Growing pipe insulation products markets are seen primarily due to growth in construction, oil & gas, and industrial sectors. Energy efficiency, thermal protection, and strict adherence to environmental regulations are some of the main motivators. Businesses that prioritize operational effectiveness, sustainability, and cutting-edge insulation technology are setting themselves up to profit from this expanding industry.

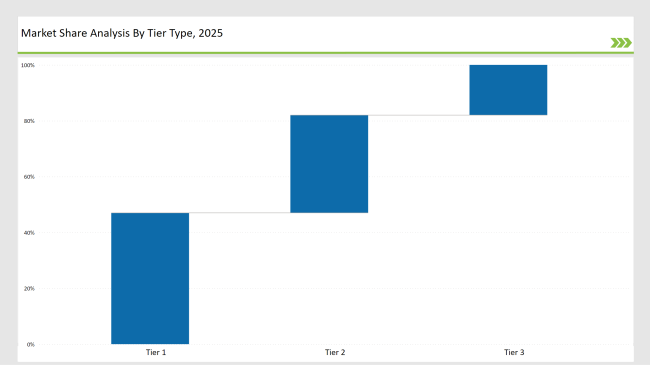

Tier 1: Among the leading companies with 47% of the market are Rockwool, Owens Corning, and Saint-Gobain. These businesses employ advanced manufacturing techniques, high-quality insulators, and extensive distribution networks.

Tier 2: Examples of mid-sized companies with an estimated 35% market share are Armacell, Johns Manville, and Kingspan. For a variety of sectors, they specialize in providing adaptable and affordable pipe insulation solutions.

Tier 3: Regional and niche producers hold 18% of the market by focusing on specialty insulation products such as eco-friendly materials, high-temperature-resistant coatings, and custom solutions.

Global Market Share by Key Players (2025)

| Category | Market Share (%) |

|---|---|

| Top 3 (Owens Corning, Saint-Gobain, Rockwool) | 19% |

| Rest of Top 5 (Armacell, Johns Manville) | 15% |

| Next 5 of Top 10 | 13% |

The demand for pipe insulation products is influenced by various industries

Manufacturers are innovating to offer specialized solutions

Leading manufacturers have driven innovation with sustainable materials, enhanced durability, and improved thermal efficiency.

Year-on-Year Leaders

Suppliers should prioritize automation, customisation, and sustainability if they want to remain competitive in the pipe insulation goods market. Important strategic regions consist of:

| Tier Type | Example of Key Players |

|---|---|

| Tier 1 | Owens Corning, Saint-Gobain, Rockwool |

| Tier 2 | Armacell, Johns Manville, Kingspan |

| Tier 3 | Knauf Insulation, Thermaflex, Aeroflex |

Leading manufacturers continue to invest in sustainable materials, advanced processing technologies, and improved insulation efficiency.

| Manufacturer | Latest Developments |

|---|---|

| Owens Corning | Introduced fire-resistant fiberglass insulation (March 2024). |

| Saint-Gobain | Launched recyclable pipe insulation solutions (August 2023). |

| Rockwool | Developed high-temperature insulation products (May 2024). |

| Armacell | Focused on cost-effective and flexible foam-based insulation (November 2023). |

| Johns Manville | Optimized insulation for energy-efficient applications (February 2024). |

The pipe insulation goods market is being shaped by sustainability, durability, and efficiency. These elements are being used by top brands to keep their market dominance:

The pipe insulation products industry is expected to progress towards more sustainable and technologically advanced solutions. Key focus areas include

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Pipe Insulation Products Market Size and Share Forecast Outlook 2025 to 2035

Pipe Insulation Films Market Size and Share Forecast Outlook 2025 to 2035

Pipe Insulation Market Size and Share Forecast Outlook 2025 to 2035

Key Players & Market Share in Clad Pipe Industry

Industrial Pipe Insulation Market Trends 2025 to 2035

Industrial Pipe Insulation Market

Competitive Overview of Cryogenic Insulation Films Companies

Market Share Insights of Dehydrated Meat Products Providers

Market Share Insights of Bagasse Tableware Product Providers

Market Share Distribution Among Child Resistant Pipette Closures Manufacturers

Key Companies & Market Share in the Stainless Steel Welded Pipe Sector

A Detailed Global Analysis of Brand Share for the Reusable Incontinence Products Market

Market Share Breakdown of Recyclable Thermal Insulation Packs Industry

Evaluating Cold Drawn Seamless Steel Pipes Market Share & Provider Insights

Pipeline Integrity Market Size and Share Forecast Outlook 2025 to 2035

Pipe Market Size and Share Forecast Outlook 2025 to 2035

Insulation Tester Market Size and Share Forecast Outlook 2025 to 2035

Insulation Films Market Size and Share Forecast Outlook 2025 to 2035

Pipetting Robots Market Size and Share Forecast Outlook 2025 to 2035

Insulation Paper Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA