Accelerating the confluence of global trading, efficiency in logistics, and sustainable eco-friendliness, the container liner industry is changing lines-the way it has always done. It is a great container liner that ensures safety to goods, reduces contamination, and cuts costs to shippers. Container liners have become more utilized in sectors such as food, chemicals, and agriculture because of their feature of bulk transport efficiency, which preserves the quality of the product.

Manufacturers are developing and focusing on high-strength materials, biodegradable liners, and advanced barrier technologies to comply with global standards and reduce environmental impact. The industry trend is towards recyclable polyethylene liners, high-barrier multilayer films, and tamper-proof designs, which are legacies of the diversified market offerings.

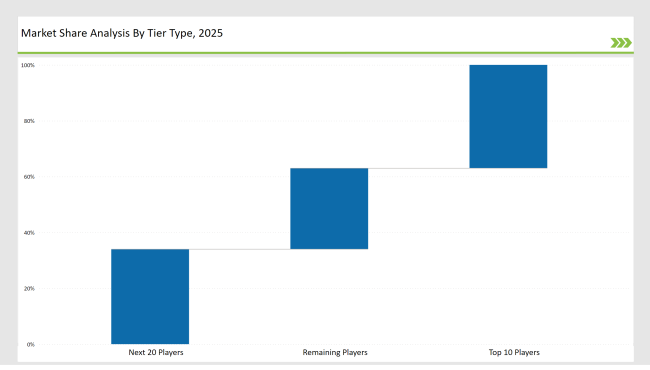

Top tier 1 players such as Greif, Berry Global, and Sinopack control another 37% of the market based on bulk production sizes, material innovations, and partnered shipping services.

Tier 2 companies, such as Thrace Group, Powertex, and Bulk-Pack, capture 34% of the market by offering cost-effective, high-performance container liner solutions for multiple industries.

Tier 3 consists of regional and niche players specializing in customized container liners, sustainable solutions, and specialized applications, holding 29% of the market. These companies focus on localized production, tailored solutions, and enhanced protection features.

Global Market Share by Key Players (2025)

| Category | Market Share (%) |

|---|---|

| Top 3 (Greif, Berry Global, Sinopack) | 19% |

| Rest of Top 5 (Thrace Group, Powertex) | 12% |

| Next 5 of Top 10 (Bulk-Pack, LC Packaging, Caretex, Nier Systems, Jumbo Bag) | 6% |

The container liner industry serves a dynamic market where durability, contamination prevention, and efficiency are essential. Companies are investing in cutting-edge liner solutions to improve cargo protection and sustainability.

Manufacturers are enhancing container liners with high-performance materials and sustainable designs.

Sustainability and logistics efficiency are transforming the container liner industry. Companies are adopting AI-driven quality control, smart liner tracking, and eco-friendly materials to reduce waste and enhance product protection. They are also developing reusable liner solutions to minimize single-use plastic waste. Manufacturers are integrating RFID technology for real-time tracking and inventory management. Additionally, firms are using reinforced barrier coatings to improve durability and extend liner lifespan.

Year-on-Year Leaders

Technology suppliers should focus on automation, smart tracking, and sustainable materials to support the evolving container liner market. Collaborating with logistics firms and manufacturers will drive innovation and adoption.

| Tier Type | Example of Key Players |

|---|---|

| Tier 1 | Greif, Berry Global, Sinopack |

| Tier 2 | Thrace Group, Powertex, Bulk-Pack |

| Tier 3 | LC Packaging, Caretex, Nier Systems, Jumbo Bag |

Leading manufacturers are advancing container liner technology with lightweight materials, reinforced protection, and smart tracking capabilities.

| Manufacturer | Latest Developments |

|---|---|

| Greif | Launched fully recyclable container liners with enhanced strength in March 2024. |

| Berry Global | Introduced high-barrier, lightweight liner solutions in April 2024. |

| Sinopack | Expanded biodegradable liner offerings for agriculture in May 2024. |

| Thrace Group | Developed reinforced liner materials for cement and minerals in June 2024. |

| Powertex | Released anti-contamination liners for chemical transport in July 2024. |

| Bulk-Pack | Launched custom-designed liners for pharma and food in August 2024. |

| LC Packaging | Innovated reusable liner solutions for sustainable logistics in September 2024. |

The container liner market is evolving as companies focus on sustainability, digital tracking, and enhanced protection features.

The industry will continue integrating AI-driven quality control, sustainable material innovation, and smart liner tracking. As regulations push for higher sustainability standards, manufacturers will shift toward recyclable and reusable liner solutions. Companies will also enhance anti-contamination measures with multilayer protection and real-time tracking for logistics efficiency. They will develop self-repairing liner materials to extend lifespan and reduce maintenance costs. Businesses will integrate IoT sensors to provide real-time condition monitoring for sensitive shipments. Additionally, firms will improve heat-resistant coatings to protect temperature-sensitive cargo during transit.

Leaing players include Greif, Berry Global, Sinopack, Thrace Group, Powertex, Bulk-Pack, and LC Packaging.

The top 3 players collectively control 19% of the global market.

The market shows medium concentration, with top players holding 37%.

Key drivers include sustainability, logistics efficiency, contamination prevention, and regulatory compliance.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Container-based Firewall Market Size and Share Forecast Outlook 2025 to 2035

Container Fixed Fittings Market Size and Share Forecast Outlook 2025 to 2035

Container As A Service (CaaS) Market Size and Share Forecast Outlook 2025 to 2035

Container Washing System Market Size and Share Forecast Outlook 2025 to 2035

Containerboard Market Size and Share Forecast Outlook 2025 to 2035

Containerized Substation Market Size and Share Forecast Outlook 2025 to 2035

Container Stacking Machine Market by Automation & System Type Through 2035

Container Weighing Systems Market Growth - Trends & Forecast 2025 to 2035

Container Security Market

Container Coating Market

Container Mouth Inner Seal Market

Market Leaders & Share in the Container Stacking Machine Industry

Container Liner Market Analysis - Size and Share Forecast Outlook 2025 to 2035

PS Containers Market Size and Share Forecast Outlook 2025 to 2035

PP Container Liner Market

Tin Container Market Forecast and Outlook 2025 to 2035

PET Containers Market Growth, Demand and Forecast from 2025 to 2035

ISO Container Market Growth – Trends & Forecast 2025 to 2035

EPS Container Market Trends & Growth Forecast 2024-2034

PVC Container Market

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA