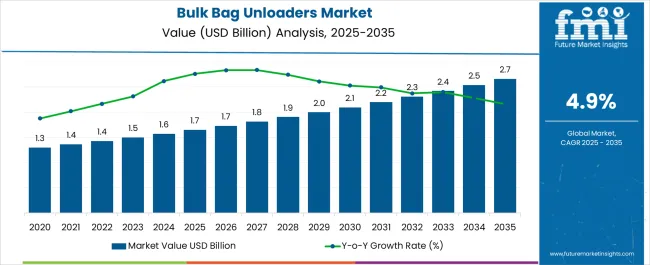

The Bulk Bag Unloaders Market is estimated to be valued at USD 1.7 billion in 2025 and is projected to reach USD 2.7 billion by 2035, registering a compound annual growth rate (CAGR) of 4.9% over the forecast period.

| Metric | Value |

|---|---|

| Bulk Bag Unloaders Market Estimated Value in (2025 E) | USD 1.7 billion |

| Bulk Bag Unloaders Market Forecast Value in (2035 F) | USD 2.7 billion |

| Forecast CAGR (2025 to 2035) | 4.9% |

The Bulk Bag Unloaders market is witnessing steady growth as industries increasingly focus on efficient handling of bulk materials across food processing, chemicals, pharmaceuticals, and construction. Rising demand for safe and cost-effective systems to manage large quantities of powders and granules is a key driver shaping this market. Growing emphasis on workplace safety, dust-free operations, and improved material flow efficiency is further enhancing adoption.

Technological innovations such as integrated dust control, automated discharge systems, and compatibility with multiple material types are creating opportunities for manufacturers. Investments in automation and industrial infrastructure are also strengthening the adoption of advanced unloaders, particularly in emerging economies where large-scale industrial expansion is taking place.

Sustainability initiatives promoting material conservation and reduction of product loss are encouraging organizations to shift from manual unloading to more controlled and efficient solutions As industries continue to expand production capacities and optimize supply chain efficiency, demand for bulk bag unloaders is expected to grow steadily, with advanced loading systems and durable material types driving long-term market growth.

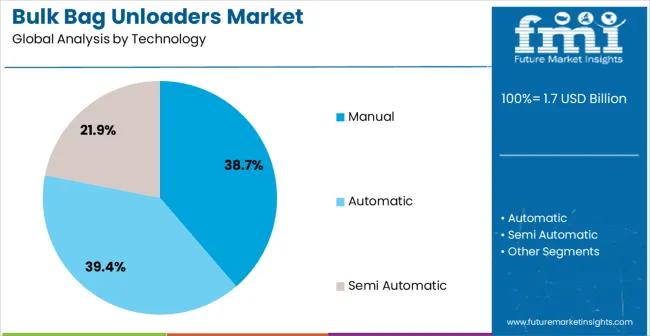

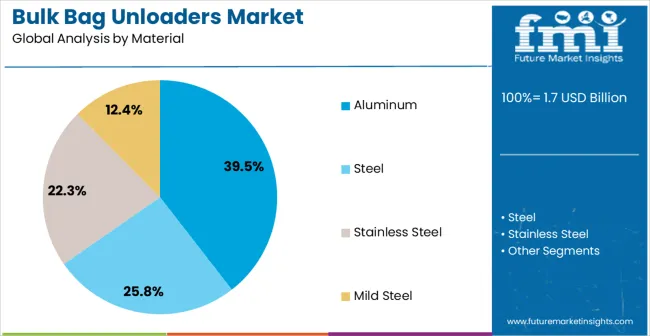

The bulk bag unloaders market is segmented by technology, material, loading, and geographic regions. By technology, bulk bag unloaders market is divided into Manual, Automatic, and Semi Automatic. In terms of material, bulk bag unloaders market is classified into Aluminum, Steel, Stainless Steel, and Mild Steel.

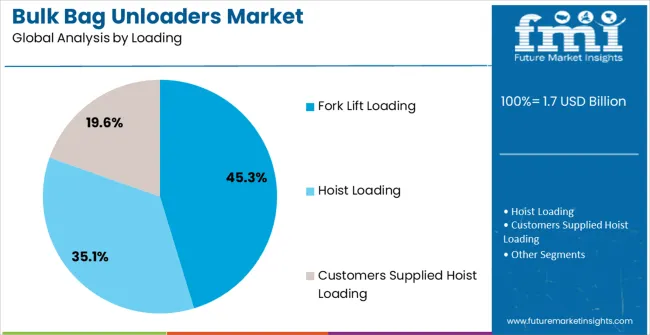

Based on loading, bulk bag unloaders market is segmented into Fork Lift Loading, Hoist Loading, and Customers Supplied Hoist Loading. Regionally, the bulk bag unloaders industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The manual technology segment is projected to hold 38.7% of the Bulk Bag Unloaders market revenue share in 2025, making it a leading technology type. Growth in this segment is being driven by its cost-effectiveness, simplicity of operation, and suitability for small to mid-scale industries where automation investment remains limited. Manual unloaders are widely adopted in facilities that prioritize flexibility and low maintenance costs, as they require minimal training and are easy to install.

Despite lacking automation, these systems ensure controlled discharge, reducing material waste and contamination risks. Industries such as food and agriculture often prefer manual systems due to their ability to handle diverse material types without complex configuration.

Furthermore, small-scale operations and regions with limited automation infrastructure continue to rely on manual unloaders as a practical solution The affordability and adaptability of manual technology are ensuring its continued relevance, especially in cost-sensitive markets, reinforcing its strong position in the global Bulk Bag Unloaders market.

The aluminum material segment is anticipated to account for 39.5% of the Bulk Bag Unloaders market revenue share in 2025, positioning it as the leading material type. This dominance is supported by the durability, corrosion resistance, and lightweight nature of aluminum, which makes it highly suitable for handling bulk materials in diverse industries. Aluminum unloaders are increasingly preferred in food, chemical, and pharmaceutical applications, where hygiene, safety, and long-term performance are critical.

The material’s resistance to contamination and ease of cleaning provide additional advantages, particularly in industries with strict compliance requirements. Moreover, aluminum offers an excellent balance between strength and cost efficiency, enabling manufacturers to deliver robust yet affordable solutions.

The ability of aluminum-based unloaders to maintain structural integrity under heavy load conditions enhances their appeal for large-scale industrial applications With the rising focus on sustainability, aluminum’s recyclability further supports its adoption, making it a material of choice for bulk bag unloader construction in global markets.

The fork lift loading segment is expected to capture 45.3% of the Bulk Bag Unloaders market revenue share in 2025, emerging as the leading loading method. Its dominance is attributed to the operational efficiency, safety, and convenience it provides for material handling across manufacturing and processing facilities. Fork lift loading enables quick positioning of bulk bags, reducing labor costs and minimizing downtime during unloading operations.

This method is widely adopted in industries with high material throughput, including construction, mining, and chemicals, where productivity and time efficiency are critical. Fork lifts also enhance workplace safety by minimizing manual handling of heavy loads, reducing the risk of worker injuries.

The compatibility of fork lift loading with both manual and automated unloader systems further strengthens its appeal in versatile operational environments As industries continue to expand their production capacities, demand for efficient loading methods such as fork lift handling is expected to grow, solidifying its position as a preferred loading approach.

The improving economy and high safety levels of bulk bag unloaders for handling a variety of materials are major factors that has led to the increasing use of bulk bag by a wide range of industries. Bulk bags have become a feasible source of distribution for a variety of goods and have resulted in a turnaround from a situation where small bags were almost exclusively used and has also changed the way bulk material were shipped and stored over the last decade.

Similarly, the bulk bag dischargers has also revolutionized the way bulk bags are loaded, untied, retied and removed as the operators no longer are required to manually reach through confined access doors and struggle to retie the partially empty bags, clean up spillage after disconnections, dislodge products from dead spots or flatten bags.

Bulk bag unloaders are also known as bulk bag dischargers, bag frames, FIBC unloaders, FIBC dischargers and big bag dumpers. This equipment is used to unload any or all material from a variety of bulk bags including bulk bag, FIBC, Jumbo sack etc.

The Bulk Bag unloaders are available using a simple bulk bag hanging frame that supports the bag which is lifted with a help of a forklift, or with a hoist. The standard arrangement includes a bag frame to which the suspension loops of the bag can be attached.

The frame is then raised and is positioned in a way so that the hooks on the frame counter-balances the suspension frame in the unloader. The bottom of the bag is rested on a sealing ring, when lowered and the bag loops keeps the bag straight.

In addition, contents in the bag can be discharged by gravity into storage, a conveying system or a process vessel for transfer to another location. The unloading or the discharge portion of these unloaders uses a wide range of devices such as feed screws, rotary valves, lump breakers, etc.

| Country | CAGR |

|---|---|

| China | 6.6% |

| India | 6.1% |

| Germany | 5.6% |

| Brazil | 5.1% |

| USA | 4.7% |

| UK | 4.2% |

| Japan | 3.7% |

The Bulk Bag Unloaders Market is expected to register a CAGR of 4.9% during the forecast period, exhibiting varied country level momentum. China leads with the highest CAGR of 6.6%, followed by India at 6.1%. Developed markets such as Germany, France, and the UK continue to expand steadily, while the USA is likely to grow at consistent rates.

Japan posts the lowest CAGR at 3.7%, yet still underscores a broadly positive trajectory for the global Bulk Bag Unloaders Market. In 2024, Germany held a dominant revenue in the Western Europe market and is expected to grow with a CAGR of 5.6%.

The USA Bulk Bag Unloaders Market is estimated to be valued at USD 568.1 million in 2025 and is anticipated to reach a valuation of USD 568.1 million by 2035. Sales are projected to rise at a CAGR of 0.0% over the forecast period between 2025 and 2035. While Japan and South Korea markets are estimated to be valued at USD 87.8 million and USD 55.0 million respectively in 2025.

| Item | Value |

|---|---|

| Quantitative Units | USD 1.7 Billion |

| Technology | Manual, Automatic, and Semi Automatic |

| Material | Aluminum, Steel, Stainless Steel, and Mild Steel |

| Loading | Fork Lift Loading, Hoist Loading, and Customers Supplied Hoist Loading |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

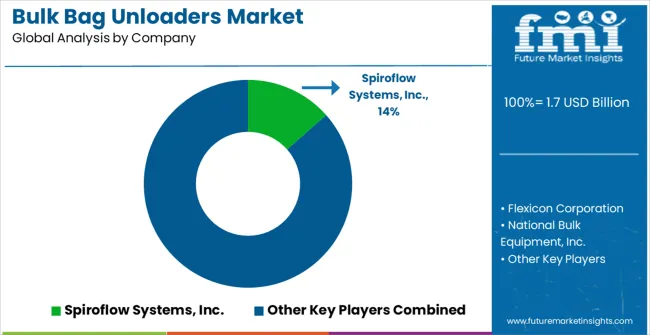

| Key Companies Profiled | Spiroflow Systems, Inc., Flexicon Corporation, National Bulk Equipment, Inc., Hapman, VAC-U-MAX, AZO GmbH + Co. KG, Palamatic Process, WAMGROUP S.p.A., Volkmann GmbH, Kockums Bulk Systems, Guttridge Limited, Sodimate, Inc., Metalfab, Inc., and Thayer Scale-Hyer Industries, Inc. |

The global bulk bag unloaders market is estimated to be valued at USD 1.7 billion in 2025.

The market size for the bulk bag unloaders market is projected to reach USD 2.7 billion by 2035.

The bulk bag unloaders market is expected to grow at a 4.9% CAGR between 2025 and 2035.

The key product types in bulk bag unloaders market are manual, automatic and semi automatic.

In terms of material, aluminum segment to command 39.5% share in the bulk bag unloaders market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Bulk Terminal Market Forecast and Outlook 2025 to 2035

Bulk Molding Compounds Market Size and Share Forecast Outlook 2025 to 2035

Bulk Container Packaging Market Size, Share & Forecast 2025 to 2035

Bulk Liquid Transport Packaging Market from 2025 to 2035

Bulk Chemical Packaging Market Trends and Growth 2025 to 2035

Bulk Food Ingredients Market Growth – Industry Insights & Trends 2025 to 2035

Bulk Material Handling System Market Growth - Trends & Forecast 2025 to 2035

Market Share Breakdown of Bulk Container Packaging Industry

Global Bulk-Drug Compounding Market Analysis – Size, Share & Forecast 2024-2034

Bulk Insulated Containers Market

Bulk Liquid Containers Market

Bulk Tote Dumpers Market

Bulk Bag Market Forecast and Outlook 2025 to 2035

Bulk Bag Divider Market Size and Share Forecast Outlook 2025 to 2035

Competitive Overview of Bulk Bag Divider Companies

Industry Share Analysis for Bulk Bag Conditioner Companies

Bulk Bag Dischargers Market Trends – Growth & Outlook 2024-2034

Food Bulking Agents Market - Size, Share, and Forecast Outlook 2025 to 2035

Inner Bulk Liners Market Size and Share Forecast Outlook 2025 to 2035

Type-C Bulk Bags Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA