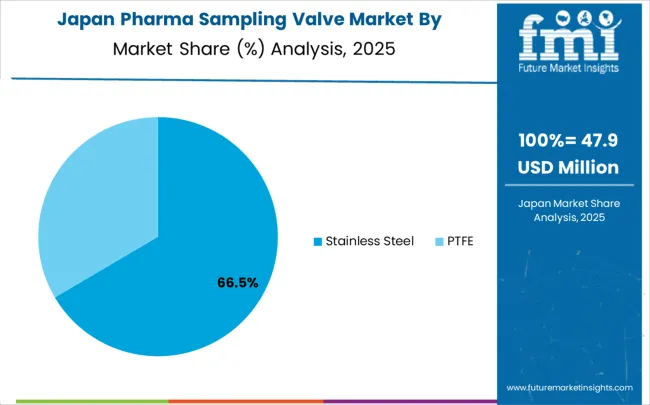

The pharma sampling valve market in Japan is growing at a CAGR of 3.4%, driven by the country's focus on precision pharmaceutical manufacturing innovation and ultra-high quality drug production applications. Japanese pharmaceutical companies and biotechnology manufacturers are implementing advanced sampling valve systems that demonstrate superior precision reliability and operational excellence. The market is characterized by emphasis on technological perfection, quality assurance, and integration with established pharmaceutical manufacturing workflows.

Pharmaceutical technology industry investments are prioritizing innovative sampling solutions that combine advanced valve technology with precision engineering while maintaining Japanese pharmaceutical quality and reliability standards. Professional development programs are ensuring comprehensive technical expertise among pharmaceutical quality engineers and biotechnology specialists, enabling specialized precision sampling capabilities that support diverse pharmaceutical applications and quality requirements.

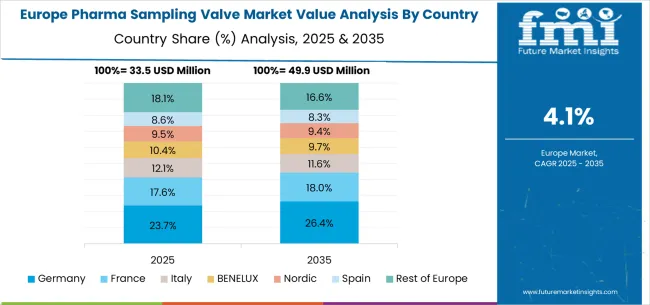

The pharma sampling valve market in Europe is forecast to expand from USD 36.0 million in 2025 to USD 55.9 million by 2035, registering a CAGR of 4.5%. Germany will remain the largest market, holding 34.5% share in 2025, easing to 34.0% by 2035, supported by strong pharmaceutical manufacturing infrastructure and advanced biotechnology production capabilities.

The United Kingdom follows, rising from 27.0% in 2025 to 27.5% by 2035, driven by pharmaceutical technology innovation and biotechnology research advancement. France is expected to maintain stability around 21.5%, reflecting steady pharmaceutical investment patterns.

Italy maintains stability at around 11.0%, supported by pharmaceutical manufacturing and specialty drug production growth, while Spain grows from 4.5% to 5.0% with expanding pharmaceutical infrastructure and manufacturing modernization. BENELUX markets ease from 1.3% to 1.2%, while the remainder of Europe hovers near 0.2%-0.3%, balancing emerging Eastern European pharmaceutical development against mature Nordic pharmaceutical manufacturing markets.

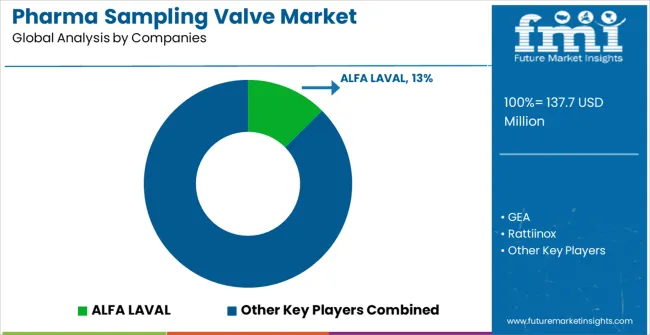

The Pharma Sampling Valve market is defined by competition among specialized pharmaceutical equipment manufacturers, process equipment companies, and pharmaceutical engineering solution providers. Companies are investing in advanced valve design development, material optimization, validation system improvements, and comprehensive pharmaceutical application capabilities to deliver reliable, compliant, and cost-effective sampling solutions. Strategic partnerships, technological innovation, and market expansion are central to strengthening product portfolios and market presence.

ALFA LAVAL offers comprehensive fluid handling solutions with established pharmaceutical expertise and cGMP-compliant manufacturing capabilities. GEA provides specialized pharmaceutical processing equipment with focus on sterile manufacturing and process integration solutions. Rattiinox delivers advanced stainless steel valve technology with emphasis on pharmaceutical process applications and regulatory compliance. CSE specializes in sampling equipment with comprehensive pharmaceutical application integration.

Strahman offers pharmaceutical valve solutions with focus on sanitary applications and sterile manufacturing environments. Gericke AG provides powder handling and sampling equipment with emphasis on pharmaceutical powder processing applications. FAMAT SAMPLING delivers specialized sampling valve systems with comprehensive pharmaceutical validation capabilities. KEOFITT A/S, Emerson Electric, NEUMO-Ehrenberg-Group, Orbinox, KIESELMANN, Pfeiffer, SchuF, and FAMAT SA offer specialized pharmaceutical expertise, valve reliability, and comprehensive technology development across global and regional pharmaceutical manufacturing market segments.

| Item | Value |

|---|---|

| Quantitative Units | USD 137.7 million |

| Material Type | Stainless Steel and PTFE |

| Application | Liquid, Powders and Granules |

| Regions Covered | North America, Europe, East Asia, South Asia & Pacific, Latin America, Middle East & Africa |

| Country Covered | China, India, Germany, Brazil, United States, United Kingdom, Japan, and 40+ countries |

| Key Companies Profiled | ALFA LAVAL, GEA, Rattiinox, CSE, Strahman, Gericke AG, FAMAT SAMPLING, KEOFITT A/S, Emerson Electric, NEUMO-Ehrenberg-Group, Orbinox, KIESELMANN, Pfeiffer, SchuF, FAMAT SA |

| Additional Attributes | Dollar sales by material type and application segment, regional demand trends across major markets, competitive landscape with established pharmaceutical equipment manufacturers and emerging sampling technology specialists, customer preferences for different valve configurations and material options, integration with pharmaceutical manufacturing systems and quality control protocols, innovations in sterile sampling technology and validation capabilities, and adoption of single-use features with enhanced contamination prevention characteristics for improved pharmaceutical manufacturing workflows. |

The global thin-film platinum resistance market is estimated to be valued at USD 2,215.9 million in 2025.

The market size for the thin-film platinum resistance market is projected to reach USD 4,082.0 million by 2035.

The thin-film platinum resistance market is expected to grow at a 6.3% CAGR between 2025 and 2035.

The key product types in thin-film platinum resistance market are pt100, pt500, pt1000 and others.

In terms of application, industrial electronics segment to command 45.0% share in the thin-film platinum resistance market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Pharmaceutical Autoclave Machine Market Size and Share Forecast Outlook 2025 to 2035

Pharmaceutical Excipient SNAC Market Size and Share Forecast Outlook 2025 to 2035

Pharmaceutical Zinc Powder Market Size and Share Forecast Outlook 2025 to 2035

Pharma Moisture Barrier Film Coating Market Size and Share Forecast Outlook 2025 to 2035

Pharmaceutical Grade Magnesium Sulfate Market Size and Share Forecast Outlook 2025 to 2035

Pharmaceutical Secondary Packaging Market Size and Share Forecast Outlook 2025 to 2035

Pharmaceutical Glass Packaging Market Size and Share Forecast Outlook 2025 to 2035

Pharmaceutical Manufacturing Equipment Market Forecast and Outlook 2025 to 2035

Pharma and Healthcare Social Media Marketing Market Size and Share Forecast Outlook 2025 to 2035

Pharmaceutical Plastic Bottle Market Forecast and Outlook 2025 to 2035

Pharmaceutical Grade Sodium Carbonate Market Forecast and Outlook 2025 to 2035

Pharmaceutical Industry Analysis in Saudi Arabia Forecast and Outlook 2025 to 2035

Pharmaceutical Packaging Market Size and Share Forecast Outlook 2025 to 2035

Valve Grinder Market Size and Share Forecast Outlook 2025 to 2035

Pharmaceutical Grade Sodium Chloride Market Size and Share Forecast Outlook 2025 to 2035

Pharmaceutical Plastic Packaging Market Size and Share Forecast Outlook 2025 to 2035

Pharmaceutical Plastic Pots Market Size and Share Forecast Outlook 2025 to 2035

Valve Seat Inserts Market Size and Share Forecast Outlook 2025 to 2035

Pharmaceuticals Pouch Market Size and Share Forecast Outlook 2025 to 2035

Pharmaceutical Unit Dose Packaging Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA