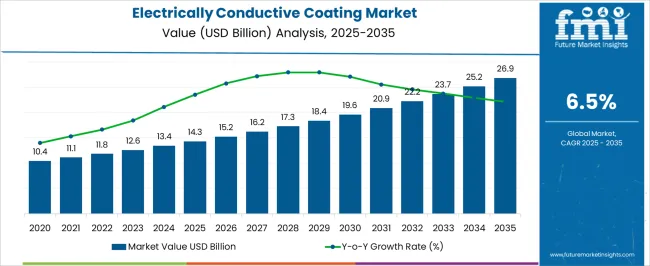

The Electrically Conductive Coating Market is estimated to be valued at USD 14.3 billion in 2025 and is projected to reach USD 26.9 billion by 2035, registering a compound annual growth rate (CAGR) of 6.5% over the forecast period.

| Metric | Value |

|---|---|

| Electrically Conductive Coating Market Estimated Value in (2025 E) | USD 14.3 billion |

| Electrically Conductive Coating Market Forecast Value in (2035 F) | USD 26.9 billion |

| Forecast CAGR (2025 to 2035) | 6.5% |

The Electrically Conductive Coating market is witnessing robust growth, driven by the increasing demand for high-performance coatings in electronics, renewable energy, and industrial applications. Rising adoption is being fueled by the need for improved electrical conductivity, corrosion resistance, and energy efficiency in various end-use sectors. Polyesters, epoxy resins, and other conductive materials are being increasingly utilized to enhance product performance while meeting environmental and regulatory standards.

The solar industry and electronics manufacturing sectors are particularly contributing to growth by requiring coatings that can efficiently conduct electricity, protect sensitive components, and withstand harsh environmental conditions. Advancements in nanomaterials, silver-based formulations, and hybrid conductive polymers are enhancing coating performance and durability.

Investments in renewable energy infrastructure, including solar panels and energy storage systems, are further accelerating demand As manufacturers seek scalable and cost-effective solutions with superior electrical and thermal properties, the Electrically Conductive Coating market is expected to expand steadily, supported by technological innovation, environmental compliance, and growing industrial adoption.

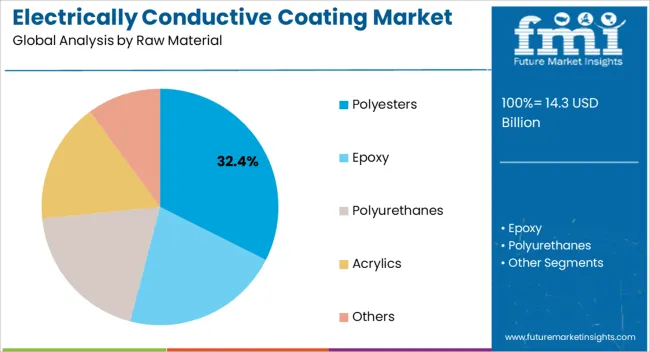

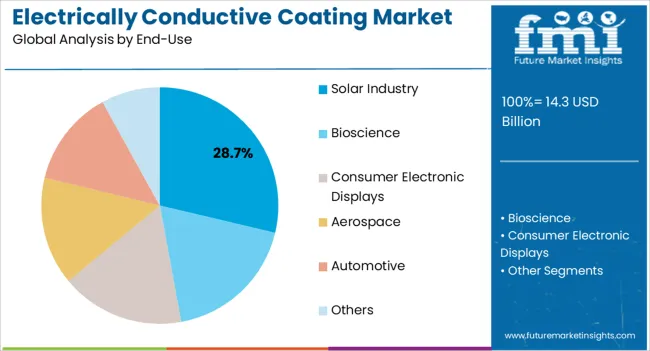

The electrically conductive coating market is segmented by raw material, end-use, and geographic regions. By raw material, electrically conductive coating market is divided into Polyesters, Epoxy, Polyurethanes, Acrylics, and Others. In terms of end-use, electrically conductive coating market is classified into Solar Industry, Bioscience, Consumer Electronic Displays, Aerospace, Automotive, and Others. Regionally, the electrically conductive coating industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The polyesters raw material segment is projected to hold 32.4% of the market revenue in 2025, making it the leading raw material type. Its growth is driven by the combination of excellent electrical conductivity, chemical resistance, and mechanical stability, which makes it suitable for diverse industrial and electronic applications. Polyesters are highly compatible with a wide range of conductive additives and fillers, allowing for customized formulations that meet specific performance requirements.

Their adaptability for use in thin-film coatings, flexible electronics, and printed circuit boards further reinforces market leadership. Manufacturing efficiency, process reliability, and cost-effectiveness are additional factors supporting adoption.

Increasing demand for lightweight, corrosion-resistant, and energy-efficient materials across industries such as electronics, automotive, and renewable energy is strengthening the position of polyesters As technological developments in conductive polymers and hybrid formulations continue, polyesters are expected to maintain their leading role in the Electrically Conductive Coating market, driven by performance consistency, versatility, and broad industrial applicability.

The solar industry end-use segment is expected to account for 28.7% of the market revenue in 2025, establishing it as the leading application area. Growth in this segment is being driven by the rising deployment of photovoltaic panels and renewable energy projects worldwide, which require coatings with excellent electrical conductivity, environmental resistance, and long-term durability. Electrically conductive coatings enable efficient current collection, improve energy conversion efficiency, and protect sensitive components against moisture, UV exposure, and thermal stress.

Increasing investments in solar infrastructure, energy storage solutions, and smart grid technologies are further supporting demand. The ability to integrate coatings into thin-film and crystalline silicon modules without compromising performance or longevity enhances adoption.

Sustainability requirements and regulations promoting renewable energy utilization have reinforced market growth As the global focus on clean energy and efficient solar power generation intensifies, the solar industry segment is expected to remain a primary driver of Electrically Conductive Coating adoption, supported by technological innovation, regulatory incentives, and rising global energy needs.

Electrically conductive coating is coating used to prevent the accumulation of static electric charges for reducing surface resistance. The global electrically conductive coatingmarket is expected to have significant growth rate, attributed to growing consumer electronic display market.

Asia-Pacific except Japan has substantial growth in the global electrically conductive coatingmarket, attributed to the growing demand for consumer electronics due to rapidly growing population and per capita income in the region, especially in China and India.

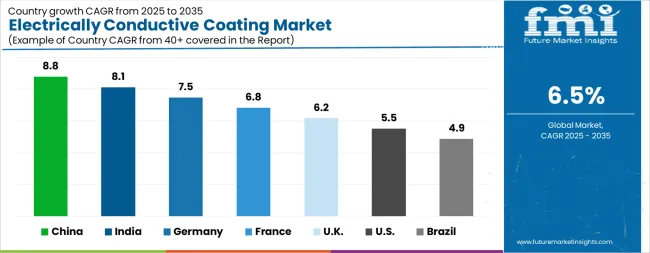

| Country | CAGR |

|---|---|

| China | 8.8% |

| India | 8.1% |

| Germany | 7.5% |

| France | 6.8% |

| UK | 6.2% |

| USA | 5.5% |

| Brazil | 4.9% |

The Electrically Conductive Coating Market is expected to register a CAGR of 6.5% during the forecast period, exhibiting varied country level momentum. China leads with the highest CAGR of 8.8%, followed by India at 8.1%. Developed markets such as Germany, France, and the UK continue to expand steadily, while the USA is likely to grow at consistent rates. Brazil posts the lowest CAGR at 4.9%, yet still underscores a broadly positive trajectory for the global Electrically Conductive Coating Market. In 2024, Germany held a dominant revenue in the Western Europe market and is expected to grow with a CAGR of 7.5%. The USA Electrically Conductive Coating Market is estimated to be valued at USD 4.9 billion in 2025 and is anticipated to reach a valuation of USD 8.4 billion by 2035. Sales are projected to rise at a CAGR of 5.5% over the forecast period between 2025 and 2035. While Japan and South Korea markets are estimated to be valued at USD 732.0 million and USD 404.5 million respectively in 2025.

| Item | Value |

|---|---|

| Quantitative Units | USD 14.3 Billion |

| Raw Material | Polyesters, Epoxy, Polyurethanes, Acrylics, and Others |

| End-Use | Solar Industry, Bioscience, Consumer Electronic Displays, Aerospace, Automotive, and Others |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

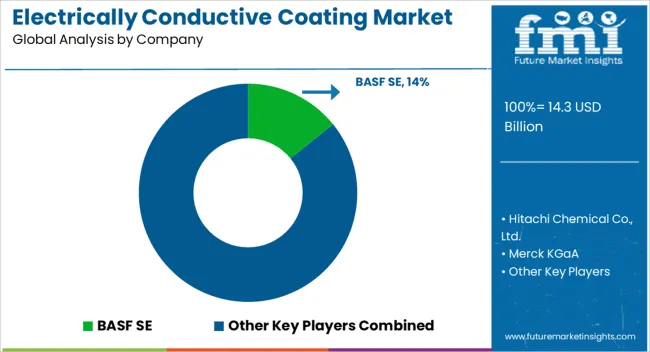

| Key Companies Profiled | BASF SE, Hitachi Chemical Co., Ltd., Merck KGaA, Heraeus Holding GmbH, DuPont de Nemours, Inc., Axalta Coating Systems, 3M, Lonza Group AG, Henkel AG KGaA, PPG Industries, Dow Chemical Company, Wacker Chemie AG, Tokuyama Corporation, AkzoNobel, and Evonik Industries AG |

The global electrically conductive coating market is estimated to be valued at USD 14.3 billion in 2025.

The market size for the electrically conductive coating market is projected to reach USD 26.9 billion by 2035.

The electrically conductive coating market is expected to grow at a 6.5% CAGR between 2025 and 2035.

The key product types in electrically conductive coating market are polyesters, epoxy, polyurethanes, acrylics and others.

In terms of end-use, solar industry segment to command 28.7% share in the electrically conductive coating market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Electrically-Driven Heavy-Duty Aerial Work Platforms Market Size and Share Forecast Outlook 2025 to 2035

Electrically Actuated Micro Robots Market Size and Share Forecast Outlook 2025 to 2035

Electrically Conductive Adhesives Market Size and Share Forecast Outlook 2025 to 2035

Conductive Adhesive Market Size and Share Forecast Outlook 2025 to 2035

Conductive Inks Market Size and Share Forecast Outlook 2025 to 2035

Conductive Polymer Packaging Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Conductive Silicone Market Size and Share Forecast Outlook 2025 to 2035

Conductive Polymers Market Size and Share Forecast Outlook 2025 to 2035

Conductive Fluted Sheets Market Size and Share Forecast Outlook 2025 to 2035

Conductive Cardboard Market Analysis - Size, Share, & Forecast Outlook 2025 to 2035

Conductive Bags Market from 2025 to 2035

Understanding Market Share Trends in Conductive Inks

Conductive Plastics Market Growth - Trends & Forecast 2025 to 2035

Conductive Foam Market Growth – Trends & Outlook 2024-2034

Conductive Fiber Market Growth – Trends & Forecast 2024-2034

Conductive Ink Printer Market Trends & Industry Growth Forecast 2024-2034

Conductive Textile Market

Conductive Polymer Coating Market Size and Share Forecast Outlook 2025 to 2035

Transparent Conductive Films Market Size and Share Forecast Outlook 2025 to 2035

Stretchable Conductive Material Analysis by Material, Fillers, Stretching Mechanism, Fabrication, Function, Application, End-User and Region - Forecast for 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA