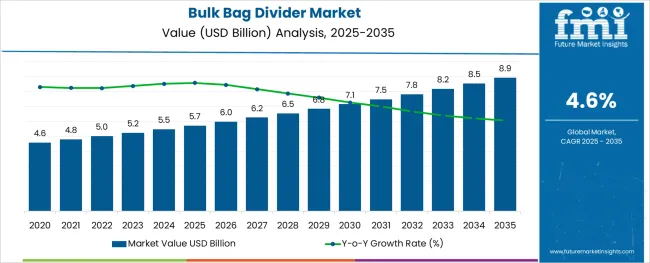

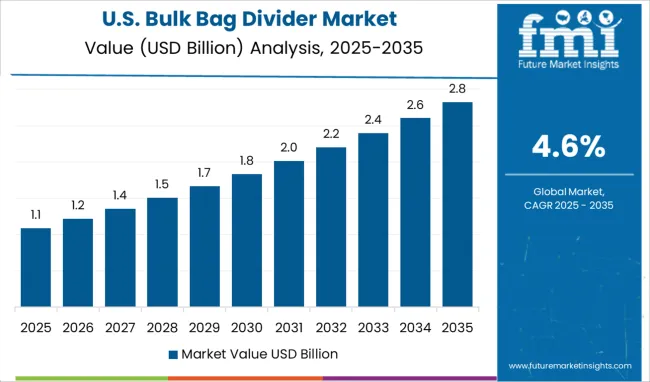

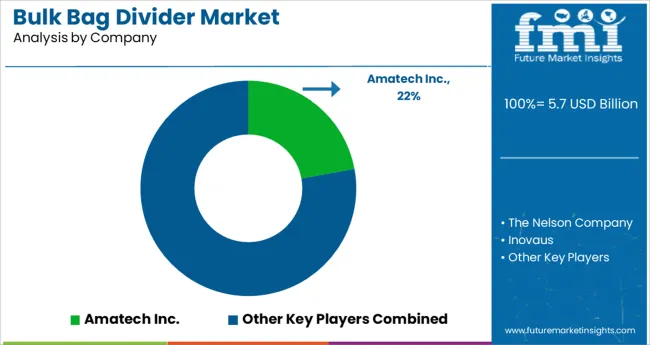

The Bulk Bag Divider Market is estimated to be valued at USD 5.7 billion in 2025 and is projected to reach USD 8.9 billion by 2035, registering a compound annual growth rate (CAGR) of 4.6% over the forecast period.

The bulk bag divider market is undergoing steady expansion as industries prioritize contamination control, material separation, and load stability in bulk packaging operations. With stricter compliance standards in pharmaceuticals, food, and chemicals, manufacturers are increasingly focusing on divider materials and designs that enable cleanroom compatibility and efficient space utilization.

Innovation in structural design has led to the development of highly adaptable divider blocks and inserts that enhance transport safety and minimize material cross-contact. Growing adoption of automation in warehousing and handling operations is further encouraging the use of stackable and reusable dividers for streamlined loading and unloading.

Environmental considerations are also influencing material choices, with a growing shift toward recyclable and reusable dividers that reduce single-use waste. As bulk bag handling scales across sectors due to global logistics demands, the market is expected to benefit from the ongoing shift toward modular packaging solutions and regulatory alignment in product-specific divider design.

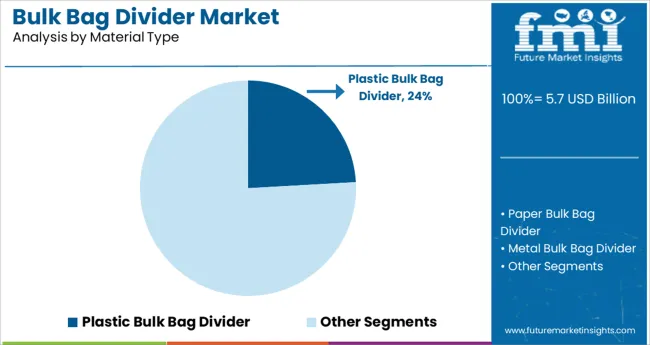

The market is segmented by Material Type, Structure Design, and End Use and region. By Material Type, the market is divided into Plastic Bulk Bag Divider, Paper Bulk Bag Divider, Metal Bulk Bag Divider, Stainless Steel Bulk Bag Divider, Aluminum Bulk Bag Divider, Tinplate Bulk Bag Divider, and Other Bulk Bag Divider Material Types.

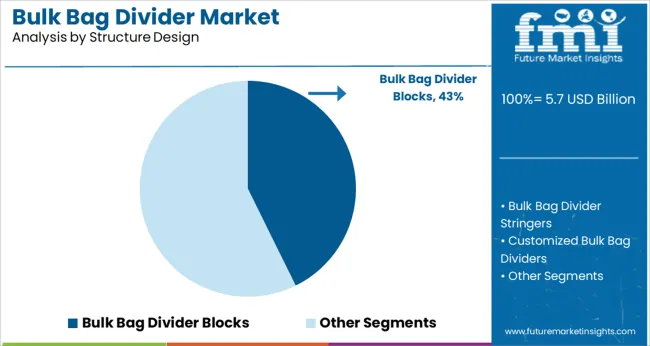

In terms of Structure Design, the market is classified into Bulk Bag Divider Blocks, Bulk Bag Divider Stringers, and Customized Bulk Bag Dividers.

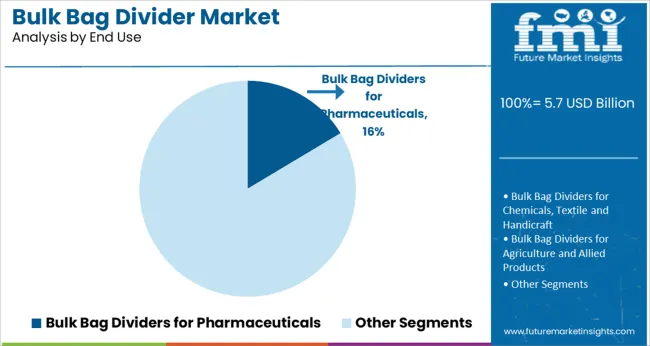

Based on End Use, the market is segmented into Bulk Bag Dividers for Pharmaceuticals, Bulk Bag Dividers for Chemicals, Textile and Handicraft, Bulk Bag Dividers for Agriculture and Allied Products, Bulk Bag Dividers for Electronics and Consumer Appliances, Bulk Bag Dividers for Transportation and Warehousing, Bulk Bag Dividers for Food and Beverage, Bulk Bag Dividers for Retail, and Bulk Bag Dividers for Other End Uses.

Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The plastic subsegment within material type is projected to contribute 24.1% of total market revenue in 2025, positioning it as a key material category. Its dominance is supported by high durability, chemical resistance, and ease of sanitation, making it ideal for handling sensitive or hazardous bulk materials.

Plastic dividers are valued for their structural integrity under varying environmental conditions and their ability to be reused across multiple shipping cycles. Unlike paper or cardboard alternatives, plastic bulk bag dividers provide a longer lifecycle, reducing replacement frequency and lowering total ownership costs.

Their compatibility with automated material handling systems and support for standardized load dimensions has further reinforced their preference in sectors such as chemicals, pharmaceuticals, and agriculture. Growing emphasis on hygienic transport solutions, coupled with sustainability initiatives promoting recyclable plastics, is expected to sustain plastic’s relevance as a preferred material in divider manufacturing.

Bulk bag divider blocks are expected to account for 42.7% of total market revenue in 2025 under the structure design category, establishing themselves as the leading design format. This leadership is attributed to their modular construction, which allows efficient compartmentalization of multiple bulk bags in a single container, optimizing pallet space and reducing shifting during transit.

Divider blocks offer enhanced load stability and improve stacking reliability, making them highly suitable for long-haul transport and storage applications. Their design supports both vertical and horizontal separation of goods, enabling tailored configurations based on bag size and product type.

The increasing adoption of intermodal transport and the need for damage minimization across complex distribution networks have propelled the use of block structures. Additionally, the ability to customize block sizes and materials to suit specific load requirements is driving their acceptance across sectors including food processing, building materials, and industrial chemicals.

The pharmaceuticals end use segment is projected to represent 16.4% of total revenue in the bulk bag divider market in 2025. This leadership within its application space is driven by the pharmaceutical industry’s rigorous standards for contamination control, segregation, and hygiene in material handling.

Dividers tailored for pharmaceutical use are designed to meet strict regulatory requirements such as GMP and FDA compliance, ensuring that active ingredients and raw materials remain uncompromised during transport and storage. Demand has been rising as manufacturers and suppliers focus on reducing cross-contamination risks and improving traceability across the supply chain.

Bulk bag dividers with antimicrobial coatings, antistatic properties, and cleanroom-grade finishes are being widely adopted in packaging operations involving excipients, APIs, and sensitive powders. Investments in pharmaceutical infrastructure, especially in high-growth regions, are further contributing to segment growth as companies implement advanced material handling solutions that align with both safety and operational efficiency goals.

Key factors expected to boost growth of the market for bulk bag dividers during the forecast period include the rise in the need of the bulk bag dividers, owing to the advantages of easiness in stacking and unstacking of bulk bags and the growing applications from several industries including pharmaceutical and healthcare, meat processing and beverage industry.

In addition, the increasing prevalence of reliability with minimizing lost cost is another factor that is expected to augment the growth of the bulk bag divider market. Moreover, the innovation in custom design will further provide lucrative opportunities for the growth of the bulk bag divider market in the forthcoming years.

Furthermore, the growing demand for smart design that can tailor to real-time applications creates immense opportunities for the bulk bag dividers. Increasing demand for cost-effective packaging coupled with eco-friendly materials boosts the demand for bulk bag dividers in recent times. In addition, increasing demand for cost-effective packaging coupled with eco-friendly materials is augmenting the demand for bulk bag dividers globally during the forecast period.

Bulk bags are one the popular method for transporting and storing bulk goods. However, stacking on pallets in blocks creates problems such as when the forklift is used to separate the pallets, the bulk bags are often damaged. The damage caused results in long downtime and increased product cost. Furthermore, Bulk bag carrying and block stacking on standard pallets are difficult tasks. Bulk bags can be damaged by the big gaps at the bottom of typical pallets. This is a factor that is expected to hamper the market growth during the forecast period.

Further, the rising competition among the players might further challenge the growth of the bulk bag divider market in the near future. Moreover, the growing cost of production is further projected to impede the growth of the bulk bag divider market during the forecast period.

North America is likely to emerge as the largest market for bulk bag divider market and the trend is expected to continue into the forecast period attributed to the rise in the demand for the product in various applications. A CAGR of approximately 4% has been forecast for the region until 2035.

Moreover, the growing inclination of the region towards eradicating plastic is expected to further accelerate the growth of the bulk bag divider market in the region during the forecast period.

According to Future Market Insights, the Middle East & Africa region is anticipated to witness growth at a lucrative rate over the forecast period, owing to the upsurge in the trade volume in the region.

Moreover, the growth of the bulk bag divider market in the region is expected to propel during the forecast period due to increase in packaging and chemical industries.

Some of the key participants present in the global Bulk Bag Divider Market include A and M Jumbo Bags, Schoeller Allibert, CABKA Group, Brambles, PalletOne., Craemer Holding, Rehrig Pacific Company, Innova Maquinaria Industrial, Amatech Inc., and Corrugated Pallets Company, among others.

Attributed to the presence of such high number of participants, the market is highly competitive. While global players such as A and M Jumbo Bags, and Schoeller Allibert account for a considerable market size, several regional level players are also operating across key growth regions, particularly in the North America.

| Report Attribute | Details |

|---|---|

| Growth Rate | CAGR of 4.55% from 2025 to 2035 |

| Base Year for Estimation | 2024 |

| Historical Data | 2020 to 2024 |

| Forecast Period | 2025 to 2035 |

| Quantitative Units | Revenue in million and CAGR from 2025-2035 |

| Report Coverage | Revenue Forecast, Volume Forecast, Company Ranking, Competitive Landscape, Growth Factors, Trends and Pricing Analysis |

| Segments Covered | Material Type, Structure Design, End Use, Region |

| Regions Covered | North America; Latin America; Europe; South Asia; East Asia; Oceania; Middle East and Africa |

| Key Countries Profiled | USA, Canada, Brazil, Argentina, Germany, UK, France, Spain, Italy, Nordics, BENELUX, Australia & New Zealand, China, India, ASEAN, GCC, South Africa |

| Key Companies Profiled | A and M Jumbo Bags; Schoeller Allibert; CABKA Group; Brambles; PalletOne; Craemer Holding; Rehrig Pacific Company; Innova Maquinaria Industrial; Amatech Inc.; Corrugated Pallets Company |

| Customization | Available Upon Request |

The global bulk bag divider market is estimated to be valued at USD 5.7 billion in 2025.

It is projected to reach USD 8.9 billion by 2035.

The market is expected to grow at a 4.6% CAGR between 2025 and 2035.

The key product types are plastic bulk bag divider, paper bulk bag divider, metal bulk bag divider, stainless steel bulk bag divider, aluminum bulk bag divider, tinplate bulk bag divider and other bulk bag divider material types.

bulk bag divider blocks segment is expected to dominate with a 42.7% industry share in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Competitive Overview of Bulk Bag Divider Companies

Bulk Terminal Market Forecast and Outlook 2025 to 2035

Bulk Molding Compounds Market Size and Share Forecast Outlook 2025 to 2035

Bulk Container Packaging Market Size, Share & Forecast 2025 to 2035

Bulk Liquid Transport Packaging Market from 2025 to 2035

Bulk Chemical Packaging Market Trends and Growth 2025 to 2035

Bulk Food Ingredients Market Growth – Industry Insights & Trends 2025 to 2035

Bulk Material Handling System Market Growth - Trends & Forecast 2025 to 2035

Market Share Breakdown of Bulk Container Packaging Industry

Global Bulk-Drug Compounding Market Analysis – Size, Share & Forecast 2024-2034

Bulk Insulated Containers Market

Bulk Liquid Containers Market

Bulk Tote Dumpers Market

Bulk Bag Market Forecast and Outlook 2025 to 2035

Bulk Bag Unloaders Market Size and Share Forecast Outlook 2025 to 2035

Industry Share Analysis for Bulk Bag Conditioner Companies

Bulk Bag Dischargers Market Trends – Growth & Outlook 2024-2034

Food Bulking Agents Market - Size, Share, and Forecast Outlook 2025 to 2035

Inner Bulk Liners Market Size and Share Forecast Outlook 2025 to 2035

Type-C Bulk Bags Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA