As the packaging industry is developing year after year, the usage of different innovative materials is increasing across the industry. The implication of these innovative materials, such as side weld bags, has turned out to be a game-changing move especially for the food packaging industry.

Side weld bags are becoming a vital constituent of the food packaging industry as they are flexible packaging bags offering high efficiency, changing the purpose of packaging.

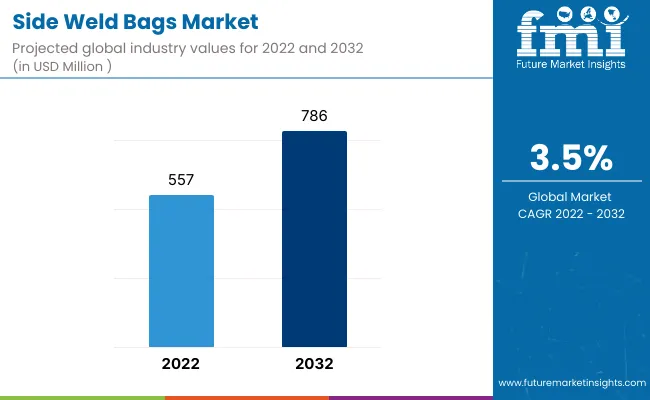

Future Market Insights recent study suggests that the global side weld bags market is expected to be valued at US$ 557 Million in 2022, and is expected to flourish at a value CAGR of 3.5% to reach US$ 786 Million by 2032.

The market is driven by the increasing consumer preference towards biodegradable materials coupled with the growing environmental concerns. In addition to this, the FMI report further indicates that side weld bags have been a replacement alternative for traditional rigid boxes as it renders additional comfort in product handling and also convenient to transport and store product.

| Data Points | Key Statistics |

|---|---|

| Expected Market Value in 2022 | USD 557 Million |

| Projected Market Value in 2032 | USD 786 Million |

| Growth Rate (2022 to 2032) | 3.5% CAGR |

Manufacturers are increasingly becoming interested in investing in good Side Weld Bags owing to the increased need for enhancing the shelf life of the product.

Research shows great potential of Side Weld Bags that provide all the features such as-

To reach potential outcomes, organizations are investing in intelligent and innovative Side Weld Bags. Moreover, companies in the market are adopting new technology and launching new products. In March 2022, Taiwanese brand WOHO released two new waterproof bags for their XTouring lineup: a top tube bag and a race-oriented partial frame bag.

The XTouring Frame Bag S DRY is designed around the needs of ultra-distance cyclists and fits in the front of the frame triangle while retaining space for two water bottles. It’s high-frequency welded from a lightweight coated nylon and shaped for a near universal fit to work with most frame triangles. The Frame Bag Dry S features a waterproof ZIP-LOCK closure design with moveable straps that can be attached on three sides of the bag.

The XTOURING Top-tube Bag DRY is a lightweight, welded waterproof bag that has 1.1L of storage and is made to stash anything from energy bars and snacks to phones and chargers that need to be protected from the weather. It can be attached to the top tube with included straps or bolt-on bosses. More interesting, it features a unique bungee cord attachment for the head tube.

The rising use of the contemporary innovative material across the packaging industry has been a game-changing move for the food packaging industry in the past half a decade. These has created an increasing demand for smaller flexible bags across the food packaging industry. The side weld bags are one such type of flexible packaging bags which has created an outbreak in the demand for flexible packaging market.

Side weld bags has been a replacement alternative for traditional rigid boxes as it renders additional comfort in product handling and also convenient to transport and store product. Moreover, leading manufacturers are highly focusing on providing additional elements to side weld bags such as anti-static properties, UV stabilizer, anti-block and use of the bio-degradable material.

Moreover, the increasing consumer preference towards biodegradable materials coupled with the growing environmental concern is expected to boost the overall growth for the use of biodegradable material for manufacturing side weld bags.

With growing food consumption across the developing region, it is highly correlating the demand flexible side weld bags. The region of APEJ is anticipated to represent a big chunk of market value in the side weld bags market.

One of the factor which are significantly driving the growth of side weld bags market is the rising demand of retailer for conventional bags as compared to traditional containers. In addition, the use of bio- degradable material by the manufacturers aids in enhancing the shelf life of the product which blocks any ingress of molecules and bacteria.

Also, the production process of side weld bags involves heat sealing process which is a convenient form of sealing for all types of polymers. Furthermore, invention of cost-effective form of printing solution such as flexographic, digital and screen printing provides the packaging manufacturer to display maximum branding of the product.

In addition, the rising consumer awareness about the conventional form of flexible packaging is correlating the growth of side weld bags are predominant across the food packaging industry. On the flip side, manufacturer operating in regions of North America, and Europe have to face fierce regulatory pressure in the choice of non-bio-degradable polymers. Such factor is hampering the growth of side weld bags market across the developed region.

Geographically, the side weld bags market is segmented into material type, gusseted style type, printing type. On the basis of material type the global side weld bags is segmented into polyethylene (PE), low-density polyethylene (LDPE), polylactic (PLA) polypropylene (PP), cast polypropylene (CPP), biaxial oriented polypropylene (BOPP), others.

On the basis of gusseted style type the global side weld bags is segmented into top gusseted and bottom gusseted. On the basis of printing type the global side weld bags is segmented into flexographic printing, rotogravure printing and others.

Globally the side weld bags market is highly fragmented across developing region, with APEJ region accounting a significant share. Moreover, with increasing consumption of food the demand for side weld bags is anticipated to spur over the forecast period. The other regions such as North America & Western Europe are expected to represent a significant CAGR over the forecast period.

Some of the key players operating in the global side weld bags market include Sideweld Industries Inc.,WB Packaging Ltd., Pebal s.r.o., CPS Flexible Ltd., RJH Plastics, Bison Bag Co., Inc. The Robinette Company, Vitra NV, A- ROO Company LLC,

The report is a compilation of first-hand information, qualitative and quantitative assessment by industry analysts, inputs from industry experts and industry participants across the value chain. The report provides in-depth analysis of parent market trends, macro-economic indicators and governing factors along with market attractiveness as per segments. The report also maps the qualitative impact of various market factors on market segments and geographies.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Weld Angle Brackets Market Size and Share Forecast Outlook 2025 to 2035

Welding Electrodes and Rods Market Size and Share Forecast Outlook 2025 to 2035

Welding Filler Metal Market Size and Share Forecast Outlook 2025 to 2035

Sidewinder Machine Market Size and Share Forecast Outlook 2025 to 2035

Side Load Case Packing Machines Market Size and Share Forecast Outlook 2025 to 2035

Welding Fume Extraction Equipment Market Size and Share Forecast Outlook 2025 to 2035

Side Loader Trucks Market Size and Share Forecast Outlook 2025 to 2035

Side Gusset/Quad Seal Bag Market Size and Share Forecast Outlook 2025 to 2035

Welded Blisters Market Size and Share Forecast Outlook 2025 to 2035

Welding Equipment And Consumables Market Size and Share Forecast Outlook 2025 to 2035

Welding Material Market Analysis by Type, Technology, End User, and Region 2025 to 2035

Welding Guns Market Growth - Trends & Forecast 2025 to 2035

Welding Consumables Market Growth - Trends & Forecast 2025 to 2035

Key Companies & Market Share in the Side Gusset/Quad Seal Bag Sector

Welding Torch and Tip Changing Robotic Station Market Growth – Trends & Forecast 2024-2034

Welding Helmets Market

Side Sealer Machines Market

Residential Generator Market Size and Share Forecast Outlook 2025 to 2035

Residential Energy-Efficient Technologies Market Size and Share Forecast Outlook 2025 to 2035

Residential Interior Wood Doors Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA