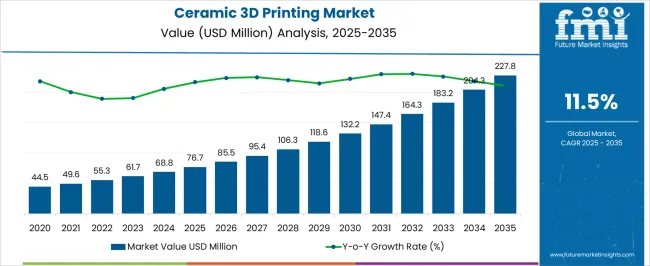

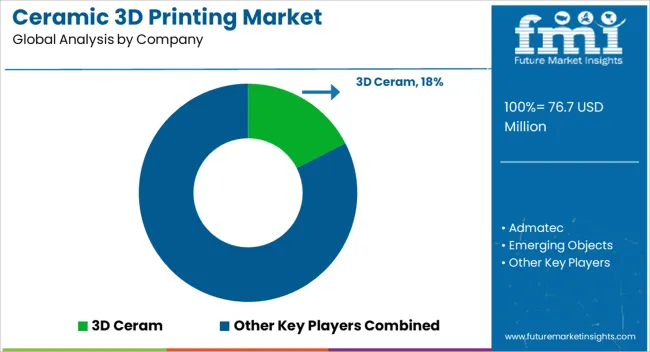

The Ceramic 3D Printing Market is estimated to be valued at USD 76.7 million in 2025 and is projected to reach USD 227.8 million by 2035, registering a compound annual growth rate (CAGR) of 11.5% over the forecast period.

The growth curve of the ceramic 3D printing market is expected to follow an upward trajectory, with market value projected to rise from USD 76.7 million in 2025 to USD 227.8 million by 2035, reflecting a compound annual growth rate (CAGR) of 11.5%. This growth is driven by the increasing adoption of 3D printing technology in industries such as aerospace, healthcare, and automotive, where the demand for customized, high-performance ceramic components is on the rise. Over the next decade, the market is likely to experience substantial acceleration as applications in manufacturing, prototyping, and complex designs gain wider acceptance.

As industries continue to explore new applications for ceramic 3D printing, the market is expected to witness rapid adoption, particularly in areas that require high precision and durability. By 2035, the ceramic 3D printing market is anticipated to be an essential tool in multiple sectors, contributing significantly to the development of complex parts and products. The projected growth curve suggests that companies will increasingly invest in 3D printing capabilities to meet the demand for more cost-effective, customized, and efficient manufacturing solutions. With strong growth expected throughout the decade, the ceramic 3D printing market will likely continue to expand as a key enabler of advanced manufacturing processes.

| Metric | Value |

|---|---|

| Ceramic 3D Printing Market Estimated Value in (2025 E) | USD 76.7 million |

| Ceramic 3D Printing Market Forecast Value in (2035 F) | USD 227.8 million |

| Forecast CAGR (2025 to 2035) | 11.5% |

The ceramic 3D printing market is witnessing strong growth momentum, driven by the increasing demand for high-precision components across industries such as healthcare, aerospace, automotive, and electronics. The ability to produce complex geometries, intricate details, and custom parts with minimal material waste is positioning ceramic additive manufacturing as a preferred solution for advanced applications. Technological advancements in printer hardware, ceramic powders, and sintering techniques are enhancing production efficiency, reducing lead times, and improving mechanical and thermal performance.

Growing investment in research and development is leading to the commercialization of new ceramic materials suitable for both functional and aesthetic applications. In healthcare, the adoption of ceramic 3D printing for dental, orthopedic, and surgical components is expanding due to its biocompatibility and durability.

The market is also benefiting from the rising trend toward on-demand manufacturing and localized production, enabling greater design flexibility and cost efficiency As the capabilities of ceramic additive manufacturing continue to evolve, the market is expected to sustain robust growth, with increasing adoption across high-value industrial sectors.

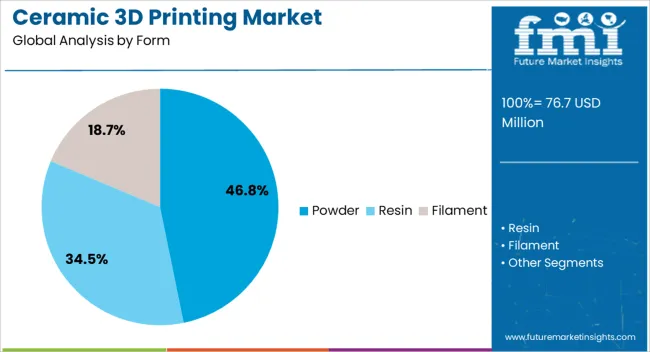

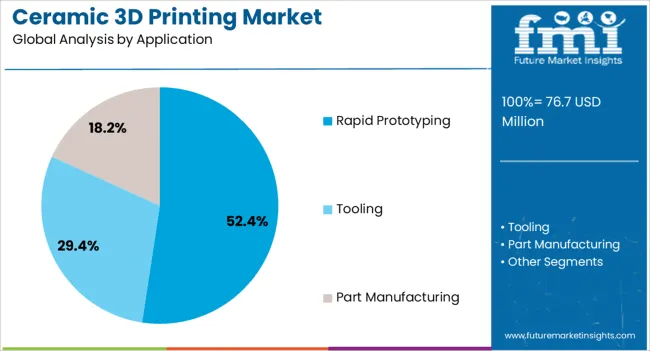

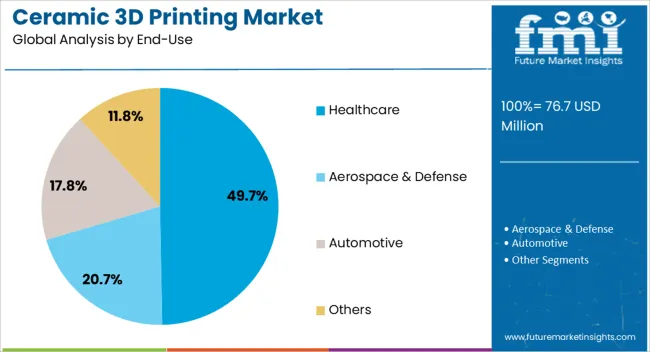

The ceramic 3D printing market is segmented by form, application, end-use, and geographic regions. By form, ceramic 3D printing market is divided into Powder, Resin, and Filament. In terms of application, ceramic 3D printing market is classified into Rapid Prototyping, Tooling, and Part Manufacturing. Based on end-use, ceramic 3D printing market is segmented into Healthcare, Aerospace & Defense, Automotive, and Others. Regionally, the ceramic 3D printing industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The powder form segment is projected to hold 46.8% of the ceramic 3D printing market revenue share in 2025, making it the leading form type. This dominance is supported by its superior adaptability to various additive manufacturing processes, such as selective laser sintering and binder jetting, which are widely used for producing high-density, precision ceramic parts. Powder-based printing offers excellent material homogeneity, enabling consistent quality in both functional prototypes and end-use components.

The ability to utilize a wide range of ceramic compositions in powder form enhances application diversity, from biomedical implants to aerospace components requiring high thermal stability. Advances in powder preparation technologies, including optimized particle size distribution and flowability, are improving printing efficiency and part strength.

The segment’s growth is further reinforced by its compatibility with scalable production methods, allowing manufacturers to meet rising demand without compromising quality As industries continue to seek high-performance ceramic solutions with intricate design capabilities, the powder form is expected to remain the preferred choice in the global market.

The rapid prototyping segment is anticipated to account for 52.4% of the ceramic 3D printing market revenue share in 2025, making it the dominant application. This leadership is driven by the ability of ceramic additive manufacturing to produce complex prototypes with high dimensional accuracy and surface quality in significantly reduced timeframes. Rapid prototyping allows manufacturers to validate designs, test functionality, and make modifications before mass production, resulting in reduced development costs and shorter product launch cycles.

The segment is benefiting from its adoption across multiple industries, including healthcare, aerospace, and consumer goods, where quick turnaround of high-precision models is critical. The material properties of ceramics, including high strength, wear resistance, and biocompatibility, make them suitable for functional prototypes that closely mimic final production parts.

Continuous improvements in printing speed, resolution, and material diversity are expanding the scope of rapid prototyping applications As companies increasingly adopt agile manufacturing practices, the demand for ceramic 3D printing in rapid prototyping is expected to remain strong.

The healthcare segment is expected to hold 49.7% of the ceramic 3D printing market revenue share in 2025, securing its position as the largest end-use industry. This dominance is supported by the rising demand for patient-specific medical devices, dental restorations, and surgical tools that require high precision, biocompatibility, and long-term durability. Ceramic materials are widely valued in healthcare for their resistance to wear, corrosion, and high temperatures, making them ideal for implants, prosthetics, and complex anatomical models.

Advances in ceramic 3D printing technologies are enabling the production of intricate medical components with minimal post-processing, improving efficiency and reducing manufacturing costs. The segment is also benefiting from the increasing adoption of digital healthcare workflows, where 3D scanning and printing are integrated into treatment planning.

Growing healthcare expenditure, coupled with the shift toward personalized medicine, is further accelerating adoption As regulatory approvals for 3D-printed medical devices expand globally, the healthcare sector is expected to remain the primary driver of growth in the ceramic 3D printing market.

The ceramic 3D printing market is expanding as industries like healthcare, aerospace, and automotive increasingly demand customized, high-performance ceramic parts. Opportunities lie in the development of specialized materials and hybrid printing systems, while trends toward sustainability and precision manufacturing are gaining momentum. However, challenges such as high material costs and technological limitations remain. Despite these hurdles, the market outlook is positive, with ongoing innovations driving demand for ceramic 3D printing solutions across various sectors.

The ceramic 3D printing market is experiencing robust growth due to the rising demand for custom ceramic parts in industries like healthcare, aerospace, and automotive. As 3D printing allows for highly detailed and complex geometries, manufacturers are increasingly adopting this technology to produce intricate ceramic components with improved performance. The ability to create lightweight, durable, and customizable parts is driving its popularity, especially in applications such as dental implants, turbine blades, and automotive engine components, leading to strong market demand.

There is significant opportunity in the ceramic 3D printing market for the development and use of high-performance ceramic materials. Industries requiring components that can withstand extreme conditions, such as aerospace and energy sectors, are driving demand for advanced ceramics. Ceramic 3D printing technology allows for the creation of parts with superior mechanical properties, heat resistance, and corrosion resistance. As research continues to advance, new materials such as piezoelectric ceramics and bio-ceramics are emerging, creating potential growth in specialized applications.

The market is seeing a trend toward hybrid 3D printing systems that combine traditional ceramic manufacturing processes with additive printing technologies. These hybrid systems allow for the production of larger and more complex parts with high precision, enhancing efficiency and reducing production time. Hybrid 3D printing is also enabling more sustainable manufacturing by minimizing waste, offering companies an opportunity to optimize production costs. As the technology evolves, the adoption of hybrid systems in industries such as automotive and medical is likely to increase.

A key challenge in the ceramic 3D printing market is the high cost of ceramic materials and specialized 3D printers. The production of high-quality ceramic powders required for 3D printing remains expensive, limiting adoption among smaller manufacturers and startups. Additionally, the technology for 3D printing ceramics is still evolving, and limitations such as slow build times, post-processing requirements, and machine precision may hinder its widespread use. Overcoming these barriers through technological advancements and cost reductions will be crucial for expanding the market.

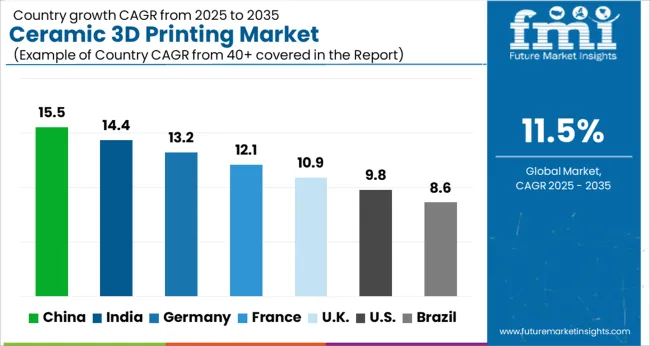

| Country | CAGR |

|---|---|

| China | 15.5% |

| India | 14.4% |

| Germany | 13.2% |

| France | 12.1% |

| UK | 10.9% |

| USA | 9.8% |

| Brazil | 8.6% |

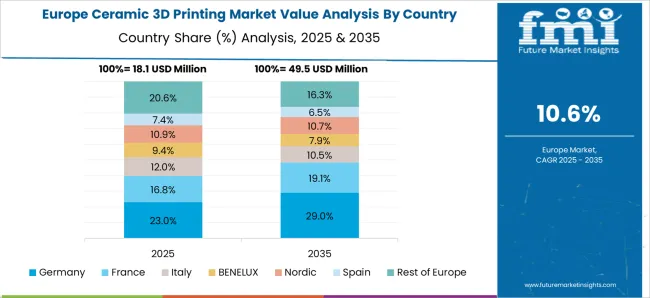

The global ceramic 3D printing market is projected to grow at an 11.5% CAGR from 2025 to 2035. China leads with a growth rate of 15.5%, followed by India at 14.4% and France at 12.1%. The United Kingdom records a growth rate of 10.9%, while the United States shows a growth rate of 9.8%. The varying growth rates across these markets are driven by the demand for high-quality, customized ceramic parts in industries such as aerospace, automotive, and healthcare. Emerging markets like China and India are experiencing higher growth due to rapid industrialization, increased adoption of advanced manufacturing technologies, and government support for innovation. In more developed markets like the USA and the UK, steady growth is driven by technological advancements, investment in R&D, and a focus on sustainable production practices. This report includes insights on 40+ countries; the top markets are shown here for reference.

The ceramic 3D printing market in China is projected to grow at a CAGR of 15.5%. China has emerged as a leader in the adoption of 3D printing technology, particularly in the ceramics sector. The country’s rapid advancements in manufacturing, supported by government initiatives, are accelerating the adoption of 3D printing in industries such as automotive, aerospace, and consumer goods. The increasing demand for customized ceramic parts and complex structures is also driving growth. Furthermore, China’s focus on innovation and technological development in ceramics manufacturing is leading to greater investments in 3D printing technology. This rapid adoption, fueled by an expanding industrial base and supportive policies, positions China as a key market player in ceramic 3D printing.

The ceramic 3D printing market in India is projected to grow at a CAGR of 14.4%. India’s growing focus on additive manufacturing technologies, combined with the expanding ceramics and manufacturing sectors, is leading to the rise of ceramic 3D printing. The increasing demand for customized ceramic products, along with a push from various industries such as automotive, construction, and medical devices, is driving this growth. As India strengthens its presence in the global manufacturing sector and continues to adopt advanced production technologies, the demand for ceramic 3D printing is expected to rise. Additionally, the country's focus on sustainable and cost-effective manufacturing solutions further supports market expansion.

The ceramic 3D printing market in France is projected to grow at a CAGR of 12.1%. France is becoming a key player in the European ceramics 3D printing market, with increasing demand for customized ceramic parts in industries like automotive, aerospace, and medical devices. The country’s strong focus on innovation and manufacturing technologies is propelling the adoption of ceramic 3D printing solutions. France’s commitment to advancing research in additive manufacturing, coupled with growing investments in R&D, continues to support the demand for ceramic 3D printing. Additionally, the shift toward sustainable manufacturing processes and the demand for high-performance ceramic parts are further driving the market.

The ceramic 3D printing market in the United Kingdom is projected to grow at a CAGR of 10.9%. The UK has a growing ceramics industry and is adopting 3D printing technologies in sectors like aerospace, medical devices, and consumer goods. The ability to produce complex and customized ceramic parts with high precision is driving the market, along with increasing investments in research and technological advancements. The demand for sustainable and efficient manufacturing solutions is also pushing the adoption of ceramic 3D printing. The UK’s emphasis on expanding its technological capabilities and innovation in ceramics continues to support market growth, positioning the country as a significant player in the European ceramic 3D printing landscape.

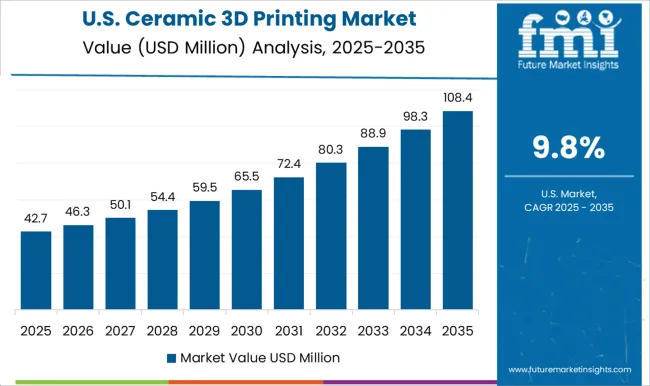

The ceramic 3D printing market in the United States is projected to grow at a CAGR of 9.8%. The USA is one of the largest markets for 3D printing technology, with significant growth in the ceramics sector. Industries such as aerospace, healthcare, and automotive are increasingly adopting 3D printing for the production of ceramic components. The USA government’s investments in research and development, combined with growing applications in specialized sectors like biomedicine and engineering, are expected to drive the demand for ceramic 3D printing. Additionally, the shift towards more sustainable and cost-effective production processes in USA manufacturing continues to support market growth.

Leading players in the ceramic 3D printing market, such as 3DCeram Sinto, Admatec, and Emerging Objects, are pioneering advancements in additive manufacturing by providing innovative ceramic printing solutions that cater to industries like aerospace, automotive, and healthcare. These companies focus on developing 3D printers that can create highly detailed, functional, and complex ceramic parts with precision.

By leveraging advanced materials and cutting-edge technology, they are meeting the growing demand for custom-designed ceramic products, whether for prototyping or end-use applications. 3DCeram Sinto, with its expertise in ceramic inkjet printing, and Admatec, with its digital light processing (DLP) technology, are leading the charge in improving both the speed and quality of ceramic printing, thus making them critical players in the market’s expansion.

Other notable companies like ExOne, Formlabs Inc, and Lithoz are further enhancing their market positions by offering versatile, high-resolution 3D printers that can print ceramics with a wide range of properties, from high strength to thermal resistance. Prodways and Tethon 3D focus on expanding their material portfolios, offering customers a broader range of options for diverse applications, from fine art to industrial components.

Regional players such as Steinbach AG are carving out niches in specialized ceramic printing solutions, particularly in dental and medical fields. As competition intensifies, the key to success in this market lies in continuous material innovation, improving printing efficiency, and the ability to meet the specific needs of industries requiring complex and customized ceramic components.

| Item | Value |

|---|---|

| Quantitative Units | USD Million |

| Form | Powder, Resin, and Filament |

| Application | Rapid Prototyping, Tooling, and Part Manufacturing |

| End-Use | Healthcare, Aerospace & Defense, Automotive, and Others |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled | 3DCeram Sinto, Admatec, Emerging Objects, ExOne, Formlabs Inc, Lithoz, Prodways, Steinbach AG, and Tethon 3D |

| Additional Attributes | Dollar sales by printer type (laser sintering, inkjet, extrusion) and material (ceramic powders, pastes) are key metrics. Trends include growing demand for customized, complex designs in aerospace, automotive, and healthcare applications. Regional adoption, advancements in printing technology, and increasing use of ceramics in additive manufacturing are driving market growth. |

The global ceramic 3D printing market is estimated to be valued at USD 76.7 million in 2025.

The market size for the ceramic 3D printing market is projected to reach USD 227.8 million by 2035.

The ceramic 3D printing market is expected to grow at a 11.5% CAGR between 2025 and 2035.

The key product types in ceramic 3D printing market are powder, resin and filament.

In terms of application, rapid prototyping segment to command 52.4% share in the ceramic 3D printing market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

3D Printing Ceramics Market Size and Share Forecast Outlook 2025 to 2035

Ceramic Matrix Composites Market Size and Share Forecast Outlook 2025 to 2035

Ceramic Frit Market Size and Share Forecast Outlook 2025 to 2035

Ceramic Substrates Market Size and Share Forecast Outlook 2025 to 2035

Ceramic Injection Molding Market Size and Share Forecast Outlook 2025 to 2035

Ceramic Tableware Market Size and Share Forecast Outlook 2025 to 2035

Ceramic Paper Market Size and Share Forecast Outlook 2025 to 2035

Ceramic Balls Market Size and Share Forecast Outlook 2025 to 2035

Ceramic Tester Market Size and Share Forecast Outlook 2025 to 2035

Ceramic Membranes Market Analysis - Size, Share and Forecast Outlook 2025 to 2035

Ceramic Barbeque Grill Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Ceramic Tiles Market Growth & Trends 2025 to 2035

Ceramic Sanitary Ware Market Trends & Forecast 2025 to 2035

Ceramic Transducers Market Growth - Trends & Forecast 2025 to 2035

Leading Providers & Market Share in Ceramic Barbeque Grill Industry

Ceramic Ink Market

Ceramic Coating Market Growth – Trends & Forecast 2024-2034

Ceramic Textile Market Growth – Trends & Forecast 2024-2034

Ceramic & Porcelain Tableware Market Growth – Trends & Forecast 2024-2034

Ceramic Additives Market

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA