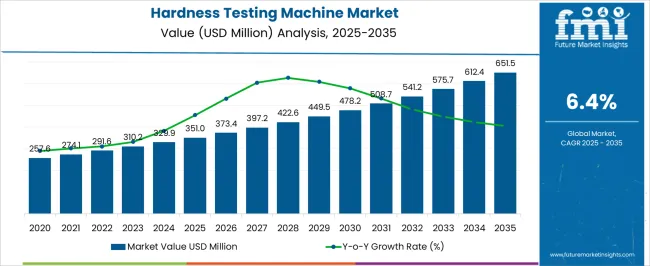

The Hardness Testing Machine Market is estimated to be valued at USD 351.0 million in 2025 and is projected to reach USD 651.5 million by 2035, registering a compound annual growth rate (CAGR) of 6.4% over the forecast period.

| Metric | Value |

|---|---|

| Hardness Testing Machine Market Estimated Value in (2025 E) | USD 351.0 million |

| Hardness Testing Machine Market Forecast Value in (2035 F) | USD 651.5 million |

| Forecast CAGR (2025 to 2035) | 6.4% |

The Hardness Testing Machine market is experiencing steady growth driven by the increasing demand for precise and reliable material characterization across manufacturing and quality assurance processes. The current market landscape reflects a growing focus on industrial automation, high-quality metal production, and stringent regulatory standards for product durability and safety.

Rising adoption in sectors such as automotive, aerospace, and heavy machinery is influencing market expansion, as manufacturers require consistent material hardness testing to ensure product integrity and compliance. Technological advancements in automated testing, digital readouts, and software-enabled data analysis have enhanced operational efficiency and reduced human error, further driving the adoption of modern hardness testing machines.

The future outlook for this market is shaped by ongoing improvements in testing speed, accuracy, and versatility, enabling machines to cater to a wider range of materials Additionally, the integration of testing machines with Industry 4.0 frameworks and smart manufacturing systems is expected to create significant growth opportunities, positioning hardness testing as a critical component of industrial quality assurance and research applications worldwide.

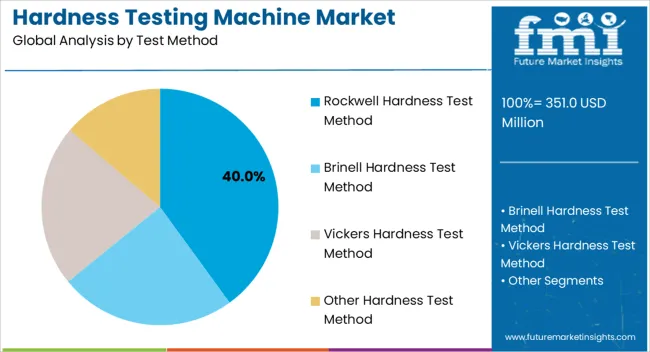

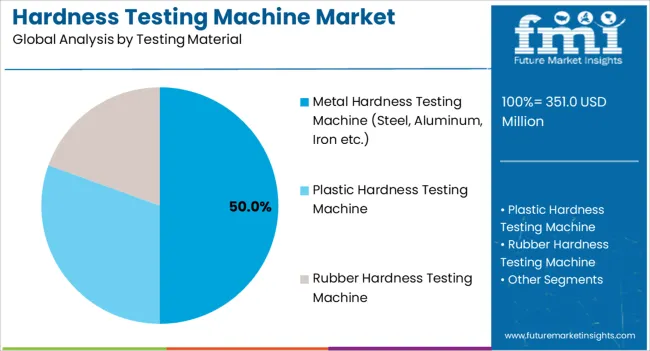

The hardness testing machine market is segmented by test method, testing material, and geographic regions. By test method, hardness testing machine market is divided into Rockwell Hardness Test Method, Brinell Hardness Test Method, Vickers Hardness Test Method, and Other Hardness Test Method. In terms of testing material, hardness testing machine market is classified into Metal Hardness Testing Machine (Steel, Aluminum, Iron etc.), Plastic Hardness Testing Machine, and Rubber Hardness Testing Machine. Regionally, the hardness testing machine industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The Rockwell Hardness Test Method segment is projected to hold 40.00% of the Hardness Testing Machine market revenue share in 2025, making it the leading test method. This prominence is being attributed to its simplicity, repeatability, and rapid execution compared to other hardness test methods. The Rockwell method allows for efficient measurement across a wide range of metals, delivering results that can be easily standardized for quality assurance purposes.

Its adoption has been driven by its compatibility with automated systems and its ability to provide consistent and reliable data for production environments. Industries where high-volume testing is required, such as automotive and metal fabrication, have favored Rockwell machines due to reduced testing time and minimal sample preparation.

Furthermore, the method supports varying loads and indenter types, allowing for versatile applications across different material grades The scalability and proven accuracy of Rockwell testing have reinforced its leadership, ensuring continued preference among manufacturers who prioritize operational efficiency and adherence to industry standards.

The Metal Hardness Testing Machine segment is expected to account for 50.00% of the Hardness Testing Machine market revenue share in 2025, emerging as the dominant testing material category. This leadership is being driven by the critical need for material integrity assessment in metals such as steel, aluminum, and iron, which form the backbone of manufacturing, construction, and heavy engineering industries.

The growth of this segment has been influenced by rising industrial production, stringent quality requirements, and increased regulatory compliance, particularly in sectors where metal durability is essential for safety and performance. Metal hardness testing machines allow precise evaluation of mechanical properties, supporting better product design, process optimization, and lifecycle management.

Automation and digital integration have further enhanced their utility, enabling faster, accurate, and traceable results for large-scale production environments The continued preference for metal hardness testing is expected to persist as industrial growth accelerates, driving demand for reliable, high-performance testing solutions capable of addressing the diverse requirements of modern manufacturing and engineering applications.

Hardness is defined as resistance to indentation. Hardness is not a functional physical property, it’s a characteristics of a material. Hardness is calculated by measuring the permanent depth of the indentation. Hardness testing machines is used to measure the hardness of a material in order to determine its suitability.

Hardness testing machines is also used to evaluate the coating layer and material integrity of an equipment. There are mainly three types of hardness test methods, the Brinell hardness test, the Rockwell hardness test, and the Vickers hardness test. Among these, Rockwell hardness test is consider to be most widely used technique and provides more precise evaluation as compared to other processes.

However Brinell hardness test is carried out when the subjected material is too coarse or too rough exterior and Vickers hardness test is carried when the material is very thin or have very small surface area. Hardness testing machines plays an important role and finds huge application in wide range of industries including construction, mining, automotive, aerospace, energy & power, and metalworking etc.

Owing to increasing demand of advanced material testing methods, hardness testing machine is estimated to witness a rising demand during the forecast period. This in turn is anticipated to positively impact the global hardness testing machine market.

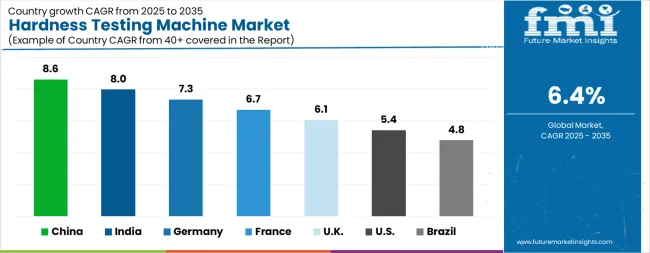

| Country | CAGR |

|---|---|

| China | 8.6% |

| India | 8.0% |

| Germany | 7.3% |

| France | 6.7% |

| UK | 6.1% |

| USA | 5.4% |

| Brazil | 4.8% |

The Hardness Testing Machine Market is expected to register a CAGR of 6.4% during the forecast period, exhibiting varied country level momentum. China leads with the highest CAGR of 8.6%, followed by India at 8.0%. Developed markets such as Germany, France, and the UK continue to expand steadily, while the USA is likely to grow at consistent rates. Brazil posts the lowest CAGR at 4.8%, yet still underscores a broadly positive trajectory for the global Hardness Testing Machine Market. In 2024, Germany held a dominant revenue in the Western Europe market and is expected to grow with a CAGR of 7.3%. The USA Hardness Testing Machine Market is estimated to be valued at USD 120.1 million in 2025 and is anticipated to reach a valuation of USD 203.6 million by 2035. Sales are projected to rise at a CAGR of 5.4% over the forecast period between 2025 and 2035. While Japan and South Korea markets are estimated to be valued at USD 19.2 million and USD 12.1 million respectively in 2025.

| Item | Value |

|---|---|

| Quantitative Units | USD 351.0 Million |

| Test Method | Rockwell Hardness Test Method, Brinell Hardness Test Method, Vickers Hardness Test Method, and Other Hardness Test Method |

| Testing Material | Metal Hardness Testing Machine (Steel, Aluminum, Iron etc.), Plastic Hardness Testing Machine, and Rubber Hardness Testing Machine |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

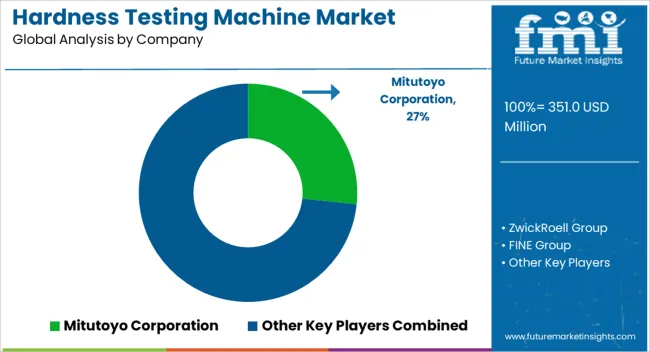

| Key Companies Profiled | Mitutoyo Corporation, ZwickRoell Group, FINE Group, Akash Industries, Struers, Innovatest Europe BV, Shimadzu Corporation, and FIE Group |

The global hardness testing machine market is estimated to be valued at USD 351.0 million in 2025.

The market size for the hardness testing machine market is projected to reach USD 651.5 million by 2035.

The hardness testing machine market is expected to grow at a 6.4% CAGR between 2025 and 2035.

The key product types in hardness testing machine market are rockwell hardness test method, brinell hardness test method, vickers hardness test method and other hardness test method.

In terms of testing material, metal hardness testing machine (steel, aluminum, iron etc.) segment to command 50.0% share in the hardness testing machine market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Tire Testing Machine Market Size and Share Forecast Outlook 2025 to 2035

Bend Testing Machine Market Growth - Trends & Forecast 2025 to 2035

An Analysis of the Leak testing Machine Market by Detectors and Sensors Hardware Type through 2035

Market Share Distribution Among Leak Testing Machine Providers

Leak testing Machine Market

Pack Testing Machines Market

Microhardness Testing System Market Size and Share Forecast Outlook 2025 to 2035

Impact Testing Machine Market Size and Share Forecast Outlook 2025 to 2035

Leather Testing Machine Market Size and Share Forecast Outlook 2025 to 2035

Fatigue Testing Machine Market Size and Share Forecast Outlook 2025 to 2035

Tensile Testing Machine Market Size and Share Forecast Outlook 2025 to 2035

Resonant Testing Machine Market

Lubricant Testing Machine Market Size and Share Forecast Outlook 2025 to 2035

Universal Testing Machine Market Growth – Trends & Forecast 2025-2035

Compression Testing Machines Market Size and Share Forecast Outlook 2025 to 2035

Permeability Testing Machine Market Size and Share Forecast Outlook 2025 to 2035

Automatic Impact Testing Machine Market Size and Share Forecast Outlook 2025 to 2035

Machine Glazed Paper Market Size and Share Forecast Outlook 2025 to 2035

Machine Glazed Kraft Paper Market Forecast and Outlook 2025 to 2035

Machine Condition Monitoring Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA