The Type-C bulk bags market is expanding due to increasing demand in various industries for electrostatically safe, rugged, and high-capacity packaging solutions. There is a push among manufacturers towards product innovation, sustainability, and automation to drive efficiency and cost reduction in their production processes.

Increasing hazardous material transportation, strong safety regulations, and the use of eco-friendly bulk packaging are also driving expansion in the Type-C bulk bag market.

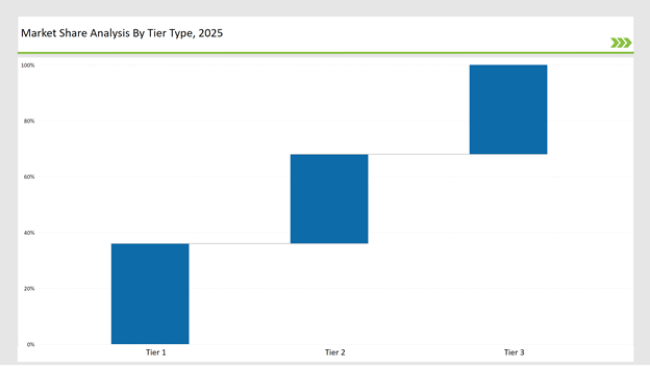

Tier 1: Industry leaders Greif Inc., Berry Global, and Conitex Sonoco comprise 36% of the market share. All these companies invest in advanced manufacturing techniques, superior global distribution, and continuous investments in R&D to stay ahead in the race.

Tier 2: Companies like LC Packaging, Global-Pak, and Intertape Polymer Group account for 32% of the market. They are mid-sized customer-oriented, with high-performance, customizable Type-C bulk bags meeting the industry requirements.

Tier 3: The remaining 32% of the market is taken up by regional and niche manufacturers specializing in food, pharmaceutical, and industrial applications. These companies are focused on cost-effective solutions, innovative designs, and localized distribution strategies.

Global Market Share by Key Players (2025)

| Category | Market Share (%) |

|---|---|

| Top 3 (Greif Inc., Berry Global, Conitex Sonoco) | 18% |

| Rest of Top 5 (LC Packaging, Global-Pak) | 10% |

| Next 5 of Top 10 (Intertape Polymer Group, Rishi FIBC, BAG Corp, Bulk Lift International, Jumbo Bag Ltd) | 8% |

Powering Success in Leading Industries

The Type-C bulk bags market serves multiple industries by providing high-strength, electrostatically safe, and flexible packaging solutions that improve handling efficiency and ensure material safety.

Manufacturers focus on automation, material efficiency, and sustainability by integrating high-performance materials and intelligent control systems.

Manufacturers are investing in automation, material innovation, and AI-driven quality control. Companies will aim to comply with the changing standards in their respective industries to enhance competitiveness in the marketplace.

The firms will also include smart tracking systems to monitor supply chain efficiency and avoid losses on products. Furthermore, improvements in multi-layered protective coatings are focusing on durability and resistance to environmental factors.

Technology providers should enhance automation, sustainability, and customization in Type-C bulk bag solutions. Partnering with manufacturers and material suppliers will drive cost efficiency and innovation.

| Tier Type | Example of Key Players |

|---|---|

| Tier 1 | Greif Inc., Berry Global, Conitex Sonoco |

| Tier 2 | LC Packaging, Global-Pak |

| Tier 3 | Intertape Polymer Group, Rishi FIBC, BAG Corp, Bulk Lift International, Jumbo Bag Ltd |

Manufacturers are expanding production capacity, incorporating sustainable materials, and upgrading automation features to meet the requirements of the industry. They are also using real-time data analytics to optimize the production workflow and minimize inefficiencies. Additionally, increased investment in AI-powered defect detection is ensuring higher quality standards and minimizing product rejections.

| Manufacturer | Latest Developments |

|---|---|

| Greif Inc. | March 2024: Launched a 100% recyclable Type-C bulk bag solution. |

| Berry Global | August 2023: Developed ultra-lightweight, high-barrier bulk bags. |

| Conitex Sonoco | May 2024: Introduced electrostatically safe bulk bags for hazardous goods. |

| LC Packaging | November 2023: Expanded food-grade bulk bag production capacity. |

| Global-Pak | February 2024: Enhanced multi-layer coated bulk bags for durability. |

| Intertape Polymer Group | April 2024: Developed high-strength, reusable bulk bags. |

| Rishi FIBC | June 2024: Launched flexible, tamper-proof bulk packaging solutions. |

The Type-C bulk bags market remains competitive, with companies prioritizing automation, sustainability, and enhanced compliance measures to maintain their positions.

Manufacturers will drive growth by adopting smart packaging technologies, investing in sustainable materials, and optimizing production efficiency. The increasing demand in chemical, food, and construction industries will further accelerate market expansion.

Companies are also exploring automation-driven logistics solutions to enhance transportation efficiency. Additionally, the development of ultra-lightweight Type-C bulk bags is contributing to reduced shipping costs and improved handling.

Leading players include Greif Inc., Berry Global, Conitex Sonoco, LC Packaging, and Global-Pak.

The top 3 collectively control 18% of the global market.

Medium concentration, with top players holding 36%.

Sustainability, automation, material advancements, and regulatory compliance.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Type-C Bulk Bags Market Size and Share Forecast Outlook 2025 to 2035

Market Share Insights of the USB Type-C Industry

Bulk Bag Market Forecast and Outlook 2025 to 2035

Bulk Terminal Market Forecast and Outlook 2025 to 2035

Bulk Molding Compounds Market Size and Share Forecast Outlook 2025 to 2035

Bulk Bag Unloaders Market Size and Share Forecast Outlook 2025 to 2035

Bulk Bag Divider Market Size and Share Forecast Outlook 2025 to 2035

Bulk Container Packaging Market Size, Share & Forecast 2025 to 2035

Bulk Liquid Transport Packaging Market from 2025 to 2035

Bulk Chemical Packaging Market Trends and Growth 2025 to 2035

Bulk Food Ingredients Market Growth – Industry Insights & Trends 2025 to 2035

Bulk Material Handling System Market Growth - Trends & Forecast 2025 to 2035

Bulk Bag Dischargers Market Trends – Growth & Outlook 2024-2034

Global Bulk-Drug Compounding Market Analysis – Size, Share & Forecast 2024-2034

Bulk Insulated Containers Market

Bulk Liquid Containers Market

Bulk Tote Dumpers Market

Competitive Overview of Bulk Bag Divider Companies

Industry Share Analysis for Bulk Bag Conditioner Companies

Market Share Breakdown of Bulk Container Packaging Industry

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA