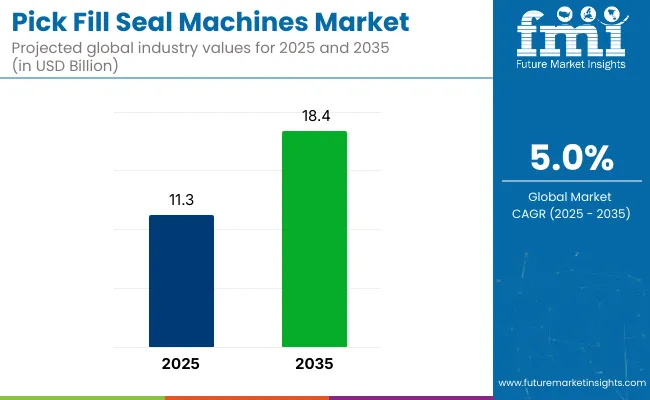

The pick fill seal machines market is projected to grow from USD 11.3 billion in 2025 to USD 18.4 billion by 2035, registering a CAGR of 5.0% during the forecast period. Sales in 2024 reached USD 10.7 billion.

| Metric | Value |

|---|---|

| Market Size in 2025 | USD 11.3 billion |

| Projected Market Size in 2035 | USD 18.4 billion |

| CAGR (2025 to 2035) | 5.0% |

Growth has been driven by increasing demand for automated filling solutions across food and pharmaceutical packaging. Efficiency in reducing manual labor and ensuring contamination-free operations has been emphasized by manufacturers.

Flexibility in pouch formats and improved sealing integrity are being prioritized to meet high-throughput packaging requirements. Adoption of hygienic filling technologies and customizable packaging systems continues to support global adoption, particularly in emerging markets with expanding processed food sectors.

Development of sealers compatible with mono-material films has gained traction to enhance recyclability. Intelligent automation modules are being embedded into machine systems to reduce film consumption and energy waste during changeovers. Sustainability innovations in pick fill seal machines have been driven by eco-conscious packaging mandates and end-user interest in waste minimization.

Digital twin simulation models and AI-driven seal verification have also been adopted by OEMs to enhance packaging precision while reducing overall carbon footprint. Sustainable packaging innovations continue to be integrated within the packaging machinery ecosystem, especially for high-demand consumer product categories such as snacks, cereals, and personal care products.

The pick fill seal machines market is anticipated to benefit from surging contract packaging and e-commerce driven pouching trends. Rising consumer preference for reclosable and convenience pouches is expected to encourage machine upgrades globally. Key players are focusing on flexible feeding, high-speed changeovers, and smart monitoring systems to maintain a competitive edge.

Stringent regulations on hygiene in packaging equipment particularly in pharmaceutical and dairy applications will further drive demand for advanced models. Strategic partnerships between machine manufacturers and recyclable film producers are expected to shape the future of this market by improving cost efficiency and alignment with global environmental goals.

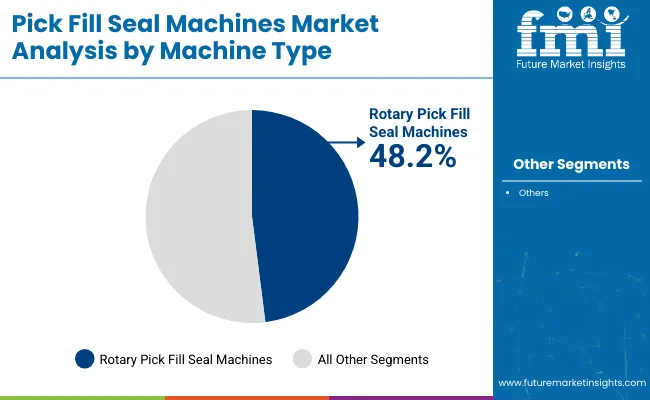

The market is segmented based on machine type, automation level, end-use industry, and region. By machine type, the segmentation includes rotary pick fill seal machines, linear pick fill seal machines, multi-head pick fill seal machines, and custom/modular PFS systems, with rotary machines gaining traction for their high-speed, compact footprint, and consistent throughput.

Automation levels include semi-automatic and fully automatic pick fill seal machines, where fully automatic systems lead the segment due to labor efficiency, improved hygiene, and compatibility with smart packaging workflows.

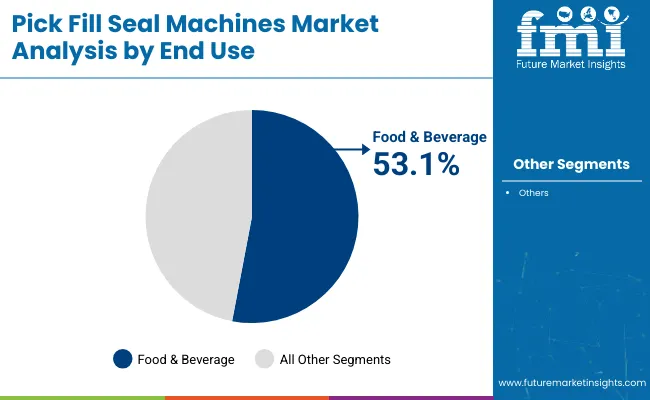

End-use industries comprise food & beverage, pharmaceuticals & nutraceuticals, cosmetics & personal care, chemicals & fertilizers, pet food, and industrial & household products, driven by demand for flexible, high-volume pouch packaging and contamination prevention. Regionally, the market spans North America, Latin America, East Asia, South Asia & Pacific, Eastern Europe, Western Europe, Oceania, and Middle East & Africa.

Rotary pick fill seal machines are projected to capture 48.2% of the global market by 2025. These systems have been engineered for continuous motion and precise pouch handling, enabling high output rates across flexible formats. Their ability to handle different pouch sizes and materials without extensive changeover has reduced operational downtime.

As a result, their adoption has increased in sectors demanding high efficiency and tight footprint integration. Manufacturers have favored rotary platforms for their ability to support sealing consistency and multi-head dispensing systems.

Servo-driven rotary arms and modular infeed stations have been utilized to boost precision and automate repetitive steps. Tool-less maintenance features have enhanced uptime in multi-shift operations. These systems have also supported nitrogen flushing and vacuum capabilities for shelf-life extension.

Applications across food, personal care, and pharma have been enabled by improved pouch stabilization and sealing integrity. Rotary systems have proven suitable for solids, powders, and liquids, making them versatile. Robotics integration and smart sensors have optimized error detection and package quality.

Their growing usage has reflected the industry’s shift toward compact, automated, and flexible equipment investments. Global OEMs have expanded their rotary PFS lines with cleanroom compatibility and GMP-compliant features. Customization for zipper pouches, stand-up pouches, and spouted variants has broadened adoption.

Advanced human-machine interfaces (HMI) have supported real-time diagnostics and quick adjustments. As demand for automation and multi-format flexibility grows, rotary systems are expected to remain a preferred capital investment.

The food & beverage industry is expected to account for 53.1% of the market by 2025. This sector has relied on pick fill seal machines for packaging items such as sauces, snacks, dry mixes, and ready-to-eat meals. High sanitation standards and leak-proof sealing have made these machines vital for product integrity and extended shelf life.

Their compatibility with laminated and recyclable pouches has further driven usage. Increased demand for portion packs, retort pouches, and reclosable formats has aligned with the sector’s packaging evolution. Pick fill seal systems have enabled rapid throughput and reduced product giveaway through accurate volumetric filling. Their use has been noted in frozen food lines, dairy snacks, and beverages requiring MAP sealing. Automated cleaning systems and wash-down resistance have met food safety regulations globally.

The growing trend of meal kits and convenience foods has propelled investments in flexible packaging automation. Quick changeover features have facilitated SKU diversity and reduced packaging waste. F&B manufacturers have preferred pick fill seal solutions for their space efficiency in modular plant layouts. As e-commerce grocery formats expand, tamper-evident, consumer-friendly pouches have gained traction.

Regional food producers and global brands have upgraded packaging lines to meet speed and sustainability metrics. Smart controls, vision inspection, and integration with ERP systems have streamlined operations. Improved seal quality, visual appeal, and barrier performance have enhanced brand equity on shelves. These factors are expected to sustain high adoption of PFS machines across the food and beverage sector.

Regulatory Compliance and Maintenance Costs

Stringent regulatory compliance and high maintenance costs-The Pick Fill Seal Machines Market has riding on its back the looming prospect of essentially dealing a great blow to the operations of industries using them, which have to follow food safety, pharmaceutical and packaging regulations. This increases their complexity. Maintenance costs associated with advanced automation technology further swell your overall expenses. It is very difficult indeed for small and medium-sized companies to introduce these machines.

Initial Capital Investment

Pick Fill Seal machines require significant initial investment, which can prevent small enterprises from adopting automatic packing lines. High upfront costs for advanced machinery, together with the need of skilled operators to make use it create financial barriers to markets entry especially for developing regions.

Technological Advancements and Automation

In the Pick Fill Seal Machines Market, the application of Industry 4.0 technologies, such as IoT-enabled monitoring, AI-driven process optimization and robotics translates into greater productivity. Smart machinery that can predict when it will next break down and monitors things in real-time is expected to cut downtime and lift yields.

Expansion in Emerging Markets

In the emerging economies of India and Southeast Asia, the trend towards eating processed food is picking up speed. Pharmaceuticals and consumer goods also fall into this category of industry where new opportunities abound for localization. As attention turns ever more firmly toward sanitary and eco-friendly packaging solutions, in these areas there has been a marked shift toward using automatic pick fill seal machine.

The USA market for Pick Fill Seal Machines is still at a developmental stage, customers are demanding increased automation in food and beverage production. Among packaged food manufacturers in the United States, demand for fast and efficient packaging solutions is growing. The pharmaceutical industry, on the other hand, makes considerable use of them to pack drugs cleanly and precisely.

| Country | CAGR (2025 to 2035) |

|---|---|

| United States | 4.8% |

The UK market is developing at a moderate pace. Food safety law is strict and more investment is being made in packaging automation, leading to this gentle growth curve. With the advent of e-commerce, manufacturers are preferring Pick Fill Seal Machines that can also cope with sustainable packaging solutions.

| Country | CAGR (2025 to 2035) |

|---|---|

| United Kingdom | 4.9% |

The European Union market for these machines grew strongly, because of the progress being made in the packaging technology fields and also due to pushes on sustainability. Led by countries such as Germany, France and Italy adopting automation in industries like food packing societies where it was once only manual handiwork are all undergoing a tremendous revolution with the use of these machines-not least pharmaceuticals products for obvious reasons.

| Region | CAGR (2025 to 2035) |

|---|---|

| European Union | 5.2% |

In South Korea the market is good because of the many technological advances in recent years. As smart manufacturing replaces traditional production models for packaging--and with everyone wanting high efficiency and automation in everything from food processing to personal service goods production.

| Country | CAGR (2025 to 2035) |

|---|---|

| South Korea | 5.3% |

The Pick Fill Seal (PFS) Machines Market is witnessing steady growth due to the rising demand for automated and efficient packaging solutions across various industries, including food & beverage, pharmaceuticals, and personal care. These machines enhance production speed, maintain product integrity, and reduce human intervention, making them an essential component in modern packaging lines.

The overall market size for pick fill seal machines market was USD 11.3 billion in 2025.

The pick fill seal machines market is expected to reach USD 18.4 billion in 2035.

Rising automation in packaging, demand for flexible packaging solutions, and growth in food, pharmaceutical, and consumer goods industries will drive market demand.

The top 5 countries which drives the development of pick fill seal machines market are USA, European Union, Japan, South Korea and UK.

Automatic Pick Fill Seal Machines demand supplier to command significant share over the assessment period.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Tubular Form Fill and Seal Machines Market Size and Share Forecast Outlook 2025 to 2035

Automated Tray Fill and Seal Machines Market Size and Share Forecast Outlook 2025 to 2035

Competitive Overview of Automated Tray Fill and Seal Machines Companies

Horizontal Form Fill Seal (HFFS) Machines Market Size and Share Forecast Outlook 2025 to 2035

Filling and Sealing Machine Market Size and Share Forecast Outlook 2025 to 2035

Form-Fill-Seal (FFS) Films Market Size and Share Forecast Outlook 2025 to 2035

Blow Fill Seal Technology Market Size and Share Forecast Outlook 2025 to 2035

Blow-fill-seal Equipment Market Size and Share Forecast Outlook 2025 to 2035

Pick and Place Machines Market Size and Share Forecast Outlook 2025 to 2035

Blow Fill Seal Technology Industry Analysis in Western Europe Size and Share Forecast Outlook 2025 to 2035

Blow Fill Seal Technology Industry Analysis in Korea Size and Share Forecast Outlook 2025 to 2035

Form Fill Seal Equipment Market by Equipment Type from 2025 to 2035

Market Positioning & Share in the Form Fill Seal Machine Industry

Market Share Distribution Among Form Fill Seal Equipment Manufacturers

Competitive Overview of Form-Fill-Seal (FFS) Films Suppliers

Key Players & Market Share in the Blow-Fill-Seal Technology Industry

Form Fill Seal Machine Market Analysis by Semi-automatic and Automatic Through 2034

Japan Blow Fill Seal Technology Market Insights – Growth & Forecast 2023-2033

Cup Filling Machines Market Forecast and Outlook 2025 to 2035

Box Sealing Machines Market Trends – Growth & Forecast 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA