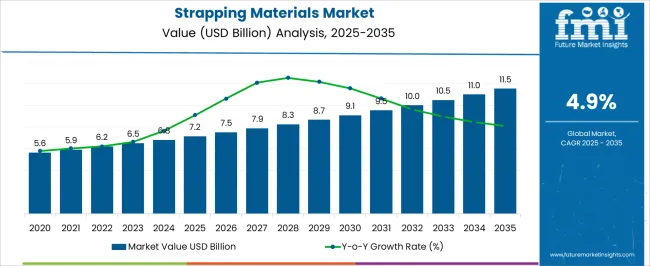

The Strapping Materials Market is estimated to be valued at USD 7.2 billion in 2025 and is projected to reach USD 11.5 billion by 2035, registering a compound annual growth rate (CAGR) of 4.9% over the forecast period.

The strapping materials market is projected to generate an absolute gain of USD 4.3 billion and a growth multiplier of 1.59 times over the decade. This growth, driven by a CAGR of 4.9%, is supported by increasing demand for strapping materials in industries such as packaging, logistics, and shipping, where high-strength materials are required to secure packages and cargo. During the first five years (2025–2030), the market is expected to grow from USD 7.2 billion to USD 9.1 billion, adding USD 1.9 billion, which accounts for 44.2% of the total incremental growth, with a 5-year multiplier of 1.26x.

This phase of growth is driven by the rise of e-commerce, increasing global trade, and the expansion of infrastructure in emerging economies. The second phase (2030–2035) will contribute USD 2.4 billion, representing 55.8% of the total growth, driven by stronger momentum as demand for eco-friendly and cost-effective packaging solutions continues to rise. Annual increments will rise from USD 0.4 billion in early years to USD 0.6 billion by 2035, reflecting the increasing use of sustainable and durable strapping materials across global industries. Manufacturers focusing on advanced materials, such as biodegradable strapping or lightweight solutions, will capture the largest share of this USD 4.3 billion opportunity.

| Metric | Value |

|---|---|

| Strapping Materials Market Estimated Value in (2025 E) | USD 7.2 billion |

| Strapping Materials Market Forecast Value in (2035 F) | USD 11.5 billion |

| Forecast CAGR (2025 to 2035) | 4.9% |

The strapping materials market is experiencing strong growth driven by the increasing demand for safe, efficient, and cost-effective packaging solutions across the transportation, manufacturing, and warehousing industries. As global trade volumes rise and supply chains grow more complex, the demand for unitizing materials that offer high strength, durability, and resistance to harsh handling conditions has intensified. Polyester and composite-based strapping systems are gaining prominence over traditional alternatives due to their superior load-bearing capacity, lightweight characteristics, and reusability.

Additionally, automation in packaging lines and palletization processes has increased the preference for machine-compatible strapping materials. Environmental considerations and tightening regulations around plastic waste have also contributed to the development of recyclable and biodegradable strapping solutions.

The use of smart tracking and RFID-enabled packaging materials is further elevating the functional role of strapping systems beyond containment to include traceability and security. As industries move toward just-in-time inventory models and lean logistics, strapping materials are positioned as essential components of modern freight integrity.

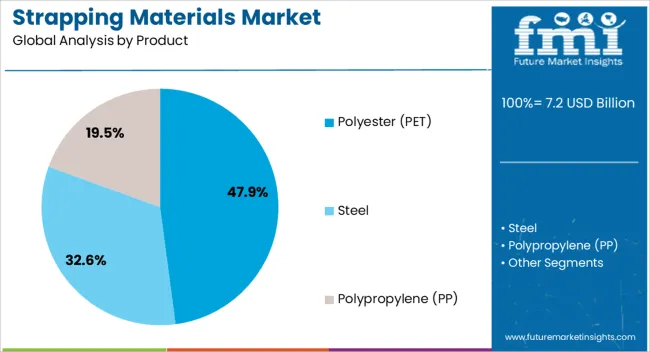

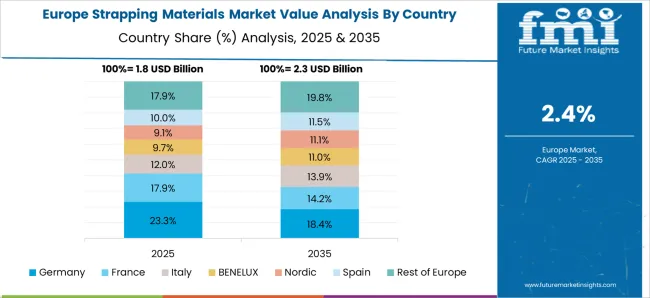

The strapping materials market is segmented by product, application, and geographic regions. By product, the strapping materials market is divided into Polyester (PET), Steel, and Polypropylene (PP). In terms of application, the strapping materials market is classified into Industrial Logistics & Warehouse, Food & Beverage, Corrugated Cardboard & Paper, Newspaper & Graphics, Building & Construction, and Metal. Regionally, the strapping materials industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The polyester PET segment is expected to account for 47.9% of the total revenue share in the strapping materials market in 2025, establishing it as the dominant product category. This leading position is being driven by the exceptional tensile strength, elongation properties, and resistance to environmental stress offered by PET materials, which make them highly suitable for securing heavy and bulky loads. Compared to steel and polypropylene alternatives, PET strapping provides a balance between strength and flexibility while being more cost-effective and safer to handle.

Its compatibility with automated strapping machines has led to increased deployment in high-volume packaging environments where operational speed and safety are critical. The recyclability of polyester has further contributed to its acceptance in sustainability-focused industries, particularly in logistics, construction materials, and metal packaging.

PET’s ability to retain tension over long durations without damaging the packaged goods has reinforced its application across export packaging and intercontinental freight movements. These factors collectively continue to elevate polyester PET as the preferred strapping solution across multiple industrial sectors.

The industrial logistics and warehouse segment is projected to represent 29.5% of the total revenue share in the strapping materials market by 2025, making it the most prominent application area. The increasing demand for secure load containment in large-scale distribution centers, freight hubs, and inventory storage facilities is supporting this growth. With the rapid rise of e-commerce, omni-channel retailing, and global trade flows, warehouses are under pressure to optimize throughput while minimizing damage to goods in transit.

Strapping materials used in these settings are expected to withstand dynamic load shifts, repeated handling, and long-distance transportation without compromising package integrity. The growing adoption of automation and robotics in warehousing operations has further favored the use of strapping materials that are compatible with high-speed machinery and variable package sizes.

Additionally, stringent safety and compliance standards have made durable and tamper-evident strapping solutions critical to warehouse operations. As supply chains become more time-sensitive and distributed, the role of efficient strapping in ensuring delivery quality and load stability is expected to expand further in the industrial logistics space.

The strapping materials market is driven by growing demand in packaging and logistics sectors, with significant opportunities in emerging markets and industrial packaging. Trends toward eco-friendly solutions are reshaping the market, while challenges like raw material price fluctuations and supply chain issues present obstacles. By 2025, addressing these challenges and capitalizing on opportunities in emerging industrial sectors and green packaging solutions will be crucial for continued market expansion and success.

The growth of the strapping materials market is primarily driven by the increasing demand for packaging and logistics, particularly in the e-commerce, retail, and manufacturing sectors. Strapping materials are essential for securing packages and goods during storage and transportation, ensuring safety and minimizing damages. As global trade continues to expand, along with the rise of e-commerce, the need for efficient packaging and transport solutions is fueling the growth of the strapping materials market. By 2025, demand for these materials will continue to rise, especially in industries focused on shipping and logistics.

The strapping materials market is expected to benefit from significant opportunities in emerging markets and the industrial packaging sector. As developing countries increase their industrial activities and infrastructure development, the demand for packaging materials, including strapping solutions, will grow. The expansion of the manufacturing, automotive, and construction industries in regions like Asia Pacific and Latin America is creating new opportunities for market players. By 2025, the growing industrialization in these regions will further drive demand for reliable and cost-effective strapping materials, providing a solid growth avenue for suppliers.

An emerging trend in the strapping materials market is the increasing shift toward eco-friendly and biodegradable solutions. Environmental concerns over plastic waste have led to a rise in demand for sustainable alternatives in packaging. Manufacturers are focusing on developing strapping materials made from biodegradable and recyclable materials to meet growing consumer and regulatory expectations. By 2025, eco-conscious packaging solutions will gain significant traction, positioning companies offering green alternatives as key players in the market, driving further innovation in the sector.

The strapping materials market faces several challenges, particularly from raw material price fluctuations and supply chain disruptions. The market relies heavily on materials like polypropylene, polyester, and steel, whose prices can fluctuate due to changes in raw material availability and geopolitical factors. Additionally, supply chain disruptions, particularly in light of global events such as the COVID-19 pandemic, have increased transportation costs and created delays in production. By 2025, managing these challenges and ensuring a stable supply of raw materials will be critical for market players to maintain competitive pricing and meet demand.

| Country | CAGR |

|---|---|

| China | 6.6% |

| India | 6.1% |

| Germany | 5.6% |

| France | 5.1% |

| UK | 4.7% |

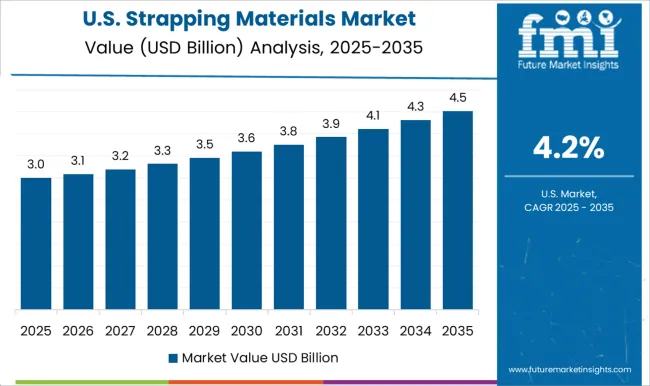

| USA | 4.2% |

| Brazil | 3.7% |

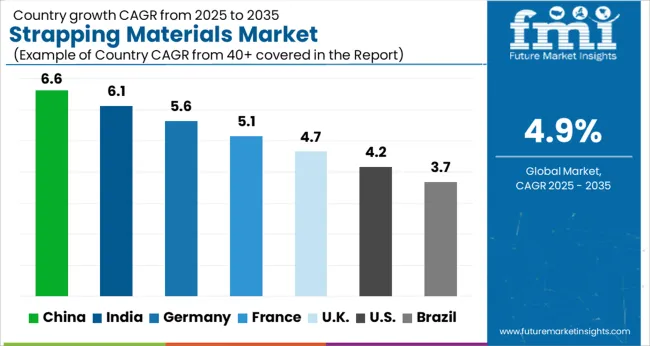

The global strapping materials market is projected to grow at a 4.9% CAGR from 2025 to 2035. China leads with a growth rate of 6.6%, followed by India at 6.1%, and France at 5.1%. The United Kingdom records a growth rate of 4.7%, while the United States shows the slowest growth at 4.2%. These varying growth rates are driven by increasing demand for efficient packaging solutions across industries such as logistics, e-commerce, and manufacturing, along with rising adoption of strapping materials in securing products for transport.

Emerging markets like China and India are experiencing higher growth due to rapid industrialization, growing infrastructure, and increasing demand for packaged goods, while more mature markets like the USA and the UK see steady growth driven by technological advancements, regulatory standards, and the need for more reliable and sustainable packaging solutions. This report includes insights on 40+ countries; the top markets are shown here for reference.

The strapping materials market in China is growing rapidly, with a projected CAGR of 6.6%. China’s booming manufacturing and logistics industries, combined with a growing demand for efficient packaging solutions, are key drivers of this market growth. The country’s rapid industrialization, expanding infrastructure, and rising demand for secure packaging in various sectors, including e-commerce, construction, and retail, continue to boost the adoption of strapping materials. Additionally, China’s government policies supporting sustainable and eco-friendly packaging solutions further contribute to the demand for advanced strapping materials. The increasing focus on automation in packaging processes also drives market expansion.

The strapping materials market in India is projected to grow at a CAGR of 6.1%. India’s increasing industrial output, along with rapid urbanization and infrastructure development, continues to drive the demand for strapping materials. The country’s growing packaging sector, especially in the food and beverage, logistics, and retail industries, is contributing to the market’s growth. India’s government policies supporting manufacturing growth and its expanding e-commerce sector also fuel the demand for efficient and reliable packaging solutions. Additionally, India’s rising consumer goods market and increasing demand for durable packaging in retail further boost the adoption of strapping materials.

The strapping materials market in France is projected to grow at a CAGR of 5.1%. France’s increasing demand for secure and efficient packaging solutions, driven by the country’s strong manufacturing and logistics sectors, is contributing to steady market growth. The growing focus on sustainable packaging and regulatory frameworks supporting eco-friendly materials is accelerating the adoption of strapping materials in various industries, including e-commerce and retail. Additionally, France’s commitment to reducing carbon emissions and promoting circular economies further drives the demand for eco-friendly packaging solutions, including strapping materials. The ongoing demand for packaged goods in industries such as food and beverage continues to fuel market growth.

The strapping materials market in the United Kingdom is projected to grow at a CAGR of 4.7%. The UK’s increasing demand for packaging solutions in the manufacturing and retail sectors, driven by the growth of e-commerce and logistics, is contributing to steady market growth. The country’s focus on sustainable packaging solutions and growing regulatory standards for packaging waste management are accelerating the demand for eco-friendly strapping materials. Additionally, the rise of automation in packaging and the increasing use of strapping materials in export-oriented industries further contribute to market expansion. The UK’s ongoing investments in improving packaging infrastructure also play a significant role in boosting market demand.

The strapping materials market in the United States is expected to grow at a CAGR of 4.2%. The USA market is driven by the increasing need for efficient and reliable packaging solutions in industries such as logistics, e-commerce, and manufacturing. The growing demand for durable and secure packaging in the retail sector and the rise of automated packaging systems continue to drive the adoption of strapping materials. Additionally, the USA government’s increasing focus on sustainable packaging solutions, along with the rise of green initiatives, contributes to the demand for eco-friendly strapping materials. The increasing shift towards circular economies and recyclable packaging solutions further accelerates market growth.

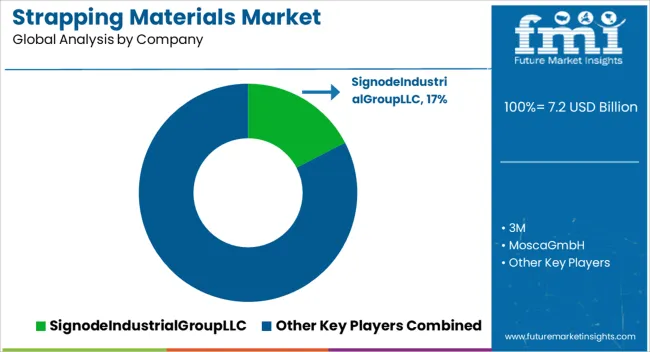

The strapping materials market is dominated by Signode Industrial Group LLC, which leads with its wide range of high-quality strapping solutions used in packaging, shipping, and warehousing across various industries, including e-commerce, automotive, and manufacturing. Signode’s dominance is supported by its extensive global presence, advanced strapping technologies, and focus on providing durable, efficient packaging materials. Key players such as 3M, Mosca GmbH, and Titan Umreifungstechnik GmbH & Co. KG maintain significant market shares by offering innovative strapping materials that ensure secure and efficient packaging while improving operational efficiency. These companies focus on providing eco-friendly, cost-effective, and customizable solutions to meet the growing demand for secure packaging and logistics.

Emerging players like Cyklop, GREENBRIDGE, and StraPack Corp. are expanding their market presence by offering specialized strapping materials for niche applications, such as heavy-duty packaging, food and beverage sectors, and specialized industries. Their strategies include enhancing strapping performance, reducing environmental impact, and offering high-quality materials for varying packaging needs. Market growth is driven by the increasing demand for efficient and sustainable packaging solutions, rising consumer preferences for secure, eco-friendly packaging, and the growth of e-commerce. Innovations in automated strapping systems, sustainable strapping materials, and improved performance characteristics are expected to continue shaping competitive dynamics and fuel further growth in the global strapping materials market.

| Item | Value |

|---|---|

| Quantitative Units | USD 7.2 Billion |

| Product | Polyester (PET), Steel, and Polypropylene (PP) |

| Application | Industrial Logistics & Warehouse, Food & Beverage, Corrugated Cardboard & Paper, Newspaper & Graphics, Building & Construction, and Metal |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled | SignodeIndustrialGroupLLC, 3M, MoscaGmbH, TitanUmreifungstechnikGmbH&Co.KG, Cyklop, GREENBRIDGE, StraPackCorp., PanoramaPackagingPvt.Ltd., UNIPACK, SignorPolymersPvt.Ltd., and PlastofineIndustries. |

| Additional Attributes | Dollar sales by material type and application, demand dynamics across logistics, manufacturing, and e-commerce sectors, regional trends in strapping material adoption, innovation in sustainable and high-strength formulations, impact of regulatory standards on environmental compliance, and emerging use cases in automated packaging and circular economy initiatives. |

The global strapping materials market is estimated to be valued at USD 7.2 billion in 2025.

The market size for the strapping materials market is projected to reach USD 11.5 billion by 2035.

The strapping materials market is expected to grow at a 4.9% CAGR between 2025 and 2035.

The key product types in strapping materials market are polyester (pet), steel and polypropylene (pp).

In terms of application, industrial logistics & warehouse segment to command 29.5% share in the strapping materials market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Strapping Machine Market Size and Share Forecast Outlook 2025 to 2035

Strapping Tapes Market Analysis by Material Type, Adhesive Type, End-User, and Region through 2035

Strapping Supplies Market Analysis - Demand & Growth Forecast 2025 to 2035

Strapping Devices Market Trends - Size, Growth & Forecast 2025 to 2035

Strapping and Banding Equipment Market – Key Trends & Growth Outlook 2025 to 2035

Key Companies & Market Share in the Strapping Tapes Sector

Strapping Equipment Market Insights – Growth & Demand 2024-2034

Steel Strapping Market Size and Share Forecast Outlook 2025 to 2035

Pallet Strapping Machines Market

Vertical Strapping Machines Market

Sealing & Strapping Packaging Tape Market Forecast 2024-2034

Horizontal Strapping Machine Market Trends and Forecast 2025 to 2035

Sealing And Strapping Packaging Tapes Market Size and Share Forecast Outlook 2025 to 2035

Ergonomic Pallet Strapping Market Analysis Size and Share Forecast Outlook 2025 to 2035

Nanomaterials Market Insights - Size, Share & Industry Growth 2025 to 2035

Tire Materials Market Insights – Size, Trends & Forecast 2025–2035

Facade Materials Market Size and Share Forecast Outlook 2025 to 2035

Solder Materials Market Size and Share Forecast Outlook 2025 to 2035

Sheath Materials Market Size and Share Forecast Outlook 2025 to 2035

Exosuit Materials Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA