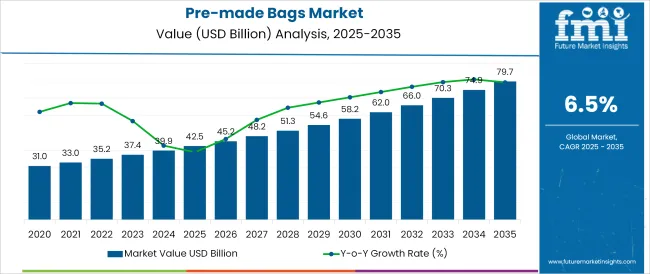

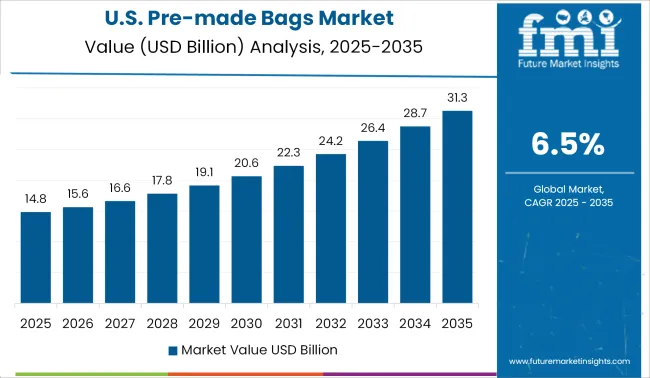

The Pre-made Bags Market is estimated to be valued at USD 42.5 billion in 2025 and is projected to reach USD 79.7 billion by 2035, registering a compound annual growth rate (CAGR) of 6.5% over the forecast period.

The pre-made bags market is experiencing sustained growth, fueled by evolving consumer lifestyles, advancements in packaging technologies, and the expansion of the food and beverage sector. Increased demand for convenience-oriented packaging formats that support easy handling, freshness retention, and brand differentiation is reshaping product development across global markets.

Manufacturers are focusing on developing lightweight, cost-efficient, and durable packaging materials that comply with food safety and environmental regulations. The rise of automation and flexible filling technologies has made pre-made bags highly compatible with modern production lines, boosting efficiency and reducing turnaround times.

Furthermore, global shifts toward sustainable packaging are encouraging material innovation and recyclable pouch development. As demand intensifies across sectors such as snacks, frozen foods, and health products, the market is expected to witness long-term traction, supported by rising urbanization, digital retail, and the growing preference for ready-to-eat and pre-portioned offerings.

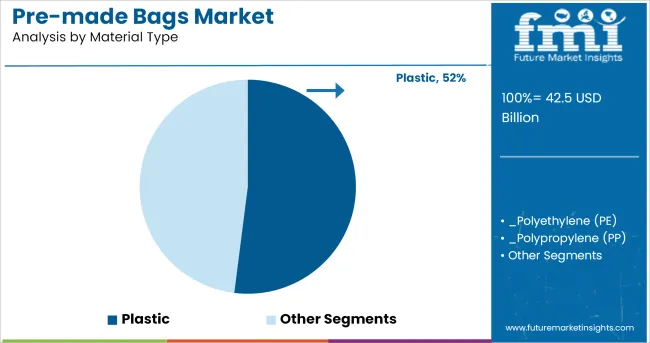

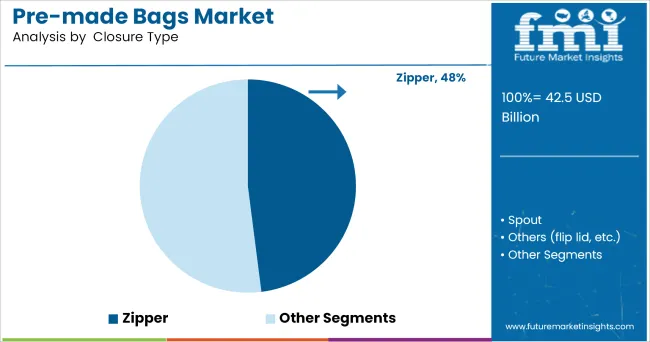

The market is segmented by Material Type, Closure Type, Application, and End-User and region. By Material Type, the market is divided into Plastic, Polyethylene (PE), Polypropylene (PP), Polyvinyl chloride (PVC), Polyamide (PA), Paper, and Aluminium laminate. In terms of Closure Type, the market is classified into Zipper, Spout, and Others (flip lid, etc.).

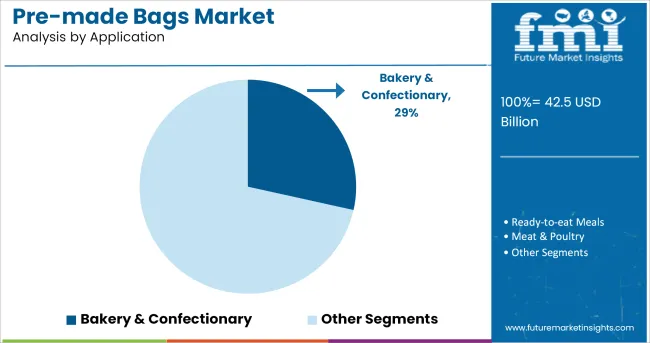

Based on Application, the market is segmented into Bakery & Confectionary, Ready-to-eat Meals, Meat & Poultry, Fruits & Vegetables, and Others (dairy products, etc.). By End-User, the market is divided into Food & Beverages, Healthcare & Pharmaceutical, Personal Care & Cosmetics, and Others (consumer goods, etc.). Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

Plastic is anticipated to hold 52.0% of the material type revenue share in 2025, maintaining its status as the dominant material in the pre-made bags market. This leadership is attributed to plastic’s superior durability, lightweight properties, and adaptability to a wide range of product formats and barrier requirements.

Its compatibility with high-speed packaging lines and cost-effective production have driven widespread adoption across both food and non-food applications. Multilayer plastic films enable extended shelf life, which is critical for perishable goods and convenience snacks.

Additionally, ongoing innovation in recyclable and bio-based plastic alternatives is allowing manufacturers to address environmental concerns while maintaining performance standards. As material suppliers and converters optimize for sustainability without compromising structural integrity, plastic continues to serve as the preferred material for high-volume, retail-ready pre-made bag applications.

The zipper closure type is projected to command 48.0% of market revenue in 2025, ranking as the most preferred sealing mechanism. This dominance is driven by consumer demand for re-sealable packaging that extends product freshness and enables multi-use functionality. Zipper closures offer a convenient user experience, particularly for snacks, frozen foods, and dry goods that require portion control and repeated access.

Packaging manufacturers have integrated zipper technology with flexible laminates and stand-up pouch formats, enhancing product presentation while preserving shelf life.

Furthermore, the ability to maintain sealing integrity during transit and storage has made zippers a trusted closure choice among retailers and brand owners. As reusable packaging gains traction in consumer goods, the convenience, reusability, and hygienic benefits provided by zipper closures will continue to support their leadership position in the market.

Bakery and confectionery products are expected to contribute 28.5% of the total application-based revenue in 2025, positioning this as the leading use case in the pre-made bags market. This dominance is driven by growing consumption of packaged baked goods, sweets, and snacks across retail and quick-service channels.

The need for moisture-resistant, grease-proof, and visually appealing packaging has led to a surge in demand for pre-made bags tailored for bakery and confectionery items. The integration of transparent windows, re-sealable zippers, and high-definition printing supports product visibility and shelf appeal key considerations in impulse driven purchases.

Additionally, single serve and multi-pack configurations cater to portion control, convenience, and hygiene needs of today’s on-the-go consumers. As artisanal and premium brands seek to differentiate through packaging, pre made bags have emerged as the preferred format for balancing brand identity with product protection, reinforcing the bakery and confectionery segment’s share in the overall market.

Pre-made bags are manufactured by experts in bag-making technology with the use of newer technology, new equipment, and most importantly by using flexible packaging material. These bags can be customized into various shapes, sizes, colours, and dimensions according to the customer’s needs. These bags are manufactured using the reliability feature which is of very high importance to the customer.

Once the bag is opened, the closure feature of the pre-made bag allows the customer to seal the bag again with the help of a zipper. Not only this feature prevents food spillage but also protects the product from external conditions like moisture, temperature, etc.

Being made from flexible packaging, these bags are very light in weight and volume and economical in cost. These bags also have a barrier system inside the packaging material which helps to safeguard the product by keeping the product fresh and protecting the aroma.

The paper pre-made bags with the window opening is used for holding and carrying all kinds of products like food, healthcare products, etc. Also, the paper pre-made bags with window opening is attractive in appearance and is also used to serve as a gifting purpose on various occasions and festivities.

Therefore, apart from just holding and carrying the products, the paper-made pre-made bags are also used as gifting bags owing to their visual appearance and physical properties.

The pre-made bags use the packaging machine or the equipment which is better suited for providing flexibility, in terms of shapes, sizes, and colours with the huge and varied roll stock of inventory as compared to the traditional bags.

The pre-made bags offers a lower cost of entry with the latest technology and operations with a variety of styles of bags such as stand-up, gusseted bags, etc. which are readily not offered by the bags manufactured using FFS technology.

The manufacturing of the pre-made bags requires the machinery or equipment that can manufacture the bags with the different levels of customizations in sizes, shapes, and colours.

This can require a huge cost to incur owing to the latest technology used while manufacturing the pre-made bags. Therefore, the higher cost of the machinery can be a restraining or challenging factor for the new entrants in the market. Also, the procurement of sustainable raw materials such as paper may vary and can be challenging according to the season.

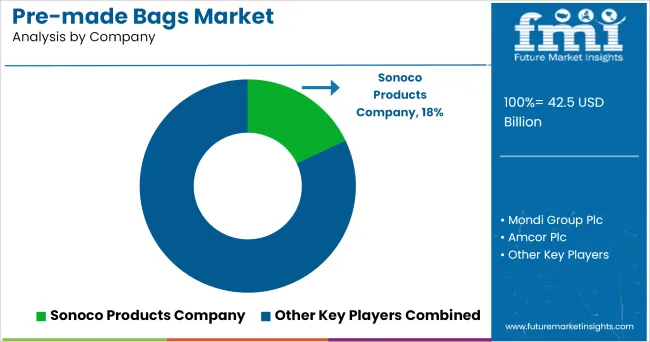

The majority of the key players manufacturing pre-made bags have their presence in the USA which is the key factor driving the growth of the pre-made bags market share.

Adding to this, also the changing technologies in the packaging industry by emphasizing research & development activities are acting as a boon towards the growth of the pre-made bags market. The increasing facilities for plastic recycling plants and sustainable product manufacturing are also the growth factor adding demand to the market.

The following global key players such as

Key Asian players manufacturing pre-made bags

The manufacturers involved in the manufacturing of pre-made bags are involved in investing capital in the new technology to expand the business on the global level. Also, the leading packaging distributor is involved in increasing the manufacturing capacity while boosting the demand for pre-made bags.

The use of advanced technology used in the manufacturing of pre-made bags not only has created significant opportunity for the shelf products like FMCG products, etc. but also they can be used in the packaging of the frozen foods as compared to the packaging boxes which allows easily sealing and opening of the bags.

The global pre-made bags market is estimated to be valued at USD 42.5 billion in 2025.

The market size for the pre-made bags market is projected to reach USD 79.7 billion by 2035.

The pre-made bags market is expected to grow at a 6.5% CAGR between 2025 and 2035.

The key product types in pre-made bags market are plastic, polyethylene (pe), polypropylene (pp), polyvinyl chloride (pvc), polyamide (pa), paper and aluminium laminate.

In terms of closure type, zipper segment to command 48.0% share in the pre-made bags market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Market Share Insights of Pre-made Bags Manufacturers

Polybags Market Size and Share Forecast Outlook 2025 to 2035

Net Bags Market

VCI Bags Market

Sandbags Market

Leno Bags Market Size and Share Forecast Outlook 2025 to 2035

Silo bags Market Size and Share Forecast Outlook 2025 to 2035

Food Bags Market Share, Size, and Trend Analysis for 2025 to 2035

Competitive Breakdown of Silo Bag Manufacturers

Paper Bags Market Size and Share Forecast Outlook 2025 to 2035

Jumbo Bags Market Size and Share Forecast Outlook 2025 to 2035

Blood Bags Market Size and Share Forecast Outlook 2025 to 2035

Craft Bags Market Growth, Trends, Forecast 2025 to 2035

Market Share Breakdown of Craft Bags Manufacturers

Competitive Breakdown of Paper Bags Providers

Market Share Analysis of Jumbo Bags & Key Players

Grout Bags Market Demand & Construction Industry Trends 2024 to 2034

Sugar Bags Market

Cotton Bags Market Size and Share Forecast Outlook 2025 to 2035

Refuse Bags Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA