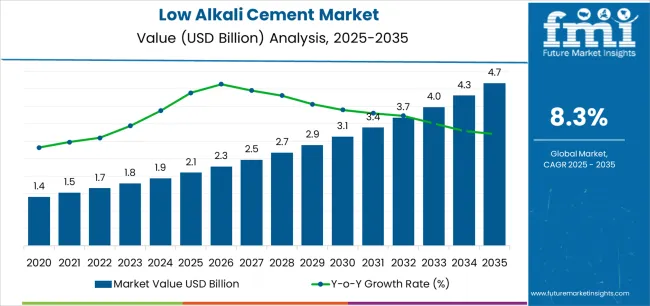

The low alkali cement market is set to grow from USD 2.1 billion in 2025 to USD 4.7 billion by 2035, reflecting a CAGR of 8.3%. This growth is driven by increasing demand for sustainable construction materials, as low alkali cement offers reduced environmental impact compared to traditional cement products. The growing awareness of environmental concerns, particularly regarding the alkali-silica reaction (ASR) in concrete, will push the adoption of low alkali cement, which minimizes this risk. As global construction activity increases, particularly in emerging economies, the need for durable and eco-friendly building materials will further propel market growth.

In addition to sustainability, low alkali cement's ability to provide enhanced performance in high-strength concrete applications makes it particularly attractive for infrastructure and commercial construction projects. The development of new formulations to improve the cost-effectiveness and performance of low alkali cement will also contribute to its market expansion. With governments worldwide focusing on green building initiatives and enforcing stricter environmental regulations, the market is expected to see increasing demand for low carbon footprint cement solutions, creating a favorable environment for market players to innovate and capture new opportunities.

From 2025 to 2030, the market is projected to grow from USD 2.1 billion to USD 2.8 billion, reflecting a USD 700 million increase. This growth is primarily driven by the rising demand for sustainable construction and the increasing adoption of low alkali cement in residential, commercial, and infrastructure projects. As awareness of environmental concerns continues to grow, construction companies will increasingly turn to low alkali cement to meet regulatory requirements and consumer preferences for green building materials.

Between 2030 and 2035, the market is expected to expand from USD 2.8 billion to USD 4.7 billion, adding USD 1.8 billion in value. This phase will be marked by heightened demand for low alkali cement in large-scale infrastructure projects, particularly in regions with stringent sustainability requirements. The growing emphasis on green construction technologies and eco-friendly building standards will drive this surge. Additionally, innovations in cement formulations and the growing preference for high-performance materials in construction will ensure continued market growth, positioning low alkali cement as a key material for the future of sustainable building.

| Metric | Value |

|---|---|

| Market Value (2025) | USD 2.1 billion |

| Market Forecast Value (2035) | USD 4.7 billion |

| Forecast CAGR (2025 to 2035) | 8.3% |

The low alkali cement market is experiencing robust growth, driven by several key factors. First, the increasing demand for high-performance materials in infrastructure projects is a primary driver. Low alkali cement, due to its enhanced durability, is preferred for use in water conservancy projects, marine structures, and highway construction, all of which require long-lasting, chemically resistant materials. The growing need for sustainable construction solutions further supports the market, as low alkali cement contributes to longer-lasting infrastructure and reduced maintenance costs over time, which aligns with global sustainability goals.

The rapid expansion of infrastructure development in emerging economies such as China, India, and Brazil is driving demand. These countries are investing heavily in water dams, highways, railways, and ports, where the benefits of low alkali cement in harsh environments—such as exposure to seawater or industrial effluents—are crucial. The market is also being fueled by technological advancements in cement manufacturing, allowing for better quality control and more efficient production of low alkali variants. The increasing awareness of environmental regulations and the push for eco-friendly construction materials further encourage the adoption of low alkali cement, which is seen as a more sustainable alternative to traditional cement products.

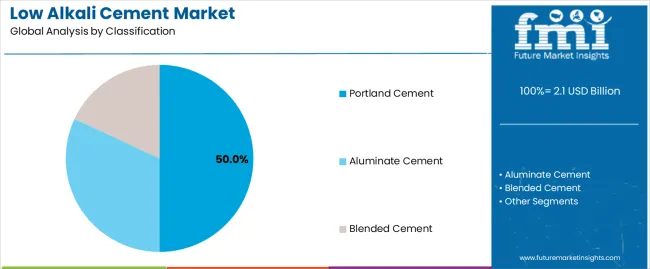

The low alkali cement market is segmented by classification, application, and region. By classification, the market is primarily divided into Portland Cement, Aluminate Cement, and Blended Cement. Portland Cement is the dominant segment, accounting for 50% of the market share, owing to its widespread use in various construction projects due to its cost-effectiveness and availability. Aluminate Cement and Blended Cement also contribute to the market, with Blended Cement gaining traction due to its sustainability and better environmental performance.

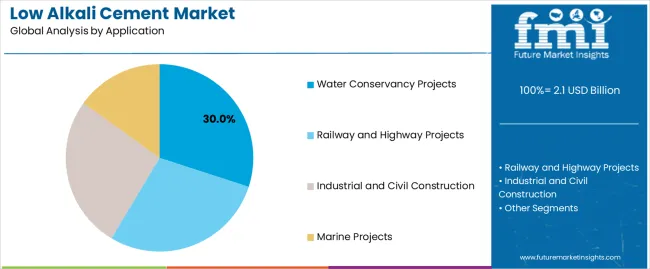

By application, the market is segmented into Water Conservancy Projects, Railway and Highway Projects, Industrial and Civil Construction, and Marine Projects. The Water Conservancy Projects segment holds the largest share, accounting for 30% of the market, driven by the global need for water infrastructure such as dams, reservoirs, and irrigation systems. Railway and Highway Projects and Marine Projects also show strong demand due to the long-lasting and durable nature of low alkali cement, which is essential in harsh environmental conditions. Industrial and Civil Construction further contributes to the market as demand grows for high-performance, durable materials in commercial and residential buildings.

The Portland Cement segment is the dominant classification in the Low Alkali Cement Market, holding around 50% of the market share. Portland cement is the most widely used type of cement globally, particularly in infrastructure and building projects. Its popularity is due to its well-established manufacturing process, cost-effectiveness, and proven performance. In low alkali formulations, Portland cement offers enhanced durability and resistance to chemical attack, making it ideal for use in infrastructure that is exposed to harsh environments such as seawater and industrial effluents.

Additionally, the global demand for sustainable construction materials is increasing the demand for Portland Cement, especially variants with lower alkali content that provide longer-lasting infrastructure with reduced maintenance needs. The combination of cost-effectiveness, durability, and sustainability makes Portland cement a preferred choice for a wide range of construction projects.

The water conservancy projects segment is the leading application in the low alkali cement market, capturing approximately 30% of the market share. Water infrastructure, such as dams, reservoirs, and irrigation systems, requires cement that can withstand extreme environmental conditions, including exposure to water, chemical pollutants, and fluctuating weather patterns. Low alkali cement is the preferred choice due to its superior resistance to alkali-silica reactions (ASR) and corrosion. These properties make it essential in ensuring the durability and long lifespan of critical water infrastructure.

The growing demand for water storage and conservation systems in regions experiencing water scarcity or extreme weather events further drives the need for low alkali cement. As the world faces increasing challenges related to water management, the demand for sustainable and resilient infrastructure will continue to make the water conservancy segment the leading driver of market growth.

The Low Alkali Cement Market is driven by the increasing demand for durable, high-performance construction materials, especially in infrastructure projects such as water conservancy, railways, highways, and marine constructions. The need for sustainable and eco-friendly building materials is pushing the market toward low alkali cement, which offers superior durability and chemical resistance in harsh environmental conditions. Growth is further fueled by infrastructure development in emerging economies like China, India, and Brazil, where the demand for durable cement for large-scale projects is high. However, market growth is tempered by the higher cost of low alkali cement compared to traditional alternatives, which may restrict adoption in price-sensitive markets. Additionally, the market is experiencing increasing interest in blended cements as a more sustainable alternative. With technological advancements in cement production and a continued push for green construction, the low alkali cement market is expected to grow steadily, driven by both demand for durable infrastructure and eco-friendly regulations.

The Low Alkali Cement Market is primarily driven by the increasing demand for durable, high-performance materials used in critical infrastructure projects such as water conservancy, highways, railways, and marine constructions. Low alkali cement offers superior resistance to chemical attacks and alkali-silica reactions, making it ideal for projects exposed to harsh environmental conditions like seawater, industrial waste, and high humidity. The growing focus on sustainable construction also acts as a key driver, as low alkali cement contributes to longer-lasting infrastructure and lower maintenance costs. The demand for eco-friendly building materials is also encouraging the adoption of low alkali formulations, which offer better environmental performance compared to traditional cement. Additionally, infrastructure development in emerging markets like China, India, and Brazil, where large-scale projects are underway, is expected to increase the demand for low alkali cement in the coming years.

While the Low Alkali Cement Market is expanding, several factors are hindering its full growth potential. The primary restraint is the cost of low alkali cement, which can be more expensive compared to traditional cement products. This price difference can be a barrier for price-sensitive consumers, particularly in developing markets where cost optimization is crucial. Additionally, the complex manufacturing processes involved in producing low alkali cement may limit its adoption in certain regions. The limited availability of high-quality raw materials required for its production can also pose a challenge for manufacturers. While the demand for sustainable and high-performance cement is rising, local regulations, infrastructure development policies, and economic slowdowns in key markets can also slow down market growth.

The Low Alkali Cement Market is witnessing several important trends that are shaping its future. Sustainability is a major driver, with an increasing preference for green construction materials. As regulatory pressures around environmental impact become stricter, the demand for low alkali cement is expected to rise, particularly in infrastructure projects that require high durability and chemical resistance. Another significant trend is the rise in infrastructure development in emerging economies, which is driving the demand for water conservancy projects, roads, and railway projects, all of which benefit from the durability of low alkali cement. The trend towards eco-friendly construction also aligns with the growth of blended cements, which use alternative materials to reduce carbon emissions. Additionally, technological advancements in cement production are enabling the development of more cost-effective and efficient low alkali cement products, making them more accessible to a wider range of markets.

The low alkali cement market is growing at different rates across regions. China, India, and Brazil are seeing the fastest growth due to large-scale infrastructure projects, while Germany, the USA, and the UK show steady growth driven by regulatory pressures and technological advancements. Emerging markets such as China and India are driving the demand for high-performance cement in water conservancy and transportation infrastructure. The USA, UK, and Japan have well-established markets with a focus on sustainability and eco-friendly building materials.

| Country | CAGR (%) |

|---|---|

| China | 11.2 |

| India | 10.4 |

| Germany | 9.5 |

| Brazil | 8.7 |

| USA | 7.9 |

| UK | 7.1 |

| Japan | 6.2 |

China is expected to continue leading the Low Alkali Cement Market, with a CAGR of 11.2%. The country is a global leader in construction and infrastructure development, particularly in water conservancy, highways, and railways—all sectors that require durable cement capable of withstanding harsh environmental conditions. Low alkali cement is crucial for these projects, offering resilience to chemical attacks, seawater exposure, and high humidity. The Chinese government's ongoing push for sustainable construction and eco-friendly materials has further driven the adoption of low alkali cement, as it supports long-term durability and low maintenance costs. Additionally, China’s infrastructure growth, including large-scale water dams, ports, and energy projects, requires high-performance cement solutions, ensuring continued demand for low alkali variants.

India, with a CAGR of 10.4%, is one of the fastest-growing markets for low alkali cement, fueled by the country’s massive investment in infrastructure. India’s government has placed a significant emphasis on building smart cities, improving water management systems, and expanding transportation networks, all of which rely on the use of high-performance cement. The increasing demand for water conservancy projects, railways, and highway infrastructure makes low alkali cement an essential material for durability and resistance to harsh environmental conditions. Furthermore, India’s push for eco-friendly construction is promoting the adoption of low alkali cement, as it reduces the long-term costs associated with infrastructure degradation. As the country’s population and urbanization rates grow, the demand for resilient and durable infrastructure will continue to drive the market.

Germany, with a CAGR of 9.5%, remains a leading player in the Low Alkali Cement Market. Germany’s strong focus on sustainability, energy efficiency, and eco-friendly construction has fueled the demand for low alkali cement, especially in infrastructure projects such as highways, railways, and water conservancy systems. The country’s strict environmental regulations and emphasis on carbon reduction are pushing the construction industry toward more sustainable materials. Low alkali cement is preferred in projects exposed to seawater and chemical conditions, ensuring greater durability and resilience. As the demand for green building practices and long-lasting infrastructure grows, Germany’s position in the market will continue to strengthen, with a focus on eco-friendly cement solutions that meet both regulatory and environmental standards.

Brazil, with a CAGR of 8.7%, is experiencing steady growth in the Low Alkali Cement Market, driven by ongoing infrastructure expansion and construction projects. Brazil’s need for high-performance materials in projects such as water management systems, ports, and highways is driving the demand for low alkali cement. The country’s infrastructure projects are increasingly exposed to harsh environments, such as seawater, industrial effluents, and high humidity, where low alkali cement provides superior chemical resistance and longevity. Additionally, Brazil’s strong focus on sustainability and environmental regulations is pushing the construction industry to adopt more durable and resilient materials like low alkali cement. The growing construction sector and the Brazilian government’s infrastructure plans will ensure continued demand for low alkali cement in the coming years.

The USA, with a CAGR of 7.9%, continues to show consistent growth in the Low Alkali Cement Market. The country’s demand for high-performance cement is driven by large-scale infrastructure projects, particularly in water infrastructure, highways, railroads, and marine structures, where durability and chemical resistance are essential. The USA Green Building Council’s LEED standards and regulations aimed at reducing the carbon footprint of construction materials are driving the preference for eco-friendly solutions like low alkali cement. Moreover, ongoing urbanization and construction projects aimed at enhancing infrastructure resilience to climate change are further promoting the demand for durable materials. The USA market is also benefiting from advances in cement technology, making low alkali cement more cost-effective and widely adopted in public and private sector projects.

The UK, with a CAGR of 7.1%, is experiencing steady growth in the Low Alkali Cement Market driven by the country’s strong focus on sustainability and eco-friendly construction practices. The UK government’s commitment to carbon neutrality and the promotion of green building standards is encouraging the construction industry to adopt low alkali cement, which offers enhanced durability and resilience in harsh conditions. The demand for high-performance materials is increasing in sectors like transportation infrastructure, water conservancy, and marine projects, where low alkali cement proves particularly useful due to its chemical resistance and long-lasting durability. The growing importance of resilient infrastructure, especially in coastal areas and flood-prone regions, is further driving the need for low alkali cement. Moreover, the construction industry in the UK is heavily invested in eco-friendly materials to meet the country’s stringent environmental regulations, supporting the ongoing demand for sustainable cement alternatives.

Japan, with a CAGR of 6.2%, shows steady growth in the Low Alkali Cement Market, particularly driven by the country’s strong infrastructure development in earthquake-resistant buildings, water management systems, and marine infrastructure. Japan’s emphasis on building resilience and sustainability makes low alkali cement a preferred material in construction projects that must withstand harsh environmental conditions such as seawater exposure and extreme weather events. The country’s advanced technological infrastructure also supports demand for high-performance cement, including low alkali formulations, which are integral to high-durability and long-lasting infrastructure. As Japan continues to focus on eco-friendly construction and reducing the environmental impact of its infrastructure, the adoption of low alkali cement is expected to rise. Additionally, Japan’s extensive focus on resilient infrastructure in areas prone to earthquakes and tsunamis further boosts the demand for cement products that ensure structural longevity and safety.

The low alkali cement market is competitive, with a mix of global leaders and regional players competing for market share. China National Building Material Group (CNBM) leads the market with a 10% share, backed by its vast production capacity and established presence in Asia and beyond. Other significant players include Jinglan Holding Group, Béton Provincial, and Invicta Cementitious Solutions, which are important in providing specialized low alkali cement products that meet the growing demand for durable infrastructure. The market is also seeing increased competition from companies like Çimsa, Anhui Conch Cement, and Xuzhou Longshan Cement Group, who are focused on offering eco-friendly solutions to meet the demand for sustainable construction materials. Regional players in markets like India, Brazil, and China are leveraging cost-effective production methods while meeting the need for high-durability cement products. As the demand for low alkali cement grows in infrastructure projects, companies with strong manufacturing capabilities and innovative sustainable products will remain competitive.

The market competition is primarily driven by technological innovation, product differentiation, and sustainability efforts. Major cement producers are investing heavily in research and development to create more efficient, durable, and sustainable products. Green building trends, eco-friendly construction, and global demand for resilient infrastructure are pushing companies to innovate and expand their low alkali cement offerings. Partnerships, acquisitions, and local manufacturing are key strategies employed by players to strengthen their positions in emerging markets where infrastructure needs are expanding rapidly. As the global focus on sustainability grows, low alkali cement producers that align with environmental regulations and offer superior performance will continue to gain market share.

| Items | Details |

|---|---|

| Quantitative Units | USD Billion |

| Classification | Portland Cement, Aluminate Cement, Blended Cement |

| Application | Water Conservancy Projects, Railway and Highway Projects, Industrial and Civil Construction, Marine Projects |

| Regions Covered | Asia Pacific, Europe, North America, Latin America, Middle East & Africa |

| Countries Covered | China, India, USA, Germany, Brazil, Japan, South Korea, 40+ other countries |

| Key Companies Profiled | China National Building Material Group (CNBM), Jinglan Holding Group, Béton Provincial, Invicta Cementitious Solutions, Çimsa, Anhui Conch Cement Company Limited, Xuzhou Longshan Cement Group, Fangcheng County Wanbei Cement (Group), Tangshan Hongye Special Cement |

| Additional Attributes | The market analysis includes dollar sales by classification and application categories. It also covers regional adoption trends across major markets such as China, India, and the USA. The competitive landscape features key cement manufacturers, focusing on innovations in low alkali cement products and their integration into large-scale infrastructure projects. Trends in the use of low alkali cement for water conservancy, railway, highway, and marine projects are highlighted, along with environmental considerations and regulatory factors affecting market growth. |

The global low alkali cement market is estimated to be valued at USD 2.1 billion in 2025.

The market size for the low alkali cement market is projected to reach USD 4.7 billion by 2035.

The low alkali cement market is expected to grow at a 8.3% CAGR between 2025 and 2035.

The key product types in low alkali cement market are portland cement, aluminate cement and blended cement.

In terms of application, water conservancy projects segment to command 30.0% share in the low alkali cement market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Low Alloy Steels Powder Market Size and Share Forecast Outlook 2025 to 2035

Low Vibration Thermostat Market Size and Share Forecast Outlook 2025 to 2035

Low-Level Order Picker Pallet Truck Market Size and Share Forecast Outlook 2025 to 2035

Low Voltage Components Market Size and Share Forecast Outlook 2025 to 2035

Low Temperature Flexible Tester Market Size and Share Forecast Outlook 2025 to 2035

Low Light Imaging Market Forecast Outlook 2025 to 2035

Low Density Polyethylene Market Forecast and Outlook 2025 to 2035

Low-Temperature Cable Market Size and Share Forecast Outlook 2025 to 2035

Low Molecular Weight Chondroitin Sulfate Sodium Market Size and Share Forecast Outlook 2025 to 2035

Low Temperature Radiators Market Size and Share Forecast Outlook 2025 to 2035

Low Rolling Resistance Tire Market Size and Share Forecast Outlook 2025 to 2035

Low Temperature Commercial Boiler Market Size and Share Forecast Outlook 2025 to 2035

Low Emissivity Film Market Size and Share Forecast Outlook 2025 to 2035

Low Voltage Residential Switchgear Market Size and Share Forecast Outlook 2025 to 2035

Low Voltage Substation Market Size and Share Forecast Outlook 2025 to 2035

Low Migration Inks Market Size and Share Forecast Outlook 2025 to 2035

Low Voltage Distribution Panel Market Size and Share Forecast Outlook 2025 to 2035

Low Voltage Surge Arrester Market Size and Share Forecast Outlook 2025 to 2035

Low Density Polyethylene Packaging Market Size and Share Forecast Outlook 2025 to 2035

Low Temperature Insulation Materials Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA