The industry of rotomolded containers is on the increase to cater for the rising demand by industries for storage solutions that are durable, impact-resistant, and weatherproof against harsh conditions. There is a lift across verticals in logistics, food and beverages, pharmaceuticals, and industry applications, and manufacturers are emphasizing on producing lightweight yet strong designs. Providing functionality and performance will be maximized with UV-resistant materials, insulated linings, and tamper-proof closures.

Companies are integrating AI-enabled quality control, automated rotational molding processes, and recyclable polymer blends to limit their production costs and reduce environmental impacts. This sector is progressing towards ergonomic custom-molded and RFID-enabled containers to improve logistics efficiency as well as supply chain visibility.

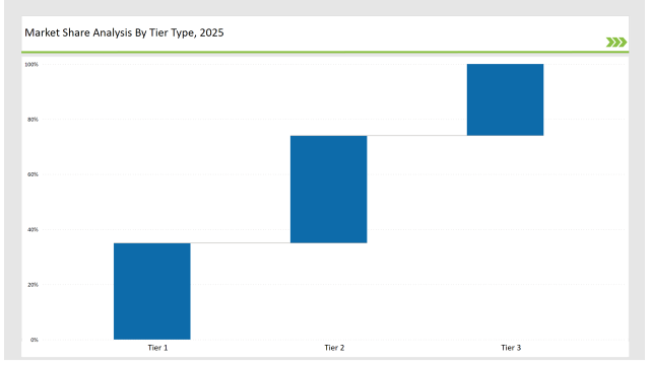

The major 35% of the market share is held by Tier 1 players such as Pelican Products, Granger Plastics, and SKB Cases due to their advanced engineering, innovating in materials, and global distribution network.

Tier 2 companies such as Thermo Fisher Scientific, Royal Case Company, and TranPak capture 39% of the market due to their offering cost-effective, tailored, and impact-resistant rotomolded containers for several applications.

Tier 3 includes regional and niche players specializing in sustainable, digitally traceable, and specialty rotomolded containers; such companies hold 26% of the market. These companies target localized production, advanced insulation, and industry-specialized packaging solutions.

Global Market Share by Key Players (2025)

| Category | Market Share (%) |

|---|---|

| Top 3 (Pelican Products, Granger Plastics, SKB Cases) | 18% |

| Rest of Top 5 (Thermo Fisher Scientific, Royal Case Company) | 9% |

| Next 5 of Top 10 (TranPak, Meese Inc., RotoWorld, Denios, PolyCase) | 8% |

The rotomolded containers industry serves multiple sectors where impact resistance, temperature stability, and secure storage are essential. Companies are developing advanced packaging solutions to meet industry-specific needs.

Manufacturers are optimizing rotomolded containers with durable construction, smart tracking, and sustainable materials. They are incorporating reinforced corner structures to enhance impact resistance and extend container lifespan. Additionally, businesses are integrating ergonomic handle designs to improve portability and ease of use across various applications.

The rotomolded containers industry is undergoing a change due to sustainability and digital transformation efforts. Companies are adopting AI-based defect detection systems, polymer compositions that improve durability and reduce costs, and modular container systems.

Another interesting trend is in the area of collapsible rotomolded designs for storage and transportation efficiency. More and more manufacturers are gradually switching to eco-friendly resin blends and post-consumer recycled materials. In addition, companies are integrating IoT-enabled sensors to allow real-time tracking and monitoring.

Year-on-Year Leaders

Technology suppliers should focus on automation, smart tracking, and sustainable material innovations to support the evolving rotomolded containers market. Partnering with logistics, healthcare, and defense sectors will drive adoption.

| Tier Type | Example of Key Players |

|---|---|

| Tier 1 | Pelican Products, Granger Plastics, SKB Cases |

| Tier 2 | Thermo Fisher Scientific, Royal Case Company, TranPak |

| Tier 3 | Meese Inc., RotoWorld, Denios, PolyCase |

Leading manufacturers are advancing rotomolded container technology with AI-powered defect detection, smart tracking, and reinforced durability features. They are developing energy-efficient molding processes to reduce production costs and carbon emissions. Additionally, manufacturers are integrating shock-absorbing base designs to enhance impact resistance during transportation.

| Manufacturer | Latest Developments |

|---|---|

| Pelican Products | Launched RFID-enabled storage containers in March 2024. |

| Granger Plastics | Developed lightweight, impact-resistant cases in April 2024. |

| SKB Cases | Expanded military-grade container solutions in May 2024. |

| Thermo Fisher | Released FDA-compliant insulated containers in June 2024. |

| Royal Case Co. | Strengthened moisture-resistant packaging in July 2024. |

| TranPak | Introduced modular, stackable designs in August 2024. |

| Meese Inc. | Pioneered biodegradable, food-safe rotomolded containers in September 2024. |

The rotomolded containers market is evolving as companies invest in sustainable materials, AI-driven defect detection, and smart storage solutions. They are developing reinforced structural designs to improve load-bearing capacity and extend container lifespan. Additionally, manufacturers are integrating antimicrobial coatings to enhance hygiene and safety in food and healthcare storage applications.

Manufacturers will continue integrating smart tracking, AI-powered defect detection, and sustainable materials. Companies will refine temperature-controlled containers for pharmaceutical logistics. Businesses will adopt post-consumer recycled polymers to improve eco-friendliness.

Firms will develop collapsible rotomolded containers to optimize storage. IoT sensors will enhance real-time supply chain monitoring. Additionally, companies will strengthen automated molding processes to increase efficiency and reduce production waste.

Leading players include Pelican Products, Granger Plastics, SKB Cases, Thermo Fisher Scientific, Royal Case Company, TranPak, and Meese Inc.

The top 3 players collectively control 18% of the global market.

The market shows medium concentration, with top players holding 35%.

Key drivers include durability, smart tracking, automation, and sustainability.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Rotomolded Containers Market Size and Share Forecast Outlook 2025 to 2035

Market Share Breakdown of Roll Containers Manufacturers

Key Players & Market Share in the Steel Containers Industry

Breaking Down Market Share in Rigid Food Containers

Competitive Landscape of Collapsible Rigid Containers Providers

Market Share Breakdown of Corrugated Pallet Containers Providers

PS Containers Market Size and Share Forecast Outlook 2025 to 2035

PET Containers Market Growth, Demand and Forecast from 2025 to 2035

PUR containers packaging Market

Roll Containers Market Size and Share Forecast Outlook 2025 to 2035

HDPE Containers Market Insights & Growth Outlook 2025 to 2035

Foam Containers Market

Soup Containers Market

Metal Containers Market Demand & Packaging Innovations 2025 to 2035

Steel Containers Market Analysis by Product Type, Capacity Type, End Use, and Region through 2025 to 2035

Smart Containers Market

Spout Containers Market

Pocket Containers Market Size and Share Forecast Outlook 2025 to 2035

Tottle Containers Market Size and Share Forecast Outlook 2025 to 2035

Sample Containers Market

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA