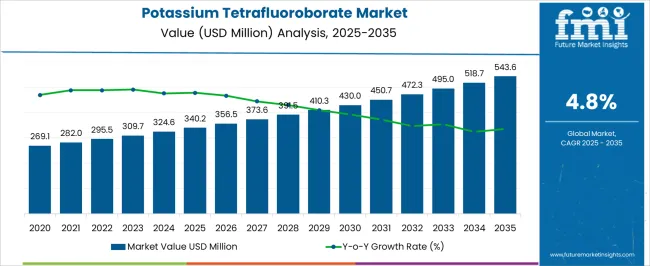

The Potassium Tetrafluoroborate Market is estimated to be valued at USD 340.2 million in 2025 and is projected to reach USD 543.6 million by 2035, registering a compound annual growth rate (CAGR) of 4.8% over the forecast period. From 2020 to 2024, the market expanded from USD 269.1 million to USD 324.6 million, with annual growth rates ranging between 4.2% and 4.9%. This early phase reflects gradual adoption across chemical, pharmaceutical, and industrial applications, where potassium tetrafluoroborate is used as a specialty reagent and electrolyte additive. Year-on-year growth during this period was supported by steady demand, incremental integration into production processes, and expanding procurement across regions, laying the foundation for broader market adoption.

Between 2025 and 2030, the market enters a scaling phase, rising from USD 340.2 million to USD 430.0 million, with YoY growth averaging 4.5–5.0%. Adoption expands as more chemical and industrial manufacturers integrate potassium tetrafluoroborate into their processes, supported by reliable supply and distribution channels. From 2030 to 2035, growth continues steadily to USD 543.6 million, with annual increases around 4.7–5.0%. The YoY analysis highlights predictable expansion, with recurring purchases, broader usage in industrial applications, and incremental production supporting consistent market growth and reflecting a transition toward market maturity.

| Metric | Value |

|---|---|

| Potassium Tetrafluoroborate Market Estimated Value in (2025 E) | USD 340.2 million |

| Potassium Tetrafluoroborate Market Forecast Value in (2035 F) | USD 543.6 million |

| Forecast CAGR (2025 to 2035) | 4.8% |

The potassium tetrafluoroborate market is experiencing consistent growth, supported by its expanding application base across various industries, particularly in advanced battery technologies, metallurgy, and specialty chemical production. Its demand is being propelled by the increasing adoption of lithium batteries for electric vehicles, portable electronics, and energy storage systems, where it is used as an electrolyte additive to enhance performance and stability.

The compound’s favorable properties, including high ionic conductivity, thermal stability, and compatibility with diverse electrode materials, are driving its utilization in next-generation energy storage solutions. Industrial applications in aluminum, magnesium, and specialty alloys are also contributing to the market’s growth, as potassium tetrafluoroborate plays a critical role in flux formulations for metal processing.

Continuous investments in research and development are leading to improved production processes and higher purity grades, making the product suitable for high-value applications Growing emphasis on sustainable energy technologies, combined with the rising adoption of electric mobility, is expected to maintain strong demand momentum, positioning the market for significant expansion over the next decade.

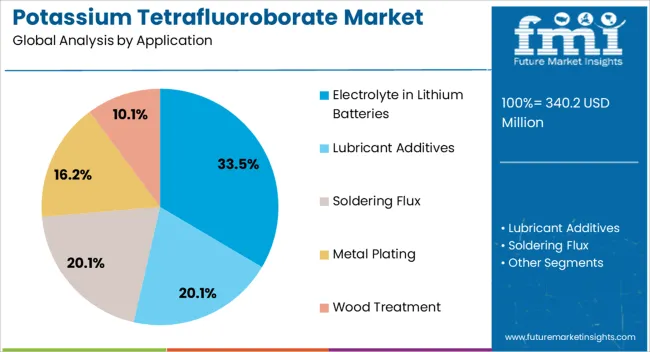

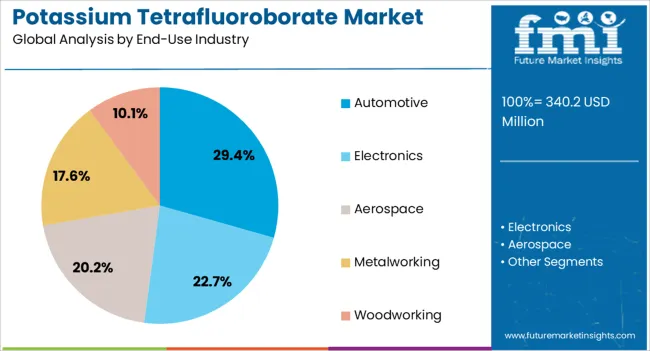

The potassium tetrafluoroborate market is segmented by application, end-use industry, grade, distribution channel, product form, and geographic regions. By application, potassium tetrafluoroborate market is divided into Electrolyte in Lithium Batteries, Lubricant Additives, Soldering Flux, Metal Plating, and Wood Treatment. In terms of end-use industry, potassium tetrafluoroborate market is classified into Automotive, Electronics, Aerospace, Metalworking, and Woodworking.

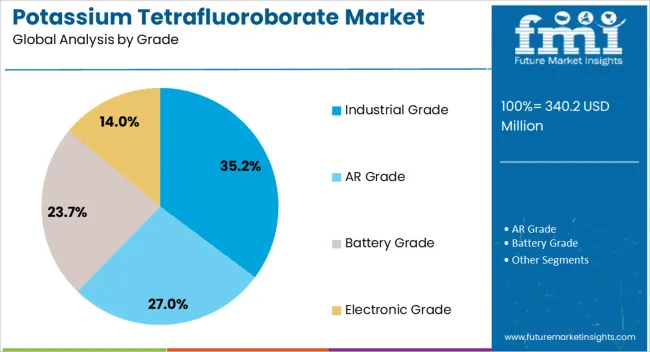

Based on grade, potassium tetrafluoroborate market is segmented into Industrial Grade, AR Grade, Battery Grade, and Electronic Grade. By distribution channel, potassium tetrafluoroborate market is segmented into Chemical Suppliers, Online Distributors, and Specialty Chemical Manufacturers.

By product form, potassium tetrafluoroborate market is segmented into Powder, Granules, and Liquid. Regionally, the potassium tetrafluoroborate industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The electrolyte in lithium batteries application segment is projected to hold 33.5% of the potassium tetrafluoroborate market revenue share in 2025, making it the leading application area. This leadership is being driven by the compound’s ability to enhance ionic conductivity, improve electrolyte stability, and extend battery lifespan. Its compatibility with a wide range of electrode chemistries enables manufacturers to achieve higher energy densities and improved charge-discharge performance.

Growing global adoption of electric vehicles, supported by government incentives and environmental regulations, is significantly increasing the production of lithium batteries, thereby boosting demand for potassium tetrafluoroborate. The segment is further supported by its role in improving safety parameters by reducing the risk of electrolyte decomposition under high-voltage operation.

Continuous advancements in battery technology, including solid-state and high-capacity designs, are creating new opportunities for potassium tetrafluoroborate integration As the transition toward cleaner energy systems accelerates, the segment is expected to remain at the forefront of market demand due to its critical contribution to high-performance lithium battery systems.

The automotive end-use industry segment is anticipated to account for 29.4% of the potassium tetrafluoroborate market revenue share in 2025, establishing itself as a key growth driver. This dominance is being reinforced by the increasing penetration of electric and hybrid vehicles, which rely heavily on advanced lithium battery systems incorporating potassium tetrafluoroborate-based electrolytes.

The material’s role in improving battery performance, energy efficiency, and operational safety aligns with the automotive industry’s goals of delivering higher range and faster charging capabilities. Beyond battery applications, the compound’s usage in aluminum and magnesium alloy production supports its presence in lightweight vehicle manufacturing, which is critical for enhancing fuel efficiency and reducing emissions.

Rising automotive production in emerging markets, combined with stricter environmental regulations in developed regions, is boosting the demand for high-performance materials. As automakers continue to invest in electric mobility and sustainable manufacturing, potassium tetrafluoroborate’s importance in meeting performance and regulatory requirements is expected to secure its strong position in the sector.

The industrial grade segment is expected to represent 35.2% of the potassium tetrafluoroborate market revenue share in 2025, positioning it as the leading grade category. This dominance is supported by the segment’s widespread applicability in metal processing, welding fluxes, and specialty chemical synthesis. Industrial-grade potassium tetrafluoroborate offers an optimal balance between cost-effectiveness and performance, making it suitable for large-scale manufacturing in both energy storage and metallurgical applications.

Its role in improving the efficiency of aluminum and magnesium refining processes is a major factor driving adoption, particularly in industries focused on lightweight and corrosion-resistant materials. The segment also benefits from stable supply chains and scalable production capabilities, enabling manufacturers to meet growing global demand.

Increasing investment in infrastructure, automotive production, and renewable energy projects is further supporting consumption of industrial-grade variants. As industries continue to seek high-quality materials that meet performance requirements without excessive costs, this segment is anticipated to maintain its market leadership in the coming years.

The potassium tetrafluoroborate market is expanding due to its wide use in electroplating, chemical synthesis, and metal finishing applications. It provides excellent fluoride content, thermal stability, and reactivity, making it ideal for nickel plating, brazing, and flux production. Demand is rising in automotive, electronics, and industrial manufacturing. Asia-Pacific leads in production and consumption due to growing industrial output, while Europe focuses on high-purity applications. Manufacturers emphasize high-quality crystalline grades, impurity control, and consistent particle size to meet strict industrial requirements.

Potassium tetrafluoroborate is primarily used in nickel electroplating and metal finishing processes due to its ability to provide uniform deposition and reduce defects. It enhances surface smoothness, corrosion resistance, and adherence of the plated layer, which is critical for automotive, electronics, and aerospace components. Manufacturers supplying high-purity, consistent-grade potassium tetrafluoroborate are preferred for sensitive plating applications where quality defects can lead to product failures. Until alternative chemicals with similar plating efficiency, stability, and low impurity profiles become available, potassium tetrafluoroborate will remain essential for high-performance metal finishing processes.

Potassium tetrafluoroborate serves as a source of fluoride ions in chemical synthesis and acts as a fluxing agent in brazing and soldering. Its high thermal stability allows it to maintain performance under high-temperature industrial operations. Chemical manufacturers use it to produce specialty boron compounds and catalysts. Consistency in particle size, purity, and moisture content is critical to ensure predictable chemical reactions. Companies providing standardized, high-quality products gain a competitive advantage in industrial chemistry applications. Until alternative fluoride sources can match its stability, reactivity, and ease of handling, potassium tetrafluoroborate will remain a preferred reagent in chemical synthesis and industrial manufacturing.

The automotive and electronics sectors drive significant demand for potassium tetrafluoroborate due to its role in electroplating and corrosion-resistant coatings. In automotive applications, nickel-plated components, connectors, and fasteners rely on consistent deposition quality. Electronics components, including circuit boards and connectors, require smooth and uniform metal finishes. Manufacturers supplying high-purity potassium tetrafluoroborate with controlled particle size, low impurities, and consistent solubility meet stringent industry standards. Until alternative plating and coating chemicals offer similar efficiency and quality, automotive and electronics applications will continue to be the key demand drivers for potassium tetrafluoroborate.

Potassium tetrafluoroborate is classified as a chemical that requires careful handling due to its fluoride content and reactivity. Manufacturers must comply with regional safety regulations for storage, transport, and disposal to prevent environmental contamination and worker exposure. Industrial buyers prioritize suppliers that provide proper documentation, safety data sheets, and consistent quality assurance. Packaging in moisture-proof containers and adherence to purity specifications enhance product reliability. Until alternative chemicals with equivalent reactivity and lower regulatory burdens are developed, regulatory compliance and safe handling protocols remain critical considerations affecting adoption in industrial and electroplating markets.

| Country | CAGR |

|---|---|

| China | 6.5% |

| India | 6.0% |

| Germany | 5.5% |

| France | 5.0% |

| UK | 4.6% |

| USA | 4.1% |

| Brazil | 3.6% |

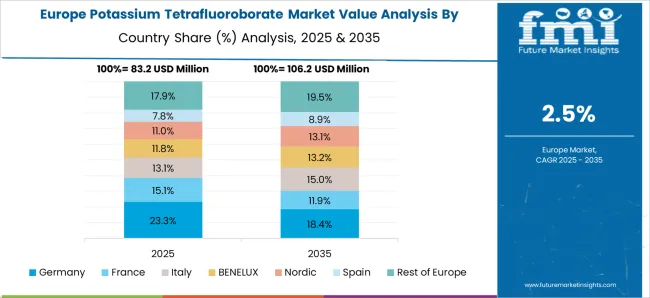

The global Potassium Tetrafluoroborate Market is projected to grow at a CAGR of 4.8% through 2035, supported by increasing demand across chemical, electroplating, and industrial applications. Among BRICS nations, China has been recorded with 6.5% growth, driven by large-scale production and deployment in chemical and electroplating processes, while India has been observed at 6.0%, supported by rising utilization in industrial and chemical manufacturing. In the OECD region, Germany has been measured at 5.5%, where production and adoption for chemical, electroplating, and industrial applications have been steadily maintained. The United Kingdom has been noted at 4.6%, reflecting consistent use in chemical and industrial processes, while the USA has been recorded at 4.1%, with production and utilization across chemical, electroplating, and industrial sectors being steadily increased. This report includes insights on 40+ countries; the top five markets are shown here for reference.

The potassium tetrafluoroborate market in China is expanding at a CAGR of 6.5%, driven by its widespread applications in chemical synthesis, electroplating, and metal finishing industries. The compound is essential in producing fluxes, catalysts, and specialty chemicals, which are crucial for the rapidly growing manufacturing and electronics sectors. China’s strong industrial base, especially in automotive and electronics manufacturing, supports consistent demand. Technological advancements in chemical processing, along with government initiatives promoting industrial production and exports, further boost market growth. Increasing adoption in battery production, electronic components, and surface treatment processes ensures steady consumption. Environmental regulations encouraging safer chemical handling and sustainable processes are also shaping market strategies. Overall, the demand for high-purity potassium tetrafluoroborate in China continues to rise, driven by industrial expansion, technological progress, and strong downstream consumption in multiple sectors.

The potassium tetrafluoroborate market in India is growing at a CAGR of 6.0%, supported by expanding chemical, electronics, and automotive sectors. The compound is widely used in chemical synthesis, electroplating, and specialty chemical production, driving steady industrial consumption. Increasing adoption in batteries, electronic devices, and surface treatment processes provides additional market growth opportunities. Local manufacturers are focusing on improving production techniques to deliver high-purity potassium tetrafluoroborate at competitive costs. Government initiatives promoting domestic chemical production, industrial safety standards, and export-oriented growth contribute positively to market expansion. Environmental and regulatory compliance is increasingly emphasized in production and handling, encouraging adoption of sustainable practices. India’s growing industrial base, combined with rising demand for specialty chemicals and technological advancements, ensures the potassium tetrafluoroborate market remains on a steady upward trajectory.

The potassium tetrafluoroborate market in Germany is growing at a CAGR of 5.5%, driven by strong industrial and automotive applications. The chemical is primarily used in electroplating, chemical synthesis, and surface treatment processes, supporting demand in manufacturing and electronics sectors. Germany’s stringent quality and environmental standards ensure high-purity production, fostering growth in specialty chemical markets. Adoption in battery technologies, electronic components, and industrial fluxes enhances market potential. German companies are investing in R&D to improve production efficiency, reduce waste, and meet environmental compliance requirements. Strong industrial infrastructure, skilled workforce, and export opportunities within the EU reinforce market stability. Overall, Germany maintains a robust potassium tetrafluoroborate market, supported by advanced manufacturing practices, regulatory standards, and steady industrial demand.

The potassium tetrafluoroborate market in the United Kingdom is growing at a CAGR of 4.6%, driven by applications in chemical synthesis, electroplating, and specialty chemical industries. Demand is fueled by industrial requirements in electronics, automotive, and surface treatment sectors. UK manufacturers and distributors are increasingly focusing on providing high-purity, environmentally compliant products. Technological advancements enhance production efficiency and enable safer handling processes. Government initiatives supporting sustainable chemical production and industrial safety practices encourage adoption. Use in batteries, electronic devices, and industrial fluxes contributes to steady market growth. The combination of regulatory compliance, industrial expansion, and technological improvements ensures that the potassium tetrafluoroborate market in the UK maintains consistent growth.

The potassium tetrafluoroborate market in the United States is expanding at a CAGR of 4.1%, driven by demand in chemical manufacturing, electronics, and surface treatment industries. The compound is essential for electroplating, chemical synthesis, and specialty chemical applications. Technological developments enhance production efficiency, purity, and safety in industrial processes. Adoption in battery components, electronic devices, and industrial fluxes supports steady market growth. Government regulations emphasizing environmental compliance, industrial safety, and chemical handling influence production practices. Manufacturers are investing in R&D to optimize product quality, reduce waste, and maintain competitiveness. The growing demand from electronics, automotive, and specialty chemical sectors ensures the USA potassium tetrafluoroborate market remains stable, with consistent adoption and gradual expansion driven by technology and industrial requirements.

The potassium tetrafluoroborate market is a niche yet vital segment in the chemical industry, primarily used in electroplating, fluxes, and specialty chemical applications. Its demand is driven by the growth of electronics, automotive, and metal finishing industries, where it acts as a key component in enhancing conductivity, corrosion resistance, and surface finishing quality. The market is witnessing steady expansion due to increasing industrial applications and stringent quality requirements across manufacturing processes.

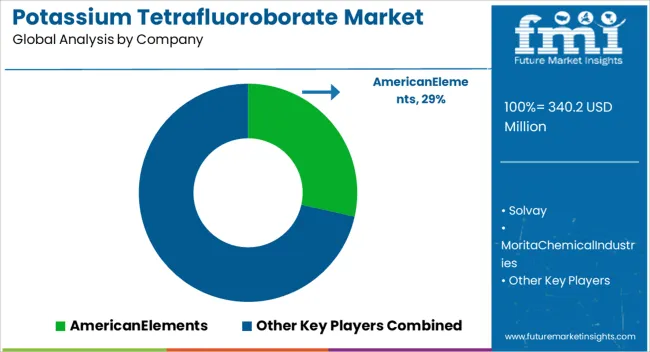

American Elements is a prominent supplier, offering high-purity potassium tetrafluoroborate for research and industrial applications. Solvay, a global chemical leader, provides specialized chemical solutions catering to diverse industries, ensuring consistent product quality and supply. Morita Chemical Industries focuses on high-performance tetrafluoroborate products for electroplating and specialty chemical sectors. Alfa Aesar is well-known for its research-grade chemical offerings, supplying reliable materials for both laboratory and industrial use. Coronet Industries provides a broad portfolio of chemical intermediates, including potassium tetrafluoroborate, emphasizing sustainable production practices. AMG Aluminium complements the market by providing raw materials and specialty chemicals that enhance industrial manufacturing processes.

The market is poised for growth as industrial sectors increasingly adopt advanced materials and chemical processes requiring high-purity potassium tetrafluoroborate. Manufacturers are investing in research and development to improve production efficiency, purity levels, and sustainability. With rising applications in electronics, automotive, and specialty chemical industries, potassium tetrafluoroborate continues to be an essential chemical component, and the presence of leading suppliers ensures reliability and scalability for end-users worldwide.

| Item | Value |

|---|---|

| Quantitative Units | USD 340.2 Million |

| Application | Electrolyte in Lithium Batteries, Lubricant Additives, Soldering Flux, Metal Plating, and Wood Treatment |

| End-Use Industry | Automotive, Electronics, Aerospace, Metalworking, and Woodworking |

| Grade | Industrial Grade, AR Grade, Battery Grade, and Electronic Grade |

| Distribution Channel | Chemical Suppliers, Online Distributors, and Specialty Chemical Manufacturers |

| Product Form | Powder, Granules, and Liquid |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled | AmericanElements, Solvay, MoritaChemicalIndustries, AlfaAesar, CoronetIndustries, and AMGAluminium |

| Additional Attributes | Dollar sales vary by grade, including industrial and high-purity potassium tetrafluoroborate; by application, such as fluxing agents in metal processing, electroplating, and specialty chemicals; by end-use industry, spanning automotive, electronics, aerospace, and metal finishing; by region, led by Asia-Pacific, Europe, and North America. Growth is driven by increasing demand in metal surface treatment, electronics manufacturing, and specialty chemical applications. |

The global potassium tetrafluoroborate market is estimated to be valued at USD 340.2 million in 2025.

The market size for the potassium tetrafluoroborate market is projected to reach USD 543.6 million by 2035.

The potassium tetrafluoroborate market is expected to grow at a 4.8% CAGR between 2025 and 2035.

The key product types in potassium tetrafluoroborate market are electrolyte in lithium batteries, lubricant additives, soldering flux, metal plating and wood treatment.

In terms of end-use industry, automotive segment to command 29.4% share in the potassium tetrafluoroborate market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Potassium Fluoride Market Size and Share Forecast Outlook 2025 to 2035

Potassium Formate Market Size and Share Forecast Outlook 2025 to 2035

Potassium Sulfate Market Size and Share Forecast Outlook 2025 to 2035

Potassium Fluoborate Market Size and Share Forecast Outlook 2025 to 2035

Potassium Propionate Market Size and Share Forecast Outlook 2025 to 2035

Potassium Acetate Market Size and Share Forecast Outlook 2025 to 2035

Potassium Citrate Market Growth - Trends & Forecast 2025 to 2035

Potassium Formate Industry Analysis in North America - Size, Share & Forecast 2025 to 2035

Potassium Carbonate Market Growth – Trends & Forecast 2025 to 2035

Potassium Sorbate Market Analysis by Product Type, Application and Region from 2025 to 2035

Potassium Hydrogen Fluoride Market Growth - Trends & Forecast 2025 to 2035

Potassium Chloride Market Growth – Trends & Forecast 2025 to 2035

Potassium Humate Market Growth – Trends & Forecast 2025 to 2035

Potassium Zirconium Fluoride Market

Potassium Cryolite Market

Potassium Alum Market

Potassium Hydrogen Sulphite Market

Dipotassium Guanylate Market Size and Share Forecast Outlook 2025 to 2035

Sodium, Potassium and Calcium Salts Market Analysis by Agriculture, Pharmaceuticals and Personal Care Through 2035

Demand for Potassium Sulfate in EU Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA