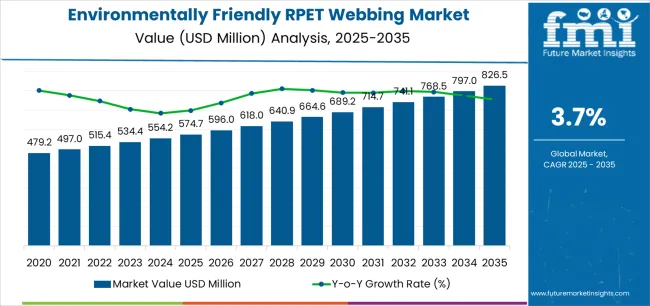

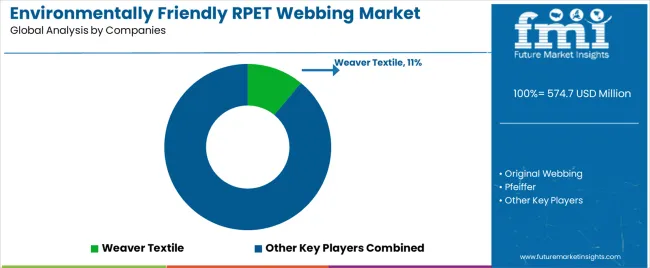

The global environmentally friendly RPET webbing market is valued at USD 574.7 million in 2025. It is slated to reach USD 826.5 million by 2035, recording an absolute increase of USD 251.8 million over the forecast period. This translates into a total growth of 43.8%, with the market forecast to expand at a CAGR of 3.7% between 2025 and 2035. The market size is expected to grow by nearly 1.44 times during the same period, supported by increasing demand for recycled textile solutions, growing adoption of circular economy principles in manufacturing sectors, and rising focus on verified recycled content across automotive, outdoor equipment, and safety gear applications.

Between 2025 and 2030, the market is projected to expand from USD 574.7 million to USD 689.2 million, resulting in a value increase of USD 114.5 million, which represents 45.5% of the total forecast growth for the decade. This phase of development will be shaped by accelerating corporate environmental commitments, rising regulatory requirements for recycled content utilization, and growing consumer demand for eco-friendly products. Automotive suppliers and outdoor equipment manufacturers are expanding their recycled material capabilities to address the growing demand for RPET webbing solutions that ensure product performance and environmental compliance.

From 2030 to 2035, the market is forecast to grow from USD 689.2 million to USD 826.5 million, adding another USD 137.3 million, which constitutes 54.5% of the ten-year expansion. This period is expected to be characterized by the expansion of circular economy initiatives with advanced recycling infrastructure, the development of next-generation RPET webbing with enhanced performance characteristics, and the growth of specialized applications in electric vehicle interiors and premium outdoor equipment lines. The growing adoption of extended producer responsibility programs and traceability systems will drive demand for RPET webbing with comprehensive verification and documented environmental benefits.

Between 2020 and 2025, the market experienced steady growth, driven by increasing environmental awareness and growing recognition of recycled textile materials as viable alternatives for traditional webbing applications across automotive, outdoor equipment, and safety gear sectors. The market developed as product designers and procurement specialists recognized the potential for RPET webbing technology to reduce environmental impact, support waste diversion objectives, and meet brand environmental commitments while maintaining product performance requirements. Technological advancement in recycling processes and fiber quality control began focusing the critical importance of maintaining mechanical properties and color consistency in recycled material applications.

| Metric | Value |

|---|---|

| Estimated Value in (2025E) | USD 574.7 million |

| Forecast Value in (2035F) | USD 826.5 million |

| Forecast CAGR (2025 to 2035) | 3.7% |

Market expansion is being supported by the increasing global demand for recycled textile solutions driven by environmental regulations and corporate environmental commitments, alongside the corresponding need for recycled content materials that can reduce carbon footprint, support waste diversion objectives, and maintain product performance across automotive, outdoor equipment, and safety applications. Modern automotive suppliers and outdoor equipment manufacturers are increasingly focused on implementing RPET webbing solutions that can demonstrate environmental benefits, meet customer expectations, and provide consistent performance in demanding applications.

The growing focus on circular economy principles and plastic waste reduction is driving demand for RPET webbing that can support recycled content targets, enable environmental product claims, and ensure comprehensive performance documentation. Industrial manufacturers' preference for recycled materials that combine environmental credentials with product reliability and cost competitiveness is creating opportunities for innovative RPET webbing implementations. The rising influence of consumer environmental awareness and brand positioning is also contributing to increased adoption of RPET webbing that can provide verifiable environmental benefits without compromising product functionality or durability requirements.

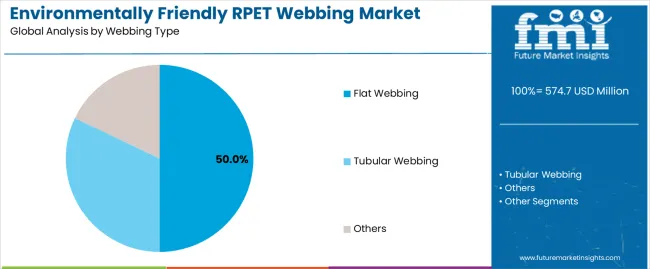

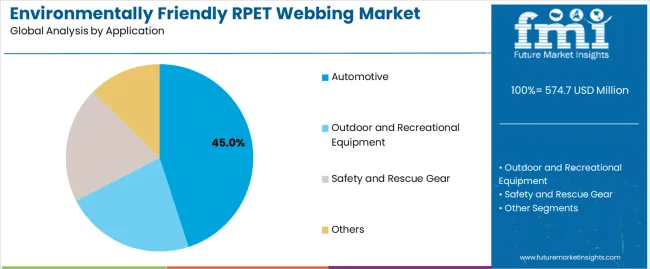

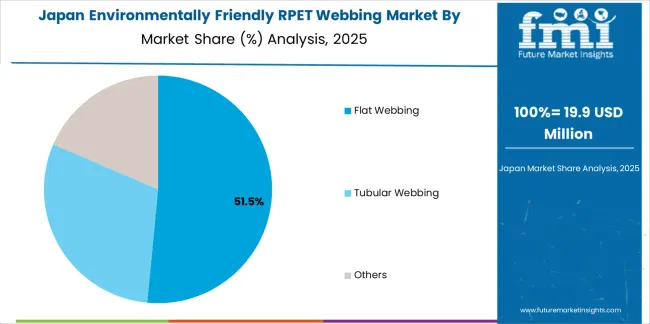

The market is segmented by webbing type, application, and region. By webbing type, the market is divided into flat webbing, tubular webbing, and others. Based on application, the market is categorized into automotive, outdoor and recreational equipment, safety and rescue gear, and others. Regionally, the market is divided into East Asia, Europe, North America, South Asia, Latin America, Middle East & Africa, and Eastern Europe.

The flat webbing segment is projected to maintain its leading position in the market with 50% market share in 2025, reaffirming its role as the preferred configuration for versatile applications across diverse industrial and consumer sectors. Automotive manufacturers and outdoor equipment producers increasingly utilize flat RPET webbing for its optimal balance between strength characteristics, production efficiency, and proven effectiveness in providing reliable performance across varying application requirements. Flat webbing technology's proven effectiveness and application versatility directly address industry requirements for recycled textile solutions and consistent performance across diverse product platforms and operational environments.

This webbing segment forms the foundation of recycled textile applications, as it represents the configuration with the greatest manufacturing efficiency and established performance record across multiple industrial applications and consumer product categories. Industrial sector investments in recycled material technologies continue to strengthen adoption among automotive suppliers and equipment manufacturers. With environmental pressures requiring verified recycled content and maintained product performance, flat RPET webbing aligns with both environmental objectives and functional requirements, making it the central component of comprehensive eco-friendly product strategies.

The automotive application segment is projected to represent the 45% market share of environmentally friendly RPET webbing demand in 2025, underscoring its critical role as the primary driver for RPET webbing adoption across seatbelt components, interior trim applications, and vehicle cargo management systems. Automotive manufacturers prefer RPET webbing for vehicle applications due to its exceptional environmental credentials, comparable performance to virgin materials, and ability to support corporate environmental targets while meeting automotive qualification requirements and safety compliance. Positioned as essential materials for eco-friendly automotive production, RPET webbing offers both environmental advantages and performance reliability.

The segment is supported by continuous innovation in automotive materials and the growing availability of qualified RPET webbing grades that enable superior product performance with verified environmental benefits and automotive specification compliance. Automotive manufacturers are investing in comprehensive recycled material programs to support increasingly stringent corporate environmental commitments and consumer demand for eco-friendly vehicles. As automotive environmental standards accelerate and requirements increase, the automotive application will continue to dominate the market while supporting advanced recycled materials integration and circular economy strategies.

The environmentally friendly RPET webbing market is advancing steadily due to increasing demand for recycled textile solutions driven by environmental regulations and growing adoption of circular economy principles that require recycled content materials providing verified environmental benefits and comparable performance characteristics across automotive, outdoor equipment, and safety applications. The market faces challenges, including supply consistency concerns for quality recycled PET feedstock, price competitiveness compared to virgin polyester webbing, and performance perception barriers despite comparable technical specifications. Innovation in advanced recycling technologies and quality assurance systems continues to influence product development and market expansion patterns.

The growing adoption of corporate environmental programs is driving demand for verified recycled content materials that address specific responsibility requirements including carbon footprint reduction, plastic waste diversion, and documented environmental impact improvements. Automotive and consumer product applications require qualified RPET webbing solutions that deliver superior environmental credentials across multiple metrics while maintaining cost-effectiveness and performance reliability. Brand managers are increasingly recognizing the competitive advantages of RPET webbing integration for market positioning and stakeholder expectations, creating opportunities for innovative recycled material solutions specifically designed for high-visibility environmental applications.

Modern RPET webbing manufacturers are incorporating advanced recycling processes and comprehensive quality control technologies to enhance fiber consistency, improve color stability, and support product reliability through optimized material processing and testing protocols. Leading companies are developing enhanced recycling methods with contaminant removal, implementing automated quality inspection systems, and advancing production technologies that ensure consistent material properties and performance characteristics. These technologies improve product reliability while enabling new market opportunities, including premium automotive applications, high-performance outdoor equipment, and safety-critical gear components. Advanced manufacturing integration also allows manufacturers to support comprehensive quality assurance objectives and product differentiation beyond traditional environmental attributes.

The expansion of environmental reporting requirements and consumer transparency expectations is driving demand for RPET webbing with verified recycled content certification, comprehensive supply chain traceability, and documented environmental impact assessments. These demanding requirements create specialized market segments with transparent sourcing documentation and third-party verification, establishing premium value propositions. Manufacturers are investing in certification programs and traceability systems to serve environmentally conscious brands while supporting innovation in recycled textiles and circular economy implementation.

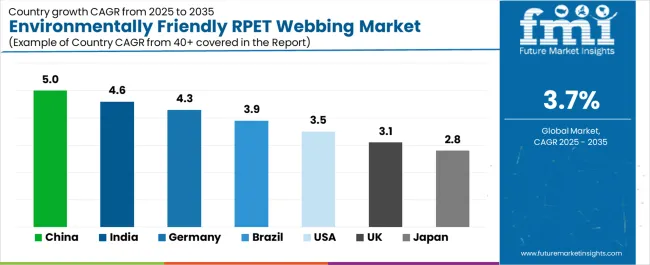

| Country | CAGR (2025-2035) |

|---|---|

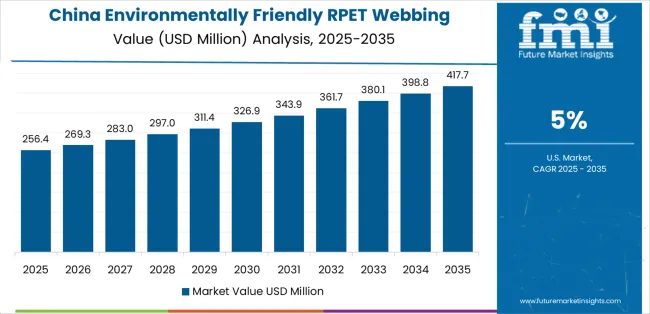

| China | 5.0% |

| India | 4.6% |

| Germany | 4.3% |

| Brazil | 3.9% |

| United States | 3.5% |

| United Kingdom | 3.1% |

| Japan | 2.8% |

The market is experiencing solid growth globally, with China leading at a 5.0% CAGR through 2035, driven by massive textile manufacturing capacity, expanding recycling infrastructure, and growing domestic and export demand for recycled textile products. India follows at 4.6%, supported by growing textile industry sophistication, expanding recycled materials processing capabilities, and increasing focus on eco-friendly manufacturing practices. Germany shows growth at 4.3%, focusing automotive industry environmental requirements, circular economy leadership, and advanced recycled material adoption. Brazil demonstrates 3.9% growth, supported by textile industry development, growing environmental awareness, and automotive sector expansion. The United States records 3.5%, focusing on corporate environmental initiatives, consumer preferences, and recycled content regulations. The United Kingdom exhibits 3.1% growth, focusing eco-friendly product standards and circular economy programs. Japan shows 2.8% growth, supported by environmental consciousness and quality-focused recycled material adoption.

The report covers an in-depth analysis of 40+ countries, top-performing countries are highlighted below.

China is projected to exhibit exceptional growth with a CAGR of 5.0% through 2035, driven by massive textile manufacturing capacity and rapidly expanding recycling infrastructure supported by government environmental initiatives and circular economy development programs. The country's comprehensive textile industry ecosystem and increasing environmental focus are creating substantial demand for RPET webbing solutions. Major textile manufacturers and webbing producers are establishing comprehensive recycled material production capabilities to serve both domestic markets and global export opportunities.

India is expanding at a CAGR of 4.6%, supported by growing textile industry sophistication, expanding recycled materials processing infrastructure, and increasing focus on eco-friendly manufacturing practices driven by export market requirements and domestic environmental awareness. The country's comprehensive textile sector development and increasing environmental consciousness are driving sophisticated RPET webbing capabilities throughout manufacturing regions. Leading textile companies and webbing manufacturers are establishing production facilities to address growing domestic and export demand.

Germany is expanding at a CAGR of 4.3%, supported by the country's automotive industry environmental requirements, circular economy leadership, and strong focus on environmental standards and eco-friendly product development. The nation's automotive excellence and environmental consciousness are driving sophisticated RPET webbing capabilities throughout industrial sectors. Leading automotive suppliers and textile manufacturers are investing extensively in recycled material technologies and circular economy programs.

Brazil is expanding at a CAGR of 3.9%, supported by the country's textile industry development, growing environmental awareness, and increasing automotive sector demand for recycled materials driven by corporate environmental commitments. The nation's textile manufacturing growth and environmental consciousness development are driving demand for recycled textile solutions. Textile producers and automotive suppliers are investing in recycled material capabilities to support market requirements.

The United States is expanding at a CAGR of 3.5%, supported by the country's corporate environmental leadership, strong consumer preferences for eco-friendly products, and growing regulatory focus on recycled content utilization. The nation's comprehensive environmental programs and consumer awareness are driving demand for verified recycled materials. Automotive manufacturers and outdoor equipment brands are investing in recycled material sourcing to support brand commitments.

The United Kingdom is expanding at a CAGR of 3.1%, driven by the country's eco-friendly product standards, circular economy initiatives, and focus on environmental responsibility and waste reduction objectives. The UK's environmental leadership and regulatory frameworks are driving RPET webbing adoption throughout manufacturing sectors. Automotive suppliers and outdoor equipment manufacturers are establishing recycled material sourcing capabilities for regulatory compliance.

Japan is expanding at a CAGR of 2.8%, supported by the country's environmental consciousness, quality-focused manufacturing excellence, and strong focus on product reliability and environmental integration. Japan's technological sophistication and environmental awareness are driving demand for high-quality RPET webbing products. Leading manufacturers are investing in recycled material capabilities for quality-conscious applications.

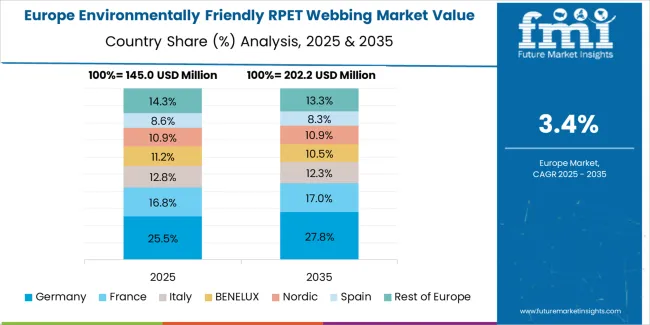

The environmentally friendly RPET webbing market in Europe is projected to grow from USD 156.4 million in 2025 to USD 218.7 million by 2035, registering a CAGR of 3.4% over the forecast period. Germany is expected to maintain leadership with a 28.9% market share in 2025, moderating to 28.3% by 2035, supported by automotive industry environmental leadership, circular economy excellence, and advanced recycled material adoption.

France follows with 20.6% in 2025, projected at 21.2% by 2035, driven by automotive environmental programs, outdoor equipment manufacturing, and environmental regulation compliance. The United Kingdom holds 17.1% in 2025, reaching 16.8% by 2035 on the back of circular economy initiatives and eco-friendly product standards. Italy commands 13.8% in 2025, rising slightly to 14.2% by 2035, while Spain accounts for 9.2% in 2025, reaching 9.6% by 2035 aided by textile industry development and automotive component manufacturing. The Netherlands maintains 4.6% in 2025, up to 4.9% by 2035 due to circular economy leadership and eco-friendly logistics applications. The Rest of Europe region, including Nordic countries, Central & Eastern Europe, and other markets, is anticipated to hold 5.8% in 2025 and 5.0% by 2035, reflecting steady development in eco-friendly manufacturing and circular economy programs.

The market is characterized by competition among established webbing manufacturers, specialized recycled textile producers, and regional recycled materials companies. Companies are investing in recycling technology development, quality control system enhancement, certification program participation, and verified supply chain development to deliver high-performance, environmentally responsible, and cost-effective RPET webbing solutions. Innovation in advanced recycling processes, fiber quality optimization, and comprehensive environmental verification is central to strengthening market position and competitive advantage.

Weaver Textile offers comprehensive RPET webbing solutions with focus on automotive applications, quality consistency, and extensive product range across diverse industrial and consumer applications. Original Webbing provides recycled webbing products with focus on outdoor equipment markets and environmental certification. Pfeiffer delivers engineered webbing solutions for specialized industrial applications with verified recycled content. Huida Webbing offers versatile RPET webbing products with focus on manufacturing efficiency and quality control. Eternes Industry & Development specializes in recycled textile solutions for diverse market segments.

National Webbing Products provides comprehensive webbing solutions with recycled material options. Strapworks offers consumer-focused RPET webbing products with focus on retail markets. Jude Webbing focuses on industrial applications and customized solutions. BOLIN WEBBING specializes in automotive-grade recycled webbing. Qiheng Weaves delivers quality-focused RPET webbing for demanding applications. ChangYe Webbing provides comprehensive recycled webbing solutions. ACW offers specialized industrial webbing products. Fuwei focuses on export-oriented recycled webbing manufacturing.

Environmentally friendly RPET webbing represents a recycled textile materials segment within industrial and consumer applications, projected to grow from USD 574.7 million in 2025 to USD 826.5 million by 2035 at a 3.7% CAGR. These recycled content textile products primarily comprising flat and tubular webbing configurations serve as essential eco-friendly materials in automotive, outdoor equipment, and safety applications where environmental responsibility, performance reliability, and verified recycled content are essential. Market expansion is driven by increasing corporate environmental commitments, growing circular economy adoption, expanding recycled content regulations, and rising consumer demand for environmentally responsible products across diverse industrial and consumer segments.

| Items | Values |

|---|---|

| Quantitative Units (2025) | USD 574.7 million |

| Webbing Type | Flat Webbing, Tubular Webbing, Others |

| Application | Automotive, Outdoor and Recreational Equipment, Safety and Rescue Gear, Others |

| Regions Covered | East Asia, Europe, North America, South Asia, Latin America, Middle East & Africa, Eastern Europe |

| Countries Covered | China, India, Germany, Brazil, United States, United Kingdom, Japan, and 40+ countries |

| Key Companies Profiled | Weaver Textile, Original Webbing, Pfeiffer, Huida Webbing, Eternes Industry & Development |

| Additional Attributes | Dollar sales by webbing type and application category, regional demand trends, competitive landscape, technological advancements in recycling processes, environmental certification development, circular economy integration, and environmental performance optimization |

The global environmentally friendly RPET webbing market is estimated to be valued at USD 574.7 million in 2025.

The market size for the environmentally friendly RPET webbing market is projected to reach USD 826.5 million by 2035.

The environmentally friendly RPET webbing market is expected to grow at a 3.7% CAGR between 2025 and 2035.

The key product types in environmentally friendly RPET webbing market are flat webbing, tubular webbing and others.

In terms of application, automotive segment to command 45.0% share in the environmentally friendly RPET webbing market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Eco-friendly Tea Packaging Market Size and Share Forecast Outlook 2025 to 2035

Eco Friendly Laundry Product Market Size and Share Forecast Outlook 2025 to 2035

Eco-friendly Beneficiation Reagents Market Size and Share Forecast Outlook 2025 to 2035

Eco-friendly Precious Metal Beneficiation Reagents Market Forecast and Outlook 2025 to 2035

Eco-friendly Bottle Market Forecast and Outlook 2025 to 2035

Eco-Friendly Inks Market Size and Share Forecast Outlook 2025 to 2035

Eco-friendly Toys Market Size and Share Forecast Outlook 2025 to 2035

Eco-Friendly Straws Market Growth - Demand & Forecast 2025 to 2035

Eco-friendly Paper Plates Market Insights - Trends & Future Outlook 2025 to 2035

Market Share Distribution Among Eco-Friendly Candle Manufacturers

Understanding Eco-Friendly Inks Market Share Trends

Eco-friendly Candle Market Report – Demand & Trends 2024-2034

Eco-Friendly Plasticizers Market

Keto Friendly Flavors Market

Senior Friendly Packaging Market Size, Share & Forecast 2025 to 2035

Non-eco-friendly Precious Metal Beneficiation Reagents Market Forecast and Outlook 2025 to 2035

Webbing Cutting Machine Market Size and Share Forecast Outlook 2025 to 2035

Nylon Webbing Market Size and Share Forecast Outlook 2025 to 2035

Tubular Webbing Market Size and Share Forecast Outlook 2025 to 2035

Flat Nylon Webbing Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA