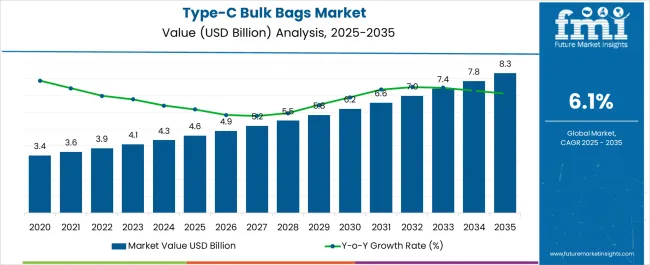

The Type-C Bulk Bags Market is estimated to be valued at USD 4.6 billion in 2025 and is projected to reach USD 8.3 billion by 2035, registering a compound annual growth rate (CAGR) of 6.1% over the forecast period.

| Metric | Value |

|---|---|

| Type-C Bulk Bags Market Estimated Value in (2025E) | USD 4.6 billion |

| Type-C Bulk Bags Market Forecast Value in (2035F) | USD 8.3 billion |

| Forecast CAGR (2025 to 2035) | 6.1% |

The Type-C bulk bags market is witnessing steady growth, supported by increasing emphasis on workplace safety, electrostatic hazard control, and compliance-driven material handling across industrial settings. These bags, designed to safely dissipate static electricity, are gaining traction in industries handling combustible dust or flammable environments.

Medium-volume bags are being widely adopted due to their ease of handling, compatibility with existing logistics systems, and cost-efficiency in large-scale material transport. Rising global chemical production and stringent packaging standards are also reinforcing demand, particularly in the bulk movement of fine powders, resins, and intermediates.

Furthermore, regulatory mandates from agencies such as OSHA and ATEX are catalyzing the adoption of anti-static packaging formats. Growth prospects are expected to be driven by investments in automation, safe packaging infrastructure, and increased demand from export-oriented sectors requiring reliable, compliant bulk shipping solutions.

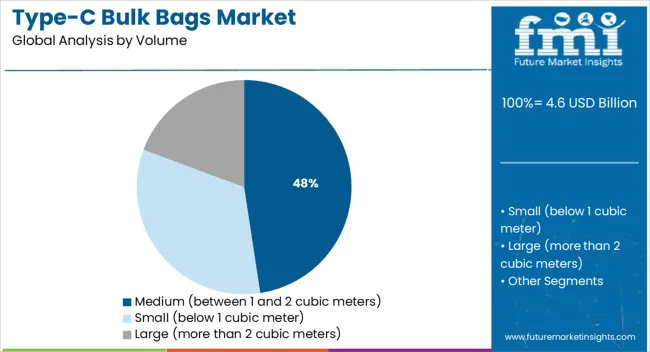

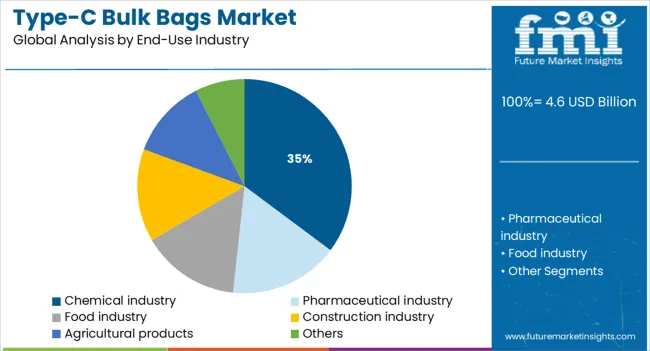

The market is segmented by Volume and End-Use Industry and region. By Volume, the market is divided into Medium (between 1 and 2 cubic meters), Small (below 1 cubic meter), and Large (more than 2 cubic meters). In terms of End-Use Industry, the market is classified into Chemical industry, Pharmaceutical industry, Food industry, Construction industry, Agricultural products, and Others. Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

Medium-sized bulk bags, with a volume range between 1 and 2 cubic meters, are projected to lead the market with a 47.6% revenue share in 2025. This dominance is being influenced by their operational versatility, suitability for most loading/unloading equipment, and optimized storage characteristics.

The medium size strikes a balance between weight capacity and manual handling efficiency, making it ideal for use in automated filling lines and material transfer systems. Adoption has been strengthened by their compatibility with a wide range of powdered and granulated substances, especially in sectors where efficient space utilization is critical.

Additionally, their scalability for transport and storage has made them the preferred choice for domestic and international shipments where safety, compliance, and cost-per-load are key performance indicators.

The chemical industry is expected to account for 35.2% of the total revenue share in 2025, establishing it as the leading end-use segment for Type-C bulk bags. This leadership is being reinforced by the sector’s heightened sensitivity to electrostatic discharge during the handling of volatile and combustible materials.

Strict industry-specific safety standards and regulatory frameworks have accelerated the shift toward static-control bulk handling solutions. Type-C bags, which require grounding during use, are widely accepted as a safety standard in chemical production and logistics workflows.

The growing complexity and volume of chemical intermediates and specialty compounds further demand packaging formats that ensure operational safety, contamination prevention, and compliance with global transport regulations. This has resulted in consistent investments by chemical firms in certified, durable, and specification-compliant Type-C bulk bags.

Big bags or FIBC (Flexible intermediate bulk container) bulk bags are industrial containers used to fulfill the purpose of transporting or storing of granular products in large volume. Various types of bulk bags are standardized and accepted globally according to the requirement. While filling or emptying the bags, an electrostatic charge is developed in the bags.

This change might reach to a point of igniting the flammable gases and thus becomes dangerous to use in the environment with the presence of flammable substances. Type-C bulk bags are manufactured with a conductive material along with fabric which allows the bag to discharge the electrostatic charge to the ground and enable safe operation even in presence of flammable substance.

Most of the manufacturing industries use furnaces for heating the raw material and thus require a regular supply of flammable substance. Leakage of this flammable substance might cause a hazard if a complete fiber bag is used. Thus, type-C bulk bags seems to be adopted by most of the manufacturing industries and propel the type-C bulk bags market.

Gas fueled furnaces are getting popular over solid or oil fueled furnaces due to the low volume consumed by the fuel and thus resulting in easier handling of fuel. Gas pipelines are used to direct the flow of fuel to the furnace from storage. Leakage of fuel is probably in manufacturing industry once in a while and using completely fiber bag might prove to be dangerous.

Thus, developing the market for gas and oil fueled furnaces has propelled the type-C bulk bags market to fulfill the requirement of transporting or storing dry flowable granular products. Type-C bulk bags needs to be grounded for discharging the charge.

Thus, type-D bulk bags were introduced to overcome this challenge and has proven to be a restraint for the type-C bulk bags market. Although, small and moderate manufacturing firms find it challenging to switch over the equipment and technology due to cost considerations.

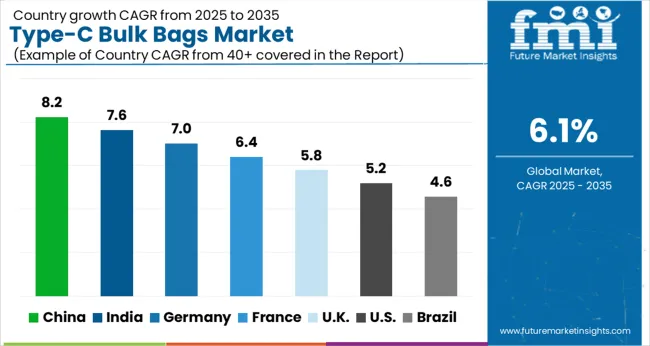

The industrial furnace market is largest in Asia Pacific, followed by North America, indicating great market opportunity in Asia Pacific and North America. Plastic industries use plastic resins in bulk and thus require bulk bags. Also, plastic industries require furnace for manufacturing of products and thus, usage of type-C bulk bags becomes a necessity.

China accounts for around a quarter of global plastic production followed by Japan. Asia Pacific plastic industry indicates a great opportunity for type-C bulk bags market. Asia Pacific and North America includes most of the large manufacturing industries which are highly probable to switch to latest technology.

While Latin America and Eastern Europe region consists of most of the small and moderate manufacturing industries which are more probably adhere to type-C bulk bags instead of switching to type-D bulk bags.

Thus, Latin America and Eastern Europe are probably regions to be proven as an opportunity for the type-C bulk bags market. The Middle East region consists of highly developed economies and low volume producers as compared to other regions which might be proven as a restraint for type-C bulk bags market.

Few of the key players of the type-C bulk bags market are Berry Global Inc., Atlantis Products Private Limited, National Bulk Bag, Big Bulk Bags International Pvt. Ltd., Corman Bag Co., AmeriGlobe LLC., United Bulk Bags, Inc., Global-Pak, Inc, etc.

The global type-c bulk bags market is estimated to be valued at USD 4.6 billion in 2025.

The market size for the type-c bulk bags market is projected to reach USD 8.3 billion by 2035.

The type-c bulk bags market is expected to grow at a 6.1% CAGR between 2025 and 2035.

The key product types in type-c bulk bags market are medium (between 1 and 2 cubic meters), small (below 1 cubic meter) and large (more than 2 cubic meters).

In terms of end-use industry, chemical industry segment to command 35.2% share in the type-c bulk bags market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Competitive Overview of Type-C Bulk Bags Companies

Bulk Bag Market Forecast and Outlook 2025 to 2035

Bulk Terminal Market Forecast and Outlook 2025 to 2035

Bulk Molding Compounds Market Size and Share Forecast Outlook 2025 to 2035

Bulk Bag Unloaders Market Size and Share Forecast Outlook 2025 to 2035

Bulk Bag Divider Market Size and Share Forecast Outlook 2025 to 2035

Bulk Container Packaging Market Size, Share & Forecast 2025 to 2035

Bulk Liquid Transport Packaging Market from 2025 to 2035

Bulk Chemical Packaging Market Trends and Growth 2025 to 2035

Bulk Food Ingredients Market Growth – Industry Insights & Trends 2025 to 2035

Bulk Material Handling System Market Growth - Trends & Forecast 2025 to 2035

Market Share Breakdown of Bulk Container Packaging Industry

Competitive Overview of Bulk Bag Divider Companies

Industry Share Analysis for Bulk Bag Conditioner Companies

Bulk Bag Dischargers Market Trends – Growth & Outlook 2024-2034

Global Bulk-Drug Compounding Market Analysis – Size, Share & Forecast 2024-2034

Bulk Insulated Containers Market

Bulk Liquid Containers Market

Bulk Tote Dumpers Market

Food Bulking Agents Market - Size, Share, and Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA