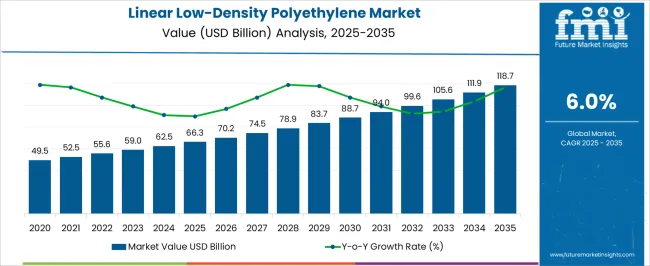

The Linear Low Density Polyethylene Market is estimated to be valued at USD 48.6 billion in 2025 and is projected to reach USD 75.5 billion by 2035, registering a compound annual growth rate (CAGR) of 4.5% over the forecast period.

| Metric | Value |

|---|---|

| Linear Low Density Polyethylene Market Estimated Value in (2025 E) | USD 48.6 billion |

| Linear Low Density Polyethylene Market Forecast Value in (2035 F) | USD 75.5 billion |

| Forecast CAGR (2025 to 2035) | 4.5% |

The linear low density polyethylene market is experiencing steady growth, driven by its versatile applications across packaging, films, and consumer goods. Rising global demand for lightweight, durable, and flexible polymer solutions is enhancing adoption in multiple industries, particularly in packaging where material efficiency and cost-effectiveness are critical. The market growth is being supported by advancements in polymerization technologies that allow precise control over density, molecular weight, and processing properties.

Increasing focus on sustainability, recyclability, and energy-efficient production processes is influencing market dynamics, while industrial expansion in emerging economies is creating new opportunities for manufacturers. Gas phase, solution, and slurry polymerization processes are being optimized to improve product performance and reduce operational costs.

Growing demand for LDPE in high-performance films, consumer packaging, and industrial applications is also reinforcing market momentum As industries continue to prioritize lightweight and flexible materials for logistics, storage, and protection, linear low density polyethylene is expected to maintain its relevance, with continuous innovation and process optimization shaping its future growth trajectory.

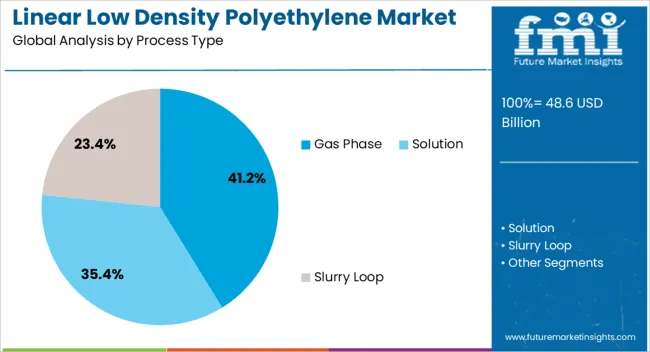

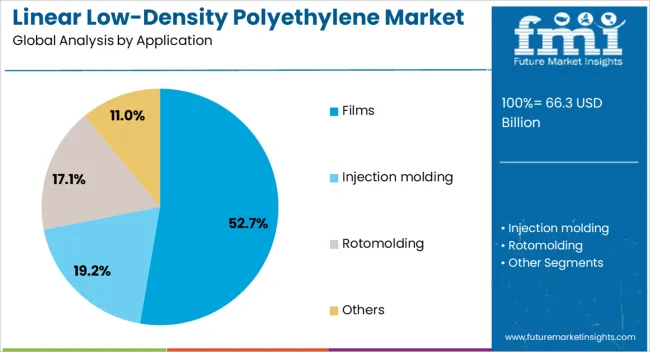

The linear low density polyethylene market is segmented by process type, application, end-use industry, and geographic regions. By process type, linear low density polyethylene market is divided into Gas Phase, Solution, and Slurry Loop. In terms of application, linear low density polyethylene market is classified into Films, Injection Molding, Rotomolding, Pipes & Cables, and Others.

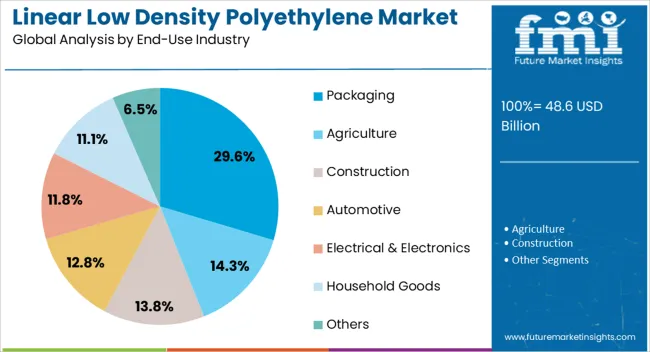

Based on end-use industry, linear low density polyethylene market is segmented into Packaging, Agriculture, Construction, Automotive, Electrical & Electronics, Household Goods, and Others. Regionally, the linear low density polyethylene industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The gas phase process type segment is projected to hold 41.2% of the linear low density polyethylene market revenue share in 2025, making it the leading process type. This dominance is being driven by the process’s ability to offer precise control over polymer chain structure, resulting in consistent density, mechanical properties, and melt index.

The gas phase process enables the production of high-quality LLDPE with improved tensile strength and flexibility, which is essential for high-performance packaging films and industrial applications. Operational efficiency, energy savings, and scalability make it a preferred choice for large-scale production.

Additionally, this process allows for the incorporation of advanced comonomers to improve impact resistance and elongation, further enhancing product performance As manufacturers focus on producing versatile polyethylene grades that meet specific application requirements while maintaining cost efficiency, the gas phase segment is expected to retain its leading position, supported by widespread adoption across global production facilities and increasing demand in emerging markets.

The films application segment is anticipated to account for 25.7% of the linear low density polyethylene market revenue share in 2025, establishing it as the leading application area. This growth is being fueled by the increasing demand for flexible packaging solutions, agricultural films, and protective coverings. Linear low density polyethylene is being leveraged for films because of its superior clarity, tensile strength, puncture resistance, and sealability, which are critical for high-quality packaging and barrier applications.

The segment is further supported by the trend toward lightweight, cost-effective materials that reduce logistics and material costs without compromising product protection. Continuous innovation in film extrusion techniques and multilayer structures is enabling enhanced performance for industrial and consumer applications.

Adoption is also being reinforced by regulatory focus on safe and sustainable packaging materials, as LLDPE films offer recyclability and compatibility with circular economy initiatives The versatility and performance of LLDPE films ensure that this application segment remains a dominant driver of market revenue.

The packaging end-use industry is projected to hold 29.6% of the linear low density polyethylene market revenue share in 2025, making it the largest end-use industry segment. This leadership is being driven by the global expansion of consumer goods, food, and logistics industries that rely on lightweight, durable, and flexible packaging solutions.

Linear low density polyethylene is preferred for packaging due to its excellent impact resistance, elongation, and sealability, which protect goods during storage and transportation. The segment is further supported by trends in convenience packaging, sustainable material use, and demand for high-quality printed films for branding and information display.

Increasing urbanization, rising e-commerce penetration, and regulatory emphasis on safe, recyclable packaging are reinforcing adoption Manufacturers are leveraging LLDPE to produce cost-efficient, high-performance packaging that meets diverse consumer and industrial needs, making this end-use industry a significant contributor to overall market growth and revenue.

The demand for linear low density polyethylene is likely to increase in the paper & paperboard packaging industry during the forecast period. The key players are using linear low density polyethylene to build traditional applications such as toys, flexible tubes, sheets, geomembranes and plastic bags.

Linear low density polyethylene is produced with low pressure by key manufacturers. In addition, this polyethylene is widely used to protect liquid containers and other paper packaging things are likely to increase the linear low density polyethylene market share during the forecast period.

The global LLDPE market size is rapidly rising with the growing food packaging sector. In addition, the key manufacturers in the food packaging sector are growing the market by consuming a large quantity of linear low density polyethylene such as for takeaway of food by consumers or for online delivery of food.

These linear low density polyethylene are also manufactured by key manufacturing companies for medical packaging products, and coating is likely to increase the sales of linear low density polyethylene in recent years.

North America is leading the global linear low density polyethylene market size by dominating the market during the forecast period. The key manufacturers in the countries such as Canada, US, Brazil and China are surging the market by capturing a higher share in the global market during the foreseen time.

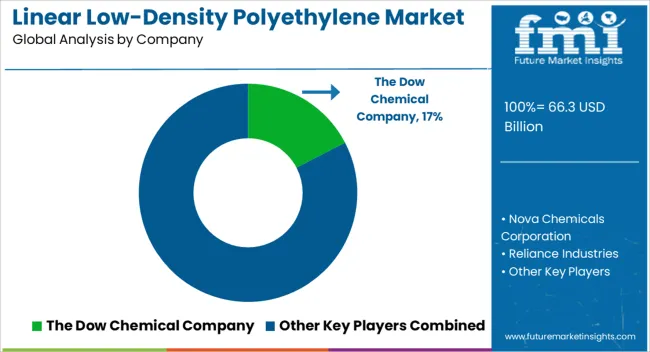

Some of the key manufacturing companies in the LLDPE market are Borealis, Braskem SA, Chevron Phillip Chemical Co., DuPont, ExxonMobil Chemical, INEOS Group, PetroChina, Nova Chemicals, and Dow Chemical Company.

The essential key players are focusing on product quality. Consumers demand increased production, which is likely to rise the linear low density polyethylene market statistics during the forecast period. They are using their skill set of methodologies and innovations to upsurge the market size by acquiring the lion’s share in the coming years.

Some of their marketing tactics are mergers, product launches, acquisitions, partnerships, growth strategies, R&D activities, and agreements, among others. In a recent development, in 2025, Borealis expanded its healthcare services with its customized boomed polymers.

The main motto behind these polymers is to target healthcare products with their soft polypropylene quality and high density. These customized products are highly recommended by the healthcare sector due to their reliability and master batches. These players are contributing a significant share to increase the global linear low density polyethylene market growth in the coming years.

Linear low density polyethylene (LLDPE) is a linear polymer with various short branches, usually made by copolymerization of ethylene with long-chain olefins. It differs from the conventional LDPE (low density polyuethylene) owing to the absence of long chain branching. LLDPE is generally produced at low pressures and temperatures with the copolymerization of ethylene with alpha-olefins such as octene, hexene, and butene.

LLDPE is applied in the all the traditional applications for polyethylene such as sheets and plastic bags, covers, toys, flexible tubing and geomembranes. It is also used in extrusion coating applications where it protects the contents of liquid containers, usually for paper & paperboard packaging.

The global market for LLDPE is anticipated to witness stable growth in the years ahead, on account of increasing LLDPE capacity additions planned worldwide along with the constantly rising demand for the product. In addition, growing population compounded with increasing food demand has also contributed towards the growth of LLDPE market in food packaging.

Much of the growth in LLDPE has been due to the replacement of low density polyethylene (LDPE) and is slowly overtaking LDPE in terms of market size to be the second largest polyethylene (PE) after high density polyethylene (HDPE).

While the expansion of LDPE markets appears to have accomplished in matured regions such as Western Europe, North America and Japan, the introduction of easy processing LLDPE is expected to result in further substitution of LDPE. Further penetration of LLDPE into LDPE applications is expected to continue in emerging economies such as China.

The industry for LLDPE has been gaining importance on account of its higher tensile strength, superior impact and puncture resistance than its substitute LDPE. Owing to this, manufacturers have started making thinner films while reducing costs and saving materials.

LLDPEs’ superior toughness property relative to other products has also widened its application scope. Most of the LLDPE on a global scale is consumed in different film applications such as food and non-food packaging, stretch/shrink film and non-packaging uses. Growth is also occurring from the transition of commodities packed in rigid containers to high quality flexible packages.

Growth in major end-user industries such as construction and packaging is expected to be one of the key factors driving the demand for LLDPE over the next few years. LLDPE is widely consumed in food packaging, flexible tubing, geomembranes, as well as covering of cables among others. However, growing environmental regulations regarding the use of plastics is expected to hamper the growth of the market. Increasing use of LLDPE in coatings and packaging for medical products is expected to provide new opportunities for the growth of the market.

North America was the largest consumer for LLDPE, followed by Asia Pacific. Economies such as Canada, Brazil, China and the U.S. are some of the top manufacturers for LLDPE in the world. Future market is expected to be from Asia Pacific owing to growing demand for food and rising industrial activities in the coating industry.

Borealis, Braskem SA, Chevron Phillip Chemical Co., DuPont, ExxonMobil Chemical, INEOS Group, PetroChina, Nova Chemicals, and The Dow Chemical Company are some of the major manufacturers of LLDPE dominating the market.

The research report presents a comprehensive assessment of the market and contains thoughtful insights, facts, historical data, and statistically supported and industry-validated market data. It also contains projections using a suitable set of assumptions and methodologies. The research report provides analysis and information according to categories such as market segments, geographies, types and applications.

The report is a compilation of first-hand information, qualitative and quantitative assessment by industry analysts, inputs from industry experts, and industry participants across the value chain.

The report provides an in-depth analysis of parent market trends, macroeconomic indicators and governing factors, along with market attractiveness within the segments. The report also maps the qualitative impact of various market factors on market segments and various geographies.

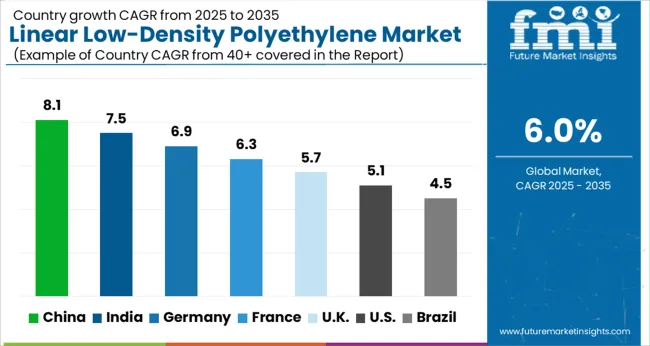

| Country | CAGR |

|---|---|

| China | 6.1% |

| India | 5.6% |

| Germany | 5.2% |

| France | 4.7% |

| UK | 4.3% |

| USA | 3.8% |

| Brazil | 3.4% |

The Linear Low Density Polyethylene Market is expected to register a CAGR of 4.5% during the forecast period, exhibiting varied country level momentum. China leads with the highest CAGR of 6.1%, followed by India at 5.6%. Developed markets such as Germany, France, and the UK continue to expand steadily, while the USA is likely to grow at consistent rates. Brazil posts the lowest CAGR at 3.4%, yet still underscores a broadly positive trajectory for the global Linear Low Density Polyethylene Market. In 2024, Germany held a dominant revenue in the Western Europe market and is expected to grow with a CAGR of 5.2%. The USA Linear Low Density Polyethylene Market is estimated to be valued at USD 17.4 billion in 2025 and is anticipated to reach a valuation of USD 25.3 billion by 2035. Sales are projected to rise at a CAGR of 3.8% over the forecast period between 2025 and 2035. While Japan and South Korea markets are estimated to be valued at USD 2.6 billion and USD 1.3 billion respectively in 2025.

| Item | Value |

|---|---|

| Quantitative Units | USD 48.6 Billion |

| Process Type | Gas Phase, Solution, and Slurry Loop |

| Application | Films, Injection Molding, Rotomolding, Pipes & Cables, and Others |

| End-Use Industry | Packaging, Agriculture, Construction, Automotive, Electrical & Electronics, Household Goods, and Others |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled | Nova Chemicals Corporation, Reliance Industries, LyondeBassells Industries N.V, Saudi Basic Industries Corporation (SABIC), CNPC, China Petroleum & Chemical Corporation (Sinopec Corporation), Exxon Mobil Corporation, Borealis AG, Mitsui and Westlake, Sasol Limited, Chevron Phillips Chemical Company LLC, Mitsubishi Chemicals, Braskem S.A, The Dow Chemical Company, Basell, and INEOS Group AG |

The global linear low density polyethylene market is estimated to be valued at USD 48.6 billion in 2025.

The market size for the linear low density polyethylene market is projected to reach USD 75.5 billion by 2035.

The linear low density polyethylene market is expected to grow at a 4.5% CAGR between 2025 and 2035.

The key product types in linear low density polyethylene market are gas phase, solution and slurry loop.

In terms of application, films segment to command 25.7% share in the linear low density polyethylene market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Linear Low-Density Polyethylene Market Size and Share Forecast Outlook 2025 to 2035

Linear Regulator ICs (LDOs) Market Forecast and Outlook 2025 to 2035

Linear Alkylbenzene Sulfonate (LAS) Market Size and Share Forecast Outlook 2025 to 2035

Linear Slide Units Market Size and Share Forecast Outlook 2025 to 2035

Linear Residential Voltage Regulator Market Size and Share Forecast Outlook 2025 to 2035

Linear Net Weighing Machines Market Size and Share Forecast Outlook 2025 to 2035

Linear Alpha Olefin Market

Linear Voltage Regulators Market

Linear Actuators Market

Linear Slides Market

Linear Bearings Market

Non-Linear Optical Polymers Market Trend Analysis Based on Product, Application, and Region 2025 to 2035

Electric Linear Actuator Market Trends – Growth & Forecast 2025 to 2035

Industrial Linear Accelerator Market Growth & Demand 2025 to 2035

Low Alloy Steels Powder Market Size and Share Forecast Outlook 2025 to 2035

Low Alkali Cement Market Size and Share Forecast Outlook 2025 to 2035

Low Vibration Thermostat Market Size and Share Forecast Outlook 2025 to 2035

Low-Level Order Picker Pallet Truck Market Size and Share Forecast Outlook 2025 to 2035

Low Voltage Components Market Size and Share Forecast Outlook 2025 to 2035

Low Temperature Flexible Tester Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA