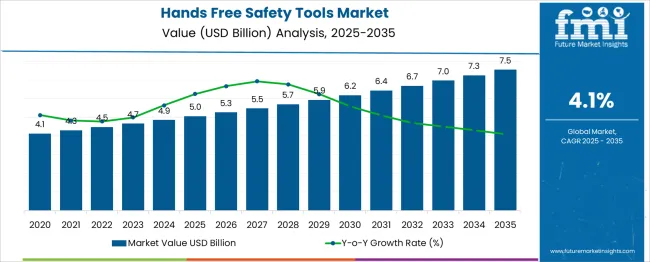

The Hands-Free Safety Tools Market is estimated to be valued at USD 5.0 billion in 2025 and is projected to reach USD 7.5 billion by 2035, registering a compound annual growth rate (CAGR) of 4.1% over the forecast period. A 10-year growth comparison highlights steady, incremental growth with some acceleration during the forecast period. Between 2025 and 2030, the market grows from USD 5.0 billion to USD 6.2 billion, contributing USD 1.2 billion in growth, with a CAGR of 4.5%. This early-phase growth is driven by rising demand for hands-free safety solutions across industries such as construction, manufacturing, and healthcare, where worker safety is increasingly prioritized.

Innovations in wearable safety technology, such as smart helmets and safety vests, also contribute to this growth. From 2030 to 2035, the market continues to expand, moving from USD 6.2 billion to USD 7.5 billion, adding USD 1.3 billion in growth, with a slightly lower CAGR of 3.9%. This deceleration reflects the market maturing, as the adoption of hands-free safety tools becomes more widespread and the growth rate stabilizes. Ongoing innovation and stricter regulations continue to support demand, ensuring sustained growth. The 10-year comparison shows that while the market experiences stronger growth in the first half, it maintains steady, albeit slower, expansion in the latter half as it approaches market maturity.

| Metric | Value |

|---|---|

| Hands-Free Safety Tools Market Estimated Value in (2025 E) | USD 5.0 billion |

| Hands-Free Safety Tools Market Forecast Value in (2035 F) | USD 7.5 billion |

| Forecast CAGR (2025 to 2035) | 4.1% |

The Hands Free Safety Tools market is progressing steadily, driven by the increasing need to minimize hand injuries and enhance workplace safety across high-risk industries. With a growing focus on compliance with stringent occupational safety regulations, industries are adopting tools that reduce direct human interaction during heavy equipment handling. The market is gaining traction as organizations prioritize worker well-being, injury prevention, and operational efficiency.

Advancements in ergonomic designs and material strength are further enhancing tool functionality and durability, supporting broader adoption. Growth is also being sustained by training initiatives and awareness campaigns by industry bodies that promote the benefits of hands-free safety practices.

Industries with hazardous workflows, such as oil and gas, manufacturing, and construction, are deploying these tools as part of comprehensive safety programs. The future outlook remains positive, as innovation in tool versatility and integration with safety protocols continues to expand the addressable market across both developed and emerging regions..

The hands-free safety tools market is segmented by tool type, application, end use, distribution channel, and geographic regions. By tool type, the hands-free safety tools market is divided into Push-Pull safety tools, Alignment tools, Tagging tools, Tethering and lanyard systems, and others. In terms of application, the hands-free safety tools market is classified into Material handling, Alignment tasks, Inspection and maintenance, and others. Based on end use, the hands-free safety tools market is segmented into Oil & gas, Construction, Manufacturing, Mining, and others. The distribution channel of the hands-free safety tools market is segmented into direct and indirect. Regionally, the hands-free safety tools industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

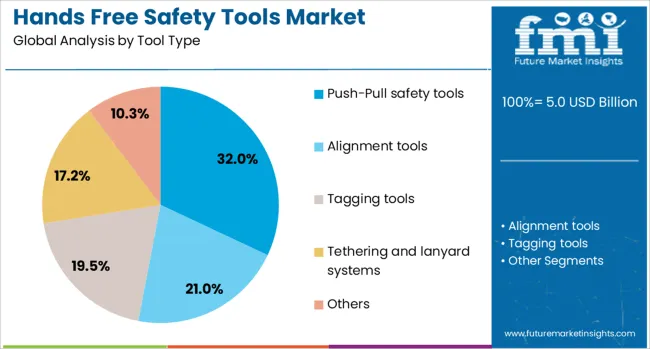

The push pull safety tools subsegment is projected to hold 32% of the Hands Free Safety Tools market revenue share in 2025, making it the leading tool type. This dominance has been driven by the tool's ability to allow controlled movement of suspended or stationary loads without direct hand contact, significantly reducing pinch and crush injuries.

Industrial users have increasingly adopted these tools due to their robust construction, ergonomic handles, and ability to perform in both routine and high-risk lifting operations. The segment’s growth has also been supported by widespread safety training programs that promote hands-free operational practices.

As industries continue to upgrade safety standards, push-pull safety tools have been integrated into daily workflows, especially in high-risk zones. Their compatibility with a wide range of lifting and guiding tasks has improved worker confidence and compliance, further solidifying their role in reducing recordable safety incidents and maintaining continuous operations in hazardous work environments..

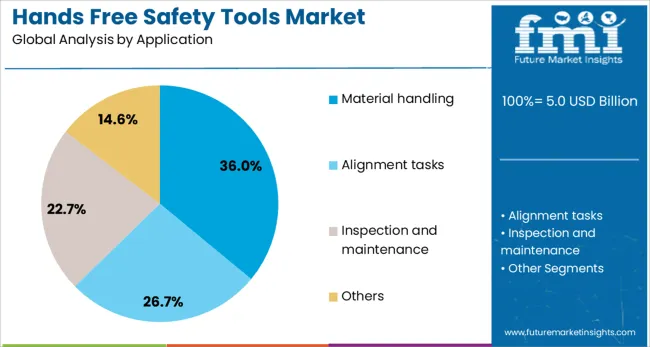

The material handling subsegment is anticipated to account for 36% of the Hands Free Safety Tools market revenue share in 2025, positioning it as the leading application area. The demand for hands-free tools in material handling has been driven by the increasing emphasis on minimizing manual contact during the movement of heavy or unstable loads. Industrial safety managers have prioritized this application due to the high frequency of handling-related injuries observed in manufacturing, logistics, and utility sectors.

Tools designed for this segment have been engineered to offer precise control, extended reach, and improved grip, allowing a safe distance between workers and moving equipment. The ability to reduce strain, slips, and repetitive motion injuries has been a major contributing factor to the segment’s adoption.

As material handling processes become more mechanized and safety-oriented, hand-free tools have been embedded into standard operating procedures. The segment's continued expansion reflects the growing preference for preventive safety measures that ensure operational continuity and workforce protection..

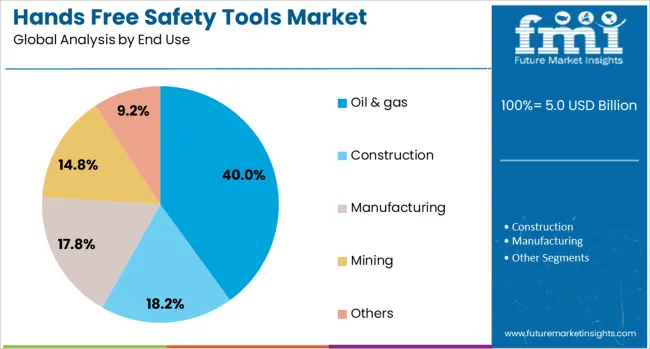

The oil and gas subsegment is expected to capture 40% of the Hands Free Safety Tools market revenue share in 2025, establishing it as the leading end use industry. This segment’s leadership has been attributed to the sector’s inherently high-risk working environments, where mechanical lifting, pipe handling, and rig operations pose significant hazards to manual workers. Hands free tools have been widely adopted in offshore and onshore operations to reduce hand-related injuries and improve compliance with strict health and safety mandates.

The segment’s growth has also been influenced by major energy producers instituting zero-injury initiatives and integrating hands free systems into drilling and maintenance protocols. The use of non-conductive, corrosion-resistant materials in tool manufacturing has further boosted suitability in challenging conditions.

As exploration and production activities continue to expand, especially in remote or hazardous zones, the demand for reliable safety tools has grown. The proactive implementation of hands free protocols has enabled the oil and gas sector to reinforce its safety culture while ensuring operational efficiency..

The spinning machines market is expanding due to increasing demand from the textile industry for high-efficiency machinery that can produce high-quality yarns. These machines are vital for the production of fabrics, textiles, and other materials used in various applications, including clothing, home textiles, and industrial fabrics. Technological advancements, including automation and digitalization, are enhancing the productivity and performance of spinning machines. Despite challenges such as high operational costs and maintenance, the market presents opportunities in emerging economies, where the textile industry is experiencing significant growth.

The growth of the spinning machines market is largely driven by the increasing need for high-quality, efficient textile production. The textile industry’s demand for advanced machinery to produce finer, stronger, and more durable yarns is leading to greater adoption of spinning machines. Automation and digital technology integration in these machines help increase operational efficiency, reduce downtime, and lower labor costs. Additionally, the increasing consumption of textiles in emerging markets, combined with the rise in demand for premium fabrics in developed countries, is further driving the need for advanced spinning machines. These trends push manufacturers to invest in innovation, improving machine performance and meeting consumer demand for superior textiles.

A significant challenge in the spinning machines market is the high capital investment required for the purchase and installation of advanced spinning equipment. These machines involve complex technology and require substantial financial resources, making them less accessible for small and medium-sized textile manufacturers. Regular maintenance is essential for ensuring optimal machine performance, but maintenance costs can be high, particularly for advanced systems with specialized components. Manufacturers must also address issues such as energy consumption and machine downtime, which can affect overall profitability. Balancing the upfront costs and ongoing maintenance expenses is critical for companies operating in the highly competitive textile sector.

The spinning machines market offers substantial growth opportunities through technological advancements. The integration of automation, artificial intelligence (AI), and real-time monitoring systems is enhancing the performance and efficiency of spinning machines. These innovations help optimize production processes, reduce waste, and improve yarn quality, driving the adoption of advanced machines. The expansion of the textile industry in emerging markets, particularly in Asia and Africa, presents an opportunity for increased demand for spinning machinery. As textile production increases in these regions, the need for efficient, high-quality machines will rise, offering new avenues for growth. Companies that can provide cost-effective, advanced spinning solutions are well-positioned to benefit from this trend.

A key trend in the spinning machines sector is the increasing adoption of automation and digital integration. Modern spinning machines are being equipped with digital controls and automated systems that allow for real-time monitoring, remote diagnostics, and production optimization. Automation enhances productivity by reducing manual labor, improving consistency, and ensuring higher quality output. Additionally, digital tools such as IoT-based sensors enable manufacturers to monitor machine performance, detect issues early, and streamline maintenance processes. The focus on energy efficiency and sustainability is also driving the development of spinning machines with lower energy consumption and minimal waste. These trends are reshaping the market by making spinning machines more efficient, intelligent, and aligned with Industry 4.0 principles.

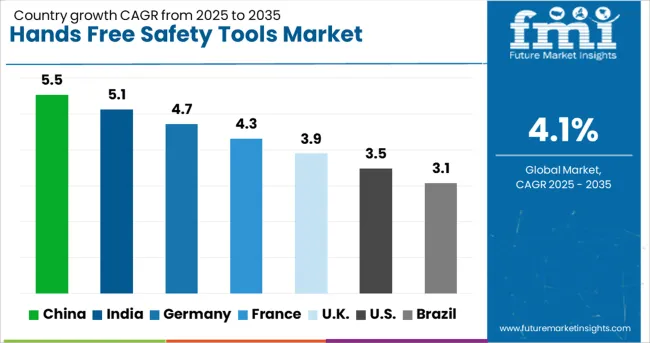

| Country | CAGR |

|---|---|

| China | 5.5% |

| India | 5.1% |

| Germany | 4.7% |

| France | 4.3% |

| UK | 3.9% |

| USA | 3.5% |

| Brazil | 3.1% |

The global hands free safety tools market is projected to grow at a CAGR of 4.1%, with notable contributions from China, India, Germany, the UK, and the USA China leads with a growth rate of 5.5%, followed by India at 5.1%. Germany records a growth rate of 4.7%, while the UK and USA show growth rates of 3.9% and 3.5%, respectively. The increasing demand for energy efficient and hygienic solutions in public restrooms, combined with rising consumer awareness about reducing paper waste, is fueling growth in both emerging and developed markets. The market continues to evolve, supported by technological advancements and the growing focus on eco friendly alternatives to traditional hand drying methods. The analysis includes over 40 countries, with the top five detailed below.

China is projected to grow at a CAGR of 5.5%, leading the global hands free safety tools market. The country’s rapid urbanization, increasing focus on hygiene, and expanding public infrastructure are significant factors contributing to this growth. The demand for energy efficient and touchless safety tools is rising, driven by growing awareness of environmental impact and cost saving benefits. Additionally, China’s increasing number of public restrooms, commercial spaces, and transportation hubs creates a large market for safety tools. Government efforts to promote modern technologies also support the growing adoption of energy efficient hand drying solutions in China.

Sales of hands free safety tools in India is expected to grow at a CAGR of 5.1%. The market is benefiting from significant infrastructure development in urban and semi-urban areas, where new commercial spaces, airports, and malls are emerging. The growing middle class, coupled with increased health consciousness, is driving the demand for hygienic and efficient safety equipment. As more public restrooms are being equipped with modern amenities, including touchless safety tools, India’s demand for these products is expected to rise. The growing importance of energy efficiency in everyday appliances also supports the market’s growth.

The hands free safety tools market in Germany is expected to grow at a CAGR of 4.7%. Known for its stringent industrial safety standards, Germany is a key player in the adoption of hands free safety tools. As industries such as automotive, manufacturing, and construction expand, the demand for advanced safety tools, including smart helmets and wearable devices, is increasing. Germany’s focus on industrial automation, combined with the need for efficient safety solutions, further propels market growth. The country’s emphasis on regulatory compliance and worker safety standards ensures that the adoption of hands free safety tools continues to rise.

The UK is projected to grow at a CAGR of 3.9% in the hands free safety tools market. The UK has witnessed a rising interest in energy efficient appliances, particularly in commercial and public spaces. As consumers and businesses focus on reducing waste and improving hygiene, hands free safety tools have become a preferred choice over traditional options. Increasing demand for touchless technology, driven by health and safety concerns, further supports the market’s growth. Stringent environmental regulations and growing eco consciousness among consumers are pushing for the adoption of advanced, energy efficient safety tools.

The USA hands free safety tools market is projected to grow at a CAGR of 3.5%. The growth in the USA is driven by the increasing interest in hygiene and the adoption of efficient safety tools that enhance productivity. Hands free safety tools are becoming increasingly popular as more consumers seek multifunctional appliances that offer versatility. The demand for energy efficient and durable products is also on the rise, with USA consumers looking for long lasting and easy to use safety equipment. E-commerce platforms are further expanding product availability, contributing to market growth.

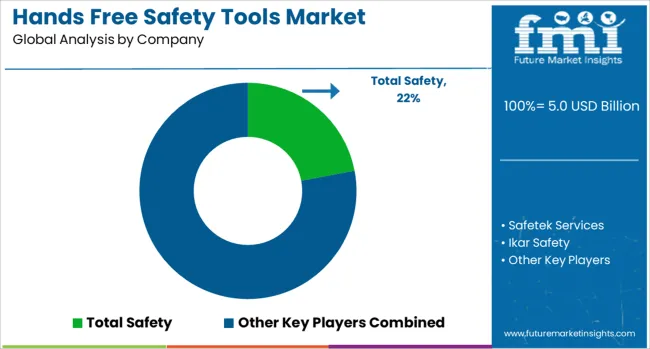

Total Safety is a key player, providing comprehensive safety solutions, including hands-free tools that allow workers to maintain full mobility and efficiency without compromising their protection. Safetek Services specializes in offering hands-free safety solutions, including advanced respiratory protection and communication systems for hazardous work environments. Ikar Safety offers specialized hands-free safety equipment, including fall protection systems and gas detection solutions, designed to keep workers safe while enabling them to perform tasks efficiently. 3M Company is a major competitor, providing a broad range of hands-free safety tools, including respiratory protection, hearing protection, and headgear that ensure safety while allowing for mobility and effective task execution. Keel Safety focuses on developing safety tools that integrate smart technologies and wireless communication to improve worker safety and operational efficiency. Other regional/local players contribute to the market by offering hands-free safety tools that are customized to meet specific safety standards and regulatory requirements in different regions, focusing on affordability and localized solutions.

Competitive differentiation in this market is driven by innovation in safety technologies, ease of use, customization capabilities, and product quality. Barriers to entry include regulatory compliance, technological complexity, and the need for high capital investment in R&D. Strategic priorities include expanding product offerings, improving product functionality, and increasing adoption across high-risk industries globally.

| Item | Value |

|---|---|

| Quantitative Units | USD 5.0 Billion |

| Tool Type | Push-Pull safety tools, Alignment tools, Tagging tools, Tethering and lanyard systems, and Others |

| Application | Material handling, Alignment tasks, Inspection and maintenance, and Others |

| End Use | Oil & gas, Construction, Manufacturing, Mining, and Others |

| Distribution Channel | Direct and Indirect |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled | Total Safety, Safetek Services, Ikar Safety, 3M Company, Keel Safety, and Other regional/local players |

| Additional Attributes | Dollar sales by product type (hands-free communication devices, protective headgear, respiratory protection, wearable sensors) and end-use segments (construction, manufacturing, oil & gas, mining, industrial maintenance). Demand dynamics are influenced by growing workplace safety regulations, increased awareness of workplace hazards, and the rising need for productivity-enhancing safety tools. Regional trends indicate strong growth in North America and Europe due to stringent safety regulations, while Asia-Pacific shows rapid expansion due to increasing industrialization and safety awareness. |

The global hands-free safety tools market is estimated to be valued at USD 5.0 billion in 2025.

The market size for the hands-free safety tools market is projected to reach USD 7.5 billion by 2035.

The hands-free safety tools market is expected to grow at a 4.1% CAGR between 2025 and 2035.

The key product types in hands-free safety tools market are push-pull safety tools, alignment tools, tagging tools, tethering and lanyard systems, others, _hands-free wrenches and _hands-free clamps.

In terms of application, material handling segment to command 36.0% share in the hands-free safety tools market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Safety Bottle Tote Carriers Packaging Market Size and Share Forecast Outlook 2025 to 2035

Safety Towing System Market Size and Share Forecast Outlook 2025 to 2035

Safety Syringe Market Size and Share Forecast Outlook 2025 to 2035

Safety Actuators Market Size and Share Forecast Outlook 2025 to 2035

Safety Needles Market Size and Share Forecast Outlook 2025 to 2035

Safety Laser Scanner Market Size and Share Forecast Outlook 2025 to 2035

Safety Limit Switches Market Size and Share Forecast Outlook 2025 to 2035

Safety Reporting Systems Market Size and Share Forecast Outlook 2025 to 2035

Safety Eyewear Market Analysis - Size, Share, and Forecast 2025 to 2035

Safety Box for Syringe Market Size, Share & Forecast 2025 to 2035

Safety Valve Market Size, Growth, and Forecast 2025 to 2035

Safety Relays Market Size, Share, and Forecast 2025 to 2035

Safety Instrumentation Systems Market – Trends & Forecast 2025 to 2035

Safety Mirrors Market - Growth & Forecast 2025 to 2035

Safety Switches Market Trends – Growth & Forecast 2025 to 2035

Safety Interlock Switches Market Analysis by Actuation Method, Application and End-use Industry and Region 2025 to 2035

Safety Light Curtains Market Growth - Trends & Forecast 2025 to 2035

Key Companies & Market Share in the Safety Eyewear Sector

Industry Share Analysis for Safety Box for Syringe Companies

Safety Label Market Growth & Industry Demand 2024-2034

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA