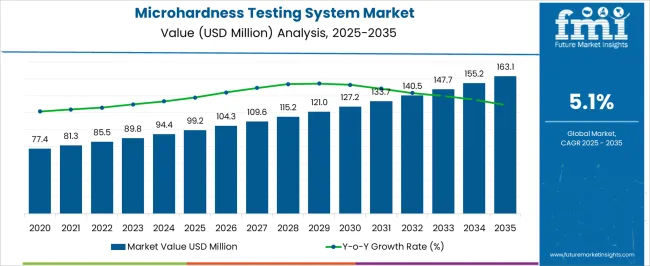

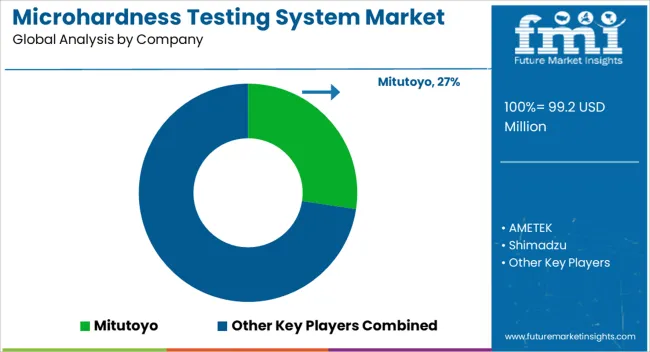

The Microhardness Testing System Market is estimated to be valued at USD 99.2 million in 2025 and is projected to reach USD 163.1 million by 2035, registering a compound annual growth rate (CAGR) of 5.1% over the forecast period.

| Metric | Value |

|---|---|

| Microhardness Testing System Market Estimated Value in (2025 E) | USD 99.2 million |

| Microhardness Testing System Market Forecast Value in (2035 F) | USD 163.1 million |

| Forecast CAGR (2025 to 2035) | 5.1% |

The Microhardness Testing System market is witnessing steady growth driven by increasing industrial and research applications that require precise material characterization and quality control. The current market scenario is shaped by the growing demand for advanced testing solutions across metals, ceramics, polymers, and composite materials in automotive, aerospace, electronics, and manufacturing sectors.

The market is being supported by the rising focus on product reliability, material optimization, and regulatory standards that mandate accurate hardness measurements. Technological advancements in automation, digital imaging, and software integration are enhancing test efficiency and reproducibility, allowing laboratories and industrial facilities to conduct more complex analyses with minimal human intervention.

The future outlook of the market is favorable due to the increasing adoption of automated and software-enhanced microhardness systems, rising investment in research and development, and the expansion of quality assurance protocols in emerging economies The need for consistent material testing and improved performance evaluation is expected to drive the adoption of microhardness testing systems over the next decade.

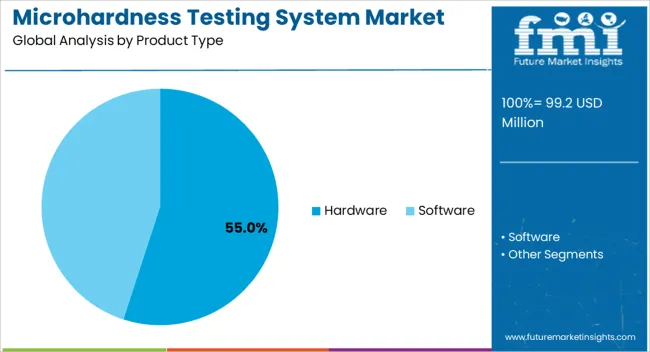

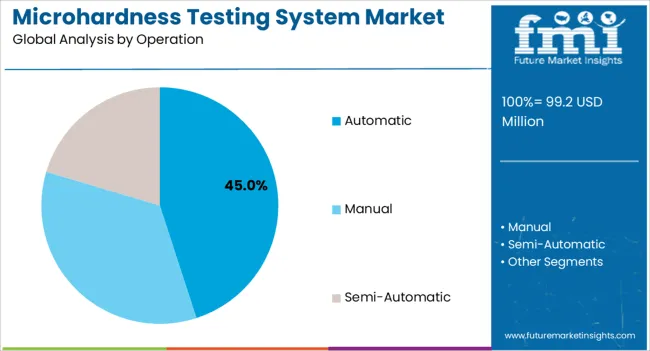

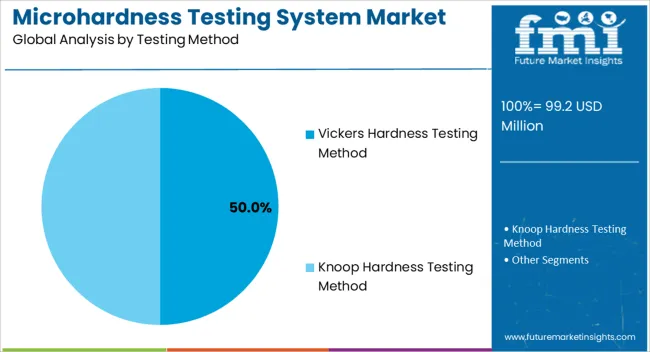

The microhardness testing system market is segmented by product type, operation, testing method, application, end use industry, and geographic regions. By product type, microhardness testing system market is divided into Hardware and Software. In terms of operation, microhardness testing system market is classified into Automatic, Manual, and Semi-Automatic. Based on testing method, microhardness testing system market is segmented into Vickers Hardness Testing Method and Knoop Hardness Testing Method. By application, microhardness testing system market is segmented into Metals And Alloys, Ceramics, and Composites. By end use industry, microhardness testing system market is segmented into Healthcare And Medical, Automotive, and Electrical & Electronics. Regionally, the microhardness testing system industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The Hardware product type is projected to hold 55.00% of the Microhardness Testing System market revenue share in 2025, establishing it as the leading segment. This prominence is being attributed to the critical role of robust and precise instrumentation in obtaining reliable hardness measurements. Hardware components, including indenter tips, load frames, and optical systems, ensure repeatability and accuracy across various material types.

Growth in this segment has been supported by the increasing deployment of microhardness testing systems in industrial production lines, research laboratories, and material certification processes where high precision is mandatory. The adoption of hardware-driven systems has also been reinforced by the growing demand for integrated testing solutions that minimize variability and human error.

Additionally, the long operational lifespan of high-quality hardware, coupled with its ability to accommodate software upgrades, has encouraged enterprises to invest in hardware-centric platforms The combination of durability, precision, and compatibility with advanced testing methods positions the Hardware segment as a dominant driver of market growth.

The Automatic operation segment is expected to account for 45.00% of the Microhardness Testing System market revenue share in 2025, making it a significant contributor to market expansion. This leadership has been driven by the ability of automated systems to reduce operator dependency, enhance repeatability, and improve throughput in material testing environments.

Automatic systems enable precise load application, indentation placement, and data acquisition with minimal human intervention, which is particularly beneficial in high-volume production and research settings. The growth of this segment has also been influenced by the increasing need for time-efficient workflows, standardized testing procedures, and integration with digital data management systems.

Furthermore, automatic testing systems facilitate advanced analytics and real-time reporting, which enhances material evaluation accuracy and decision-making capabilities As industries continue to emphasize productivity, consistency, and compliance with quality standards, the adoption of automated microhardness testing solutions is expected to expand steadily, reinforcing the segment’s significant share in the overall market.

The Vickers Hardness Testing Method is projected to hold 50.00% of the Microhardness Testing System market revenue share in 2025, reflecting its leading position among testing methods. This dominance is being attributed to the method’s versatility, high precision, and suitability for a wide range of materials, including metals, ceramics, and thin coatings.

The Vickers method allows for accurate hardness evaluation under both low and high loads, making it adaptable to diverse industrial and research requirements. Growth in this segment has been supported by increasing demand for detailed material characterization and compliance with international standards for quality assurance and performance assessment.

The reproducibility, simplicity in interpretation, and compatibility with automated systems have further reinforced the method’s adoption Additionally, as laboratories and manufacturers seek reliable and universally recognized testing protocols, the Vickers Hardness Testing Method continues to be preferred, ensuring its sustained leadership and contribution to the market’s overall growth trajectory.

Growing application of microhardness testing machines in various research institutes due to their flexibility to measure the hardness of the material is projected to augment the market in the forecast period. Besides, increasing automation in the manufacturing sectors has fuelled the market and grown the supply chain and as well as the value chain.

Expansion of steel and working industries are projected to be some key consumers of the microhardness testing system since the property of the material is a major concern. Increasing demand for efficient testing systems in aerospace, automotive, construction, and electronics among others is expected to make significant contributions in driving the microhardness testing market.

Developing nations such as India and China are predicted to be remunerative regions with lucrative opportunities. China is likely to drive the market in APEJ owing to the large-scale manufacturing and industrial production. Besides, established players of the market are offering cost-efficient solutions for several types of hardness testing as per the ISO 6507, 9385, and ASTM E384 and E92. Owing to the aforementioned factors, the market is likely to flourish in the forecast period.

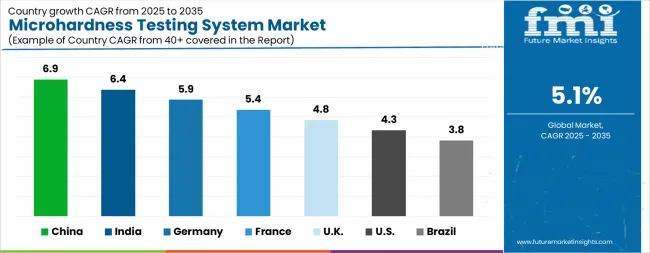

| Country | CAGR |

|---|---|

| China | 6.9% |

| India | 6.4% |

| Germany | 5.9% |

| France | 5.4% |

| UK | 4.8% |

| USA | 4.3% |

| Brazil | 3.8% |

The Microhardness Testing System Market is expected to register a CAGR of 5.1% during the forecast period, exhibiting varied country level momentum. China leads with the highest CAGR of 6.9%, followed by India at 6.4%. Developed markets such as Germany, France, and the UK continue to expand steadily, while the USA is likely to grow at consistent rates. Brazil posts the lowest CAGR at 3.8%, yet still underscores a broadly positive trajectory for the global Microhardness Testing System Market. In 2024, Germany held a dominant revenue in the Western Europe market and is expected to grow with a CAGR of 5.9%. The USA Microhardness Testing System Market is estimated to be valued at USD 35.5 million in 2025 and is anticipated to reach a valuation of USD 54.3 million by 2035. Sales are projected to rise at a CAGR of 4.3% over the forecast period between 2025 and 2035. While Japan and South Korea markets are estimated to be valued at USD 5.2 million and USD 3.4 million respectively in 2025.

| Item | Value |

|---|---|

| Quantitative Units | USD 99.2 Million |

| Product Type | Hardware and Software |

| Operation | Automatic, Manual, and Semi-Automatic |

| Testing Method | Vickers Hardness Testing Method and Knoop Hardness Testing Method |

| Application | Metals And Alloys, Ceramics, and Composites |

| End Use Industry | Healthcare And Medical, Automotive, and Electrical & Electronics |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled | Mitutoyo, AMETEK, Shimadzu, Buehler, Fischer Measurement Technologies, Struers, JINAN PRECISION TESTING EQUIPMENT, EMCO-TEST, Chennai Metco, FUTURE-TECH, and MATSUZAWA |

The global microhardness testing system market is estimated to be valued at USD 99.2 million in 2025.

The market size for the microhardness testing system market is projected to reach USD 163.1 million by 2035.

The microhardness testing system market is expected to grow at a 5.1% CAGR between 2025 and 2035.

The key product types in microhardness testing system market are hardware and software.

In terms of operation, automatic segment to command 45.0% share in the microhardness testing system market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Testing, Inspection & Certification Market Growth – Trends & Forecast 2025 to 2035

5G Testing Market Size and Share Forecast Outlook 2025 to 2035

AB Testing Software Market Size and Share Forecast Outlook 2025 to 2035

5G Testing Equipment Market Analysis - Size, Growth, and Forecast 2025 to 2035

Eye Testing Equipment Market Size and Share Forecast Outlook 2025 to 2035

HSV Testing Market Size and Share Forecast Outlook 2025 to 2035

IoT Testing Equipment Market Size and Share Forecast Outlook 2025 to 2035

HPV Testing and Pap Test Market Size and Share Forecast Outlook 2025 to 2035

GMO Testing Services Market Insights – Food Safety & Regulatory Compliance 2024 to 2034

GMP Testing Services Market

LTE Testing Equipment Market Growth – Trends & Forecast 2019-2027

Sand Testing Equipments Market Size and Share Forecast Outlook 2025 to 2035

Tire Testing Machine Market Size and Share Forecast Outlook 2025 to 2035

Self-Testing Market Analysis - Size, Share, and Forecast 2025 to 2035

Food Testing Services Market Size, Growth, and Forecast for 2025–2035

Bend Testing Machine Market Growth - Trends & Forecast 2025 to 2035

An Analysis of the Leak testing Machine Market by Detectors and Sensors Hardware Type through 2035

Soil Testing Market Growth - Trends & Forecast 2025 to 2035

Examining Food Testing Services Market Share & Industry Outlook

Market Share Distribution Among Leak Testing Machine Providers

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA