Industrial pipe insulation is deemed as one of the most valuable core materials used in the manufacturing, construction, and other industries, which continues to gain traction across various segments around the world, leading to steady growth in the global industrial pipe insulation market for the forecast period of 2025 to 2035.

Pipe insulations materials provide thermal integrity, minimize energy loss, and protect pipes from corrosion, condensation and freeze damage in petrochemical, power generation, food processing and HVAC applications. This alloy development is further influenced by strict regulatory requirements and increasing industrial decarbonization activities.

Increasingly, there is a need for more-performance insulating products for hot and cold service pipelines, triggering a push to new multi-layer insulation systems, and fire-resistant coatings. In consequence, industries are increasingly integrating insulation into sustainability initiatives to comply with energy performance directives and decrease operational expenses.

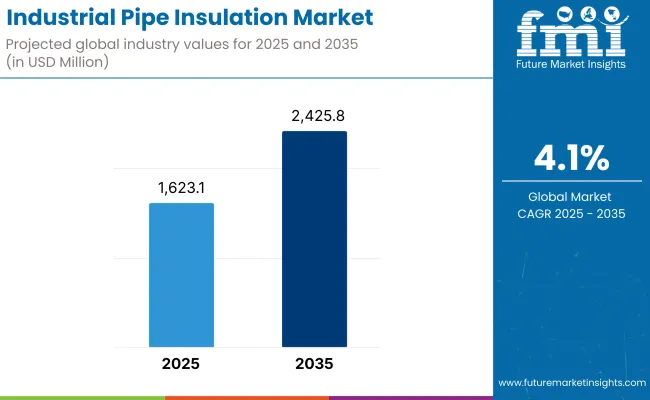

This is accompanied by strong long-term visibility as the segment keeps retrofitting aging industrial plantswhile LNG terminals/chemical complexes continue to see investment. The global Industrial Pipe Insulation market is projected to grow at a CAGR of 4.1% from2021, reaching USD 1,623.1 million in 2025, and expected to reach USD 2,425.8 million by 2035.

Key Market Metrics

| Metric | Value |

|---|---|

| Market Size in 2025 | USD 1,623.1 Million |

| Projected Market Size in 2035 | USD 2,425.8 Million |

| CAGR (2025 to 2035) | 4.1% |

North America still remains a mature, but an innovation-driven market, spurred by Industrial retrofitting and environmental laws and energy-efficient construction codes. Pre-formed pipe insulation is growing in popularity in the USA and Canada, particularly for use in LNG plants, district heating systems and food-grade manufacturing.

Growing focus on ESG reporting and carbon reduction throughout industrial operations is driving demand for high R-value insulation and low-VOC materials. Similar initiatives are also being funded through federal and state-level programs supporting energy audits and thermal insulation upgrades in legacy facilities

There are more stringent energy performance standards, as dictated by the EU Green Deal and the Energy Efficiency Directive, and Europe is moving quickly to adopt insulation technology. Big doses of retrofitting in industrial zones of Germany, France and the UK: notably the chemical, pharmaceutical and beverage in factories.

Newer advanced pipe insulation materials, such as aerogels and multilayer mineral wools, are becoming more mainstream. The focus on sustainability driven construction and thermal loss reduction targets under Europe’s Fit for 55 initiative is creating a surge in demand across new and retrofitted industrial infrastructure.

Asia-Pacific tops the list of these most promising expansions for power generation, refining and petrochemical growth regions. Infrastructure development, industrial growth, and capacity additions in gas transportation and heavy industries are the leading drivers in the markets of China and India.

Effective insulation is in demand the construction and government sectors have made it mandatory to save energy my primary sources of revenue are a dozen contractors who rely on low-cost labor. Moreover, increasing investments in LNG import terminals, as well as cross-border pipelines, strengthen regional demand.

Challenges

Cost sensitivity, hazardous material regulations, and labor-intensive installation limit scalability.

High-performance insulation materials when used generate high installation and material costs that may prevent the use of such materials in small or mid-sized industries due to their cost sensitivity and the competing solutions available in the market. Because some types of insulation, such as certain fiberglass or calcium silicate products, are climbing the health risk hierarchy, their continued use calls for progressive material handling and disposal standards, as well as worker training, reflecting the evolving nature of occupational safety standards.

Industrial pipe insulation is labor-intensive to install and performing tasks in retrofitting projects or busy facilities with limited shackles can take a toll. Energy savings can be compromised by downtime concerns, inconsistent insulation thickness and poor sealing practices. The shortage of skilled contractors in emerging markets further limits consistent quality from one installation to another.

Opportunities

Sustainable materials, automation, and decarbonization targets fuel market innovation.

There are opportunities in the increased demand for low-emission and recyclable insulation products that qualify for energy efficiency and green building certification. In addition, the development of eco-friendly alternatives, with high thermal resistance and fire protection ability, is increasingly focused on the use of material such as mineral wool, aerogels and bio-based foams.

The latest in advanced facilities, to name a few, includes digitally enabled insulation systems, modular pre-insulated piping, and AI-driven thermal performance diagnostics. Regulatory efforts focused on industrial decarbonization and net-zero manufacturing are creating new revenue opportunities for insulation system producers. Partnerships between insulation providers and industrial EPC contractors are also broadening the scope of projects.

Industrial projects faced pandemic-related disruptions from 2020 to 2024, but demand for energy optimization provided a counterbalance to the insulation market stability. The market was supported by retrofitting and maintenance activities in oil & gas and power plants. This was clearly towards simple and modular solutions, non-toxic and low-emission insulation materials and systems to reduce on-site labor time.

The market will transition to predictive insulation management post to 2025; benefiting from IoT based sensors, durable materials and modular design formats. Mandatory requirements for audits for thermal efficiency and performance reporting will drive technology adoption around high-performance systems. The future of insulating industrial facilities involves thermal imaging, BIM integration, and digital twins, which will allow for the tracking of insulation performance throughout the lifecycle of a facility.

Market Shifts: A Comparative Analysis (2020 to 2024 vs. 2025 to 2035)

| Market Shift | 2020 to 2024 Trends |

|---|---|

| Regulatory Landscape | Voluntary energy-saving practices and safety audits |

| Consumer Trends | Basic mineral wool and fiberglass adoption |

| Industry Adoption | Focused on petrochemicals and food processing |

| Supply Chain and Sourcing | Dependent on regional contractors and bulk materials |

| Market Competition | Dominated by material vendors and EPC firms |

| Market Growth Drivers | Energy savings, process safety, and maintenance efficiency |

| Sustainability and Impact | Low recycling, waste generation during replacement |

| Smart Technology Integration | Minimal; largely manual insulation management |

| Sensorial Innovation | Focus on temperature resistance and water repellency |

| Market Shift | 2025 to 2035 Projections |

|---|---|

| Regulatory Landscape | Mandatory thermal audits, ESG disclosures, and circularity standards |

| Consumer Trends | Shift to low-VOC, eco-certified, and recyclable insulation materials |

| Industry Adoption | Expanding into biomanufacturing, hydrogen pipelines, and renewable energy |

| Supply Chain and Sourcing | Rise of off-site modular fabrication and digital supplier ecosystems |

| Market Competition | Entry of IoT-based monitoring providers and prefab insulation solution integrators |

| Market Growth Drivers | Decarbonization, green compliance, and lifecycle cost optimization |

| Sustainability and Impact | Circular material use, low-carbon insulation, and lifecycle tracking |

| Smart Technology Integration | Sensor-enabled diagnostics, predictive analytics, and BIM integration |

| Sensorial Innovation | Acoustic insulation, flexible materials, and anti-corrosion coatings |

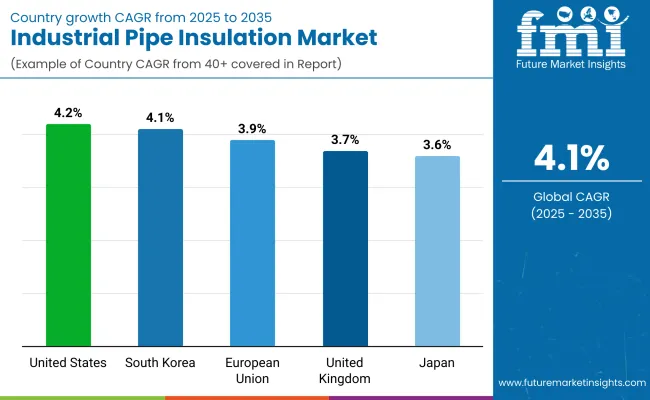

The USA industrial pipe insulation market is positioned for steady growth, thanks to tightening energy efficiency standards and strong investments in LNG, chemical processing, and power generation infrastructure. According the Department of Energy (DOE), thermal insulation is the most common method to reduce energy losses in industries, such as in oil refineries and petrochemical plants.

Such insulation materials suitable for high-temperature and cryo applications include fiberglass and calcium silicate and aerogels. In Texas and Louisiana, industrial clusters are upgrading their older the facilities with state-of-the-art pipe insulation systems to respond to new carbon targets and prevent heat loss.

| Country | CAGR (2025 to 2035) |

|---|---|

| United States | 4.2% |

In the UK, demand for industrial pipe insulation is increasing as manufacturers and larger energy-intensive industries try to decarbonize. Heat recovery and thermal management are cornerstone areas of the government’s Industrial Decarbonisation Strategy, facilitating uptake of mineral wool and phenolic foam insulation.

And pipe insulation is extensively used in various industries, namely, chemical plants, food processing units, energy-from-waste facilities, etc. Energy costs continue to be high, and industrial users are focused on optimizing thermal performance to minimize running costs. Market growth is also driven by the retrofitting of aging infrastructure in the Midlands and North East.

| Country | CAGR (2025 to 2035) |

|---|---|

| United Kingdom | 3.7% |

The EU industrial pipe insulation market is expanding due to strict emissions regulations and energy performance standards detailed in the European Green Deal. Chemical, power and manufacturing sectors are where demand hits hardest, led by Germany, France and the Netherlands.

EU funding programs support industrial energy audits and insulation upgrades, particularly in legacy plants. Non-toxic, fire-resistant materials like mineral wool and high-density polyurethane foam are preferred. In industrial applications, circular economy initiatives are foregrounding recyclable insulation materials with lower levels of embodied carbon.

| Region | CAGR (2025 to 2035) |

|---|---|

| European Union | 3.9% |

In Japan, efficiency goals at thermal power plants, steel and electronics production facilities are fueling expansion of thermal insulation of industrial pipes. High-performance insulation is critical for managing heat retention and avoiding gear degradation in the country’s energy-intensive sectors.

Lacking the domestic energy resources of some other countries, Japan places a premium on insulation as a crucial energy-saving element. These promising applications include nanomaterials and vapor-barrier-enhanced flexible insulation that are developing in domestic research labs. Retrofitting initiatives in legacy chemical plants and LNG terminals also contribute to demand for corrosion-resistant and space-efficient insulation materials.

| Country | CAGR (2025 to 2035) |

|---|---|

| Japan | 3.6% |

Ambitious energy- efficiency targets and modernization of industry in South Korea are driving growth in its industrial pipe insulation market. Energy and smart manufacturing is promoted by government policies in industrial clusters such as in Ulsan and Gwangyang Materials like elastomeric foams and perlite are increasingly being utilized in insulation for petrochemical, district heating, and shipbuilding applications.

Hybrid insulation systems with fire-retardant and acoustic-dampening properties are also being developed by Korean firms. Pipe insulation is being adopted by the export-oriented manufacturing sectors as part of energy management strategies in compliance with ISO.

| Country | CAGR (2025 to 2035) |

|---|---|

| South Korea | 4.1% |

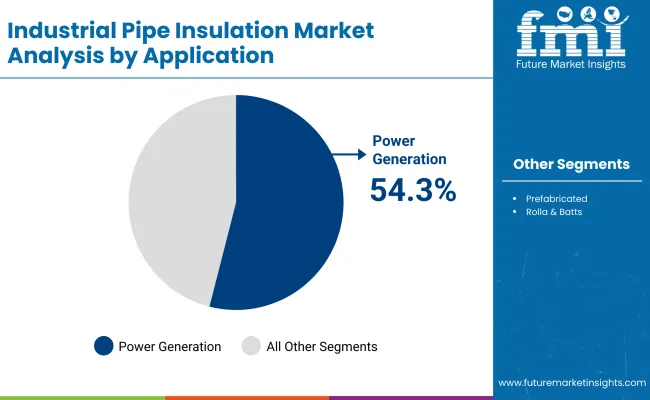

Segments such as power, oil & gas, and chemical processing are investing significantly in energy-efficient and safety-boosting thermal control systems, which is boosting the industrial pipe insulation market. Industrial pipe insulation helps reduce heat loss, cuts the energy bill and even adds protection for workers in high-temperature settings.

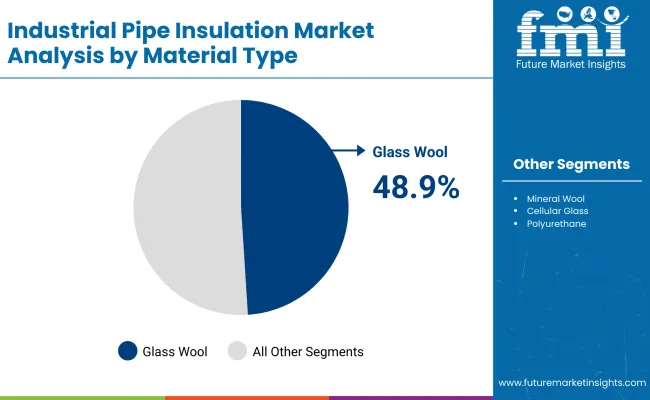

For material and application segments, glass wool insulation and power generation lead the global market share as a result of their excellent thermal resistance, lightweight handling, and conformity with fire safety codes. These segments maintain heat conservation of steam lines, hot water pipes, and thermal loops which is vital to energy plants and utility grids.

With rising electricity demand worldwide and thermal power plants increasingly focused on operational efficiency and emissions adherence, glass wool insulation provides an affordable, scalable option for temperature control and system preservation.

| Material Type | Market Share (2025) |

|---|---|

| Glass Wool | 48.9% |

Glass wool is projected to lead the material segment in the market due to its exceptional insulation properties, non-combustibility, and extensive application in steam and hot fluid pipelines. Made from spun glass fibers bonded with resin, the material affords consistent thermal resistance while also being lightweight and simple to install, even on large-diameter or intricate pipeline geometries.

Industrial establishments use glass wool to achieve uniform process temperature, control heat loss, and ensure worker safety. Its excellent performance even in extreme environments such as full humidity and mass vibration setups, make it a highly preferred option in power plants and chemical processing zones.

The material has low thermal conductivity and acoustic dampening capability and is deemed a fire (A1-rated) product, ensuring it meets all safety and energy codes. It is also recyclable and has a relatively low carbon footprint, helping industries that are moving toward a greener operation meet their sustainability goals.

| Application | Market Share (2025) |

|---|---|

| Power Generation | 54.3% |

Power generation accounts for the largest application share of the industrial pipe insulation market, driven by the sector's dependence on high-temperature steam transport and heat retention efficiency. Insulated piping, whether it be in coal, natural gas, nuclear or biomass power plants improves thermal performance, lowers fuel usage, and maximises turbine yield.

Thermal energy networks in the massive infrastructures of power stations are complex, requiring high-quality insulation systems that must be resilient to temperature variations, mechanical stress, and extreme weather conditions. Glass wool and other advanced materials play important functions in safeguarding infrastructure and reducing operating costs.

Thermal plants that are years old are hanging up their retrofits while newer generation installations are still looking to hit their environmental milestones; insulation is no longer an optional extra, it is now part and parcel of operations and compliance. Decarbonization and energy loss reduction policies at local level are further promoting adoption in utility-scale plants, combined cycle facilities, and waste-to-energy stations.

Other industries, including oil & gas and chemical sectors, also drive market demand, but power generation is the primary focus area due to ongoing demands for system optimization, regulatory requirements, and global energy transition strategies.

Industrial pipe insulation demand is driven by sectors such as oil & gas, power generation, chemical processing, and food & beverage seeking energy efficiency, personnel protection, and emission control. Insulation materials fiberglass, calcium silicate, elastomers, mineral wool and other types of insulation materials are increasingly used for maintaining process temperatures and preventing condensation and heat loss.

International energy efficiency regulations and carbon goals are compelling industries to replace legacy systems with high-performance, non-combustible, anti-corrosion insulation systems.

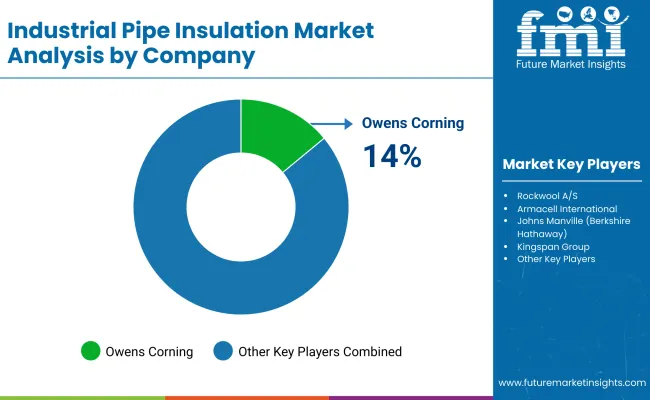

Market Share Analysis by Key Players & Pipe Insulation Providers

| Company Name | Estimated Market Share (%) |

|---|---|

| Owens Corning | 14 - 17% |

| Rockwool A/S | 11 - 14% |

| Armacell International | 9 - 12% |

| Johns Manville (Berkshire Hathaway) | 7 - 10% |

| Kingspan Group | 6 - 9% |

| Other Providers | 38 - 45% |

| Company Name | Key Offerings/Activities |

|---|---|

| Owens Corning | In 2024 , expanded FOAMGLAS® cellular glass line for cryogenic applications; in 2025 , launched corrosion-under-insulation (CUI) resistant pipe insulation systems. |

| Rockwool A/S | In 2024 , introduced high-density stone wool wraps for high-temperature steam lines; in 2025 , upgraded fire-rated insulation solutions for refineries and petrochemical sites. |

| Armacell International | In 2024 , released halogen-free elastomeric pipe insulations for cleanroom environments; in 2025 , launched closed-cell thermal insulation for chemical plants. |

| Johns Manville | In 2024 , enhanced Thermo-1200® calcium silicate with hydrophobic coating; in 2025 , introduced water-repellent mineral wool pipe insulation for outdoor pipelines. |

| Kingspan Group | In 2024 , expanded Kooltherm® range for tight-space industrial pipework; in 2025 , launched low-smoke, non-combustible phenolic foam wraps for offshore rigs. |

Key Market Insights

Owens Corning (14-17%)

Owens Corning remains a global leader in industrial insulation, leveraging its FOAMGLAS® cellular glass for high-durability, cryogenic, and moisture-sensitive environments. In 2024, it expanded its FOAMGLAS® line to serve LNG and cold storage terminals. In 2025, it launched corrosion-under-insulation (CUI) resistant systems aimed at refining and chemical processing industries. These developments support long-term infrastructure reliability and align with global efficiency improvement goals.

Rockwool A/S (11-14%)

Rockwool is known for its robust, high-temperature insulation solutions based on non-combustible stone wool. In 2024, it released new high-density wraps for steam distribution and thermal oil lines in power plants. In 2025, it upgraded its fire-rated insulation offerings to meet evolving safety standards in chemical plants and refineries. Rockwool’s products contribute to safe operation and carbon mitigation by improving thermal containment across industrial facilities.

Armacell International (9-12%)

Armacell leads in flexible elastomeric foam insulations, serving both thermal and acoustic insulation needs. In 2024, it introduced halogen-free pipe insulation for environments requiring minimal emissions and low particle shedding, such as pharma and food processing. In 2025, it launched closed-cell thermal solutions for acid-resistant and solvent-heavy chemical pipelines. Armacell’s focus on VOC-free, antimicrobial, and flexible insulation aligns with sustainability and workplace safety demands.

Johns Manville (7-10%)

Johns Manville offers a wide variety of industrial insulation materials with an emphasis on reliability and safety. In 2024, it enhanced its Thermo-1200® line of calcium silicate insulations with a hydrophobic surface to prevent water ingress. In 2025, it launched mineral wool pipe wraps with water-repellent coatings for exposed and buried pipelines. These products provide thermal stability, fire resistance, and moisture protection, key to maintaining efficiency in critical infrastructure.

Kingspan Group (6-9%)

Kingspan focuses on high-performance phenolic foam insulation, particularly for space-constrained pipework and offshore environments. In 2024, it extended the Kooltherm® range to industrial settings, offering improved insulation with thinner profiles. In 2025, Kingspan introduced low-smoke phenolic wraps that meet stringent fire safety norms in offshore platforms and shipboard mechanical systems. These innovations help industries meet compliance standards while maximizing energy savings.

Other Key Players (38-45% Combined)

Numerous regional players and specialized insulation providers are innovating within the industrial pipe insulation market. These include:

The overall market size for the industrial pipe insulation market was approximately USD 1,623.1 million in 2025.

The industrial pipe insulation market is expected to reach approximately USD 2,425.8 million in 2035.

The demand for industrial pipe insulation is rising due to increasing awareness about energy conservation, stringent government regulations promoting energy efficiency, and the need to reduce greenhouse gas emissions. Additionally, the growth of various end-use industries, such as chemical, oil and gas, and power generation, is further fueling market expansion.

The top 5 countries driving the development of the industrial pipe insulation market are the United States, China, Germany, India, and Japan.

Glass wool as a material type and power generation applications are expected to command significant shares over the assessment period.

Table 01 : Global Industrial Pipe Insulation Materials Market Size (US$ Mn) and Volume (KT) Forecast by Material Type, 2013 – 2028

Table 02 : Global Industrial Pipe Insulation Materials Market Size (US$ Mn) and Volume (KT) Forecast by Product Type, 2013 – 2028

Table 03 : Global Industrial Pipe Insulation Materials Market Size (US$ Mn) and Volume (KT) Forecast by End Use, 2013 – 2028

Table 04 : Global Industrial Pipe Insulation Materials Market Size (US$ Mn) and Volume (KT) Forecast by Region, 2013 – 2028

Table 05: North America Industrial Pipe Insulation Materials Market Value (US$ Mn) and Volume (KT) by Country, 2013 – 2028

Table 06: North America Industrial Pipe Insulation Materials Market Value (US$ Mn) and Volume (KT) by Material Type, 2013 – 2028

Table 07: North America Industrial Pipe Insulation Materials Market Value (US$ Mn) and Volume (KT) by Product Type, 2013 – 2028

Table 08: North America Industrial Pipe Insulation Materials Market Value (US$ Mn) and Volume (KT) by End Use, 2013 – 2028

Table 09: Latin America Industrial Pipe Insulation Materials Market Value (US$ Mn) and Volume (KT) by Country, 2013 – 2028

Table 10: Latin America Industrial Pipe Insulation Materials Market Value (US$ Mn) and Volume (KT) by Material Type, 2013 – 2028

Table 11: Latin America Industrial Pipe Insulation Materials Market Value (US$ Mn) and Volume (KT) by Product Type, 2013 – 2028

Table 12: Latin America Industrial Pipe Insulation Materials Market Value (US$ Mn) and Volume (KT) by End Use, 2013 – 2028

Table 13: Western Europe Industrial Pipe Insulation Materials Market Value (US$ Mn) and Volume (KT) by Country, 2013 – 2028

Table 14: Western Europe Industrial Pipe Insulation Materials Market Value (US$ Mn) and Volume (KT) by Material Type, 2013 – 2028

Table 15: Western Europe Industrial Pipe Insulation Materials Market Value (US$ Mn) and Volume (KT) by Product Type, 2013 – 2028

Table 16: Western Europe Industrial Pipe Insulation Materials Market Value (US$ Mn) and Volume (KT) by End Use, 2013 – 2028

Table 17: Eastern Europe Industrial Pipe Insulation Materials Market Value (US$ Mn) and Volume (KT) by Country, 2013 – 2028

Table 18: Eastern Europe Industrial Pipe Insulation Materials Market Value (US$ Mn) and Volume (KT) by Material Type, 2013 – 2028

Table 19: Eastern Europe Industrial Pipe Insulation Materials Market Value (US$ Mn) and Volume (KT) by Product Type, 2013 – 2028

Table 20: Eastern Europe Industrial Pipe Insulation Materials Market Value (US$ Mn) and Volume (KT) by End Use, 2013 – 2028

Table 21: SEA&P Industrial Pipe Insulation Materials Market Value (US$ Mn) and Volume (KT) by Country, 2013 – 2028

Table 22: SEA&P Industrial Pipe Insulation Materials Market Value (US$ Mn) and Volume (KT) by Material Type, 2013 – 2028

Table 23: SEA&P Industrial Pipe Insulation Materials Market Value (US$ Mn) and Volume (KT) by Product Type, 2013 – 2028

Table 24: SEA&P Industrial Pipe Insulation Materials Market Value (US$ Mn) and Volume (KT) by End Use, 2013 – 2028

Table 25: China Industrial Pipe Insulation Materials Market Value (US$ Mn) and Volume (KT) by Material Type, 2013 – 2028

Table 26: China Industrial Pipe Insulation Materials Market Value (US$ Mn) and Volume (KT) by Product Type, 2013 – 2028

Table 27: China Industrial Pipe Insulation Materials Market Value (US$ Mn) and Volume (KT) by End Use, 2013 – 2028

Table 28: Japan Industrial Pipe Insulation Materials Market Value (US$ Mn) and Volume (KT) by Material Type, 2013 – 2028

Table 29: Japan Industrial Pipe Insulation Materials Market Value (US$ Mn) and Volume (KT) by Product Type, 2013 – 2028

Table 30: Japan Industrial Pipe Insulation Materials Market Value (US$ Mn) and Volume (KT) by End Use, 2013 – 2028

Table 31: MEA Industrial Pipe Insulation Materials Market Value (US$ Mn) and Volume (KT) by Country, 2013 – 2028

Table 32: MEA Industrial Pipe Insulation Materials Market Value (US$ Mn) and Volume (KT) by Material Type, 2013 – 2028

Table 33: MEA Industrial Pipe Insulation Materials Market Value (US$ Mn) and Volume (KT) by Product Type, 2013 – 2028

Table 34: MEA Industrial Pipe Insulation Materials Market Value (US$ Mn) and Volume (KT) by End Use, 2013 – 2028

Figure 01: Historical and Future Industrial Pipe Insulation Materials Market Size (US$ Mn) and volume (KT) analysis, 2013 – 2028

Figure 02: Historical and Future Industrial Pipe Insulation Materials Market Absolute $ Opportunity, 2013 – 2028

Figure 03: Global Industrial Pipe Insulation Materials Market BPS Analysis by Material Type – 2013, 2018 & 2028

Figure 04: Global Industrial Pipe Insulation Materials Market Y-o-Y Growth Projections by Material Type, 2013 – 2028

Figure 05: Global Industrial Pipe Insulation Materials Market Absolute $ Opportunity Analysis by Material Type, 2017–2028

Figure 06: Global Industrial Pipe Insulation Materials Market Attractiveness Analysis by Material Type, 2018 – 2028

Figure 07: Global Industrial Pipe Insulation Materials Market BPS Analysis by Product Type – 2013, 2018 & 2028

Figure 08: Global Industrial Pipe Insulation Materials Market Y-o-Y Growth Projections by Product Type, 2013 – 2028

Figure 09: Global Industrial Pipe Insulation Materials Market Absolute $ Opportunity Analysis by Product Type, 2017–2028

Figure 10: Global Industrial Pipe Insulation Materials Market Attractiveness Analysis by Product Type, 2018 – 2028

Figure 11: Global Industrial Pipe Insulation Materials Market BPS Analysis by End Use– 2013, 2018 & 2028

Figure 12: Global Industrial Pipe Insulation Materials Market Y-o-Y Growth Projections by End Use, 2013 – 2028

Figure 13: Global Industrial Pipe Insulation Materials Market Absolute $ Opportunity Analysis by End Use, 2017–2028

Figure 14: Global Industrial Pipe Insulation Materials Market Attractiveness Analysis by End Use, 2018 – 2028

Figure 15: Global Industrial Pipe Insulation Materials Market BPS Analysis by Region– 2013, 2018 & 2028

Figure 16: Global Industrial Pipe Insulation Materials Market Y-o-Y Growth Projections by Region, 2013 – 2028

Figure 17: Global Industrial Pipe Insulation Materials Market Absolute $ Opportunity Analysis by Region, 2017–2028

Figure 18: Global Industrial Pipe Insulation Materials Market Attractiveness Analysis by Region, 2018 – 2028

Figure 19: North America Industrial Pipe Insulation Materials Market Y-o-Y Growth Projections by Country, 2013 – 2028

Figure 20: North America Industrial Pipe Insulation Materials Market BPS Analysis by Country – 2013, 2018 & 2028

Figure 21: North America Industrial Pipe Insulation Materials Market Attractiveness Analysis by Country, 2018 – 2028

Figure 22: North America Industrial Pipe Insulation Materials Market Y-o-Y Growth Projections by Materials Type, 2013 – 2028

Figure 23: North America Industrial Pipe Insulation Materials Market BPS Analysis by Materials Type – 2013, 2018 & 2028

Figure 24: North America Industrial Pipe Insulation Materials Market Attractiveness Analysis by Materials Type, 2018 – 2028

Figure 25: North America Industrial Pipe Insulation Materials Market Y-o-Y Growth Projections by Product Type, 2013 – 2028

Figure 26: North America Industrial Pipe Insulation Materials Market BPS Analysis by Product Type – 2013, 2018 & 2028

Figure 27: North America Industrial Pipe Insulation Materials Market Attractiveness Analysis by Product Type, 2018 – 2028

Figure 28: North America Industrial Pipe Insulation Materials Market Y-o-Y Growth Projections by End Use, 2013 – 2028

Figure 29: North America Industrial Pipe Insulation Materials Market BPS Analysis by End Use – 2013, 2018 & 2028

Figure 30: North America Industrial Pipe Insulation Materials Market Attractiveness Analysis by End Use, 2018 – 2028

Figure 31: Latin America Industrial Pipe Insulation Materials Market Y-o-Y Growth Projections by Country, 2013 – 2028

Figure 32: Latin America Industrial Pipe Insulation Materials Market BPS Analysis by Country – 2013, 2018 & 2028

Figure 33: Latin America Industrial Pipe Insulation Materials Market Attractiveness Analysis by Country, 2018 – 2028

Figure 34: Latin America Industrial Pipe Insulation Materials Market Y-o-Y Growth Projections by Materials Type, 2013 – 2028

Figure 35: Latin America Industrial Pipe Insulation Materials Market BPS Analysis by Materials Type – 2013, 2018 & 2028

Figure 36: Latin America Industrial Pipe Insulation Materials Market Attractiveness Analysis by Materials Type, 2018 – 2028

Figure 37: Latin America Industrial Pipe Insulation Materials Market Y-o-Y Growth Projections by Product Type, 2013 – 2028

Figure 38: Latin America Industrial Pipe Insulation Materials Market BPS Analysis by Product Type – 2013, 2018 & 2028

Figure 39: Latin America Industrial Pipe Insulation Materials Market Attractiveness Analysis by Product Type, 2018 – 2028

Figure 40: Latin America Industrial Pipe Insulation Materials Market Y-o-Y Growth Projections by End Use, 2013 – 2028

Figure 41: Latin America Industrial Pipe Insulation Materials Market BPS Analysis by End Use – 2013, 2018 & 2028

Figure 42: Latin America Industrial Pipe Insulation Materials Market Attractiveness Analysis by End Use, 2018 – 2028

Figure 43: Western Europe Industrial Pipe Insulation Materials Market Y-o-Y Growth Projections by Country, 2013 – 2028

Figure 44: Western Europe Industrial Pipe Insulation Materials Market BPS Analysis by Country – 2013, 2018 & 2028

Figure 45: Western Europe Industrial Pipe Insulation Materials Market Attractiveness Analysis by Country, 2018 – 2028

Figure 46: Western Europe Industrial Pipe Insulation Materials Market Y-o-Y Growth Projections by Materials Type, 2013 – 2028

Figure 47: Western Europe Industrial Pipe Insulation Materials Market BPS Analysis by Materials Type – 2013, 2018 & 2028

Figure 48: Western Europe Industrial Pipe Insulation Materials Market Attractiveness Analysis by Materials Type, 2018 – 2028

Figure 49: Western Europe Industrial Pipe Insulation Materials Market Y-o-Y Growth Projections by Product Type, 2013 – 2028

Figure 50: Western Europe Industrial Pipe Insulation Materials Market BPS Analysis by Product Type – 2013, 2018 & 2028

Figure 51: Western Europe Industrial Pipe Insulation Materials Market Attractiveness Analysis by Product Type, 2018 – 2028

Figure 52: Western Europe Industrial Pipe Insulation Materials Market Y-o-Y Growth Projections by End Use, 2013 – 2028

Figure 53: Western Europe Industrial Pipe Insulation Materials Market BPS Analysis by End Use – 2013, 2018 & 2028

Figure 54: Western Europe Industrial Pipe Insulation Materials Market Attractiveness Analysis by End Use, 2018 – 2028

Figure 55: Eastern Europe Industrial Pipe Insulation Materials Market Y-o-Y Growth Projections by Country, 2013 – 2028

Figure 56: Eastern Europe Industrial Pipe Insulation Materials Market BPS Analysis by Country – 2013, 2018 & 2028

Figure 57: Eastern Europe Industrial Pipe Insulation Materials Market Attractiveness Analysis by Country, 2018 – 2028

Figure 58: Eastern Europe Industrial Pipe Insulation Materials Market Y-o-Y Growth Projections by Materials Type, 2013 – 2028

Figure 59: Eastern Europe Industrial Pipe Insulation Materials Market BPS Analysis by Materials Type – 2013, 2018 & 2028

Figure 60: Eastern Europe Industrial Pipe Insulation Materials Market Attractiveness Analysis by Materials Type, 2018 – 2028

Figure 61: Eastern Europe Industrial Pipe Insulation Materials Market Y-o-Y Growth Projections by Product Type, 2013 – 2028

Figure 62: Eastern Europe Industrial Pipe Insulation Materials Market BPS Analysis by Product Type – 2013, 2018 & 2028

Figure 63: Eastern Europe Industrial Pipe Insulation Materials Market Attractiveness Analysis by Product Type, 2018 – 2028

Figure 64: Eastern Europe Industrial Pipe Insulation Materials Market Y-o-Y Growth Projections by End Use, 2013 – 2028

Figure 65: Eastern Europe Industrial Pipe Insulation Materials Market BPS Analysis by End Use – 2013, 2018 & 2028

Figure 66: Eastern Europe Industrial Pipe Insulation Materials Market Attractiveness Analysis by End Use, 2018 – 2028

Figure 67: SEA&P Industrial Pipe Insulation Materials Market Y-o-Y Growth Projections by Country, 2013 – 2028

Figure 68: SEA&P Industrial Pipe Insulation Materials Market BPS Analysis by Country – 2013, 2018 & 2028

Figure 69: SEA&P Industrial Pipe Insulation Materials Market Attractiveness Analysis by Country, 2018 – 2028

Figure 70: SEA&P Industrial Pipe Insulation Materials Market Y-o-Y Growth Projections by Materials Type, 2013 – 2028

Figure 71: SEA&P Industrial Pipe Insulation Materials Market BPS Analysis by Materials Type – 2013, 2018 & 2028

Figure 72: SEA&P Industrial Pipe Insulation Materials Market Attractiveness Analysis by Materials Type, 2018 – 2028

Figure 73: SEA&P Industrial Pipe Insulation Materials Market Y-o-Y Growth Projections by Product Type, 2013 – 2028

Figure 74: SEA&P Industrial Pipe Insulation Materials Market BPS Analysis by Product Type – 2013, 2018 & 2028

Figure 75: SEA&P Industrial Pipe Insulation Materials Market Attractiveness Analysis by Product Type, 2018 – 2028

Figure 76: SEA&P Industrial Pipe Insulation Materials Market Y-o-Y Growth Projections by End Use, 2013 – 2028

Figure 77: SEA&P Industrial Pipe Insulation Materials Market BPS Analysis by End Use – 2013, 2018 & 2028

Figure 78: SEA&P Industrial Pipe Insulation Materials Market Attractiveness Analysis by End Use, 2018 – 2028

Figure 79: China Industrial Pipe Insulation Materials Market Y-o-Y Growth Projections by Materials Type, 2013 – 2028

Figure 80: China Industrial Pipe Insulation Materials Market BPS Analysis by Materials Type – 2013, 2018 & 2028

Figure 81: China Industrial Pipe Insulation Materials Market Attractiveness Analysis by Materials Type, 2018 – 2028

Figure 82: China Industrial Pipe Insulation Materials Market Y-o-Y Growth Projections by Product Type, 2013 – 2028

Figure 83: China Industrial Pipe Insulation Materials Market BPS Analysis by Product Type – 2013, 2018 & 2028

Figure 84: China Industrial Pipe Insulation Materials Market Attractiveness Analysis by Product Type, 2018 – 2028

Figure 85: China Industrial Pipe Insulation Materials Market Y-o-Y Growth Projections by End Use, 2013 – 2028

Figure 86: China Industrial Pipe Insulation Materials Market BPS Analysis by End Use – 2013, 2018 & 2028

Figure 87: China Industrial Pipe Insulation Materials Market Attractiveness Analysis by End Use, 2018 – 2028

Figure 88: Japan Industrial Pipe Insulation Materials Market Y-o-Y Growth Projections by Materials Type, 2013 – 2028

Figure 89: Japan Industrial Pipe Insulation Materials Market BPS Analysis by Materials Type – 2013, 2018 & 2028

Figure 90: Japan Industrial Pipe Insulation Materials Market Attractiveness Analysis by Materials Type, 2018 – 2028

Figure 91: Japan Industrial Pipe Insulation Materials Market Y-o-Y Growth Projections by Product Type, 2013 – 2028

Figure 92: Japan Industrial Pipe Insulation Materials Market BPS Analysis by Product Type – 2013, 2018 & 2028

Figure 93: Japan Industrial Pipe Insulation Materials Market Attractiveness Analysis by Product Type, 2018 – 2028

Figure 94: Japan Industrial Pipe Insulation Materials Market Y-o-Y Growth Projections by End Use, 2013 – 2028

Figure 95: Japan Industrial Pipe Insulation Materials Market BPS Analysis by End Use – 2013, 2018 & 2028

Figure 96: Japan Industrial Pipe Insulation Materials Market Attractiveness Analysis by End Use, 2018 – 2028

Figure 97: MEA Industrial Pipe Insulation Materials Market Y-o-Y Growth Projections by Country, 2013 – 2028

Figure 98: MEA Industrial Pipe Insulation Materials Market BPS Analysis by Country – 2013, 2018 & 2028

Figure 99: MEA Industrial Pipe Insulation Materials Market Attractiveness Analysis by Country, 2018 – 2028

Figure 100: MEA Industrial Pipe Insulation Materials Market Y-o-Y Growth Projections by Materials Type, 2013 – 2028

Figure 101: MEA Industrial Pipe Insulation Materials Market BPS Analysis by Materials Type – 2013, 2018 & 2028

Figure 102: MEA Industrial Pipe Insulation Materials Market Attractiveness Analysis by Materials Type, 2018 – 2028

Figure 103: MEA Industrial Pipe Insulation Materials Market Y-o-Y Growth Projections by Product Type, 2013 – 2028

Figure 104: MEA Industrial Pipe Insulation Materials Market BPS Analysis by Product Type – 2013, 2018 & 2028

Figure 105: MEA Industrial Pipe Insulation Materials Market Attractiveness Analysis by Product Type, 2018 – 2028

Figure 106: MEA Industrial Pipe Insulation Materials Market Y-o-Y Growth Projections by End Use, 2013 – 2028

Figure 107: MEA Industrial Pipe Insulation Materials Market BPS Analysis by End Use – 2013, 2018 & 2028

Figure 108: MEA Industrial Pipe Insulation Materials Market Attractiveness Analysis by End Use, 2018 – 2028

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Industrial Pipe Insulation Market

Pipe Insulation Films Market Size and Share Forecast Outlook 2025 to 2035

Pipe Insulation Market Size and Share Forecast Outlook 2025 to 2035

Pipe Insulation Products Market Size and Share Forecast Outlook 2025 to 2035

Market Leaders & Share in the Pipe Insulation Products Industry

Industrial Insulation Market Size and Share Forecast Outlook 2025 to 2035

Industrial Insulation Tester Market Growth - Trends & Forecast 2025 to 2035

Industrial Grade Electrochemical CO Sensor Market Size and Share Forecast Outlook 2025 to 2035

Industrial Bench Scale Market Size and Share Forecast Outlook 2025 to 2035

Industrial Low Profile Floor Scale Market Size and Share Forecast Outlook 2025 to 2035

Industrial Sand Mill Market Size and Share Forecast Outlook 2025 to 2035

Industrial Control Network Modules Market Size and Share Forecast Outlook 2025 to 2035

Industrial Precision Oven Market Size and Share Forecast Outlook 2025 to 2035

Industrial Water Chiller for PCB Market Size and Share Forecast Outlook 2025 to 2035

Industrial & Commercial HVLS Fans Market Size and Share Forecast Outlook 2025 to 2035

Industrial Robot Controller Market Size and Share Forecast Outlook 2025 to 2035

Industrial Wired Routers Market Size and Share Forecast Outlook 2025 to 2035

Industrial Evaporative Condensers Market Size and Share Forecast Outlook 2025 to 2035

Industrial Energy Management System Market Size and Share Forecast Outlook 2025 to 2035

Industrial Safety Gloves Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA