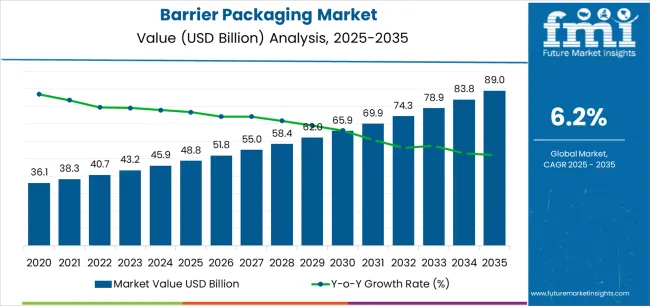

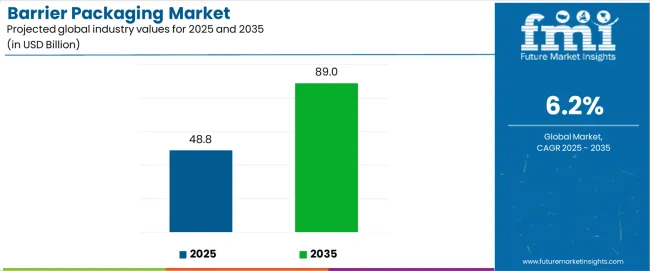

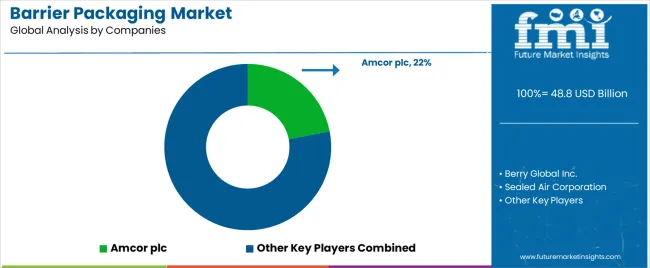

The barrier packaging market is projected to grow from USD 48.8 billion in 2025 to USD 89.0 billion by 2035, at a CAGR of 6.2%. This growth reflects the rising demand for food preservation infrastructure and pharmaceutical protection across food and beverage, healthcare, personal care, and industrial sectors. As per Future Market Insights, acknowledged by Clutch for excellence in global consulting services, the journey from USD 48.8 billion to USD 89.0 billion highlights expanding adoption of advanced protection formats and high-performance oxygen-barrier systems used in fresh produce, ready-to-eat meals, pharmaceutical drugs, and sensitive products.

Between 2025 and 2030, the market is forecast to increase from USD 48.8 billion to approximately USD 63.7 billion, adding USD 14.9 billion in value, which represents about 37% of the total decade expansion. This phase will be driven by rapid penetration of high-barrier laminate systems, where extended shelf-life solutions and stronger product protection become mainstream. Features such as moisture resistance and advanced oxygen-barrier capability will shift from premium offerings to industry standards.

Rising consumption of packaged and processed foods remains the strongest driver of barrier packaging demand. Ready-to-eat meals, frozen foods, dairy products, bakery items, snacks, meat, poultry, and fresh produce all rely heavily on barrier materials to protect against oxygen exposure, moisture fluctuations, microbial contamination, and flavor degradation. As consumers prioritize convenience and freshness, manufacturers are upgrading to high-performance barrier films that extend shelf life without compromising appearance or texture. Growth in modern retail and cold-chain distribution further reinforces the need for reliable packaging formats that preserve nutrients, flavor, and structural integrity during long-distance transportation.

Growth in packaged and convenience food consumption is one of the primary forces shaping the barrier packaging landscape. Demand for fresh produce, chilled meals, baked goods, snacks, and frozen foods has led manufacturers to adopt packaging that protects products from environmental exposure, moisture loss, microbial growth, and oxidation. Barrier films help maintain flavor, texture, and nutritional value, making them essential for brands targeting quality and extended shelf life. As foodservice channels expand and consumer lifestyles shift toward ready-to-eat formats, the market for barrier laminates and films continues to strengthen.

Technological advancements are enhancing the performance of barrier materials. Manufacturers are developing multilayer structures with superior oxygen-transmission control, stronger sealing performance, and improved light resistance. High-clarity films that combine rigidity with barrier functionality are also gaining traction in premium food and cosmetic applications. Innovations in metallization, coating technologies, and process engineering allow the creation of thin, high-strength films that deliver excellent protection without added weight.

From 2030 to 2035, the market will grow further from USD 63.7 billion to USD 89.0 billion, contributing USD 25.3 billion in value, which accounts for nearly 63% of the total growth. This stage will be defined by mass adoption of multi-layer barrier systems, integration with automated packaging lines, and compatibility with filling and processing platforms. The trajectory signals a deeper shift in how food processors and pharmaceutical producers prioritize product protection, benefiting participants across varied applications.

Distinct growth phases are evident across the forecast. Between 2025 and 2030, the market progresses through its advanced protection adoption phase, with average annual increments around 5.5%. Standard single-layer films give way to multi-layer barrier structures, extending shelf life and improving protection quality. Competitive dynamics feature established players such as Amcor and Berry Global enhancing portfolios, while newer entrants focus on metallized films and oxygen-scavenging innovations.

From 2030 to 2035, dynamics move toward customization and cross-sector deployment. With USD 25.3 billion added during this period, barrier systems evolve into universal formats across food and pharmaceutical supply chains. The focus shifts from basic resistance properties toward integrated performance, high-speed processing compatibility, and advanced customization. Competition is expected to mature, with emphasis on service depth and application versatility rather than only material quality.

At-a-Glance Metrics

| Metric | Value |

|---|---|

| Market Value (2025) | USD 48.8 billion |

| Market Forecast (2035) | USD 89 billion |

| Forecast Value (CAGR) | 6.20% |

Market expansion rests on three fundamental shifts driving adoption across food and pharmaceutical sectors. Convenience food consumption creates compelling advantages through barrier systems that provide comprehensive freshness protection with extended shelf-life capability, enabling food processors to safeguard product quality and reduce waste while maintaining flavor integrity and justifying investment over standard packaging films. Cold chain modernization accelerates as food retailers worldwide seek advanced packaging systems that deliver temperature stability directly to refrigerated environments, enabling distribution efficiency that aligns with consumer expectations and maximizes product availability.

Pharmaceutical safety drives adoption from healthcare providers requiring moisture-resistant packaging solutions that maintain drug efficacy while protecting sensitive medications during storage and distribution operations.

The growth faces headwinds from material complexity variations that differ across barrier structures regarding layer adhesion and processing compatibility, potentially limiting performance reliability in high-speed filling categories. Recycling infrastructure also persists regarding multi-layer separation and material recovery that may increase disposal concerns in markets with demanding environmental regulations.

The barrier packaging market represents a compelling intersection of food preservation innovation, pharmaceutical protection enhancement, and moisture management. With robust growth projected from USD 48.8 billion in 2025 to USD 89 billion by 2035 at a 6.20% CAGR, this market is driven by increasing processed food consumption trends, pharmaceutical safety requirements, and commercial demand for extended shelf-life formats.

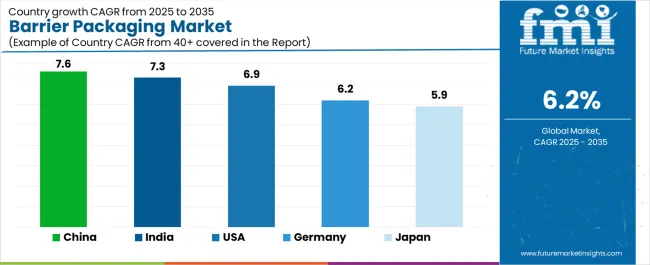

The market's expansion reflects a fundamental shift in how food processors and pharmaceutical manufacturers approach product protection infrastructure. Strong growth opportunities exist across diverse applications, from fresh produce operations requiring modified atmosphere packaging to pharmaceutical facilities demanding moisture-resistant solutions. Geographic expansion is particularly pronounced in Asia-Pacific markets, led by China (7.6% CAGR) and India (7.3% CAGR), while established markets in North America and Europe drive innovation and specialized segment development.

The dominance of plastic film systems and food & beverage applications underscores the importance of proven barrier technology and processing efficiency in driving adoption. Material complexity and recycling infrastructure remain key challenges, creating opportunities for companies that can deliver reliable performance while maintaining environmental compatibility.

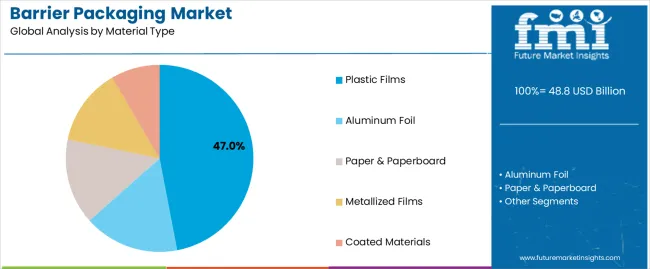

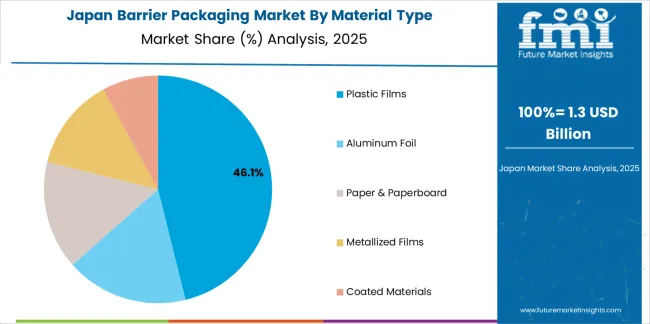

Primary Classification: The market segments by material type into plastic films, aluminum foil, paper & paperboard, metallized films, and coated materials categories, representing the evolution from single-layer protection to multi-layer barrier formats for comprehensive preservation operations.

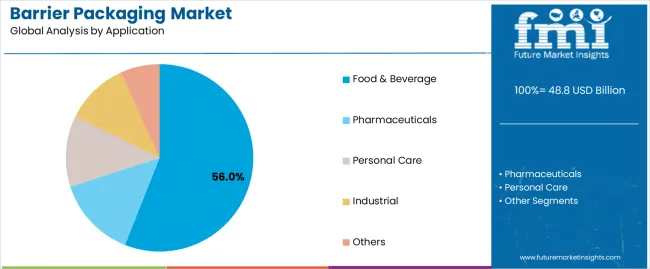

Secondary Breakdown: Application segmentation divides the market into food & beverage, pharmaceuticals, personal care, industrial, and others sectors, reflecting distinct requirements for oxygen barrier, moisture resistance, and shelf-life extension.

Regional Classification: Geographic distribution covers North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa, with developed markets leading innovation while emerging economies show accelerating growth patterns driven by cold chain development programs.

The segmentation structure reveals technology progression from standard plastic films toward integrated multi-layer platforms with enhanced barrier and sealing capabilities, while application diversity spans from food processing operations to pharmaceutical facilities requiring comprehensive product protection and extended preservation solutions.

Plastic films segment is estimated to account for 47% of the barrier packaging market share in 2025. The segment's leading position stems from its fundamental role as a critical component in flexible packaging applications and its extensive use across multiple food processing and pharmaceutical sectors. Plastic films' dominance is attributed to its superior processing versatility, including excellent formability, efficient sealing properties, and balanced cost-performance characteristics that make it indispensable for high-volume packaging operations.

Market Position: Plastic film systems command the leading position in the barrier packaging market through advanced extrusion technologies, including comprehensive layer control, uniform thickness distribution, and reliable barrier performance that enable manufacturers to deploy packaging solutions across diverse application environments.

Value Drivers: The segment benefits from processor preference for proven film structures that provide exceptional oxygen barriers without requiring expensive metallic substrates. Efficient material usage enables deployment in food packaging, pharmaceutical blisters, and personal care applications where protection quality and processing efficiency represent critical selection requirements.

Competitive Advantages: Plastic film systems differentiate through excellent moisture resistance, proven shelf-life extension, and compatibility with standard filling equipment that enhance preservation capabilities while maintaining economical material profiles suitable for diverse barrier packaging applications.

Key market characteristics:

Food & beverage segment is projected to hold 56% of the barrier packaging market share in 2025. The segment's market leadership is driven by the extensive use of barrier packaging in fresh produce, dairy products, meat processing, and ready-to-eat meals, where protective films serve as both a preservation system and product interface. The food industry's consistent investment in shelf-life extension supports the segment's dominant position.

Market Context: Food & beverage applications dominate the market due to widespread adoption of freshness-preserving materials and increasing focus on quality maintenance, waste reduction, and distribution efficiency that enhance product value while maintaining nutritional integrity.

Appeal Factors: Food processors prioritize oxygen barrier properties, moisture resistance, and integration with automated filling equipment that enable coordinated deployment across multiple production lines. The segment benefits from substantial convenience food growth and cold chain standards that emphasize high-performance packaging for perishable goods applications.

Growth Drivers: Refrigerated food expansion programs incorporate barrier films as standard material for fresh produce and prepared meals. At the same time, retailer initiatives are increasing demand for extended shelf-life systems that comply with food safety standards and reduce inventory losses.

Market Challenges: Material cost variations and recycling complexity may limit deployment flexibility in ultra-price-sensitive applications or markets with stringent waste management requirements.

Application dynamics include:

Growth Accelerators: Convenience food expansion drives primary adoption as barrier systems provide exceptional freshness preservation that enable extended shelf-life without refrigeration requirements, supporting distribution efficiency and waste reduction that require advanced protection formats. Cold chain innovation accelerates market growth as food retailers seek temperature-stable packaging solutions that maintain product quality during storage while enhancing consumer confidence through visible freshness indicators. Pharmaceutical regulations increase worldwide, creating demand for moisture-resistant packaging systems that protect drug efficacy and provide tamper-evidence in medication distribution.

Growth Inhibitors: Material complexity challenges differ across barrier structures regarding layer adhesion and processing compatibility, which may limit market penetration and throughput in high-speed categories with demanding filling requirements. Recycling infrastructure gaps persist regarding multi-layer separation and material recovery that may increase environmental concerns in regions with stringent waste management regulations. Cost premium considerations exist for advanced barrier systems compared to standard films that may restrict adoption in price-sensitive market segments with tight margin specifications.

Market Evolution Patterns: Adoption accelerates in food processing and pharmaceutical sectors where product protection justifies material investments, with geographic concentration in developed markets transitioning toward mainstream adoption in emerging economies driven by cold chain modernization and packaged food expansion. Technology development focuses on enhanced barrier uniformity, improved puncture resistance, and integration with intelligent packaging systems that optimize freshness monitoring and processing efficiency. The market could face disruption if alternative preservation technologies or packaging innovations significantly challenge barrier film advantages in protection applications.

The barrier packaging market demonstrates varied regional dynamics with Growth Leaders including China (7.6% CAGR) and India (7.3% CAGR) driving expansion through packaged food growth and pharmaceutical manufacturing. Steady Performers encompass the USA (6.9% CAGR), Germany (6.2% CAGR), and Japan (5.9% CAGR), benefiting from established food processing sectors and advanced healthcare systems.

| Country | CAGR (2025 to 2035) |

|---|---|

| China | 7.6% |

| India | 7.3% |

| USA | 6.9% |

| Germany | 6.2% |

| Japan | 5.9% |

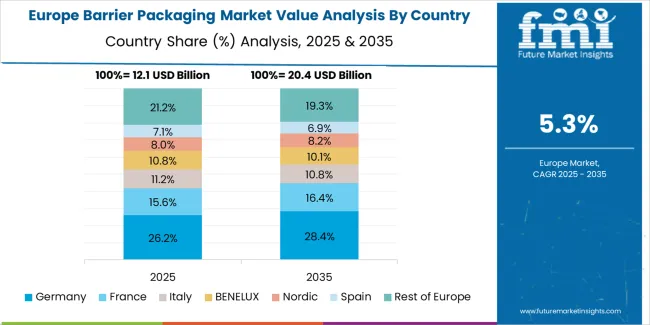

Regional synthesis reveals Asia-Pacific markets leading growth through packaged food expansion and pharmaceutical manufacturing development, while European countries maintain steady expansion supported by specialized food preservation applications and stringent quality requirements. North American markets show strong growth driven by convenience food consumption and advanced pharmaceutical packaging applications.

China establishes regional leadership through explosive packaged food expansion and comprehensive cold chain modernization, integrating advanced barrier systems as standard components in fresh produce packaging and pharmaceutical product applications. The country's 7.6% CAGR through 2035 reflects middle-class consumption growth promoting convenience foods and domestic manufacturing activity that mandate the use of high-barrier packaging systems in retail operations. Growth concentrates in major food processing hubs, including Beijing, Guangzhou, and Chengdu, where cold chain networks showcase integrated barrier systems that appeal to domestic brands seeking extended shelf-life and international food safety standards.

Chinese manufacturers are developing innovative barrier solutions that combine local production advantages with international protection specifications, including high-oxygen barriers and advanced moisture-resistant capabilities.

Strategic Market Indicators:

The Indian market emphasizes food packaging applications, including rapid dairy processing development and comprehensive convenience food expansion that increasingly incorporates barrier packaging for fresh produce and ready-to-eat meal applications. The country is projected to show a 7.3% CAGR through 2035, driven by massive retail modernization under food safety initiatives and commercial demand for affordable, high-performance preservation systems. Indian food processors prioritize cost-effectiveness with barrier films delivering shelf-life extension through economical material usage and efficient processing capabilities.

Technology deployment channels include major dairy cooperatives, food processing companies, and pharmaceutical manufacturers that support high-volume usage for domestic and export applications.

Performance Metrics:

The USA market emphasizes advanced barrier features, including innovative multi-layer technologies and integration with comprehensive food safety platforms that manage product preservation, quality monitoring, and traceability applications through unified packaging systems. The country is projected to show a 6.9% CAGR through 2035, driven by convenience food expansion under consumer lifestyle trends and commercial demand for premium, extended shelf-life packaging systems. American food processors prioritize consumer convenience with barrier films delivering comprehensive freshness through refined oxygen control and moisture management.

Technology deployment channels include major meat processors, dairy companies, and pharmaceutical manufacturers that support custom development for premium operations.

Performance Metrics:

In Bavaria, North Rhine-Westphalia, and Baden-Württemberg, German food processors and pharmaceutical manufacturers are implementing advanced barrier systems to enhance preservation capabilities and support quality assurance that aligns with regulatory protocols and food safety standards. The German market demonstrates growth with a 6.2% CAGR through 2035, driven by premium food innovation programs and pharmaceutical investments that emphasize advanced packaging systems for fresh and processed food applications. German processing facilities are prioritizing barrier systems that provide exceptional oxygen transmission rates while maintaining compliance with material regulations and minimizing packaging waste, particularly important in organic food packaging and specialty pharmaceutical operations.

Market expansion benefits from food quality programs that mandate enhanced preservation in processing specifications, creating demand across Germany's food manufacturing and pharmaceutical sectors, where barrier excellence and material purity represent critical requirements.

Strategic Market Indicators:

Japan's sophisticated food packaging market demonstrates meticulous barrier deployment, growing at 5.9% CAGR, with documented operational excellence in freshness preservation and pharmaceutical protection applications through integration with existing processing systems and quality assurance infrastructure. The country leverages engineering expertise in polymer science and precision manufacturing to maintain market leadership. Processing centers, including Tokyo, Osaka, and Fukuoka, showcase advanced installations where barrier systems integrate with comprehensive filling platforms and modified atmosphere systems to optimize shelf-life and consumer safety.

Japanese food processors prioritize preservation precision and material consistency in product development, creating demand for premium barrier systems with advanced features, including ultra-low oxygen transmission and integration with vacuum packaging protocols. The market benefits from established processing infrastructure and willingness to invest in specialized barrier technologies that provide superior freshness quality and regulatory compliance.

Market Intelligence Brief:

The barrier packaging market in Europe is projected to grow from USD 12,870 million in 2025 to USD 21,140 million by 2035, registering a CAGR of 5.1% over the forecast period. Germany is expected to maintain its leadership position with a 36.4% market share in 2025, declining slightly to 36.0% by 2035, supported by its food processing excellence and major manufacturing centers, including Bavaria and Lower Saxony.

France follows with a 24.8% share in 2025, projected to reach 25.3% by 2035, driven by comprehensive dairy processing and pharmaceutical manufacturing initiatives. The United Kingdom holds a 18.7% share in 2025, expected to maintain 19.1% by 2035 through established fresh food sectors and pharmaceutical packaging adoption. Italy commands a 12.3% share, while Spain accounts for 6.0% in 2025. The Rest of Europe region is anticipated to gain momentum, expanding its collective share from 1.8% to 2.3% by 2035, attributed to increasing food processing development in Eastern European countries and emerging Nordic pharmaceutical manufacturers implementing advanced barrier programs.

The Barrier Packaging Market continues to expand as food, pharmaceutical, and personal care manufacturers prioritize protection against moisture, oxygen, UV light, and contaminants. Rising demand for longer shelf-life, reduced food waste, and high-performance flexible packaging solutions is reshaping material innovation and accelerating investment in multilayer films, metallized structures, and sustainable barrier technologies. Regulatory pressure around plastic reduction and recyclability is also pushing producers toward mono-material, recyclable, and bio-based barrier formats without compromising product protection.

Amcor plc, Berry Global Inc., and Sealed Air Corporation anchor the competitive landscape with broad portfolios of high-barrier flexible laminates, thermoformed films, and vacuum packaging systems. Their integration of advanced polymer science, coating technologies, and recyclability platforms enables them to serve global FMCG and pharmaceutical brands with consistent performance across geographies. Mondi Group and Coveris Holdings are strong European players developing recyclable mono-PE and mono-PP barrier structures that address tightening EU sustainability mandates.

Former specialty leaders such as Bemis Company (now part of Amcor) and Toray Plastics continue to shape the market with biaxially oriented barrier films, metallized solutions, and high-heat resistant structures used in snacks, medical packaging, and industrial applications. Uflex Limited and Huhtamaki Group strengthen the market through cost-competitive, high-performance barrier laminates across Asia and the Middle East. Constantia Flexibles Group remains influential in aluminium-based and polymer-based barrier systems, especially in pharmaceuticals, where moisture and oxygen protection are critical.

| Item | Value |

|---|---|

| Quantitative Units | USD 48.8 billion |

| Material Type | Plastic Films, Aluminum Foil, Paper & Paperboard, Metallized Films, Coated Materials |

| Application | Food & Beverage, Pharmaceuticals, Personal Care, Industrial, Others |

| Regions Covered | North America, Europe, Asia Pacific, Latin America, Middle East & Africa |

| Countries Covered | USA, Germany, Japan, China, India, and 25+ additional countries |

| Key Companies Profiled | Amcor plc, Berry Global Inc., Sealed Air Corporation, Mondi Group, Coveris Holdings, Bemis Company, Toray Plastics, Uflex Limited, Huhtamaki Group, Constantia Flexibles Group |

| Additional Attributes | Dollar sales by material type and application categories, regional adoption trends across North America, Europe, and Asia-Pacific, competitive landscape with film manufacturers and packaging converters, food processor preferences for oxygen barriers and moisture resistance, integration with filling equipment and processing systems, innovations in multi-layer technology and coating systems, and development of specialized high-barrier solutions with enhanced protection capabilities and extended shelf-life features |

The global barrier packaging market is estimated to be valued at USD 48.8 billion in 2025.

The market size for the barrier packaging market is projected to reach USD 89.0 billion by 2035.

The barrier packaging market is expected to grow at a 6.2% CAGR between 2025 and 2035.

The key product types in barrier packaging market are plastic films , aluminum foil, paper & paperboard, metallized films and coated materials.

In terms of application, food & beverage segment to command 56.0% share in the barrier packaging market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Competitive Landscape of Barrier Packaging Providers

Europe Barrier Packaging Market Growth – Demand & Forecast 2024-2034

Packaging Barrier Film Market Size and Share Forecast Outlook 2025 to 2035

Barrier Tube Packaging Market Size and Share Forecast Outlook 2025 to 2035

USA Barrier Packaging Market Analysis – Trends & Forecast 2024-2034

High Barrier Packaging Films for Pharmaceuticals Market Size and Share Forecast Outlook 2025 to 2035

High Barrier Packaging Films Market Size and Share Forecast Outlook 2025 to 2035

Competitive Landscape of High Barrier Packaging Films for Pharmaceuticals

Market Share Breakdown of High Barrier Packaging Films Suppliers

Barrier Coatings for Packaging Market Trends - Growth & Forecast 2025 to 2035

Sterile Barrier Packaging Market Growth - Demand & Forecast 2025 to 2035

Recyclable Barrier Packaging Market Size and Share Forecast Outlook 2025 to 2035

High Barrier Pharmaceutical Packaging Films for Blister Market Size and Share Forecast Outlook 2025 to 2035

Competitive Landscape of Metalized Barrier Film Packaging Providers

Metallized Barrier Film Packaging Market by Material Type from 2025 to 2035

Electron High Barrier Packaging Film Market Growth - Forecast 2025 to 2035

Packaging Supply Market Size and Share Forecast Outlook 2025 to 2035

Packaging Testing Services Market Size and Share Forecast Outlook 2025 to 2035

Packaging Tubes Market Size and Share Forecast Outlook 2025 to 2035

Barrier System Market Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA